How else to use the drill

Like a drilling machine

A well-equipped home workshop necessarily includes an electric drill stand. Only by using this guide attachment can complex work be done. For example, a hole is drilled with special accuracy, up to tenths of a millimeter. The drill stand with a fixed drill turns into a drilling machine.

It is necessary when working with hard materials that are difficult to process. Without a strict direction, the drill does not sink into the depth, but only scratches such a surface.

If the movable tripods are firmly fixed on the desktop, they drill both perpendicularly and at the desired angle to the workpiece surface. In addition, the tripods keep the drill from shifting to the side. The set screws will help you accurately maintain the desired drilling depth.

The drill is clamped in the rack - the compact home drill with smooth feed is ready to go. Manufacturers only allow the use of a tool marked "professional" in it.

Video: homemade electric drill stand

If you attach a milling machine with an upper spindle to a rack, you get a home milling machine.

Like a screwdriver

The drill easily replaces the screwdriver. To work with screws, screws, to remove jammed nozzles, include a reverse stroke. Screws and bolts are tightened at low speed.

The directions of rotation are switched with the reverse lever after the drill stops.

Drill like a mixer

Manufacturers produce drill mixer attachments that mix liquid and powder materials from the bottom up. The drill will handle a volume of no more than 10 liters. It is better not to practice such a regime for a long time. Not suitable for heavy concrete mixes.

It is better to use special drill mixers. They have additional handles in their design. The intended purpose is the mixing of mixtures. Comes with attachments in the complete set, it works for a long time without overheating. As a drill, it only supports the drilling mode. The price of such units is much higher.

The drill mixer has additional handles

Drill: unexpected uses

An electric drill is bought for drilling. Then they discover great new application ideas.

- Cut steel cable, copper and aluminum cable with a sector nozzle.

- Remove dust by connecting a dust extraction attachment to the vacuum cleaner.

- Thread blind holes without fear of breaking the tap at minimum torque.

- Calibrate PP-R pipes with a calibrator nozzle.

- Pump and pump out liquids with a pump nozzle.

- Pinch a bird. The soft, punctured fingers of the attachment do not damage the hide.

- Cream the honey with a stainless steel mixer-like attachment.

Can I drill with a screwdriver? -.

Manufacturers offer a variety of tools. Almost everyone can choose a tool for their financial capabilities and technical needs. The screwdriver is increasingly found in the home workshop. Therefore, questions arise, what else can you do with it. Today we are figuring out whether it is possible to drill with a screwdriver?

Basic moments

Experts do not recommend working with concrete. Such a hard material may not even take a drill with good technical characteristics. But, if your model has an impact function, then you can try to overpower thin concrete, stone or brick. As a rule, modern buildings are erected from aerated concrete or sand-lime bricks. Such surfaces can be drilled with the most common model, which does not contain an impact function. The main thing is to use the correct drill.

What can a screwdriver handle without problems? If you plan to work with wood, plaster, metal or plywood, then you can safely get the tool. It will help not only tighten the screws, but also come in handy for drilling.

How to choose a tool?

To safely use the device for drilling, you should choose it correctly

What should you pay attention to? If you want it to be always ready for work, then buy a network device or a rechargeable one, but with a spare battery. The rotational speed affects the ability to drill in various materials.

For example, 500 rpm is sufficient for tightening. For the drilling function, the speed must be up to 1300 revolutions

It is also important to pay attention to the torque. If it is small, then such a screwdriver is only suitable for drilling wood.

Summing up the results, we can say with confidence that you can drill with a screwdriver. Modern models are able to cope with almost any surface. Even with thin concrete or bricks. If you are just looking for a new model of the instrument, then heed our advice.

.

Tool selection

If you plan to drill concrete not for industrial purposes and volumes, but for the house during the renovation, then you can use a conventional drill in the classic version, because winder drills for a drill are normal practice. But there is one nuance that must be mentioned: for easier work, the drill should be capable of not only rotational movements, but also translational ones.

If you use a conventional drill, you need to use a metal pin or rod during the break between drilling, which needs to be driven into concrete from time to time with a hammer, and it is better to periodically moisten the drill with water to cool it down.

As far as we know, concrete contains reinforcement, the step of which is difficult to predict. This fact must be taken into account from the point of view of the fact that it is easy to rest against the iron reinforcement with a victorious drill and stop, since such a drill will not pass metal.

In this case, it is best to replace the victorious drill with a metal drill and go through the reinforcement layer with this drill. Then, if necessary, continue working with the victor drill.

What you need to know when working with concrete drills

Drilling a concrete wall

Drilling a concrete wall

Using a concrete drill is not as easy as it might seem at first glance. But it is not very difficult either.

You just need to know some wisdom in order to quickly and efficiently teach how to make mounting holes:

- Under no circumstances should the drill be allowed to heat up. It is necessary to take a short technical break every 15 seconds so that it can cool down. Only this process should take place in a natural way without the use of water and other tricks.

