Selection rules

Countersink drills must be selected according to the same principles as traditional tools used in metalworking, woodworking

The focus is on the type of work to be done. When it comes to drilling and countersinking metal products, you should give preference to models with a spiral cutting part, made of tool or alloy steel - with higher strength characteristics, corrosion resistance

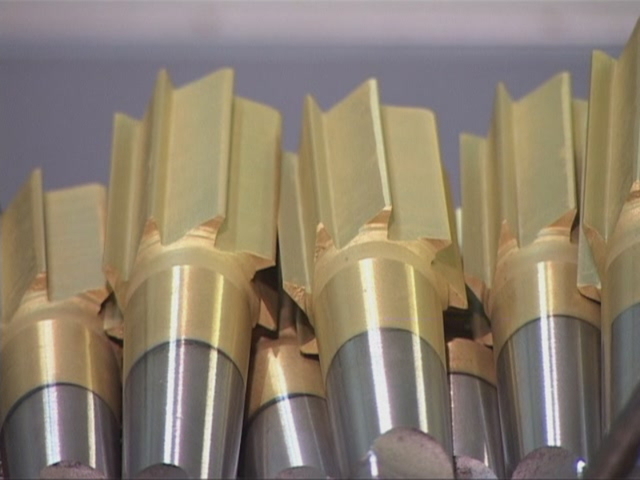

Visual inspection is also important. The color of the cutting part of the drill will tell a lot about what kind of processing the tool was subjected to.

- Products treated with titanium nitride acquire a rich golden hue. They are very durable and have an extended service life.

- The black color is typical for countersink drills treated with steam. Typically, these products are made from high speed tool steel.

- Products in which stress relief has been performed acquire a yellow tint; the tempering method is usually used. Accordingly, the steel part has been hardened, will provide sufficient strength.

- The gray color, typical for ordinary steel, is for tools that have not received additional processing. Their strength characteristics and capabilities are inferior to conventional ones.

An important component of the choice of drills with a countersink is the type of fastener for which the hole is drilled. Conical or cylindrical type of construction is determined by this very factor.

It is worth paying attention to the working diameter. Countersink drills are produced in the most popular sizes, while the thickened part of the cut is usually 16 mm in diameter when it comes to woodwork

Considering all the recommendations, you can find a suitable option for specialized cutting tools for use in the workshop or in production.

The following video talks about countersink drills.

Features and Applications

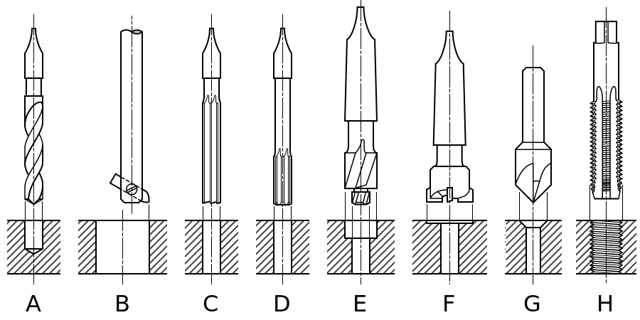

A drill with a countersink is a specialized type of tool that can perform several operations at once. Such devices are especially in demand today in the furniture industry, where assembly Euro screws are used. The countersink allows you to drill holes with varying diameters without changing the cutting tool. This element can be one-piece or made in the form of a replaceable attachment.

Modern countersink drills for metal, wood and other materials are manufactured in various diameters. The tail piece can be cylindrical or hexagonal, well suited for installation in a screwdriver or drill.

When using a classic drill, the hole has 1 diameter along the entire length. A traditional countersink - a separate tool used in industry and workshops - also only produces through holes of the same size. The combined version allows you to solve several problems at once, avoiding changing nozzles during operation. Depending on the type and purpose of products, the number of steps in them can vary - usually there are 2 or 3. Each implies a change in diameter.

Combined products such as countersink-drill allow you to achieve high quality and cleanliness of the finish. They can have both straight and helical grooves.

Tool tips

The main criterion is the type of surface to be treated.For working with metal, classic twist drills made of HSS or alloy steel are perfect.

Pay attention to the appearance of the instrument. Color can tell a lot about the degree of processing:

- Gray or steel. No processing was carried out.

- Black. The countersink was processed with steam.

- Yellow. Internal stress in the tool was relieved by tempering.

- Bright gold. The surface is treated with titanium nitride. This material is highly durable, which extends the life of the drill.

