Vise design development

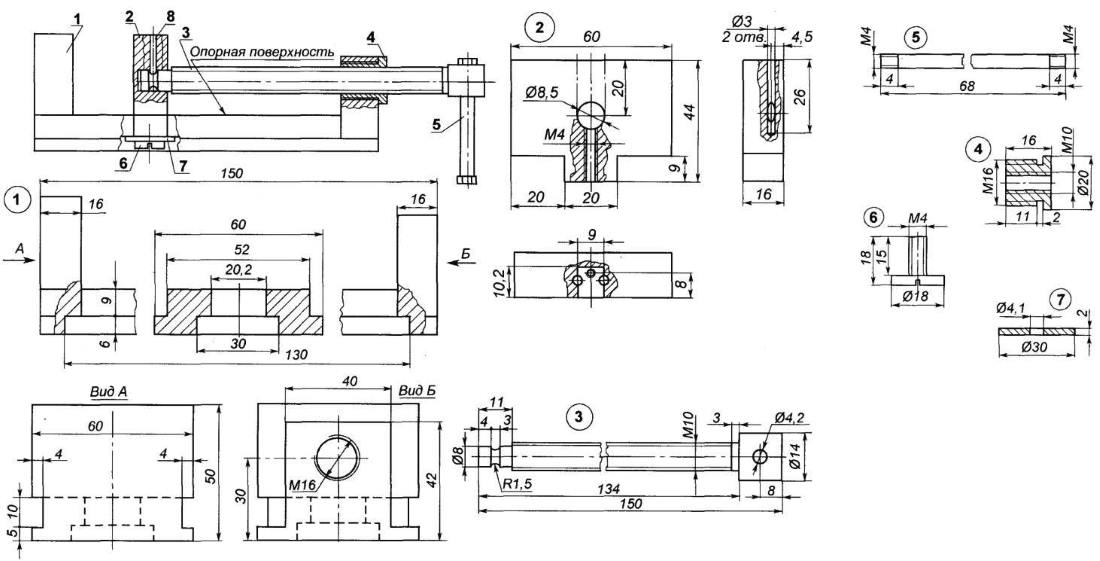

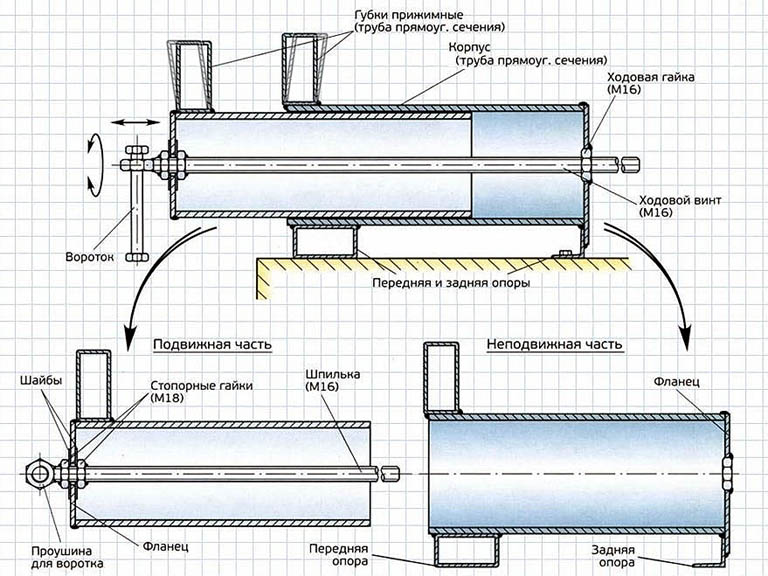

Homemade vise drawing

If you want to make your own design yourself, you need to prepare drawings (sketches). As a basis, you can take rolled corners, channels, I-beams. Iron casting is used in industrial devices. Small in size can be made from a channel.

Self-made people use different types of wood or rolled metal.

Wooden structure

As part of wood products, metal elements are used:

- screw. Use studs with a standard thread. If a jack is available, then a rectangular thread will be used in the product being developed;

- screw. It is matched to the existing clamping screw;

- fasteners are used for stiffening.

Easily removable design

By design, the device can be:

- stationary vice, permanently placed in one place;

- portable (easily removable) vice. They can be quickly removed and stowed in a vehicle for work at the place of repair.

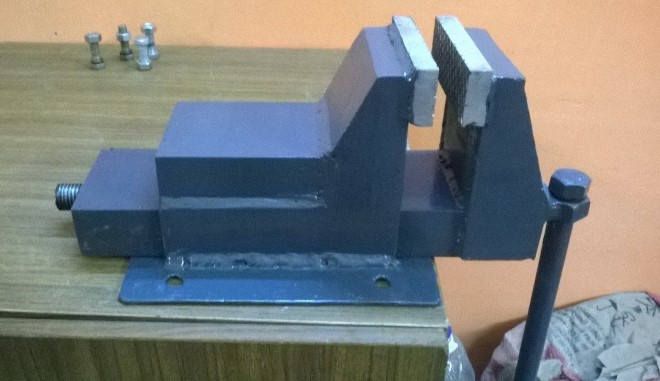

DIY vise

Reading time ≈ 4 minutes

The most important tool of a locksmith is a vice. Without them, it is impossible to perform most locksmith operations. Therefore, any novice locksmith, first of all, wants to purchase this necessary tool. A situation may also arise when the old factory vice is simply broken and cannot be repaired.

In such cases, buying a new similar instrument is not always profitable, since they are far from cheap. Therefore, many locksmiths decide to make a vice with their own hands, which in turn can be a good experience for beginners, and experienced specialists can make high-quality and comfortable vice for themselves.

You can make such a tool in one day from scrap materials, or you can collect the necessary components within a month and make a vice that is not much different from the factory one. In fact, the truth is somewhere in between. This article will describe in detail instructions on how to make a vice with your own hands for several days at no special cost.

Vise drawings

Such work can be performed only in a small locksmith's workshop with the obligatory presence of a welding machine, an electric drill, a grinder and other hand tools.

In addition, it is necessary to purchase such materials as a piece of steel channel No. 6, 0.5 m long, 0.3 m2 of sheet steel 4-5 mm thick and 30 cm of steel angle 50x50 mm, 18 M6 bolts with nuts and a piece of thick sheet metal for making sponges.