- For more accurate drilling, turn off the hammer drill and tilt it against the wall at low speeds. Only after that you can turn on the shock mode and add revolutions.

- Ensure the position of the electrical cables before drilling. This can be done using a metal detector and a wiring diagram.

- If you plan to install plastic dowels, then you need to make a hole about 1 cm deeper than the length of the fastener.

- When working with a supporting structure, be sure to arm yourself with a hammer drill. Using a hammer drill with a drill will not produce the desired results. But on the other hand, there is a great risk of breaking both the drill and the tool itself.

- Concrete drills can also be used to drill ceramic tiles. Just do not forget to turn off the shock mode, as with it fragile ceramics can simply crack.

- If an obstacle is encountered during drilling, then to overcome it you need to have a specialized tool with you. For example: for metal - drill bits for metal, and for stone - a bump stop. When all the obstacles have been overcome, you can continue to drill with the concrete nozzle.

Drilling concrete products

Drilling concrete products

To avoid such awkward moments, requiring additional resourcefulness and the involvement of additional tools, you can sharpen the drill for concrete so that they can work on metal. How to sharpen a drill for concrete with your own hands, we will consider below.

Concrete drill sharpening

Sharpening the drill at home

Sharpening the drill at home

Having touched upon the topic of universality, I drilled, and puzzling over whether it is possible to drill concrete with a drill for metal, the answer will be categorical - no. Such a drill will simply break or become dull very quickly - even a drill with d = 20 mm. Therefore, we do not save money, and we buy diamond or victorious drills. But such devices also work well for metal.

The video below will clearly show how to properly sharpen a drill for processing hardened and other steel.

A simple instruction will tell you in detail how to sharpen a victorious drill correctly if it is blunt. When buying a new bit, it is not necessary to sharpen it. Over time, such drills grind down, and first inconveniences begin, and later - and serious problems when drilling.

To sharpen, you need a sharpener or grinder. For these purposes, a universal one is suitable. If you are engaged in construction and repair professionally, then it is best to purchase a special grinding machine for drills.

Grinder

Grinder

Take a close look at the tip of the drill. It is formed by two "shelves". It is these shelves that must be of the same length so that the drill does not break, and high-quality mounting holes are obtained. It is optional to measure from. A close gaze and a good eye are enough.

The working surface of the drill

The working surface of the drill

- The sharpening process itself is quite simple. The main thing is to monitor the evenness of the "shelves".

- If it is planned to drill soft and pliable materials, then it is necessary to observe the alpha angle up to 400, and when working with a dense and hard surface, this angle should be in the range of 200-300.

- In this case, it is worth making sure that the cutting edges do not touch the grinding wheels, otherwise the drill may simply break.

- Another important detail is that the drill should not heat up when sharpening. Periodically you need to stop and cool it. This can be done using ordinary water. But if the tip is cracked, leave it to cool under natural conditions, since when dipped in water, the metal will not withstand and will crack.

- Sharpening drills requires special skill, and homework is not very accurate. Therefore, it is best to have recourse to the services of a professional in this field.

Well sharpened drills

Well sharpened drills

Having learned how to choose and sharpen a concrete drill correctly, you can safely go to the store for long-awaited purchases, and not be afraid to drill any type. The main thing is not to overdo it, and observe the "siesta" in the evening hours of rest to maintain a truce with neighbors.

What are concrete drills, their varieties

Drills for concrete have special solders from a very strong alloy, close to diamond in terms of hardness. It is called "win." The victorious drill for concrete is by far the most durable and has no analogues in this parameter.

Drills for concrete are divided into:

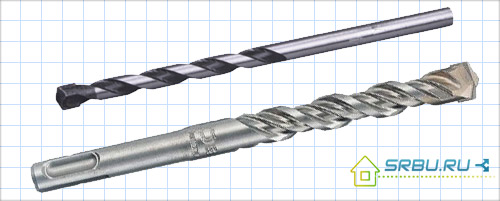

- a drill for concrete for a drill, has a shank in the form of a cylinder or polyhedron;

- a drill for concrete for a rotary hammer, has a shank in the form of a cylinder and marks SDS-plus or SDS-max.

If you use a drill and drills for it during construction work, then drilling such hard materials as, for example, reinforced concrete will not work. For this, there is a perforator tool and a percussion drill for concrete. It is commonly referred to as a concrete drill. Boers are of three types:

- screw - allow you to make deep holes;

- spiral - allow you to make large holes;

- shallow - allow you to make passages of small size and depth.

Such drills snap into the drive chuck, for this they have a thickening at the end.This tool is intended for professional use. With its help, holes from 4 mm to 3 cm are obtained.

If you need to make a larger hole, use a crown drill for concrete. It allows the creation of indentations up to 12 cm in highly durable materials. Core drill is:

- diamond - a tube or crown fixed on a rod, along the edges of which there is diamond dusting;

- victorious - a nozzle having the same structure as the above-described option, only instead of diamond spraying, small victorious teeth.

Core drills come to the rescue when it is necessary to make a recess for an outlet or switch, to carry out communications, etc.

