Hitachi DS 14DCL and DS 18DSFL screwdriver tests

We divided the test tests into two parts: the first concerned the power, the second - the battery life.

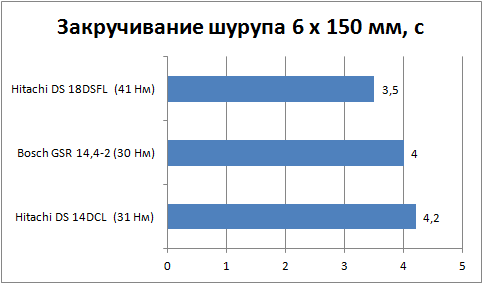

For a practical comparison of power and speed of work, we screwed two types of screws into a dry pine log: 6 x 150 with a PZ head and 6 x 120 with a turnkey head. The process was recorded on video, which was then used to determine the time spent.

The results from several attempts were averaged, and the results turned out to be quite predictable:

The results of the Bosch GSR 14.4-2 screwdriver (30 Nm, 1400 rpm) were added to the second diagram. To get in the middle between the two Hitachi screwdrivers, it seems to have been helped by slightly higher revs. However, in practice, when working with screws of the mentioned size, there is not much difference between the three screwdrivers.

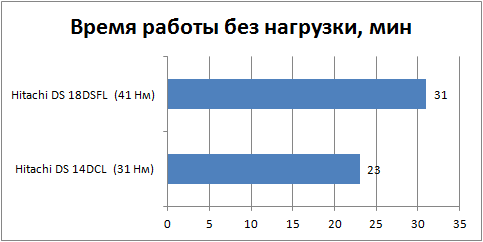

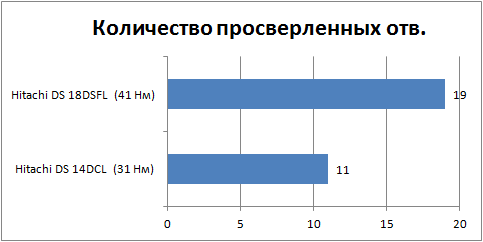

To check the operating time, the screwdrivers underwent two tests. In the first case, the time of continuous operation without load was measured, and in the second, the number of holes drilled with a 25 mm feather drill in a dry pine board "fifty" was recorded. The tests were repeated several times and a new drill was used for each repetition.

If in terms of idle time the difference between screwdrivers is quite predictable, then the fight against dry pine "fifty" was a little surprised. For the 14-volt model, this turned out to be a difficult task and even felt externally - the Hitachi DS 14DCL bit into dry wood, albeit smartly, but not as evil as the Hitachi DS 18DSFL. For the most part, the difference was felt in the last 1.5-2 centimeters of each of the holes, where the drill was forced not only to deepen, but also simultaneously grind the sawdust that had accumulated in the hole and had not yet been thrown out.

On the other hand, if the test load were small, for example, working with 4 x 50 mm self-tapping screws, then the difference between the models would be approximately equal to what we got in the idle test.

Description

Based on the specified characteristics and the tests carried out, Hitachi screwdrivers have formed a reputation for tools with decent characteristics, which are not much inferior to their German counterparts. In light of this, Japanese screwdrivers have been holding leading positions in terms of demand for several years.

The brand regularly works to improve devices, thanks to which new tools become more ergonomic as well as safe. Now on the shelves of supermarkets and construction markets there are more than three dozen various Japanese screwdrivers. Tools can have different characteristics regarding basic parameters, such as the type of battery, dimensions, as well as a list of tasks that the product can handle during construction and repair work.

The distinctive properties that distinguish Hitachi drills and screwdrivers are a number of parameters.

- The body of all products is made from high quality raw materials of the latest generation - polyamide. This material provides reliable protection of the mechanism, since it has anti-shock properties.

- The ergonomic handle of the screwdriver has a non-slip effect, due to which, during work, the tool provides a perfect grip on the hand of the specialist.