Stages of making a homemade vise

An approximate step-by-step instruction on how to make a vice with your own hands at home may look like this:

The grinder cuts off a piece of the channel 30 cm long. It will serve as the movable part of the vise. On one side, a 4 mm thick plate with a recess is welded to the base of this workpiece, into which a clamping screw with a groove is inserted. In order for the screw itself in this recess to be securely fixed, a lock plate of the same thickness is attached to this plate from the inside with two bolts.

Using a grinder, a 25x6.2 cm plate is cut out of the sheet, to which two corners 50x50 25 cm long are welded. This design is a fixed part of the vice. 6 holes with a diameter of 6 mm are drilled in the shelves of this workpiece.

From the same sheet, the grinder cut another workpiece 30x20 mm in size with a side protrusion 10x8 mm in size.12 holes with a diameter of 6 mm are drilled in it along the edges. It will serve as the base for the vise, on which the entire structure is attached. Two lock plates for the fixed nut are welded to it on the protruding part.

Two workpieces are cut from the angle steel, holes are drilled, and a thread is cut to secure the clamping jaws. Then one of these blanks is welded to the stationary part of the vise, and the second to the one that will move inside the bed.

Previously, the bed itself is bolted to the locksmith's table. Holes are also drilled in the jaws through which they are bolted to the clamping plates. A knob is inserted into the screw and the reliability of the fastening is checked again.

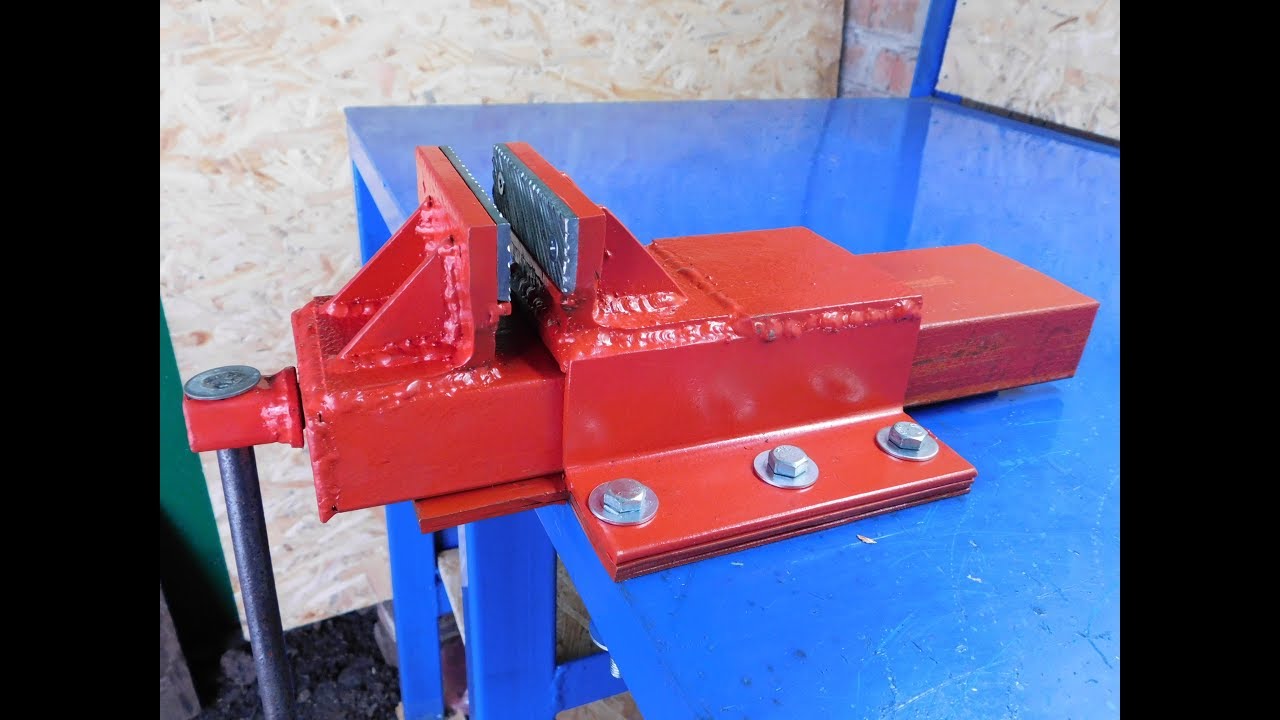

Additionally, the vise structure can be reinforced by welding gussets and stop plates as shown. on video and photo... Such locksmith vices are easily disassembled, so it is advisable to paint them with anti-corrosion paint for metal and install them in a permanent place.

