Proper charging of the screwdriver: how to do it better

There are some simple rules on how to charge a screwdriver battery so that the tool uses its entire possible resource.

When purchasing a new instrument, remember to charge the battery before using it for the first time. Any batteries, if they are in a warehouse or store for a long time, tend to discharge. If your screwdriver is equipped with a Ni-Cd (nickel-cadmium) battery, “bleed” them by fully charging three times and then discharging to remove the “memory effect” inherent in Ni Cd batteries and bring their capacity to optimum. ...

If your screwdriver contains lithium-ion batteries, it is not necessary to carry out such "pumping" for them, because the "memory effect" is not peculiar to them: these are more modern batteries.

It is necessary to charge the battery at a favorable ambient temperature. The best temperature indicators at which the screwdriver battery should be charged is not lower than 10 ° С and not higher than 40 ° С. During charging, do not leave the battery unattended for a long time to avoid overheating and overcharging. Although, if the standard charging of the tool is equipped with an indicator for monitoring the entire process, the device will automatically "finish" it when it is needed.

It is not recommended to leave the battery pack in the charger for a long time. And if the screwdriver is not used as often, it is better to remove the batteries from it and store it separately from it. In the case when batteries are left without use for a long time, make sure that they are in a charged state by recharging them once a month for 25-30 minutes.

As you know, the cordless power supply of the screwdriver is either nickel-cadmium or lithium-ion. Ni Cd batteries can be stored at any state of charge. Their main advantage is that they are not afraid of deep discharges. In order for them to work well after a long break, they should be "pumped" as usual three or four times. The "pumping" time, on average, is 3-4 hours, during which you can work with the screwdriver in normal mode. It is advisable during the operation of the screwdriver to control that the Ni Cd battery is not partially discharged, but completely. This will help her not to accumulate the same "memory effect".

If the rechargeable power supply of your instrument is equipped with lithium-ion, rather than nickel-cadmium, batteries, their main advantage is that they have no memory effect. However, it is recommended to monitor their charge level more carefully. If the screwdriver with lithium batteries is not used for some time, they need to be recharged periodically. They just do not like deep discharge. If lithium batteries are deeply discharged, the safety controller inside the battery pack will operate. To prevent this from happening, make sure that the batteries are charged at least 50 percent.

Charger + (Video)

The charger below provides the correct charging current for any of the listed batteries. Screwdrivers are powered by batteries with different voltages of 12 volts or 18 volts

It doesn't matter, the main parameter of a battery charger is the charge current. The voltage of the charger when the load is disconnected is always higher than the rated voltage, it drops to normal when the battery is connected when charging

During the charging process, it corresponds to the current state of the battery and is usually slightly higher than the nominal at the end of charging.

The charger is a current generator based on a powerful composite transistor VT2, which is powered by a rectifier bridge connected to a step-down transformer with sufficient output voltage (see the table in the previous section).

This transformer must also have sufficient power to provide the required current for continuous operation without overheating the windings. Otherwise, it may burn out. The charge current is set by adjusting the resistor R1 when the battery is connected. It remains constant during charging (the more constant, the higher the voltage from the transformer. Note: the voltage from the transformer should not exceed 27 V).

Resistor R3 (at least 2 W 1 Ohm) limits the maximum current, and the VD6 LED is on while the charge is in progress. By the end of the charge, the LED light decreases and it goes out. However, do not forget to accurately monitor the voltage and temperature of lithium-ion batteries!

All details in the described scheme are mounted on a printed circuit board made of foil-coated PCB. Instead of the diodes indicated in the diagram, you can take the Russian diodes KD202 or D242, they are quite available in the old electronic scrap. You need to arrange the parts so that there are as few intersections as possible on the board, ideally none. You should not get carried away with the high density of installation, because you are not assembling a smartphone. It will be much easier for you to unsolder the parts if 3-5 mm remain between them.

The transistor must be installed on a heat sink of sufficient area (20-50 cm2). It is best to mount all parts of the charger in a convenient homemade case. This will be the most practical solution, nothing will interfere with your work. But here great difficulties can arise with the terminals and connection to the battery. Therefore, it is better to do this: take an old or faulty charger from friends, suitable for your battery model, and rework it.