- The components of the gearbox, as well as the locking systems of the device, are made exclusively of heat-resistant steel. This feature reduces the likelihood of breakdowns, in light of which tools rarely fail.

- The dimensions and configuration of the devices are selected based on the individual characteristics of a person's constitution, due to which the drill-screwdriver in most cases stands out for its minimum size.The average weight of the tool is about 1.5 kilograms, most of which is accounted for by the battery.

- The best tool models have a perpendicular handle for maximum efficiency.

- The screwdrivers are equipped with systems for adjusting and controlling the speed switch of the device.

- The line of Japanese devices includes network and battery models, the latter gradually replacing electric types of tools.

- Hitachi offers the following cordless screwdriver models - 10.8, 12, 14.4, 18 volts. With a capacity from 1.4 to 5 A. h.

Selection Tips

In order not to be mistaken with the choice of a working tool, first of all, you should clearly define the range of tasks that the purchased model will perform.

In light of the wide range of Hitachi screwdrivers, experts recommend adhering to the following principles for selecting a device:

- determine the frequency and intensity of the use of the tool;

- to focus on the conditions in which the device will function in the future;

- decide on the power indicators that the screwdriver must correspond to.

After analyzing the above components, comparing them with the technical characteristics of the proposed tool, you can make a guaranteed correct choice.

As practice shows, for household needs, you can purchase multifunctional units that can cope with a number of simple tasks associated with small amounts of work.

Larger models tend to stand out from the rest with their performance. For some consumers, device mobility is fundamental, as some sites may not have a primary power source. Therefore, in this situation, Hitachi cordless screwdrivers will be able to meet the needs with a large selection of different models of such devices.

For more information on Hitachi screwdrivers, see the following video.

Nomenclature and model range of Hitachi screwdrivers

Before getting to know the test participants in more detail, I would like to say a few words about the range of Hitachi screwdrivers, because there are a lot of models, and the manufacturer uses only alphanumeric designations in the names, which will not give an outsider the opportunity to quickly navigate.

So, the names of the models consist of three segments: the first two letters (determine the type of model), numbers (speak of voltage) and two or four letters at the end serve as an indicator of some features.

Model type: DS - hammerless drills, WH - screwdrivers with tangential impact, DV - impact drivers, WM - impulse screwdrivers, WP - oil impulse.

Features: the letters S and L that occur indicate the type of battery (L - Li-ion, S - slider (sliding), which slides onto the base of the handle, and is not inserted into it); F - apparently means a very fast charger (30-45 minutes); the combinations DBL, DBDL and DDL denote screwdrivers equipped with brushless motors. Sometimes at the very end of the model index there is a figure showing which generation this model belongs to.

Now let's take a look at the technical characteristics of our test participants.

Advantages and disadvantages

All models of the latest sample can be safely called multifunctional highly efficient devices. This applies to both professional and household devices. To have an objective picture of the characteristics of a Japanese instrument, it is worth highlighting a number of positive and negative points.

The advantages of screwdrivers include a number of characteristics.

Professional construction products have a special speed distribution for drilling or hammering work.

There are models of screwdrivers that, in addition to the standard capabilities for working with wood and metal, can also be used during work with concrete surfaces.

An important positive feature of the Japanese brand's products is the presence of good lighting, which will be a very useful additional function during work. In this case, the devices are equipped with LED backlighting.

- The device models are equipped with an engine cooling system.

- The gearbox can handle high standard loads during operation.

- The tool can be used in different climatic conditions, as it tolerates any temperature well.

- Hitachi screwdrivers have electronic speed control.

- If necessary, all components are available in the public domain.

- The instruments are also distinguished by the tightness of the case.

However, the tools also have some disadvantages:

- while working with concrete or metal, you will need to take short breaks, since the cooling system may not cope with the incoming heat from the frictional force, as a result, overheating is possible;

- the cartridges on the tool quickly become clogged with small particles, which scatter from exposure to the working surface, in light of which they will need to be regularly cleaned;

- in comparison with a similar tool, Japanese screwdrivers will be heavier;

- the products belong to the expensive line of construction tools.

Equipment and accessories

A feature of Hitachi screwdrivers is the use instead of double-sleeve chucks in the entire line of quick-release mechanisms. Such a moment made it possible to significantly facilitate the adjustment, since the fixing process itself is carried out using the external panel of the part.

However, all the equipment of the models is made in strict accordance with international metric standards, so that Hitachi screwdrivers can perfectly work together with parts and accessories of other brands with the corresponding dimensions.

The complete set of screwdrivers is as follows:

- Battery;

- charger;

- bag for transportation and storage;

- warranty card, instructions and other documentation for the tool;

- cartridge with adapters for nozzles;

- a set of bits, including bits, drills and screwdrivers.

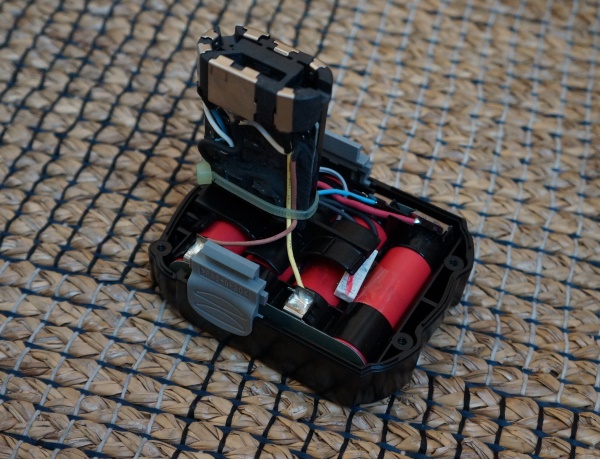

Batteries: 14 volts versus 18

One of the main differences between the models is the batteries. They differ not only in characteristics, but also in the fastening mechanism. In the 18-volt version (BSL), the battery is of a slide type. The fundamental difference is that these batteries are universal and interchangeable for a huge number of different Hitachi cordless tools, which include saws, jigsaws, trimmers, rotary hammers, etc. one you can purchase it without anything in the kit (batteries, charger), thereby saving money. And use the batteries and "charger" from those tools that you already have. This approach is very popular, for example, in the USA. But here he is just beginning to practice.

Both batteries are based on the same 3.7-volt Sanyo UR 18650W2 Li-ion cells with a capacity of 1.5 Ah. The same cells are very popular and are used in many laptop batteries, as well as, for example, in the Tesla Model S. The difference is that there are 4 of them in the 14-volt battery, and 5 in the 18-volt battery. Accordingly, in the latter case, not only the voltage is no longer, but also the energy reserve - 27 Wh versus 22 Wh.

If necessary, these elements can be purchased independently (~ 150-200 rubles per piece) and replaced. To do this, you will have to unscrew four screws on the case and remember the skills of soldering or come up with another way of fixing the contacts on the "banks".

In addition to the Li-ion cells themselves, the batteries contain a control board, which is vital for this type of battery. One of its main tasks is to prevent the deep discharge of the elements, which is extremely destructive for them.When the voltage on the battery drops to a certain value, the controller simply de-energizes the external contacts of the battery pack, thereby preserving its life.

According to our observations, for a 14-volt BCL 1415 battery, the voltage under load, at which it is disconnected, is 10.5 volts, and after the voltage on the cells rises to 12.8 volts, the battery becomes "active" again. A fully charged battery will supply 16.45 V.

For the 18-volt BSL 1815, it turns off at 14 volts, at 14.5 it turns on again. A fully charged unit has a terminal voltage of 20.45 volts. What's more noteworthy is that the screwdriver itself seems to have built-in battery protection as well. Despite the fact that a discharged battery at its terminals produces a voltage of 14.5 volts, the screwdriver itself does not turn on.

So, if we take the voltage at which the batteries become active again and divide it by the number of cells, we get two curious numbers: 3.2 V for the cells in the younger model and 2.9 V for the cells in the older one. According to the specification for these battery cells, the steady-state voltage, at which they practically do not give current, is 2.75 V. this means a "zero" discharge, in which the elements degrade extremely quickly.