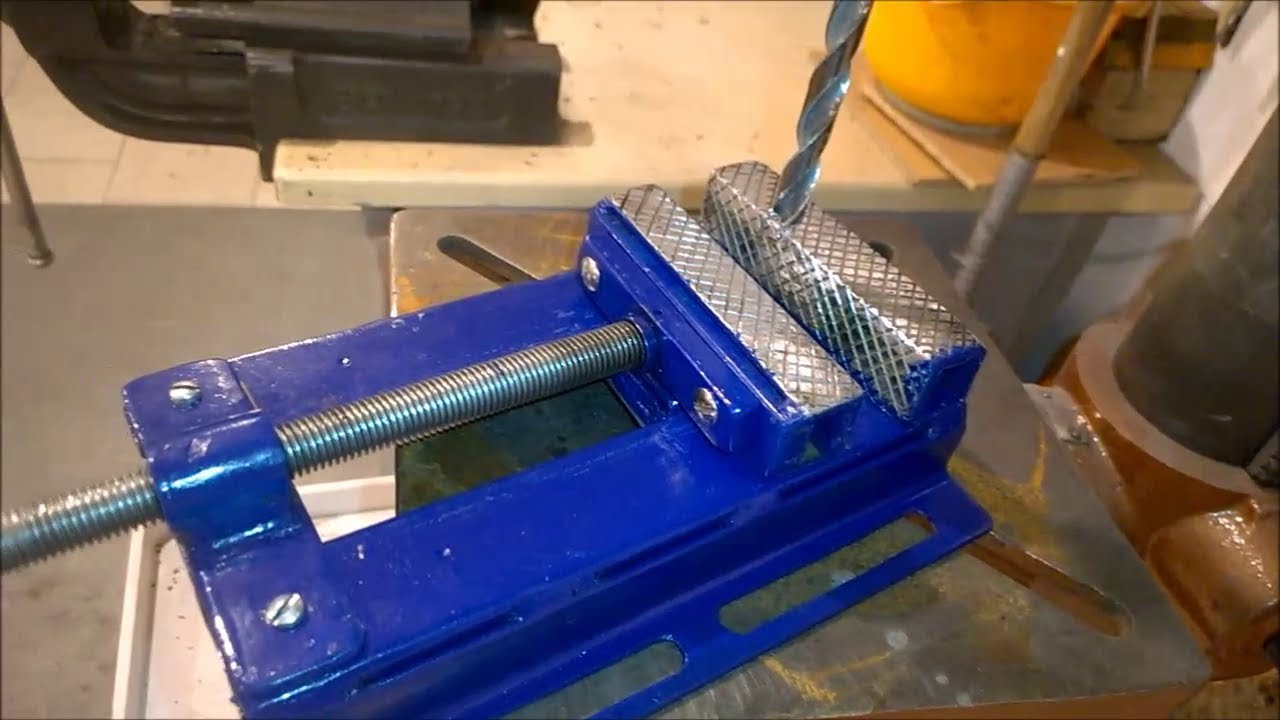

In the same way, you can make a vice for a drilling machine, only in this case the attachment to the machine bed will differ slightly depending on its design.

DIY vise making video

"Naked" smithy - without a forge - the height of indecency

If you speak pompously, then we can say that the forge is the heart of the forge, only there “steel obeys obediently”, turning almost into plasticine. The device is simple: coal is burned in the crucible of such a furnace, and a metal blank is placed there, which is heated to the required temperature. The smallest forge can even be built from a tin can. And he will allow you to make forged things as successfully as his solid "colleague" in the craft. True, their sizes will be appropriate.

The main task assigned to the operation of this equipment is to provide a fairly high temperature for heating steel. The best option would be a solid fuel hearth that uses coal. He also has a competitor - the Kuznetsk gas forge.

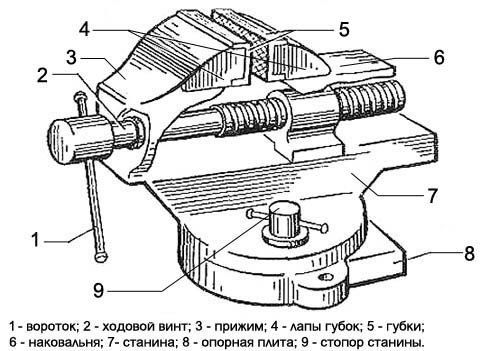

Varieties of vise: which fixtures to choose for different jobs

There are several types of vise, which are classified according to different parameters. One of the main identifying elements is the type of clamping mechanism. Based on this factor, the following types of vice are distinguished:

- screw;

- wedge-shaped;

- with installed diaphragm;

- eccentric;

- with pneumatic device.

Depending on the purpose, the vice is divided into the following types:

- carpentry;

- locksmiths;

- machine tools;

- manual.

Taking into account the material used, these devices are also divided into types. Joiner's vice for a workbench is most often made of wood, and locksmith's - of metal.

Vices are wedge-shaped, screw, eccentric and pneumatic

A locksmith vise is the most common type of tool in question. These devices have their own subspecies, they differ in size, or rather, in the width of the jaws. This figure can vary from 63 to 200 mm. Small vices are used mainly for household purposes. They are fastened with a lower clamp screw on a small machine, but more often on a table or an ordinary stool. Larger vices are installed in industrial workshops and large workshops for the purpose of processing large parts.

Locksmith vices: price, features and varieties

A vise for locksmithing is a must-have item in any industrial workshop. Such equipment is necessarily present in the workshop of an experienced, self-respecting master. Moreover, depending on the shape, type of fastening and the material to be processed, they are divided into several types.

Pipe vise is used to fasten pipes or cylindrical parts.

The main advantage of the rotary vise is the ability to fix the part in the required plane and at the right angle for organizing the workflow. With their help, it is possible to process the most inaccessible parts and their areas. At the same time, it is almost impossible to do this on an ordinary vice. Like all installations of this type, rotary products can be stationary - these are bench joinery vices that are attached to workbench tables. Another subtype is a vise with a built-in clamp for attaching to a table.

A vise for locksmith work is a necessary tool not only in the industrial workshop, but also in the home workshop.

Hydraulic vise is designed to provide more reliable fixation of especially large parts. Clamping in them is carried out under the pressure of compressed air. Basically, such tools are installed in large industrial enterprises. The price of this type of joinery vice is high, and the device is rather complicated, so the tool is not intended for home workshops.

Self-centering vise is necessary in high-precision production, that is, wherever precise fixation of a part in a certain position is required. Typically, this type of vise design requires a bearing base.

Features and varieties of joinery vice

Joiner's vice is used for processing wood parts. This type of work is specific, therefore it assumes a special design of the tool itself, which is different from the device of a locksmith's vice. Most often, joinery vices are made from solid wood, and the fixing of the parts is done using wooden vise sponges. In this regard, they should be wider than that of a locksmith's vice, in addition, they assume a significantly larger clamping area.

Joinery vice most often has one base, but two guides. With their help, the movable jaw is held, which makes it possible to avoid distortions. In this case, the guides can be an integral part of the workbench, or they can be removed if necessary.

Joiner's vice is designed for processing wood and plastic workpieces

Carpentry vices are also classified based on the technology used in the screw activation process. On this basis, they can be manual or pneumatic. If design features are taken into account in the classification, then the vice is subdivided into rotary and non-rotary.

As mentioned above, carpentry models are used to process wood and plastic blanks. Therefore, wooden parts are mounted on the jaws, which helps to avoid clamping marks. When the device is front mounted, there is a chance to work vertically with fixed parts.

Do-it-yourself joinery vice

Do-it-yourself joinery vice for a workbench

These joinery vices, also called Moxon vices, are well suited for various types of joinery work, they are convenient to use for clamping wide boards or panels, sawing and processing ends. Vices do not take up much space, they can be placed even in a small workshop, and besides, manufacturing is not expensive. Many designs of this type can be found on the internet, you can compare them to this version of the bench vise, which have their own advantages and the dimensions can be adjusted according to your needs. The design is not complicated, how to do it yourself, look at the step-by-step photos.

