How to make a trailer for a walk-behind tractor with your own hands?

By design, the bodies are divided into:

- Whole. The peculiarity of their design lies in the tight fixed connection of the bottom and walls.

- Body with drop sides. A feature of this device is the ability to transport bulky goods.

- Tipper body. This body will perfectly cope with unloading work.

Preparation of a drawing of a trailer for a walk-behind tractor

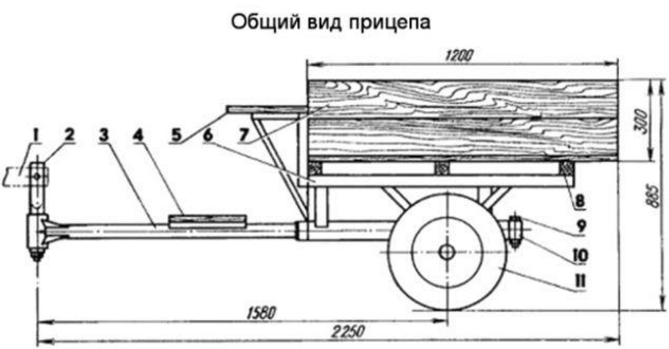

What size should a homemade trailer for a walk-behind tractor be:

- If you have a light type of walk-behind tractor, then the width of the trailer should be equal to 1 m, and the length should be 0.85 - 1.15 m. The carrying capacity of such a trailer is about 300 kg.

- If you have a walk-behind tractor with a capacity of more than 5 liters. with., then there will be the following dimensions: width - 1 m, length - 1.4 - 1.5 m.

- For heavy units, a trailer with a width of 1.2 m and a length of 2 - 3 m is suitable. They are more often biaxial.

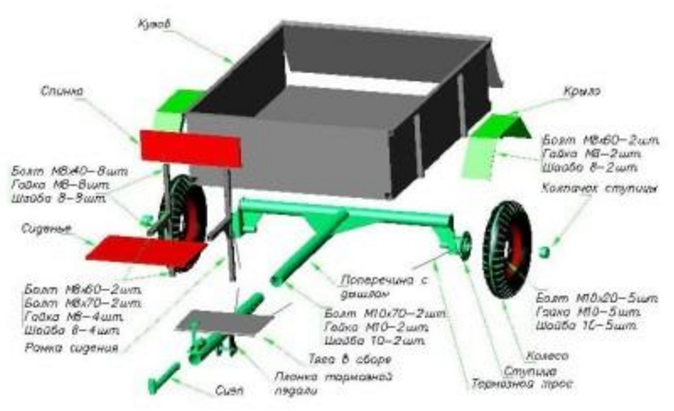

Next, you need to create drawings with your own hands and choose the dimensions of the trailer you need. Only its exact scheme will allow you to successfully create a structure that will serve for many years. Here is an example of a drawing of such a body.

Body frame drawing

How to make a trailer for a walk-behind tractor with your own hands - assembly steps

