Characteristics and working principle

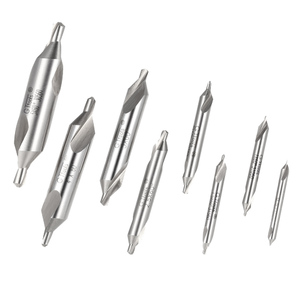

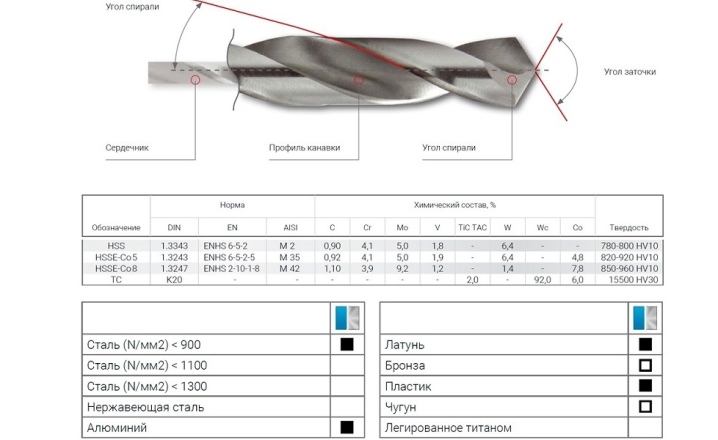

Left hand drills come in two tail shapes: cylindrical and tapered. Regardless, the drills have the same components.

- The main working part, made of victorious alloy or specialized high-speed steel. This part consists of two cutting edges.

- Calibrating part for cleaning the drilled hole.

- The tail part, with which the product is fixed in the chuck of the power tool.

As mentioned earlier, such atypical drills are used to extract creases from the hole. The principle of operation of such accessories is quite simple. The drill is inserted into a power tool that is driven. As soon as the drill touches the crease, it will drill out. There is one important point: drills for metal rotation should be 2-3 mm smaller than the thread size. Otherwise, it may be irretrievably damaged.

Uses of citric acid

This method is suitable for removing small diameter drill bits from small parts.

-

Take a container made of stainless steel.

-

Prepare a water solution (20 g citric acid per 100 g water).

-

Dip the part into the mixture with the hole down

-

Place the container on an adjustable heating device.

-

Set the temperature to 90 ° C.

It will take several hours to extract the drill fragment using this method.

Removal of drill debris using strong electrolytes

This method of pulling out the drill is suitable if the workpiece is made of aluminum. An aqueous solution of nitric acid is used.

Before using this method, it is necessary to lubricate the area next to the broken drill with wax or paraffin. After that, apply a solution of nitric acid to the debris, wait until the compound corrodes the cutting edges, and then knock out the stuck piece of the drill with a plumber's bit.

Note! The ambient temperature must be at least 20 ° C.

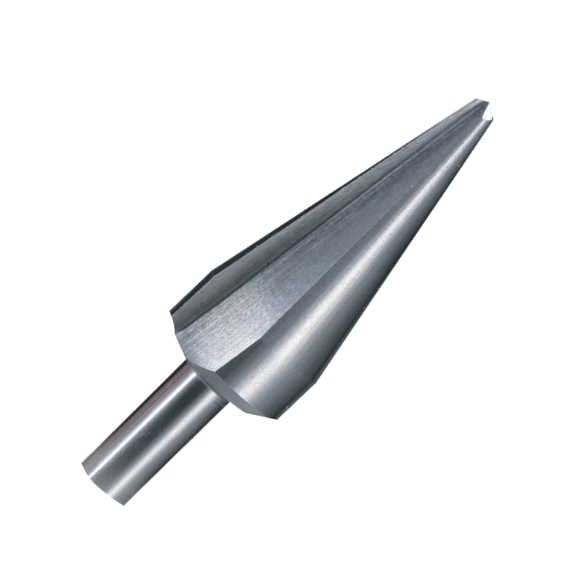

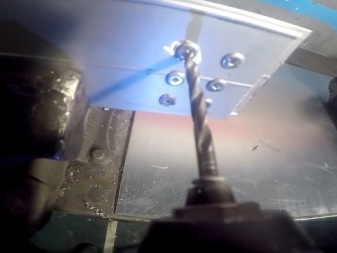

Drilling

Use a tool made of a harder material to drill out a piece of drill.