Another version of the Moxon vise, made from plywood. The vise can be made in a variety of ways and materials, this version used plywood sheets, wood glue, several screws, two screws for clamping, two tubes to serve as clamping screws. Two T-nuts and matching carriage bolts to ensure sliding.

How to make a twin screw joinery vice

If you need a really powerful Moxon joinery vice, this model will surely interest you. M20 Bolts from a Tow Hook can give a force of several tons, so this is an excellent option for a vice.

The assembly procedure is shown in step-by-step photos, only you should pay attention to such nuances as installing bushings so that the screws do not break the wood in the clamp. The author also used silicone glue to fasten the spacers.

You can use clamps to attach to a table, but I preferred metal brackets.

Moxon Mini Vise

Here's how to make a DIY Moxon Mini Vise. The photos below show step by step how to do this, the construction will not be expensive, and besides, they are quite simple to manufacture. Materials will require pieces of wood, screws, nuts, washers and leather. From tools a table saw, a router, a chisel, glue, sandpaper. 2 types of wood were used for the manufacture. Beech for clips and nut for wheels. In the picture you can see the dimensions of all the parts. After trimming the edges, sand it with sandpaper. Use a drill and sandpaper to round the edges of the wheels. Use a table saw to chamfer. To make screws, buy a long threaded rod and cut into two short pieces. Then insert the nuts into the holes. Stick the leather on the clips and just cut off the excess. To protect the surface, you can use tung oil, unlike other agents used for wood processing, it polymerizes not only on the surface, but in the mass of the wood, where it quickly penetrates. When the oil is dry, just put all the pieces together. Ready

Vise manufacturing instruction: option number 2

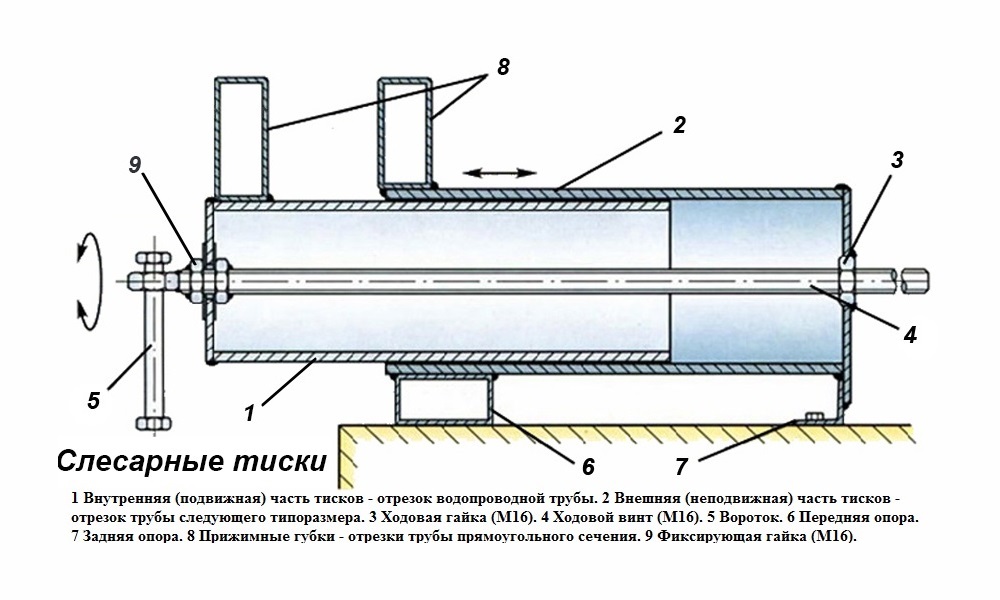

Homemade vise does not require complex design developments and calculations. You can use the numerous photos and drawings of such devices, which are easy to find on the Internet. A fairly simple, but at the same time very effective design is created on the basis of metal pipes.

As you know, pipes used for the installation of water and gas pipelines are produced in such a way that a product of a certain diameter fits tightly into a pipe of a subsequent standard size. It is this feature of pipes that allows them to be used for such a device as a homemade locksmith vice. A visual drawing, a photo and a description of the manufacturing process will help you to make these vices yourself.

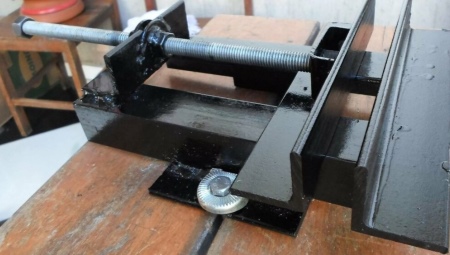

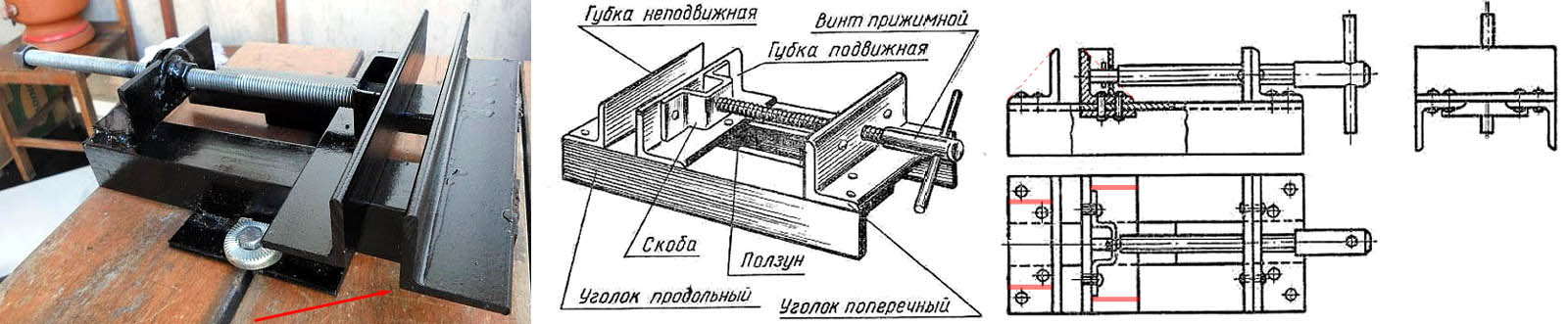

A drawing of a homemade vise. Below are two photos with the finished product

The constructive elements of which the homemade vise will consist are:

- a piece of metal pipe, which will act as the inner movable part of the device;

- a piece of metal pipe of the next standard size, which will serve as an external fixed part;

- running nut with a thread diameter M16;

- lead screw with thread diameter M16;

- a knob, due to which rotation will be imparted to the lead screw;

- front and rear supports, due to which the stationary pipe will be fixed on the base;

- pieces of rectangular pipe (future clamping jaws of the vice);

- two lock nuts with thread diameters M16 and M18.