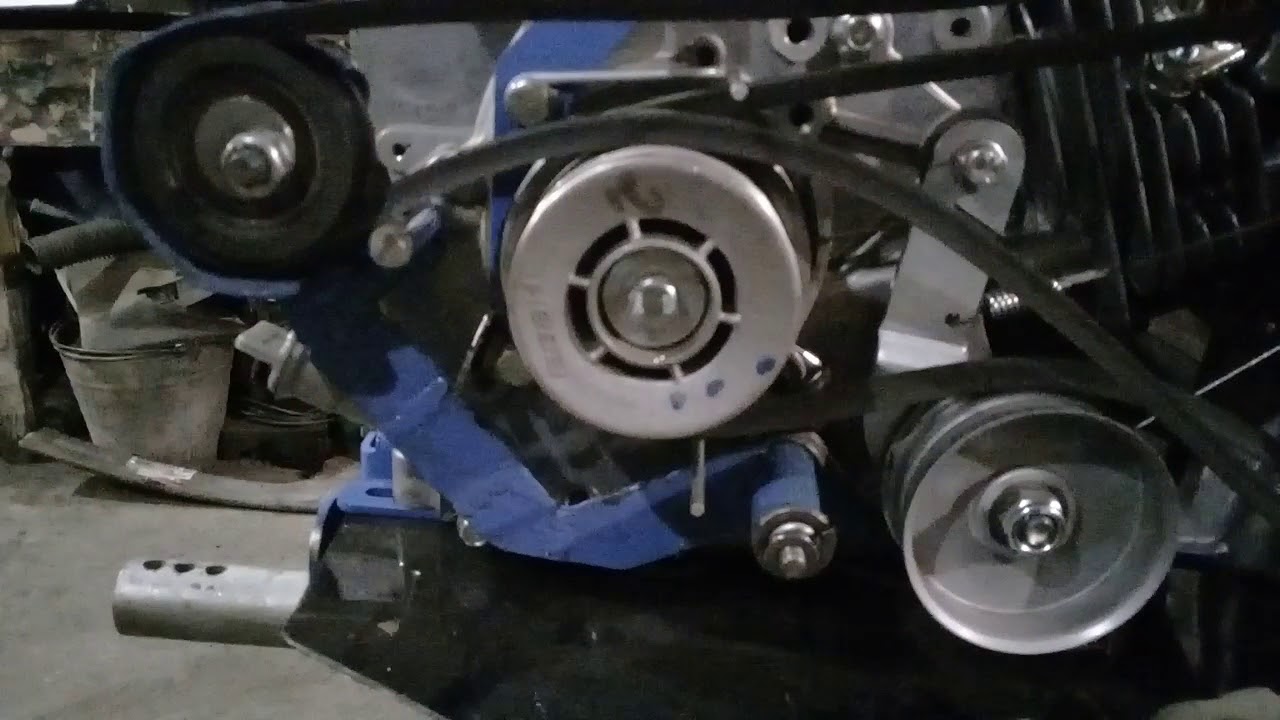

For a regular frame, we only need 2 tubes and wheels with bearings. We can attach the body itself to the finished frame. In order to soften the shaking on potholes, you just need to install a spring.

We collect a homemade motoblock trailer. To begin with, an additional pipe is attached to the main pipe, which will act as an axis. Then, on the other side, a hitch for the walk-behind tractor is mounted. We weld the hubs to the ends of the axial tube. Next, we fix the wheels and fix the parking stop

We attach the body, fenders and seat.

The body is best made of wood or metal.

Particular attention should be paid to the trailer hub, it must be strong and reliable.

How to make brakes on a trailer for a walk-behind tractor?

In order to put homemade brakes on the body and ensure a safe ride on a walk-behind tractor, it is worth acquiring several parts for its design:

- Brake pads from a motorcycle.

- Motorcycle brake drum.

- Spokes from a motorcycle wheel.

- Better to set the brake on both wheels. This will allow the equipment to brake effectively.

Stages of work:

- We remove the rods and cables from the disc and clean it.

- We put on the drilled drums on the hubs and fix them at the back.

- The free space that has formed between the ribs of the drums must be wrapped with metal wire.

- We put the already collapsible disc on the axle and fasten it with bushings.

- We weld a piece of metal onto the axle to exclude the displacement of the disc.

- We mount the cables on the drums and extend them to the control.

- The control system can be a gear lever.

In principle, having a good scheme with accurate calculations, you can easily design both a single-axle and a two-axle dump body yourself. The main thing is to know how to do it and follow all the instructions. Having made such equipment yourself, you will find an incredible assistant for working on the sites.

TPM 01

The mass of such a device is 85 kilograms, due to this, in comparison with the previous model, the carrying capacity increases by 50 kilograms. The device is 3 meters long, 1 meter wide and 1.23 meters high. The maximum speed is similar to the TM 360 model, but the unloading type differs from the previous models, it is dumping.

Main characteristics

Having studied the various models of trailers for the walk-behind tractor, the following main characteristics of the devices can be distinguished: carrying capacity, dimensions, type of unloading.

There are three types of carts: heavy, medium, light. These differences depend on the maximum weight that the trailer can lift. The manufacturer Neva produces models with a carrying capacity that varies between 250-1000 kilograms. This parameter depends on the engine power of the unit.

Heavy trolleys are designed to transport loads weighing 500-1000 kilograms, they are used for motor cultivators with an engine power of more than 10 horsepower. As a rule, such structures are produced biaxial with a length of 3 meters and a width of 1.5 meters.