The answer to the question, "What kind of drill to drill with concrete?" Also depends on the required depth and width of the hole.

Drills for concrete, depending on the diameter, have the following length:

- diameter 4 mm - length 50 mm;

- diameter 5 mm - length 100 mm;

- diameter 6 mm - length 150 mm;

- diameter 8 mm - length 250 mm;

- diameter 10 mm - length 540 mm;

- diameter 12 mm and more - length up to 1000 mm.

As you can see from the list, a long concrete drill has a large diameter, because the thin one simply will not withstand and will break during work.

Drill sharpening

Cutting tapered edge of the drill

Cutting tapered edge of the drill

In this case, effective preparation of the drill is needed, which consists in sharpening it. You can do this yourself on a grindstone with a corundum grindstone.

The technology of work is similar to the restoration of the cutting edge of any similar tools, but taking into account some nuances:

- Strong overheating of the surfacing must not be allowed. From exposure to high temperatures, the adhesion of the steel base is reduced, which reduces the strength of the joint;

- If the moment has been missed and the drill is hot, it takes enough time for it to cool down so that the process proceeds slowly. It is forbidden to lower the tool into water: due to the temperature difference, cracks will appear on it;

- The drill is sharpened along a cone, or along a helical surface. In the first case, no additional devices are required;

- When sharpening in a tapered shape, the edges should converge exactly in the center of the drill. When the place of intersection of the edges is displaced: the tool will move to the side during operation, moreover, one of the edges will become blunt much faster;

- It is better to use screw sharpening when working on foam or aerated concrete, and sharpening the working part of the tool is on a special sharpening machine.

Choosing a tool and working with it

It is best to buy drills in large hardware stores in Moscow and other large cities. In this case, the device will have a guarantee that allows you to repair the device free of charge if it breaks down. In addition, preference should be given to drills from trusted manufacturers. When choosing a device, you also need to take into account that a device equipped with a percussion mechanism can be called a perforator.

In hammer mode, you can drill a hole even in thick concrete

There are a number of other parameters that you should pay attention to when choosing a tool.

It is desirable that the tool be equipped with a speed regulator. It allows you to adjust the speed. This will allow for more accurate work. When the device is turned on at maximum speed, it is possible to drill holes of large diameter, but there is a possibility of chips and other defects. It is desirable that the device be equipped with a speed lock and reverse. In addition, the drill must have a smooth start.

Considering which device is better, you need to pay attention to the presence of an auxiliary handle. The powerful impact drill is heavy, so with the optional handle you can hold it with 2 hands during operation

Another important parameter that you should pay attention to when choosing a tool is the presence of a drill insertion depth regulator.It makes it easier to control the process of making holes when you need them to be of the right depth.

In addition, it is important that even large diameter drills can be inserted into the chuck.

It is necessary to pay attention to the presence of fuses to ensure the safe use of the drill.

It is important that when working with the tool it is convenient to hold the drill at right angles to the surface. This will prevent damage to the coating and distortion of the hole.

Start working with the tool only after it has warmed up, having worked for some time at idle speed. This will get the drill ready for use. In addition, it will reduce the risk of condensation forming inside the tool due to sudden temperature changes.

This will prevent damage to the coating and distortion of the hole. Start working with the tool only after it has warmed up, having worked for some time at idle speed. This will get the drill ready for use. In addition, it will reduce the risk of condensation forming inside the tool due to sudden temperature changes.

It is important that when working with the tool it is convenient to hold the drill at right angles to the surface. This will prevent damage to the coating and distortion of the hole.

Start working with the tool only after it has warmed up, having worked for some time at idle speed. This will get the drill ready for use. In addition, it will reduce the risk of condensation forming inside the tool due to sudden temperature changes.

Safety engineering

Compliance with these rules guarantees that the work will be successfully carried out without harm to human health.

It is important to inspect the surface before any work. If a small element is drilled, then most likely it will need to be fixed in a special vice

For example, when it comes to timber. The work piece must never be placed in a poorly fixed spindle.

Worker clothing should not have any hanging ends. The shirt is usually tucked into the pants. In no case should you clean your clothes during work, this can lead to serious consequences. Craftsmen use safety glasses - masks to protect the skin of the face and eyes.

Gloves must be worn to prevent the tool from slipping out of your hands during operation. If the drill is massive, then it is best to work with rubber gloves. They not only help to ensure that the tool does not slip out of the hands, but also prevent various injuries to the skin of the hands.

Be sure to hold the tool with both hands. Do not work while standing on stairs or other loose surfaces. Do not use blunt rigs, this will lead to an increase in construction time. Do not insert or remove the drill bit with an adjustable wrench - this will damage the chuck and the tool. Do not use the drill in snow or rain, even light rain, as this may cause a short circuit and electric shock.

Whatever work needs to be done with a drill, it is important to remember that the quality of the work performed directly depends on taking into account the peculiarities of drilling. The main thing is to believe in yourself and not stray from the planned work plan.