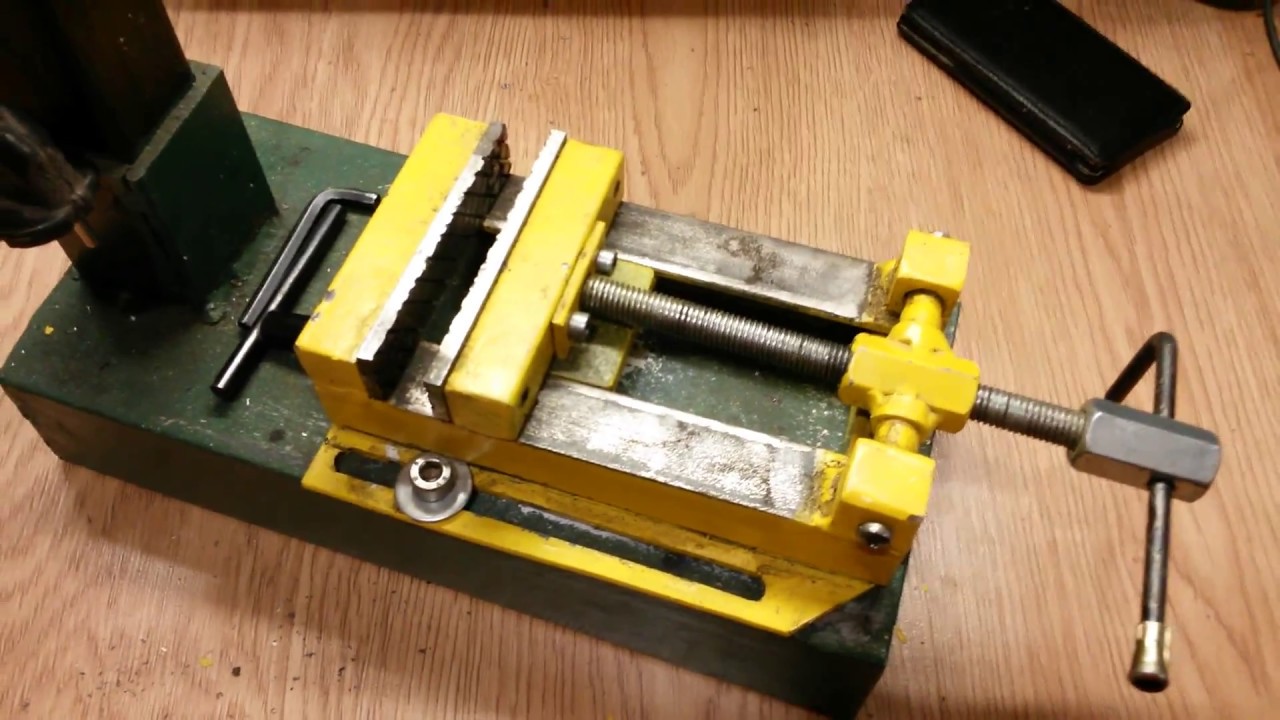

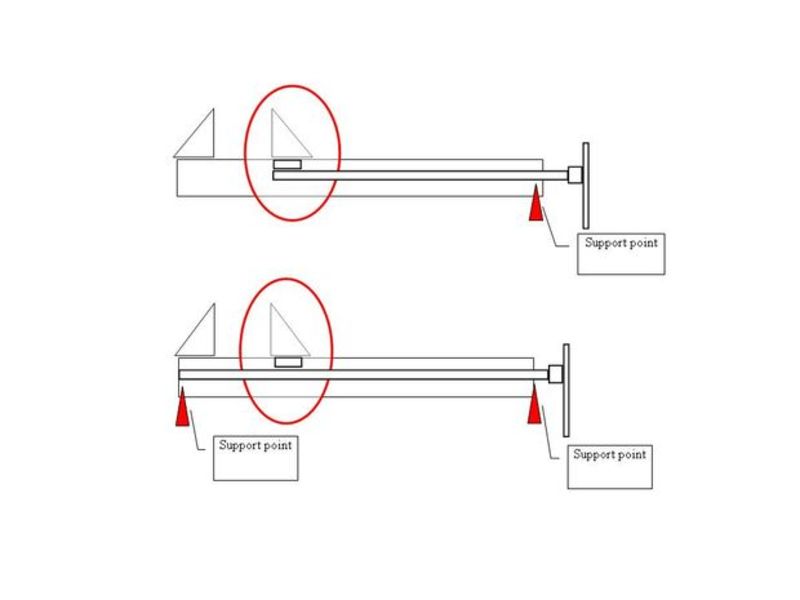

Two main parts of the vise (movable and fixed)

They begin to make such a vice with their own hands by welding a flange to the end of a section of a pipe of a larger diameter, which will act as a fixed element. An M16 threaded nut must be welded into the center hole of the flange. A flange with a central hole is also welded to the end of a section of a movable pipe of a smaller diameter, into which the lead screw will be passed.

At some distance from the edge of the lead screw, an M18 nut is welded to it (it will become a fixing element). After that, the end of the lead screw, to which the nut is welded, must be passed through the inner part of the movable pipe and inserted into the hole in the flange.In this case, the nut should press against the flange from its inner side.