Medium trailers are designed for unit power from 4.8 to 10 liters. with. The device is uniaxial with a body length of about 1.5 meters and a width of one meter. The carrying capacity of such a trailer varies between 25-500 kilograms.

Carts are classified into 3 types

Carts are classified into 3 types

For lightweight structures, trolleys with one axle and dimensions of 1.2 × 1 m are used. They are designed for motoblocks with a capacity of less than 4.8 horsepower, since the maximum weight that they can transport is 250 kg.

For ease of use, such devices have rear folding sides, some varieties are equipped with removable side bumpers.

An important parameter is the type of unloading. Most of the Neva models are equipped with a tipper type of unloading. The presence of this characteristic makes it much easier for the owner to perform unloading of goods.

All modern models of walk-behind tractors are initially equipped with a universal hitch, which makes it possible to attach exactly the model of a trailed trolley that you like to the self-propelled mechanism. However, in this case, it is necessary to carefully study the characteristics of the structure and its compliance with the Neva motor cultivator.

Basic rules for choosing a trolley for the Neva walk-behind tractor

Trailers for motoblocks, be it Centaur, AGRO, Neva MB2 or Motor Sich, are not designed for driving on busy roads, let alone highways. Their main purpose is to transport goods from vegetable gardens and summer cottages, while it is better to move them outside the road network so as not to create an emergency situation on the roads.

When choosing a trailer for a Neva walk-behind tractor, as for any other brand, you need to correctly correlate the trailer's load capacity and the power of your mechanical worker. If we talk about the choice of a trolley for the Neva walk-behind tractor, then, with the exception of the model range of heavy MB-23 models, the rest of the model line is equipped with engines from 5.5 to 7.5 hp. Therefore, the optimal solution for them would be the choice of a towing device with a carrying capacity of 250 to 500 kg. The trailer device for the Neva MB 23 walk-behind tractor can be taken with a carrying capacity of up to 1 ton. - these powerful mechanisms will have enough strength to drag such a load.

The rest of the rules when choosing a trailed cart for any walk-behind tractor, incl. and for the Neva, they are dictated not so much by concern for the walk-behind tractor as by common sense and ease of use

When choosing, you need to pay attention to:

- Body material. It is better to choose a cart, the body of which is made of galvanized steel - it is not afraid of frost, heat, rain and dirt.

- The presence of tailgate and dump body dumping to load and unload the cart was easier and more convenient.

- Availability and quality of brakes. Since it is often necessary to transport loads with a walk-behind tractor on uneven terrain, the presence of reliable brakes on a steep descent will save you from major troubles.

Observing these simple rules, you can choose such a trailer for the Neva walk-behind tractor, which will serve you for many years. But if, for some reason, you do not want to buy a factory trailer, then it is easy to make it yourself.The main thing is to find good drawings of a self-made trailing device and acquire the necessary tools and materials for this. But that's another topic for conversation.

Main characteristics of trailed trolleys for the Neva

At different times, 4 trailer models were developed directly for Neva motoblocks:

- Single-axle dump truck with dimensions 110x90 cm and a side height of 35 cm. Loading capacity -250 kg, dead weight -56 kg;

- Two-axle chassis trolley with dimensions of 110x90 cm and a side height of 35 cm. Carrying capacity - 500 kg, dead weight - 40 kg;

- TPM trolley with dimensions 133x110 cm and side height - 30 cm. Carrying capacity - up to 250 kg, dead weight - 110 kg;

- TPM-M trolley with dimensions of 140x82.5 cm and a side height of 25 cm. Carrying capacity - only up to 150 kg, dead weight - 85 kg.

However, this does not mean at all that only these 4 carts can be hooked to the Neva walk-behind tractor. The vast majority of modern trailers are equipped with a universal hitch that allows them to be attached to any self-propelled mechanism, so you can safely take any one you like. But before buying another brand of trailer, it is better to first make sure that the hitch on it is suitable for your model of two-wheeled assistant.

Trailed aggregators for motoblocks "Neva"

Trailed aggregators for Neva walk-behind tractors include:

- snow blowers;

- trailers;

- couplings;

- weighting agents.

Snow blowers

Snow blower SMB "NEVA"

With the help of this type of equipment, it is possible to carry out winter harvesting work on land plots.