According to our observations, the safe residual steady-state voltage on a cell of this type is 3.1 - 3.2 V. This will mean the presence of ~ 10-15% of the maximum charge, at which the battery can stay in full health for some time. Of course, it is perfectly acceptable to discharge them to a value of 3 V, provided that after that they are immediately placed on charging. Hitachi fits well into this framework with all of the above reservations. Therefore, the instructions indicate: if you feel that the battery is running out (and somewhere just at 3.1 volts from the "can" the sound of the working instrument begins to change noticeably), put it on charge. Then it will serve you for a long time. If you do not put it on charge, but put it in storage, in a month or two the battery will turn into a "pumpkin".

Battery charging

Before moving on to the tests, let's share our numbers regarding the battery charging process and economy. The 14-volt one charged stably for 2-3 minutes less than the prescribed 60 minutes, and the 18-volt one was 5 minutes longer than the prescribed 40.

As shown by our standard Eco-worthy PMB-2-EU wattmeter, during the charging of the 14-volt one from the 220 V network, 27 W was "taken" with the declared capacity of 22 W Wh In both cases, the process efficiency was 72%, which is quite typical.

Description and equipment Hitachi DS 14DCL

The Hitachi DS 14DCL screwdriver comes in two configurations, which can be distinguished in the price lists by the RA and RC suffixes. The Hitachi DS 14DCL-RA set differs from the Hitachi DS 14DCL-RC by the presence of a flashlight that attaches to the standard battery from the set and a box with bits. Of course, this requires a larger case. The RA also has a 13mm cartridge, while the RC has a 10mm.

Hitachi DS 14DCL-RA delivery set:

- screwdriver Hitachi DS 14DCL;

- two Li-ion accumulators BCL 1415 1.5 Ah, 14.4 V;

- charger Hitachi UC 18YKL;

- lamp with an incandescent lamp UB 18D;

- a set of 6 bits with a holder;

- a bit with two PH heads;

- user manual;

- large plastic case.

The entire set is housed in a specially molded case. It is not fixed there very tightly, therefore, during transportation, all this can slightly rattle and knock. But what is really missing in the case is pockets and mounts for bits, drills and other things. For all this there is only one groove, where no more than three short bits will fit.

The included flashlight should be familiar to owners of advanced Hitachi configurations. The presence of a flashlight is rather a tribute to tradition, because Li-ion batteries do not need to be fully discharged before the next charging, for which it was convenient to use a flashlight. Those.now it should only be used for its intended purpose. Therefore, it is a little annoying that it did not become LED.

The lantern shines brightly enough and has a very narrow light beam. It is very good for them to shine into the distance or illuminate the working area from a distance of several meters. The reflector head can be rotated 120 degrees vertically and has 5 locking positions.

The Hitachi DS 14DCL screwdriver itself has quite large, but quite typical dimensions for its class. Its real weight is considerable - 1.6 kg, which is slightly more than stated. The handle has a green rubberized part. The screwdriver is well balanced in both planes, but the bottom feels a little heavier than the top. It is comfortable to hold in the hand, but the grip may seem a little thick, especially for people with a small hand. The reason for this disadvantage lies in the wide "leg" of the battery, which is inserted into the handle.

On the positive side, I would also like to note the presence of two bit holders on the screwdriver body and a place for attaching a strap, which is initially attached to the flashlight.

The torque adjustment clutch has 22 positions, adjusting the torque in the range from 1 to 6 Nm, plus the drilling mode. The gear selector is in its traditional place. Shaft blocking, alas, no.

The tool is excellent at work. We have no complaints about the drilling or screwdriving processes. Everything is clear and predictable. A cooling fan is installed on the shaft inside the housing, which actively drives air inside the housing and throws it out through the slots near the end. Even during continuous operation with high loads (almost continuous drilling with a 25 mm core drill), the housing only remains warm to the touch.