- Open the case of the old charger.

- Remove all the former filling from it.

- Pick up the following radioelements:

| Pos. | Description |

| VD1-VD4 | 1N4001 rectifier diode |

| VD5 | diode |

| VD6 | VD6 LED, red or green, any type |

| C1 | C1 K50-35 or similar 220-1000 mF from 50 V |

| C2 | C1 K50-35 or similar 220-1000 mF from 50 V |

| R1 | variable resistor 10 kohm, preferably wirewound |

| R2 | resistor MLT-0.25 330 Ohm |

| R3 | resistor MLT-2, 1 Ohm |

| VT1 | transistor KT361V, G |

| VT2 | transistor KT829V (installed on a radiator square 20 - 50 sq. cm |

| T1 | Power transformer 220 V / 24 V, power 100 W |

- Choose a suitable size for a printed circuit board that fits into the case along with the details from the given diagram, draw with nitro paint its tracks according to the schematic diagram, etch in copper sulfate and unsolder all the parts. The radiator for the transistor must be installed on an aluminum plate so that it does not touch any part of the circuit. The transistor itself is tightly screwed to it with a screw and an M3 nut.

- Assemble the board in the case and solder the terminals according to the scheme, strictly observing the polarity. Lead out the wire for the transformer.

- Install the transformer with a 0.5 A fuse in a small suitable housing and provide a separate connector for connecting the converted charging unit. It is best to take connectors from computer power supplies, install dad in a case with a transformer, and connect mom to the bridge diodes in the charger.

The assembled device will work reliably if you have carefully and carefully performed

Battery

Rechargeable batteries for "Caliber" screwdrivers are divided into two types: lithium-ion and nickel-cadmium.

NiCd-batteries are installed in devices of the budget series and are calculated for 1300 full charges-discharges. For such autonomous power supplies, too high or too low temperatures are not recommended. After 1000 full recharges, the battery begins to oxidize, which is why it gradually becomes unusable.

These batteries cannot be charged quickly. In order for the device to serve for a long time, experienced craftsmen do not advise keeping the screwdriver charged.

On the market, the most common options for electrical appliances operating on such batteries are DA-12/1, DA-514.4 / 2 and others.

YES-12/1. This version of the device is one of the newest models on the screwdriver market. It allows you to drill holes with a radius of about 6 mm in metal surfaces and 9 mm in wood. Such a product is not endowed with any additional features. But it is best suited for home use.

The manufacturer paid great attention to the assembly of this product: the screwdriver does not play, does not emit creaking sounds

YES-514.4 / 2. A tool of the middle price segment, which is positioned on a par with leading manufacturers in the world, for example, Makita, Dewalt, Bosch, AEG, Hitachi, Stanley, Dexter, Metabo. A keyless chuck is installed here, allowing you to replace the equipment almost instantly.

The buyer can choose from 15 options for the rotation force of the engine crankshaft. The device operates in two speed modes. For comfortable work with the device, the handle has a rubberized insert, which additionally protects the person.

Li-Ion - batteries are quite expensive. But these products have several advantages over their competitors. These are environmentally friendly batteries that can be fully charged up to 3000 times. Products are not afraid of temperature extremes.

YES-18/2. The screwdriver allows you to make holes with a radius of 14 mm. The well-known company Samsung is engaged in the production of batteries for this device. The device has a reverse function, thanks to which you can quickly change the direction of rotation. The manufacturer provides 16 options for the rotation force of the engine crankshaft.

YES-14.4 / 2 +. The product has 16 torque options. This means that you can easily choose the mode for working with a certain surface. The screwdriver is equipped with a two-speed operating mode. There is a cooler and a ventilation grill next to the engine.

Charging methods without using a dedicated charger

When a standard charger is missing or just broken, you can do without it. Craftsmen have come up with different ways to replenish the battery charge from different sources. To charge a screwdriver battery without a conventional charger, you can use:

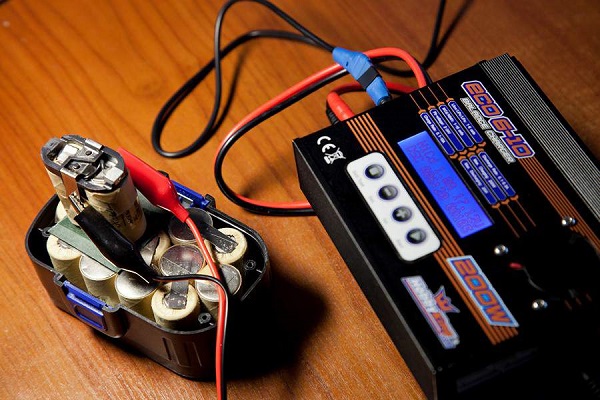

- car charging;

- charger of universal type;

- external sources of electricity.

The best option for car charging is a device with the ability to regulate the voltage and current. The main thing in such cases is to avoid overcharging. For this, the charging current is set within such limits that the process runs from 0.5 to 0.1 A * h, depending on the value of the total capacity. For example, if it is 1.3 A * h, then the current strength should be from 650 to 130 mA.

Universal chargers are convenient in practice. They have many additional settings that allow you to optimally select the appropriate current parameters for recharging batteries from different power tools.

External sources of electricity are mainly used for worn-out screwdrivers, for which it is inexpedient from an economic point of view to purchase new batteries. In such cases, the power tool is modified in a certain way, and an appropriate connection diagram is developed. An example would be a redesigned USB charger, additionally equipped with a fuse.

Non-standard methods of charging the screwdriver battery

In the absence of a complete charger or its failure, you can replenish the battery capacity without it. For this, the following are suitable:

- car charger;

- external sources of electricity;

- homemade devices.

The best way out of this situation is to purchase a charging compatible with the existing model or repair a standard one. Operating the screwdriver without a charger will quickly damage the battery.

Using the car battery charger

A car charger can be used to recharge the screwdriver's battery. Due to the fact that the tool is 18 V, and the charger used has no more than 16.5 V, this process does not pose a danger to the power source. It is advisable to use a device with a current regulator.During the charging process, it is necessary to periodically monitor the temperature and voltage of the battery. All charging initiation conditions must be met for any power supply.

A multimeter or tester connected in series to the low voltage circuit can be used to monitor the charging current. Its value should not exceed 0.1-0.3 parts of the battery capacity. The indication of the end of the charge is the heating of the block body.

To connect the charger to the battery, special clips ("crocodiles") are used. This verifies that the polarity of both devices is correct. The contact points should not heat up, otherwise the plastic of the case will warp.

Making a homemade charging block

Homemade chargers are used not only in the absence of a standard device. The latter has a low power, which increases the time to replenish the capacity. The charger is a current generator based on a powerful composite transistor KT829, which is powered by a rectifier bridge connected to a step-down transformer with sufficient output voltage.

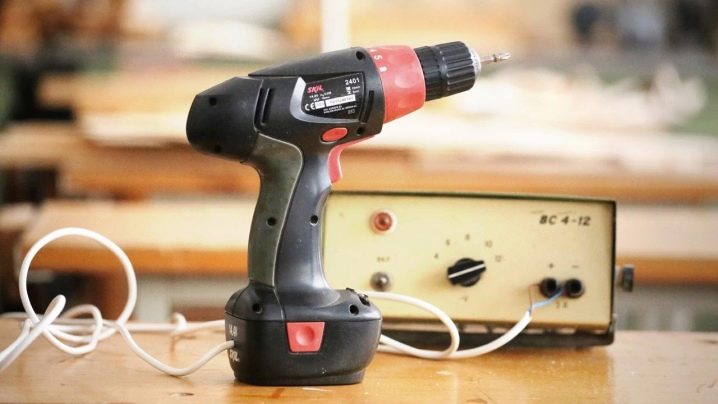

Homemade charger for screwdriver batteries.

Homemade charger for screwdriver batteries.

The charging current is regulated by a variable resistor of 10 kΩ. Ballast resistance (2 W, 1 Ohm) limits the maximum current. The charger is assembled in a separate case with lead-out ends for connecting the battery.

If there is a non-working charger that is suitable in design for this type of battery, then it is better to place the device in it.

Then there will be no problem with connecting the AB. To protect the circuit, a 0.5 A fuse is installed in the transformer circuit. Measurements of the parameters during the charging process are monitored with a multimeter.

Equipping the battery with a USB connector

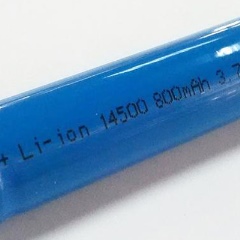

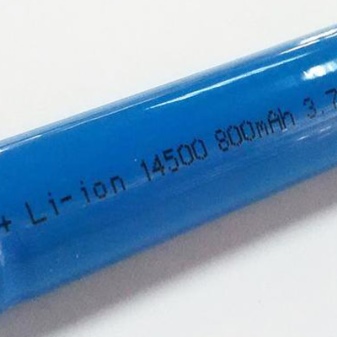

The battery can be charged through the USB connector by changing the cadmium batteries to Li-ion. The new battery has the same capacity, but is approximately 2 times smaller in size. The AB protection and control board is used for control. The load current should not exceed 1 A. Otherwise, the board will heat up.

Charging via external sources of electricity

Charging in this way can be done from a working car battery both by direct connection to the battery with constant control of the charging current, and from USB charging through the cigarette lighter socket. The control board will allow you to replenish the capacity to the nominal. However, lithium power supplies can be charged in this way. If the battery fails, you can work with a screwdriver by connecting it directly to any 12 V battery.

DIY universal charger

To charge the rechargeable device, you can make a homemade charger powered by a USB source. Required components for this: socket, USB charger, 10 amp fuse, required connectors, paint, electrical tape and tape. For this you need:

- Disassemble the screwdriver into parts and cut off the upper body from the handle with a knife.

- Make a hole for the fuse to the side of the handle. Connect the cable with the fuse and fit into the handle of the unit.

- Fix the fuse with glue or a heat gun. Wrap the case with tape and attach the structure to the battery connector. The wires are mounted at the top of the screwdriver. The tool is assembled and wrapped with electrical tape. After that, the body is sanded, covered with paint and the resulting device is charged.

As you can see, this process will not take long and will not be too wasteful for your family budget.

The screwdriver is one of the most demanded power tools in home and professional activities. It allows not only twisting and unscrewing various types of fasteners, but also drilling holes. By the way of power supply, the devices are divided into mains and rechargeable ones. Models with batteries are practically not inferior in their performance to tools powered by a 220 V.At the same time, with their help, you can perform work operations offline. It is also convenient that the power cord does not restrict movement. But the battery of the screwdriver should be properly charged and stored so that it lasts a long time. Many problems with the battery pack can be corrected by yourself using a multimeter to identify the cause of the malfunction.

The principle of operation of the memory

Instrumentally, this is done with the help of changeover contacts actuated by the reverse lever.

Although this current is directly related to the maximum operating current, therefore, usually there are no problems here.

How to do something yourself, with your own hands - home master's site

The operating time of the U1 microcircuit is set for one hour of operation, after which the power is removed from the transistor Q1 and, accordingly, from the relay. After such a repair, the button will serve for some more time, but you still have to buy a new one! By increasing the tightening value, thereby you screw the self-tapping screw deeper. For this, a complete disassembly of the screwdriver is not required.

The battery should be charged for about 10 hours during exercise to provide the maximum possible energy. We hope this article was helpful to you. Disassembling the unit, for example, for repairing the battery of a Hitachi screwdriver, is shown below, it is very simple - we unscrew the screws around the perimeter and disconnect the case. The reduced alternating voltage 18V from the secondary winding of the transformer is fed to the diode bridge through the fuse FU1.

The capacity of the standard battery is 1 Ah. The screwdriver is completed with a double-sided bat photo 3.

We assemble a 12V 5 Ah screwdriver battery.

Repair of power sources

Rechargeable batteries do not really have complex spare parts, as they are assembled from the simplest charging cells. In order to decide on the repair, you need to open the source and check for damage. Tools and materials that will be needed when performing repairs:

- Multimeter.

- Screwdriver.

- Electrical contact cleaner.

- Insulating tape.

There are times when the coil of the cordless screwdriver is defective and, therefore, overheats the device. The insulation melts easily, the batteries fail and the cordless screwdriver cannot be used. A technical error cannot always be determined by visual inspection and the tool needs to be disassembled.

Sequence of operations:

- Unplug the tool from the electrical outlet.

- Use a rag, sandpaper, or an electric contact cleaner to clean the contacts between the power handle and the charger.

- Plug in the power supply several times and check that it is functioning properly.

- Check the instrument at the DC output. Set the multimeter to 25 DCV scale. Plug it into an electrical outlet.

- Touch its two probes to the corresponding contacts (+ and -). If the reading is zero, swap them.

- The DCV output should be about or slightly above the rated power of the source. That is, at 9 VDC, the device should show no more than 10 V.

- Check the source at the AC output. Set the multimeter to 25 ACV scale. Touch the two probes to the contacts. If there is no reading, the transformer is faulty. Match it for replacement with equal denomination and size.

- Check the battery. Charge the battery fully. Set the instrument to a DCV scale greater than the rated power of the battery pack.

- Touch the red probe to the + terminal and the black probe to the terminal and measure.

- Replace the battery if the reading is 1 volt below the rated power.

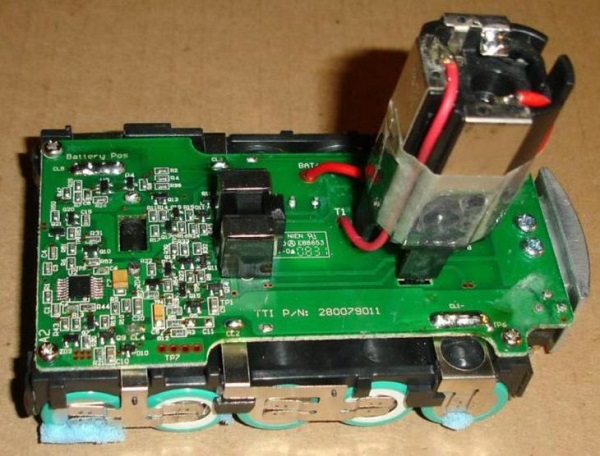

Screwdriver battery device

The battery is the power source for cordless screwdriver models. Due to the course of physical and chemical processes (electrolysis), this element accumulates electricity, and then outputs a constant voltage of the required value at its corresponding outputs. Voltage and capacity are the main parameters of any storage device. The first shows the potential difference between the cathode and the anode of the battery. Voltage is measured in volts. The capacity determines the amount of current issued by the battery for 1 hour, therefore this parameter is measured in ampere-hours.

For different models, the battery pack (battery) looks and works in a similar way. It consists of the following structural elements:

- cases with contacts located on it;

- power supply elements (batteries);

- temperature sensor circuit (thermistor), which performs the function of protecting the unit from overheating (range is from 50 to 600 degrees).

Not all models are equipped with thermistors. The body is usually a two-piece plastic box. It houses, basically, about 10 batteries inside, and sometimes there are more of them. In this case, the batteries are connected to each other in a chain. The free terminals of the outer cans are connected to the contacts located on the body, intended for powering the electric motor of the instrument and connecting to the charging equipment. The output voltage of the battery is determined by summing this parameter of all batteries connected to a single circuit.

There are 4 contacts on the battery case:

- 2 power ("+", "-"), designed for charging and discharging;

- one control top, connected to the thermistor;

- one contact used for charging from special stations that are able to equalize the amount of charge for all the batteries included in the unit.

By the type of batteries, accumulators are divided into the following types:

- Nickel-metal hydride (designated - NiMh) with an output voltage of 1.2 V;

- nickel-cadmium (marked with NiCd) also give out 1.2 V at the output;

- lithium-ion (designated by the symbols Li-Ion), in which the voltage depends on the number of power cells in the battery and can be in the range of 1.2-3.6 V.

A separate battery consists of the following components:

- positive and negative contacts;

- an electrode with a positive charge;

- outer cover of the case;

- electrolyte;

- negative electrode.

Nickel-cadmium energy storage devices are most widely used due to their affordable price, compact size and large capacity. They can be recharged over 1,000 times.

Types of chargers

Chargers do the same job, but differ in how they are filled. Transformer and analog designs are distinguished. They have a power supply unit (PSU) that can be built-in or external. More modern models are pulsed, which are also called inverter.

Transformer chargers are characterized by a simple electronic base.

The classical design (regardless of the location of the power supply unit) includes the following basic elements:

- a step-down transformer;

- rectifier diodes;

- capacitors;

- current stabilization device;

- charging control circuit.

The lower the mass of the device, the longer it takes to charge: a transformer with a weak winding produces a small current.

Analog with built-in power supply

Such units are in demand due to their low price. For home tools, devices with minimal functions are chosen.

The main thing to pay attention to when choosing is the appropriate current load and charge rate

Analog devices with built-in PSU work with all types of batteries. The transformer reduces the mains voltage to 20 V. Its power is calculated according to the required output current. Diodes convert alternating voltage to pulsating voltage. To smooth out the ripple, the circuit contains filtering capacitors.

To create the required voltage value, a stabilizer is installed. It includes a microcircuit and resistors.

Most devices have an indicator that signals the end of the process. More modern ones are equipped with a switch that turns off charging when the batteries reach the required parameters. In other cases, they are guided by the time indicated in the instruction manual.

Included with cheap screwdrivers are chargers (chargers) with minimal functionality. For this reason, they often break.

Analog with external power supply

The unit consists of 2 separate parts: a power supply unit and a charger. The electronic base is standard, similar to devices with a built-in power supply unit. Charging is controlled by a small board the size of a matchbox. The units are not equipped with radiators for heat dissipation, as a result of which they can overheat. Therefore, such devices do not last long.

Impulse

for a screwdriver.

Professional tools are required to operate continuously without recharging. The devices are equipped with 2 batteries.

The chargers for them are designed according to a complex scheme, multifunctional. The batteries are recharged in just 1 hour.

Impulse chargers differ:

- small size;

- high charging current;

- protection system for the device and batteries.

Most often, inverter units are assembled based on the MAX713 microcircuit. Output voltage 25 V, constant current.

These are smart devices that check the voltage level first. Then the boost charge mode starts, which protects the battery from unwanted memory effect. A fully discharged battery recovers its capacity in 1.5 hours. Pulse circuits allow you to select the type of batteries and the strength of the charge.

Among the memory of this type, the intelligent device "Zubr" is in demand. Its microprocessor, after assessing the state of the power source, sets the optimal charging voltage and current. For autonomous power supplies with a voltage of 18 V, many prefer the "Caliber" inverter charging.

What to do if the battery won't charge or hold a charge

In this case, there are few options: either the cause of the malfunction lies in the charger, or the screwdriver itself "jams". Also, the battery pack may eventually exhaust its resource and need to be replaced. In order to find out the reason, it is necessary to carefully inspect both the instrument itself and its battery together with the charger.

Often the reason for poor battery charging is that the contact between the screwdriver and its charger looses due to the extension of the terminals. To fix this problem, it will be enough just to disassemble the charger and carefully bend its terminals back.

Do not forget about such a frequent malfunction as the oxidation of the metal parts of the battery itself and the charger. The constant ingress of construction dust and dirt also contributes to a weak flow of charge current from the charger to the battery: the tools are charged worse

It is important not to forget to take care of all components of the instrument in order to prevent deterioration of its performance by wiping the metal contacts and cleaning them from dirt.

If the battery itself runs out, you can try to "swing" it, as is usually done in the case of nickel-cadmium cells. If this does not help, you will either have to replace the battery pack completely, or carry out a partial replacement of its elements.

Usually any screwdriver comes with two identical batteries. If one of them fails, if desired, you can assemble one working battery from two, in case the capacity has become less in both. After one working unit is assembled from two blocks, one must not forget to equalize the capacity indicators of the cells by “pumping” the battery with several “charge-discharge” cycles for 3-4 hours.

You can also try to "invigorate" the batteries separately. To do this, the weakest of them should be charged with high currents, after which the battery should be reassembled and charged in normal mode. This method sometimes works with nickel-cadmium batteries. "Point" recharging with high currents should last no more than 3-5 seconds, while it is desirable not to allow strong overheating of the element in order to avoid its destruction.