The use of a snow blower will help to quickly clear a large area, and not necessarily the territory of a land plot, but also an open space, for example, a courtyard of a private house, a lawn, areas of a garden without trees.

Trailers

A useful item in agriculture is a trailer.

An irreplaceable addition to the walk-behind tractor, which allows you to harvest crops, put things in order on the land, transport small and medium loads across the territory of the dacha, etc. Trailers differ in capacity (small ones are usually called bogies), carrying capacity, overall dimensions.

Couplings

The hitch is a universal fastening part for coupling any type of attachment with the Neva walk-behind tractor.

Double universal hitch

It is not supplied in kits and must be purchased separately. You can order a hitch at the time of buying a walk-behind tractor or when purchasing any type of additional functional parts.

Weights

Weights are used to give the walk-behind tractor more weight, therefore, to increase the impact of trailed equipment on the ground, in particular, on such indicators as the depth of plowing the soil, lowering the level of mowing, digging potatoes at a greater depth, etc.

Simply put, with the help of a weighting agent, you can make the walk-behind tractor heavier, which means more powerful in terms of impact on the ground. As an example, we can cite a ten-kilogram weight-weighting agent for the Neva walk-behind tractor, mounted on wheels, or a weight-weighting weight weighing 17 kg, fixed on a motor-block pin.

Good luck

-

PROMOTIONAL:

Lol, l ± l, l, l -

PRINCIPLE:

14500 Ð ± РеÐ

Power supply. SHOULDER, SHOULDER, SHOOT, SHOULD, SHOULD, SHOULD, SHOULD Burgundy bore Bump, bump, bump - bump, bump, bump

Saucer, saucer, saucer, saucer, saucer , Long and short.Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Back and forth, back and forth, back and forth. Tartar, tartar, tartar, tartar, tartar, tartar, tartar On and on, on and on, on and off. Flush.

Bark, bark, bark, bark, bark, bump, bump Saucer 500 saucer

Rose: Rose 222, Rose 112. Rose 120. Rose Contact. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Contact. ÐÑмÐμÑÑ ÑÐ ° кжÐμ ÑоÑоÑÑÑ ÑоÑмоР· нÑÑ ÑиÑÑÐμмÑ, вÑÐμ вÑпоР»Ð½Ðμно пÑоÑÑо и ÑоÑоÑо ÑмоÑÑиÑÑÑ, ÑикÑÐ ° ÑÐ¾Ñ ÑÑоÑноÑного ÑоÑмоР· Ð ° ÑÐ ° Ñпол ожÐμн нРDonut, donut. Saucer, saucer, saucer, saucer, sartorial, sartorial ÑÑÑ.

Bumpy flap

REFERENCE

- Goodbye

- Food

- Close up

Good

Rose Rose

Hearth

Re-equipment of "Neva" walk-behind tractors into a tractor

Many owners of land plots perform such manipulations as re-equipment of Neva walk-behind tractors into a tractor.

Mini tractor from the Neva walk-behind tractor

In general, this task is quite real, however, to implement it, a certain amount of additional equipment will be required, but first of all, a high-power walk-behind tractor will be needed. After all, the more area you need to process, the more powerful the unit will be required.

To save resources, it is better to opt for diesel models. You will also need an extra pair of wheels, steering and braking system. Describing in a nutshell how to create a tractor from a walk-behind tractor is a difficult task.

Video: Mini tractor from the Neva walk-behind tractor

However, the general principle is this: having a powerful Neva walk-behind tractor at its disposal, making a tractor for work on an agricultural site will be much easier and cheaper than purchasing a ready-made tractor.

We collect the chassis

You don't need a lot of details to create a comfortable driver's seat. The heavily loaded parts are the turn signal and also the drawbar, so they need to be reinforced with stiffeners. To attach the driver's seat to the walk-behind tractor, you need a hinge.

As the saying goes, "you don't need to invent a bicycle." An excellent option would be a pipe-in-pipe design. Thanks to this connection, a semblance of a hinge system is obtained, due to which the wheelbase of the driver's seat pivots on its own. This connection reduces the chance of deformation of the trailer bogie.