This method, which requires patience, caution and care, is rarely used for two reasons.

-

Drilling out the debris can deform the workpiece and cause bending. In this case, the stuck piece of the drill will penetrate even deeper into the body of the part and at an angle.

-

When working with equipment, there is a possibility of chips getting into important components and mechanisms.

If you don't mind the part, drill a larger hole in this place, and then pick up the piece with any suitable device and pull it out.

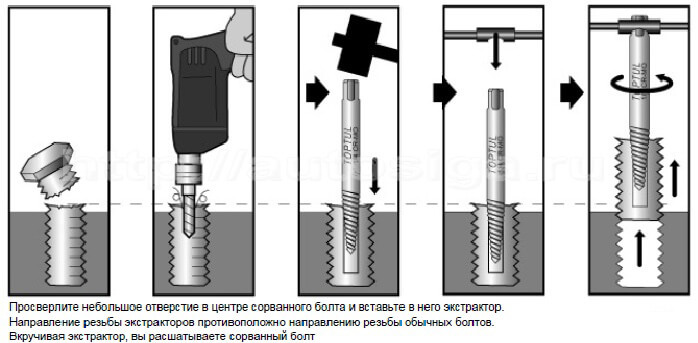

Using special extractors

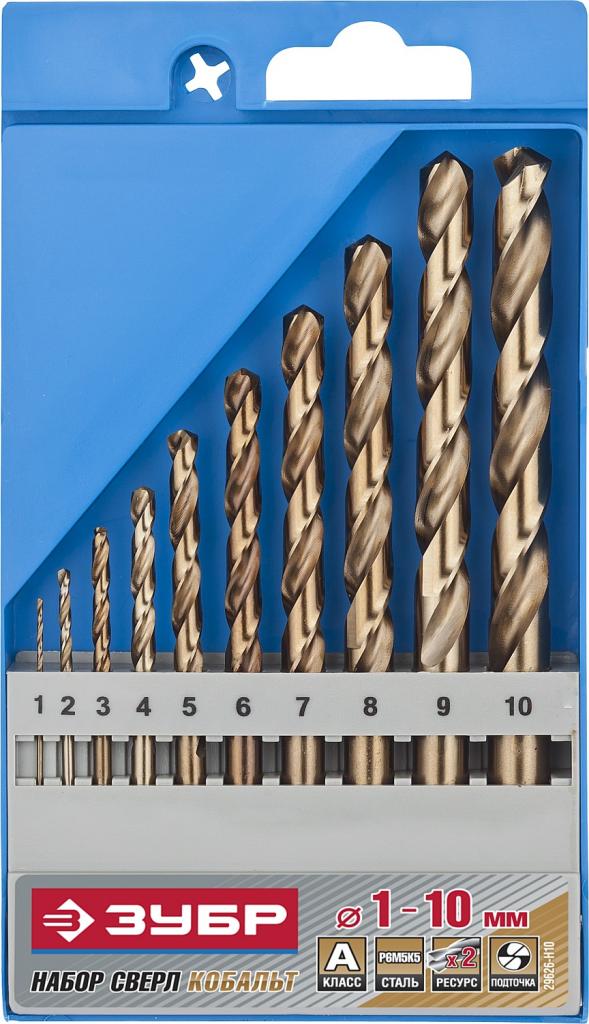

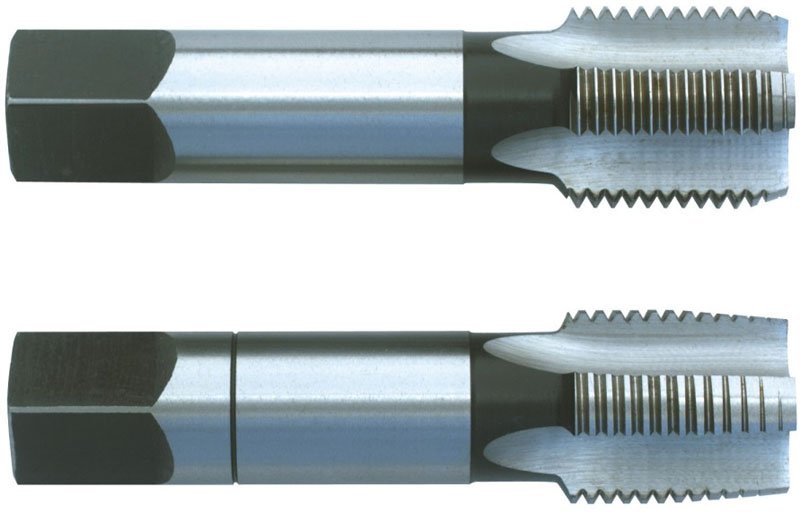

Photo # 3: extractors

These tools are specially designed for removing stuck drill bits, bolts, studs, etc. To remove a broken drill bit with an extractor, proceed as follows.