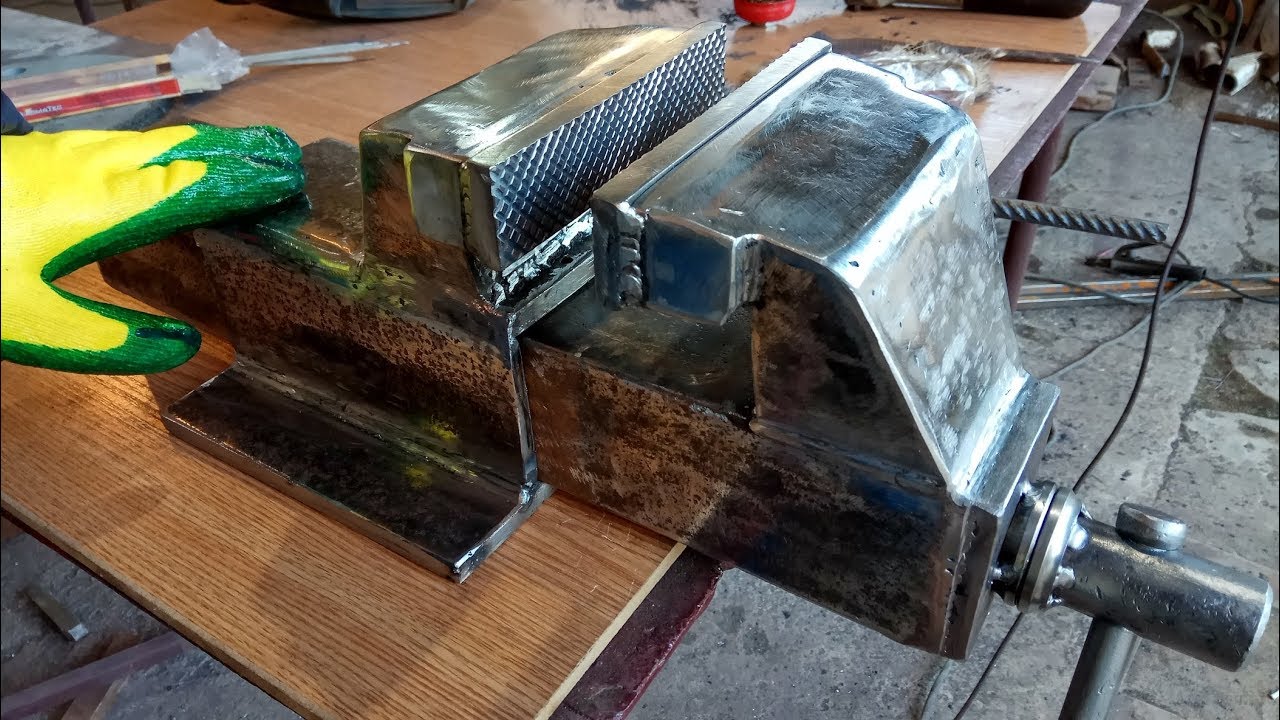

Assembled vise (in the photo, a hammer is clamped in them)

A washer is put on the end of the lead screw, protruding from the outside of the flange, and an M16 nut is screwed on, which is then welded to the screw. A washer must also be fitted between the inner nut and the flange face to reduce friction. To correctly complete this stage of making a homemade vise, it is better to focus on the corresponding video.

After the movable vise assembly is assembled, insert it into the fixed pipe of the larger diameter and screw the other end of the lead screw into the nut of the second flange. To connect the lead screw with the wrench, a nut or washer can be welded to its end protruding from the side of the movable pipe, into the holes of which the wrench will be passed.

The clamping jaws of such a vice can be made from pieces of rectangular pipes that are welded to the moving and stationary parts. To give the structure stability, two supports are welded to the bottom of the fixed pipe, which can be angles or rectangular pipes.

The inner tube can also rotate during the rotation of the lead screw, which makes the use of such a vice very inconvenient. To prevent this from happening, a longitudinal slot can be made in the upper part of the fixed pipe, and a fixing screw can be screwed into the movable pipe, which will move along this slot and prevent the moving part from rotating.

In many photos of homemade vices of a similar design, devices are presented, the movable and fixed parts of which are made of pipes of a square or rectangular profile. The use of such pipes also avoids rotation of the movable part of the vise.

If you do not plan to heavily load the vice, then it is quite possible to make them from wood according to a simple scheme