There is a wide selection of tools from various manufacturers on the market. We recommend giving preference only to proven brands - this will be a guarantee of the quality of the device.

Peculiarities

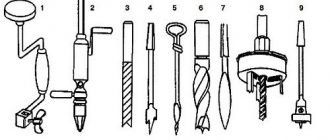

Wood countersink drills allow you to create and process holes in the material. At the same time, attachments of this type are small products that create recesses for wide mountings.

Countersinks for these tools are drills with multiple cutting components and are most commonly used to work with tapered or cylindrical holes. Such metal elements make it possible to make depressions of different types in the material.

Also, a countersink drill is often used to slightly increase the diameter of the recess, to make machining of holes already made. The difference between the countersink tool and other models is that the first option uses more than two blades.

Often such attachments are needed for professional production machines. With this tool, many users carry out grinding of the holes made, processing the end of the structures, while hiding all the roughness and other irregularities on the surface.

The rest of the product is called the shank. This element is necessary to connect the tool to the chuck of a drill or machine tool. This part can also be of different shapes and sizes.

There are shanks of the following shapes: cylindrical, hexagonal, triangular, tetrahedral or canonical. In this case, the first option is the most common; it must correspond to the diameter of the cutting part. So, for a counterbore with a larger diameter, a shank with a smaller diameter is used. For some of the smallest drills, shanks slightly larger than themselves may be selected.

The canon shank is used commercially. All other varieties can only be used for certain types of chuck (three-jaw, conventional).

Any user will be able to make a countersink on his own, without buying at a hardware store. To do this, you first need to prepare an unnecessary self-tapping screw or a regular drill, such elements will become the basis for the future product. Then these parts should be trimmed a little by adding a few thin blades.

Self-made designs can be customized, if necessary, for an individual configuration.

Purpose and types of drills with countersink

First of all, it is necessary to define the concept of "countersink". It is often confused with another metalworking tool - a countersink. Although they sound similar, they are designed for completely different processes. Surface countersink is a recess in the top of a pre-drilled hole.

A countersink drill is a multi-edge metal cutting tool. It is classified as equipment for the semi-finishing of existing holes. Use before applying the sweep.

Universal countersink drills are most commonly used in the woodworking industry. In the serial production of furniture, the quality of the holes comes first. The reliability of the assembly depends on this. The tool in question allows you to get a neat hole for a countersunk self-tapping screw, screw or other fastener.In addition, the countersink drill increases productivity by reducing machining operations.

The drill acts as a guiding element to obtain a high precision hole.

In the process of manufacturing middle-class furniture, special fasteners are used - euro screws. To prepare holes for these hardware, processing devices are used that look like countersink drills. They are also referred to as combined instruments. The two-stage design allows you to drill a hole and chamfer a Euro screw in one pass.

Zenker do it yourself

Wood countersink is quite a popular tool on the market, but your store may not have it, but the thing is necessary. And in the case when all the necessary components are already there, in this case, you can build a countersink machine with your own hands. The equipment will be far from professional units that are used in enterprises and factories, but it has advantages over expensive counterparts. In order to build a machine, you need the following things:

Powerful drill;

The base for the machine is made of wood or metal;

Sturdy angled tripod, also made of wood or iron;

Homemade stand for added stability;

Spring mechanism for reverse movement of the drill.

These are the basic components from which a machine can be assembled to ensure stable and precise machining. Strength, weight, durability, construction price will depend on the choice of material. It is not worth saving too much in this matter, because countersinking is an exact process, and any deviation or defect can lead to poor results.

To create the nozzle itself, use a self-tapping screw or a drill that needs to be cut by adding new blades. This design has many advantages:

Created at home from available components;

Do not require large investments;

Can be customized at any time for individual configurations;

The ability to carry out a variety of stationary work with a drill;

But even taking into account all the advantages, the handicraft countersink has a number of disadvantages. Some minuses are minor and easy to fix, but they exist and are mostly associated with miscalculations during modeling and improper assembly of the structure. These are the cons:

An error during sharpening can lead to an overestimated value of the diameter;

Rapid wear of the nozzles;

Any defect and mistake leads to a loss of quality;

Therefore, you need to pay attention to calculating the design and test the machine before using it directly. And if you do everything right, then such a machine will be an excellent assistant in working with wooden parts.

And if desired, the equipment can be converted for iron parts.

A video describing the sequential process of creating a countersink for wood