-

Carefully drill a smaller hole in the jammed drill bit.

-

Drive an extractor into it.

-

Put the holder on it

-

Unscrew the stuck piece.

Image # 1: The technology of using extractors to pull out broken drills

What it is?

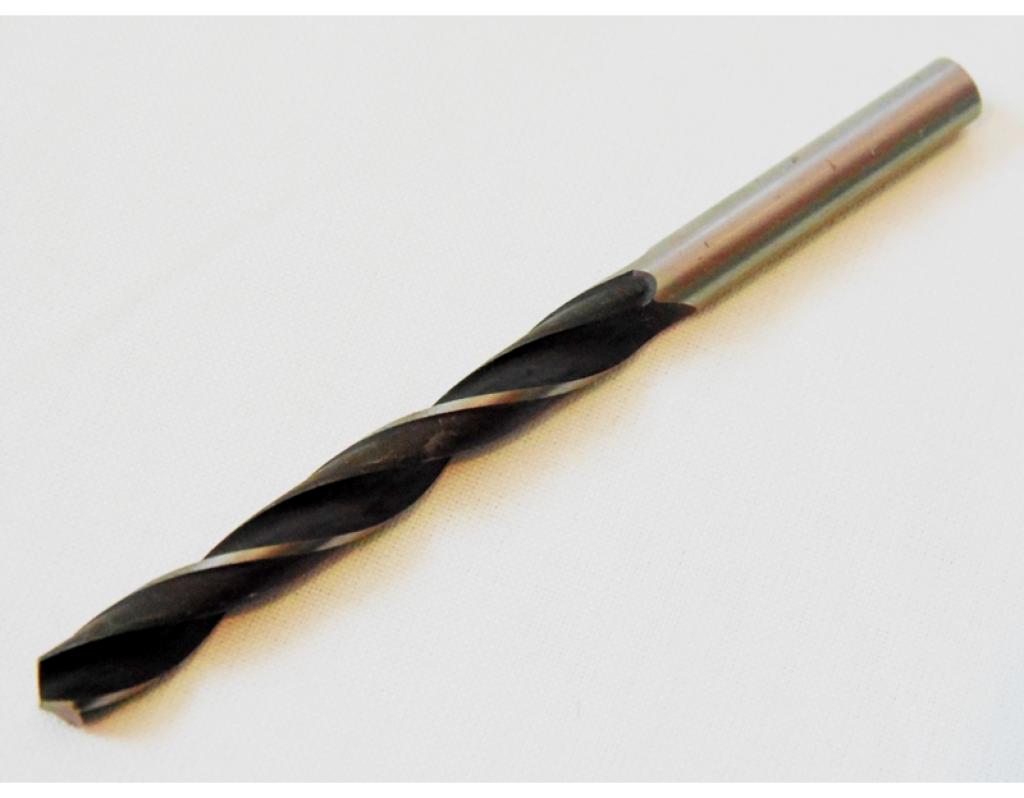

A drill is a tool that is fixed in the machine or chuck of a manual, pneumatic or electric drill, and is designed to make holes in a variety of materials.Metal drills are the most versatile drills available, with varying degrees of success but are capable of handling wood, plexiglass, ceramics, plastics, concrete and other materials. The scope of their use is endless: the tool is used in a wide variety of areas of construction activities and for household needs. And products differ not only in diameter.

The drill only at first glance seems to be an ordinary tool, but in practice its choice must be made wisely so that it does not blunt at the third hole and does not break. Drills are the main consumable when working with machines, drills, the main load falls on it, since making holes happens during various works.

Removing the blind rivet

Everyone knows that a rivet is a disposable fastener that is used to securely hold two or more elements together. For a number of reasons, situations may arise when a rivet needs to be riveted. In this case, only the tools at hand will come to the rescue, since there is no specialized device.