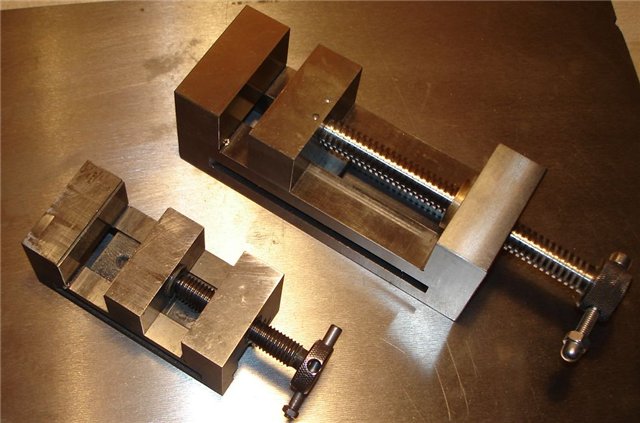

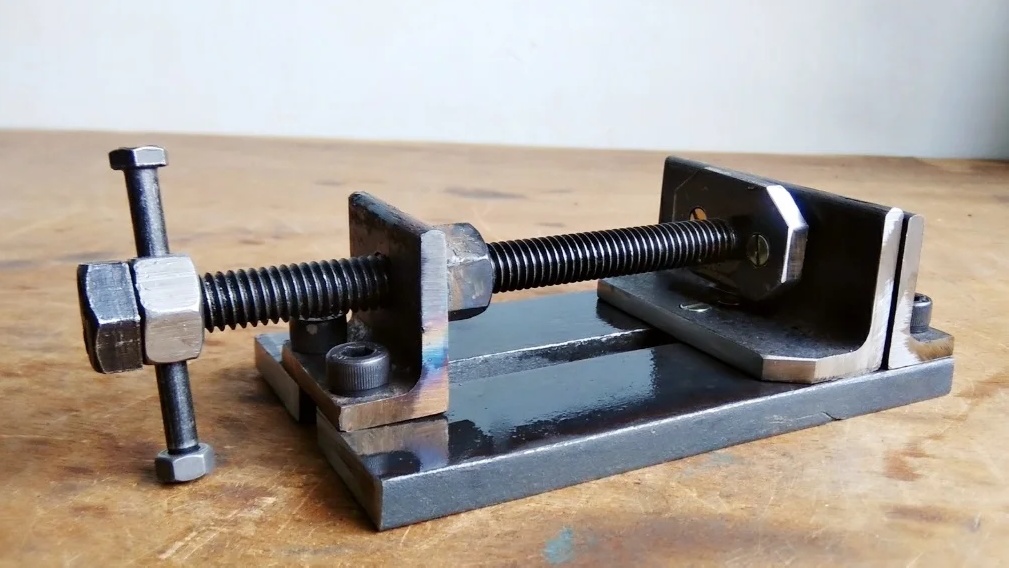

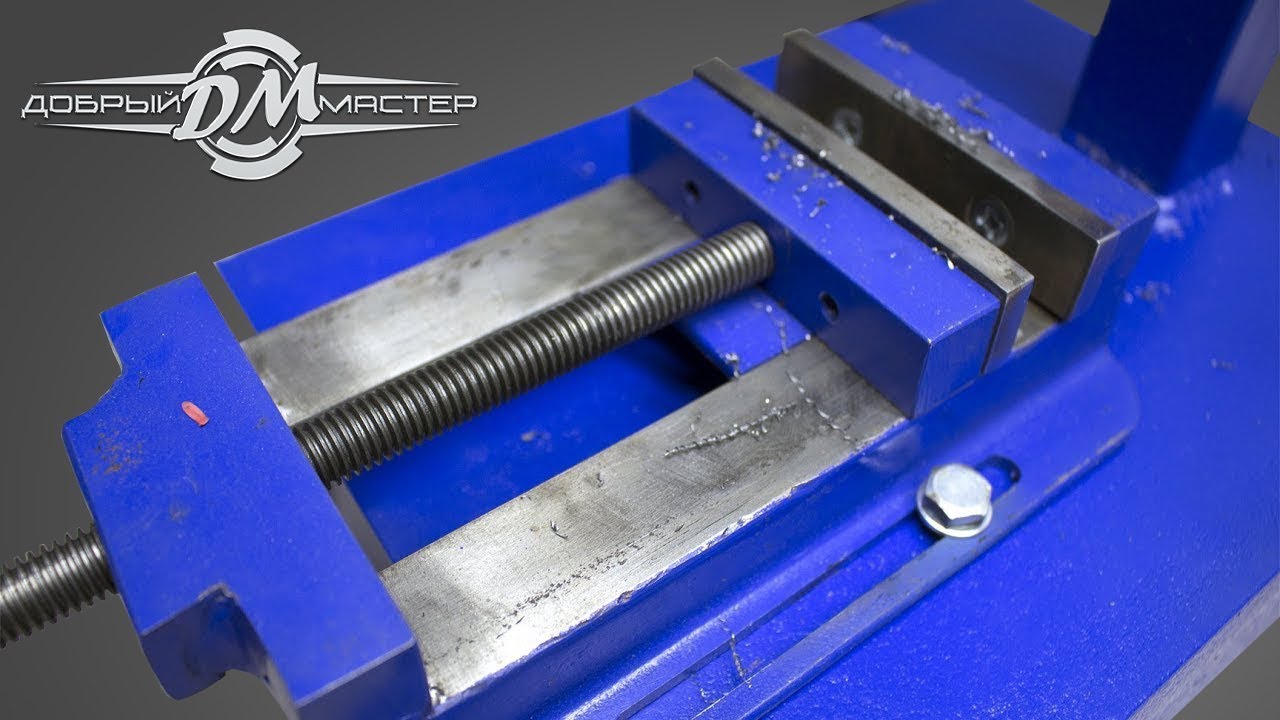

How to make a machine vise for drilling equipment at home?

First of all, you need to decide on the material from which the vice will be made. The ideal option would be to use a profile (square) pipe, 60 by 40 millimeters in size.

A square needs to be cut out of sheet metal, it will serve as the basis for the mechanism, four holes are made in it on each side. These holes are required to attach the vise to the drilling device.

Then we make two jaws from a profile pipe, drill a hole in one of them and insert a washer into it, and then a threaded screw will adjoin the plane and move it back and forth, pressing and releasing the part for drilling.

In order for the plate to move along the same axis with the fixed jaw, you need to make guides. The rails can be a corner welded along the edges of the plate on both sides, but so that they do not interfere with pressing the part.

Then it is necessary to work out the rotation mechanism, which will set the clamping jaws in motion. To do this, weld a nut with a clamp to the base.

Clamp nut

Clamp nut

Such a unit must be made very strong, since when the plate moves, the main emphasis will be on the nut.

Then a threaded screw is screwed into the nut and it is inserted into the hole of the plate with a washer, inside this part and the nut is tightened so that the bolt pulls the plate back. Now you need to fix the vise to the drilling machine using ordinary bolts and nuts and test it.

A vise for a drilling machine must go through all stages of verification, otherwise the result of work on such a unit will not meet the standards of state regulations. Swivel vices have their own specifics, so the setup process should not be rushed.

Swivel vise

Swivel vise

All manipulations with the unit must be carried out in a ventilated room with the required lighting level.All machines must be located in the home workshop with a distance of at least 70 centimeters from each other.

The rotary vise is used not only in large enterprises, but also in home workshops. With their help, it is easy to carry out small parts that require accurate marking of the dimensional lines.

Rotary lathes are popular in the modern industry for the production of large parts, as well as in the aggregate construction complex. Thanks to their high functionality, they can carry out small, meticulous processes without constant dimensional control.

Design and function of clamping devices

Since the machine vise is necessary to securely hold the workpiece in place during machining, it consists of strong steel elements. Depending on the type and purpose of the machine vice, their design can vary greatly.

The most inexpensive and least functional vise is of the non-rotating type, but such models have the most rigid design. By the way, homemade vices for a drilling machine are most often non-rotating.

The mid-range model includes rotary models, the functionality of which allows you to perform drilling operations more efficiently. The advantages of the first and second types are combined in universal attachments for a drilling machine, which, naturally, makes the cost of such devices quite high.

Even a vice of the same type, but produced by different companies, may have certain design differences. This is due to the fact that each of the manufacturers is trying to endow their products with additional options, to make them more reliable and convenient in operation.