Install the driver's seat to the central tube using bolts, as well as studs and locknuts. Pre-cut an oblong hole in the pipe for high-quality fixation of the bolt and free rotation.

Springs, awnings and wheels are installed from any cars and sidecars, but in strict accordance with the expected loads. It is advisable to weld these parts to the beam, while the ends must be attached to the spar.

For the drawbar, a pipe with a cross section (60 × 30 mm) is often taken, which must be welded to the front of the side members. The edges must be welded to the drawbar.Thus, a kind of analogue of the factory version of the drawbar comes out.

Do-it-yourself trolley for a motorized towing vehicle

A motorized towing vehicle (motorized dog) is a device for transporting goods, traveling through snow and wetlands. The towing vehicle itself has a caterpillar track and is complemented by a sled. A sleigh trailer is convenient in winter, provided there is a large snow cover, however, in summer or in snowless winters, using such a trailer is problematic.

Agricultural machinery manufacturers offer a wide range of trailers, adapters and carts, including those for a motorized towing vehicle. Some owners of such equipment create a cart with their own hands. Its device practically does not differ from a trolley for a walk-behind tractor.

The main difference between a motorized towing vehicle, which dictates the features of the device of trailers, is a caterpillar track. These vehicles are ideal for off-roading, so the trailer must meet the same requirements.

Two types of trailers are recommended for motorized dogs: a loading platform and a skidder. Both options are complex in execution, so it is better to adapt the finished trolley for the walk-behind tractor. Drawings and dimensions for the trolley of a motorized towing vehicle and a walk-behind tractor will be almost the same, so you can use any.

The main feature of the trailer for this type of equipment is the low pressure wheels. They have a high shock-absorbing effect and are excellent for off-road use. A trolley with such wheels can be used at any time of the year. This modification requires axle reinforcement from the bogie, as well as wheel attachment. All other parts of the cart can remain unchanged.

Types and types of hook-on devices for motoblocks Neva

Single-axle trolley trailed to the APM adapter

It is a simple trolley with one axle and a body on top. It is simple in its design, but at the same time there is nothing superfluous in it. It is durable, reliable and practical.

Single-axle trolley trailed to the APM adapter

The trolley is intended for use in conjunction with the adapter of the Neva walk-behind tractor.

The trolley is used to transport any goods weighing up to 250 kg. Plus this trailer is equipped with pneumatic tires. They significantly reduce vibration and shaking when moving over bumps and bumps.

- The single axle trailer has a ground clearance of 180 mm and a track of 870 mm.

- Overall dimensions of this trolley model: length is 150 cm, width - 72 cm, height - 96 cm.

- The weight of this model is 56 kg.

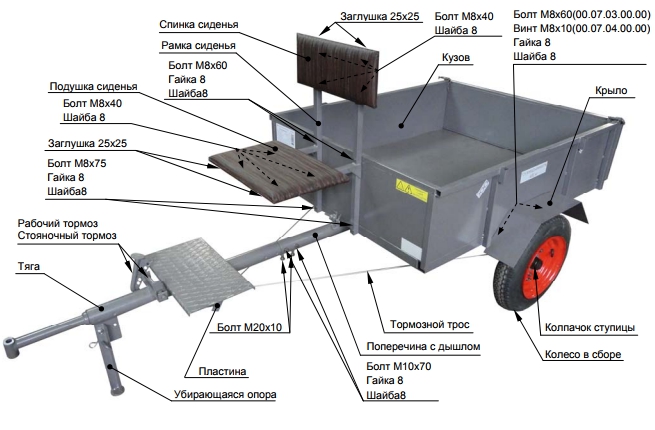

This trolley is delivered disassembled with detailed instructions for assembly and further operation.

The assembly is simple and intuitive. This usually takes about 10 minutes.

Read more in the instruction manual

If you need to transport the trolley, you can disassemble it and fold it compactly for transportation.

Two-axle trolley trailed to the APM adapter

The structure of this trolley consists of a frame and two attached axles.

Two-axle trolley trailed to the APM adapter

The difference from the previous model is that it is not intended for the transportation of bulk cargo.

There is no bottom, but this can be fixed with a sheet of metal or plywood of the appropriate size. In this case, the length of the sheet can be changed if necessary.

However, the maximum carrying capacity is twice that of the single-axle version and amounts to 500 kg.

- The two-axle bogie has a ground clearance of 18 cm and a track of 99 cm.

- The two-axle bogie is distinguished by its great maneuverability, as well as the presence of pneumatic tires.

- The maximum travel speed is 12 km / h.

- Overall dimensions: length adjustable from 190 cm to 250 cm, width - 41.5 cm, and height 110 cm

Assembly diagram and operating instructions

Adapter APM

APM models work only with additional equipment with an adapter.

Adapter APM

This is the axle on which the seat and rear hitch are installed for further installation of the trailer. This equipment is used not only with a trailer, but also with many other attachments.

Trailed trolley TPM

This bogie is an improved version of the single axle version. It can be used without an adapter because the seat is installed in front.

Trailed trolley TPM

During aggregation, its height ideally coincides with the Neva walk-behind tractor.

Trailed trolley is designed for use in construction, agriculture or country houses, where there is a need to transport any type of cargo.

- The maximum lifting capacity of the TPM is 150 kg. And the weight of the structure itself is 100 kg.

- The recommended travel speed is 10 km / h.

- The overall dimensions are 270 cm long, 125 cm wide and 120 cm high.

- The ground clearance is 30 cm and the track is 1 m.

There is a folding side on the back of the cart, which facilitates the process of loading and unloading.

Trailed trolley TPM-M

The letter M in the name indicates that this is a trailer trolley TPM M only modernized.

Engineers reduced the size of the bogie, but the performance remained the same.

This model measures 222 cm long, 112.5 cm wide, 120 cm high. The weight of the improved model is also less. Now he is 85 kg.

Trailed trolley (VRMZ)

This is the only model that is not produced by Krasny Oktyabr. Based on the name it is clear that it is manufactured at the Volga plant "VRMZ".

By its design, it is an improved TPM model.

Trailed trolley (VRMZ)

The main characteristic of the bogie should be its carrying capacity. In this case, it is 400 kg! And this is almost three times more than that of TPM. Therefore, it is very popular among construction companies or owners of large barns and warehouses, where it is necessary to transport large loads and travel twice unprofitable.

Moreover, there is no need to purchase an adapter to use a VRMZ trailer. It connects directly to the gearbox shaft. And it is operated sitting on the board of the trolley.

The distance from the road to the bottom of the trailer is 30 cm.

The track gauge is 117 cm. Despite the increased carrying capacity, its weight is only 95 kg.

For convenient and safe operation, a hand brake is installed on the frame, thanks to which you can quickly stop the movement.

Like all other trailers, this model is supplied unassembled with instructions for assembly and operation.

How to make do-it-yourself lugs

Homemade grousers for a walk-behind tractor can be made from machine disks. If a farmer has an old car, which is a pity to throw in a landfill, with whole discs and rims, then they can be used to make lugs for a walk-behind tractor from car disks.

For this you will need:

- rims;

- welding machine (or grinder);

- square plates;

- drawing or diagram of lugs for the walk-behind tractor (it will greatly facilitate the work).

So, in order to make lugs for the walk-behind tractor from the disks of the machine, you need to weld the axle shaft to them, on which the bearings are then put on. Square plates must be welded to the disks from the car.

After the performed procedures, it is necessary to make plate-teeth that will bite into the soil, providing the necessary adhesion to it. The teeth can be made from solid metal layers by cutting out the required size with a welding machine or by welding small plates together.

The teeth are welded to square plates on discs at a distance of 15-16 cm from each other. A deviation of 2-3 cm is permissible, but for the best operation of the unit, you must carefully follow the instructions of the drawings and diagrams.

If the old car is not available, but there is a used gas cylinder, then there is another way to make lugs on the walk-behind tractor with your own hands.

For this you will need:

- gas bottle (used);

- grinder or welding machine;

- metal teeth plates;

- drawings or diagrams of grousers of the motoblock of the desired brand.

First, you need to cut out two discs from the cylinder, which will serve as rims for the wheels of the walk-behind tractor.Then, as in the first option, weld square plates, and teeth to them.

Another option is to weld steel lugs. For this you will need:

- steel layers 4-5 mm thick;

- steel layers 6-8 mm thick;

- welding machine or grinder;

- drill or hammer drill.

A thinner sheet must be cut into two discs, in the center of which holes must be made for the hub. Cut sawtooth waves along the outer edges, with a wave depth of 100 mm. Triangles with cut corners must be cut out of a denser steel layer, welded perpendicular to the waves. The structure is ready for use.

Of course, such lugs differ in appearance from their counterparts, but they also have many advantages.

Blueprints

Before starting the construction of a trailer, you should carefully consider its purpose. The dimensions of the device largely depend on this. In this case, the parameters of the trailer must coincide with a certain walk-behind tractor, so that it is convenient to use them together. According to the power of motoblocks, the following types of trailers are distinguished:

-

lungs;

-

medium;

-

heavy.

Motoblocks with a capacity of up to 5 liters. with. go well with trailers on the same axle. The body of such devices has a maximum dimensions of 1 by 1.15 meters and is considered light. Medium trailers are suitable for motoblocks with a capacity of 5 to 10 liters. with. The dimensions of such devices can be 1 by 1.5 meters or 1.1 by 1.4 meters. They are designed for the carriage of goods weighing from 300 to 500 kg.

For cultivators with a capacity of 10 liters. with. it is best to use a body with two axles. Its dimensions will be approximately 1.2 by 2 meters. In such a trailer it will be possible to transport goods weighing up to 1 ton. These are the ones that are considered heavy.

A simple trailer consists of the following basic components:

-

carrier, consisting of several parts;

-

sturdy frame;

-

comfortable body with a frame;

-

wheels of a suitable size.

The carrier includes such parts as a body for the unit responsible for turning, a drawbar made of a pipe, a footboard frame, a stop made of a pipe, ribs for stiffness, overhead parts in the form of strips. Parts are connected, as a rule, using a welding machine. The greatest load falls on the place where the drawbar meets the swivel unit. It is precisely this that needs to be well strengthened with the use of stiffening ribs.

The frame is most often made of steel, or, more precisely, rods (pipes), the diameter of which is at least 3 cm. Connections on the frame are made using welding, kerchiefs, spars, supports at the corners, the body of the longitudinal hinge. Each frame must include a number of terrain-specific features that will be used, such as pits, bumps and more.

The body can be made of both metal and wood. It can be solid or made of rods.

In order to make a wheel axle, you should use a steel rod. Its diameter should be approximately 3 cm and its length should be approximately 1.07 m. These parameters are best suited and do not allow the wheels to protrude from the trailer body. As for the wheels, they are suitable for almost any technique. The main thing is that they fit the size of the design.

When preparing, it is necessary to take into account that the scheme includes a number of subtleties. An important point is the presence of not only main, but also auxiliary nodes

It is also important to choose in advance the method by which the knots will be fastened.

Usage Tips

It is undesirable to entrust the control of a walk-behind tractor with a cart to those who are under 14 years old. Sticks and other controls should be adjusted to the height of the operators. Before each drive, it is necessary to check the serviceability of all connections and couplings. In a number of designs, a console provides a hitch between the trailer and the walk-behind tractor. In any case, the docking should take place taking into account the standard tractor bracket. For harsh environments, a swivel joint should be selected.

Prohibited:

- operation of overloaded carts;

- driving on an unreasonably steep slope;

- transportation of people and animals on a trailer.

See below for details.

Model overview

The trailer trolley TM-360 is capable of transporting both agricultural and construction goods. It moves from 250 to 500 kg at a time, has a ground clearance of 31.5 cm and a track of 145 cm. The highest speed is 10 km / h. The weight of the structure is 90 kg.

If you need to choose a cart that is compatible with adapters, it is better to give preference to the APM model. It is capable of moving any kind of cargo with a maximum mass of 250 kg. The advantage of the design is the availability of pneumatic tires. This allows you to almost not feel the shaking while driving. However, the ground clearance is only 18 cm, so the trailer will not pass on a very bad road.

If you need to haul hay, any of the models described will do. But for the transportation of cement, soil, bricks and other heavy cargo, it is more correct to use the VRM-Z trolley. She takes on board 400 kg, which allows you to safely deliver to the dacha all or almost all of the garden equipment

Importantly, an adapter is not required in this case. The VRM-Z trailer is connected directly to the shafts of the gearboxes