You need to start riveting by removing the ring, which was formed at the time of fixing the fastener. If the master has such an opportunity, at the time of compression of the construction material, it is necessary to insert a saw blade for metal. In this case, the fasteners can be cut off, and the spire can be removed by pulling it out by the rod. If it is not possible to cut or saw down, then you can use a method proven over the years - a drill.

As practice shows, the countersunk ring can only be removed by drilling, and the heads can be gently knocked down with a hammer. It is worth considering that this method is applicable only if the strength of the bonded material is greater than that of the fasteners themselves. In addition, the procedure itself is considered traumatic, since there is a high risk of injuring the fingers.

Originally posted 2018-04-18 12:28:24.

Features and purpose of the drill with left rotation

Left hand drills are produced with a conical and cylindrical shank for different equipment chucks. The tool has found industrial application in mechanical engineering, machine tool building and repair plants. Also, the left rig can be used in workshops and for household needs. The main feature of specialized drills is that they have a left-hand helical channel and a correspondingly located cutting edge.

There are two main areas where you can use the equipment of this configuration:

- High precision holes. High performance left hand drills are excellent at drilling channels in cast iron, unalloyed and alloyed steels, short-chip alloys such as aluminum, brittle chip alloys such as bronze and brass, as well as any other materials with a tensile strength of 900 N / m². The holes can be both through and blind.

- Repair work. As mentioned above, the left-hand tool is indispensable if you need to drill out rusted or broken hardware. These can be bolts, screws, all kinds of pins and other original threaded fasteners with a right-hand thread.

When choosing a cutter, the following points must be taken into account:

- The material to be drilled in. For heavy-duty alloys, left-handed drills are used.

- Equipment used as a rotational propulsion system. The number of shaft revolutions is important here. It should be within the tool's operating speed range.

- Geometric parameters of the tooling.

Application methods

In the process of work in car repair shops or when restoring equipment, there are times when it is impossible to unscrew a certain bolt or, for some reason, the fastening element was broken off.The difficulty in this situation is to pull out the remainder of the broken bolt from the hole and at the same time not to spoil the thread. An instrument with an ordinary screw thread will only worsen the situation by clamping the crease in the channel even more. In such a matter, a left-hand cutting tool can help.

It is inserted into the electric drill by means of a key (if the chuck is key), then the drill is clamped in the chuck. After that, the reverse of the electric drill switches to the opposite rotation. In the "reverse" mode on electric drills the same speed as when rotating to the right.

If it is necessary to drill, for example, the crease of the door hinge screw, then the drill is attached to the surface (without punching), then the drill is easily pressed and the usual drilling begins. The right screw of the door hinges is unscrewed to the left (against the course of the clock hand), and the left drill rotates in the same direction. In other words, when a left-hand drill enters the surface of a screw with a broken head, it simply unscrews. Studs and bolts are unscrewed in the same way.

The following video provides an overview of the left hand drills.

The ways

To pull out any rivet, you will need to grind or cut off its head to open the shank. The work must be done sequentially. First, the dimensions and material of the parts are found out, which are connected using such fasteners. At the same time, the material from which the rivets themselves were made is determined. When these characteristics are known, suitable tools can be selected and the maximum force that should be applied to remove the fastener can be estimated. The impact method with a hammer and chisel is not recommended in cases where the material of the fastened products is very thin or fragile, since these products can be easily damaged and destroyed.

To remove rivets, you can use a variety of tools, which we talked about above. Let's consider some of the methods in more detail.

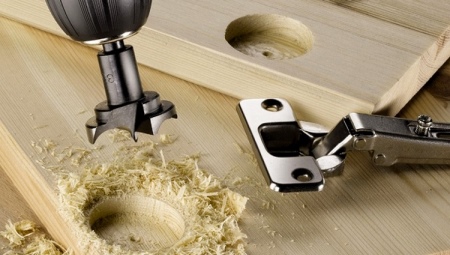

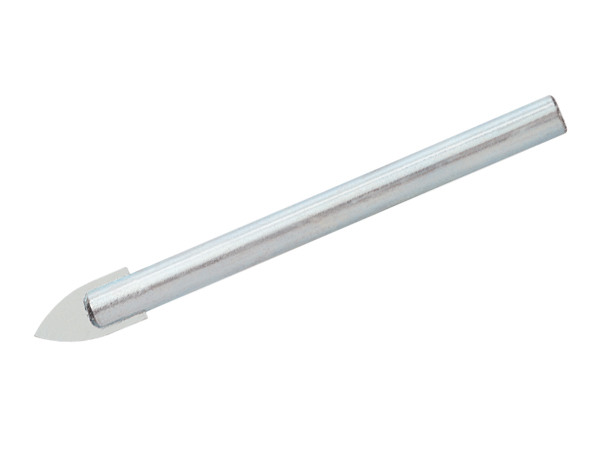

Grinder and drill

A drill is in the arsenal of almost every man, so quite often they decide to simply drill a threaded or ordinary metal rivet. Before starting drilling, set the power tool to the minimum number of revolutions of the chuck. As a result of this action, the work will be done not only with high quality, but also with a good speed for such conditions.

The tip of the drill is placed in the recess in the center of the head, and the axis of the drill is located perpendicular to the surface of the fastened elements. In the process, it is necessary to carefully monitor so that the tool does not slip, otherwise damage is inevitable.

The fastener collapses the moment the drill passes through the head of the hardware. Sometimes the rod will not fall out on its own, so you need to use a hammer and punch to remove it. Usually 1-2 blows to the surface of the fastened structure are enough to remove the rivet shank. The force of impacts must be appropriate for the situation, taking into account the material of construction.

If you are careful, the work will not affect the integrity of the surface, so you can not be afraid of damage. After removing one rivet, you can tackle the next.

You can cut the product with an ordinary grinder. The work is carried out as quickly as possible, however, experts note that this method is notable for the risk of injury.

With the help of a grinder, you should cut off all the heads on the rivets. The remains are removed with a screwdriver. The heads have to be removed at an angle, so it is very easy to damage the material. In addition, you should take care of your own safety, using the necessary protective equipment.

Chisel

Most often, exhaust fasteners are made of mild steel or non-ferrous alloys. That is why the head of such a rivet can be easily removed with a chisel.To do this, the cutting edge of the tool is carefully placed under the edge of the head, after which it is hit with a hammer until the top of the rivet is sheared off. The remainder is removed using a punch.

This method is not suitable in some cases. For example, if the surface is painted, it is recommended to refuse it. The fact is that in the course of work to remove the fasteners, the paint will inevitably suffer significant damage.

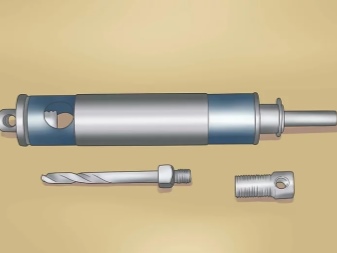

Rivet head

This tool has been gaining popularity in recent years, and you can easily find it in specialized stores. The riveting nozzle is designed directly for removing fasteners. In fact, it is an attachment for an electric drill.

The principle of operation does not differ significantly from using a conventional drill, but in this case it turns out to achieve maximum speed and accuracy. With the help of such a device, the drill is placed exactly in the center of the head, and the setting allows you to strictly limit the depth of penetration, which is enough to remove the upper part of the fastener.

However, there is a disadvantage that there is no universal adaptation. For hardware of different diameters, you will have to use different attachments. For this reason, experts recommend using the product only when a sufficiently large amount of work is to be done, as well as for removing rivets in extreme conditions.

Choice

When choosing a left-hand drill, there are many important nuances to consider.

Attention should be paid to the following parameters

- Shank. You need to immediately look at its shape. And in order to determine the choice, you need to know the type of cartridge in the power tool that will be used. Depending on this, you will need to choose a drill with a cylindrical or taper shank.

- Manufacturing material. High-speed steel products are considered to be of the highest quality.

- Sharpening angle. Here, the material in which you want to make holes will help to determine. So, if it is cast iron, then the angle should be 110-120 ° C. For softer materials, you need to take less.

- The size. It all depends on individual requirements.

Also, when buying, you need to look at the information about the manufacturer. The highest quality and most popular are the models made under the brands Bosch, Makita, Interskol and Zubr. There is practically no difference in products from foreign and domestic manufacturers. They differ only in cost. And so it all depends on individual preferences and capabilities. It is not recommended to buy products from questionable suppliers or those that do not have any information about the manufacturer.

See below for an overview of a counter-rotating drill.