Professional machine vices can be equipped with various clamping bars

Whatever functionality the machine vise has, the basis of their design is made up of mandatory elements, which include:

- strips that act as the base of the vise;

- two jaws providing clamping of the workpiece to be processed;

- a screw with a handle, due to which the movement of the movable clamping jaw is ensured;

- plates serving as working elements of the clamping jaws;

- a number of additional details.

The device of the simplest machine vice

The bar, which serves as a base, is a supporting element on which all other parts of the vice are fixed. It is on the bar, which is made of hard and wear-resistant metal, that a hole for a screw is drilled, movable and fixed jaws are mounted. To ensure accurate movement, the lower part of the movable jaw has a rectangular shank, which is inserted into a cutout made on the fixed jaw.

The shank responsible for the parallel movement of the jaws

The screw responsible for the movement of the movable jaw is in connection with it, which is provided by a special retaining ring. Rotating in the threaded hole of the base bar, the screw moves the movable jaw, thereby providing clamping of the workpiece being processed on the drilling machine. To understand how the vise works, you can watch the corresponding video.

Both serial models and home-made vices for a drilling machine can be made according to various schemes for the effect of a screw on a movable jaw. In the simplest vise models, which are easy to make with your own hands, the screw is directly connected to a movable jaw, which it either pulls (unclenches the jaws) or pushes (compresses the jaws), which depends on the direction of its rotation. In more complex models, which may include both fixed and rotary vices, the rotation of the screw is transmitted by gears, which facilitates the work of the drilling machine operator. Thanks to the gears, very little force is required to compress or unclench the vise jaws.

It should be borne in mind that the presence of a gear mechanism is not at all a criterion that should be emphasized when choosing clamping devices for a drilling machine. Many well-known manufacturers, whose products are popular with specialists all over the world, produce devices whose principle of operation is implemented according to a standard scheme, which does not make them less effective or inconvenient to use.

Hydraulically reinforced vise provides stable compression independent of shock and vibration

Pressure plates, or strips, are important structural elements of any type of vice that undergo significant loads during operation and ensure reliable fixation of the workpiece being processed. These elements, made of durable metal, are attached to the working surfaces of the clamping jaws using screw connections.

In the standard version, the clamping strips have a flat working surface, on which a cross cut is applied. More specialized types of strips are also used, which are necessary for processing workpieces of a certain shape. The working surfaces of such strips can be made in various shapes (angular, concave, etc.). In some modern vise models, the clamping bars may be spring-loaded. This design makes it possible to slightly increase the convenience of fixing the parts in the clamping device of the drilling machine.

Vise with prismatic jaws

DIY drilling vise instructions

Making non-rotatable machine clamps with your own hands is quite simple. Homemade vise for a drilling machine is convenient, economical, and does not take much time to make. When making homemade machine clamps, it is recommended to use strong metal, such as steel.

To make homemade clamps, you will need: a base (a metal box in the shape of a rectangle with high ends, the inner part must be hollow), two plates that act as clamping jaws, a screw, a lever, a clamp for jaws (two small parts with which you can connect a movable sponge and screw), nuts.

The first thing to do is to draw a drawing of the future vice for the drilling machine, adjust all dimensions. You can use the training video in which the dimensions have already been calculated. Then, you need to select or buy blank parts for homemade clamps. After all the parts are in stock, you can start manufacturing:

- Drill a hole in the base of one of the ends. The diameter must match the screw diameter.

- Drill 4 holes in the base of the workpiece, with which the machine vice will be fixed on the table.

- Weld a plate to one end of the base, which will act as a fixed jaw.

- Insert a threaded pipe or screw into the hole at the end.

- Connect the movable jaw with the clamps to the screw.

- Drill a hole in the free end of the screw.

- Insert the lever into the screw hole. In the role of a lever, you can use a long screw or, suitable in diameter, a metal rod.

Each type of machine clamps is designed for a specific type of work. For home use, an inexpensive fixed vise is best. For mass production, it is certainly more cost-effective to purchase a rotary vise. Making homemade clamps is a simple and quick process. If you use the training video, the production time will be reduced several times.

Dear visitors of the site "Samodelkin friend" today we will look at detailed step-by-step instructions for creating a small vice for a drilling machine with your own hands from scrap metal ..Every artisan knows perfectly well how sometimes it is inconvenient to drill small workpieces and parts with a drilling machine, because the part needs to be held firmly, and it always strives to scroll and fly out or, even worse, injure the master. So, for more convenient and safe work, namely fixing the workpiece, small VISES were invented, with their help you can quickly fix the part and quietly drill without fear of what will turn)

You can easily make such a vice yourself, for which you need a metal corner from which the base and sponges are made. The movable part of the vise consists of a stud and nuts, a bearing for support is installed in the end part. Length 260 mm, width 180 mm.

Materials (edit)

Instruments

Step-by-step instructions for creating a vise for a drilling machine with your own hands.

A diagram was previously drawn up.

2 metal corners were cut off. Marking on the vise jaws. We drill holes for attaching wooden sponges. Bearing hole. Nuts for the moving part. Hairpin and knob. The movable part of the vice. Painting. Assembly. Installed wooden sponge pads. These are the vices)

The use of a drilling machine provides for the fact that you have clearly fixed the workpiece and it will not move until the moment when the drilling process is completely completed. Only after the person is satisfied with the result, the part can be removed and used in other conditions.

The simplest type of vise for a machine tool

To clamp the parts in the desired position, a table vise for a drilling machine is used

It is difficult to overestimate the importance and influence that the machine vice has on the entire process of work, which is associated with the manufacture and boring of various parts.

This article will talk about machine vise models, their varieties and features.

Varieties and benefits

Factory vise models are made universal, so they cannot always fix absolutely any part well. They also have a large mass and dimensions. Do-it-yourself vices can be made most convenient for performing a certain type of work. This will help increase labor efficiency and reduce time spent.

Any craftsman who constantly works in his workshop knows that it is difficult to do without such a tool as a good vice. Such a clamping device helps to carry out various operations with wood, plastic and metal products. The use of a vise can guarantee efficiency and good accuracy in various types of work. It will also ensure human safety. When it is not possible to buy a factory model of such a device, then it is quite simple to make it yourself. This operation will take little time and effort.

Homemade vices are usually divided into the following types: