Top manufacturers

It is noteworthy that products from China are not of high quality. In the case of stepped drills, preference should be given to Russian and European manufacturers, among which the following stood out.

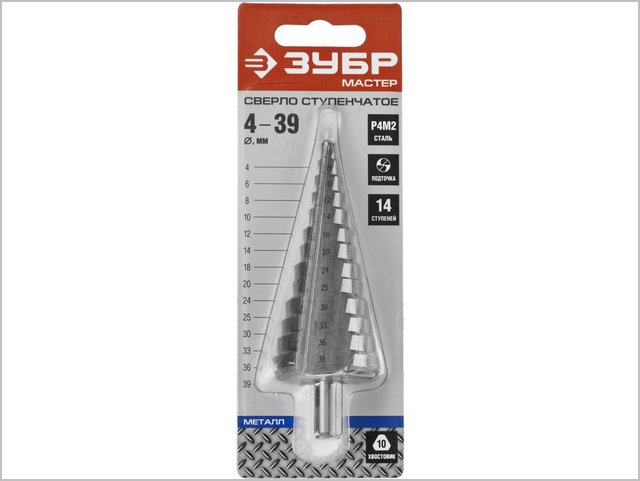

"Bison". The company is engaged in the production of stepped drills of acceptable cost and high quality. The domestic brand makes tools from special steel, additionally covering the surface of the drills with wear-resistant alloys.

There are other manufacturers whose tools are also of high quality and reliable. However, the listed companies are considered the most popular both among professional craftsmen and among those who purchase drills for work at home.

Why does an electrician need a step drill for metal

The step drill can be used by an electrician. This device is necessary for him when installing electrical wiring. For example, an electrician must drill a hole in a steel profile to pass a wire through the plasterboard cladding. The thickness of the metal profile sometimes reaches 0.5 mm. The diameter of the cable to be passed is 16 mm. It is difficult to drill this profile with a simple tool, since the holes will come out uneven. A multi-stage option can be used to make a hole in a workpiece with a thickness of 16, 20, 25 mm.

Step drills are necessary for an electrician to work in electrical panels. It is often necessary to drill a hole in the switchboard to install control buttons, indicators, various switches, fittings or a lock. The electrical panel is 1 mm thick. Mounting the gland on the shield requires drilling a large opening in the shield.

Openings in metal cable boxes are made with a stepped product for wire output. If the openings for the wire outlet are rigidly fixed in the box, then an additional hole must be made for mounting the gland and plug.

Multistage drill for metal - advantages and disadvantages

All cutting tools have their own distinctive characteristics, from which positive and negative properties can be distinguished. The advantages of tapered step drills include:

Drill holes of various diameters with just one bit.

Improved wear resistance compared to conventional cylindrical tools.

The speed of work. Thanks to the high speed of action, the original properties of the drill are preserved, since the cutting edges simply do not have time to heat up.

During work, preliminary punching of the drilling site is not required, since the thin tip instantly cuts into the surface.

Combination of drilling and grinding function.

Smooth transition from a smaller to a larger diameter eliminates deformation of the workpiece

This is very important when working with thin sheets.

Versatility of use, allowing the use of the attachment both on a stationary machine and on a hand-held power tool.

Some models have an additional abrasive coating for increased durability.

No need for frequent sharpening.

The main advantage of the tapered nozzle is drilling without defects in the hole edge

The main advantage of the tapered nozzle is drilling without defects in the hole edge

Despite the many positive aspects, the cone drill is not an ideal tool. Users highlight the main drawback - the high price.

How to choose a step drill for metal - basic technical characteristics

Since these products are distinguished by their high prices, before choosing, it is necessary to carefully study the main technical characteristics so that in the store where you can buy a step drill for metal, you know exactly what to look for. GOST defines the basic standards according to which all drills must be made of high-strength alloy steel and have the following parameters:

- diameter from 5 to 80 mm;

- cone length - 58-85 mm;

- shank diameter - 6-12 mm.

These are the main indicators that are determined by the standards, but there are a number of parameters that make it possible to judge the quality of the product.

Bright golden hue - evidence of sputtering for increased durability

Bright golden hue - evidence of sputtering for increased durability

Colour

By the color, one can judge the quality of the material from which the instrument is made, which will allow us to weed out defects at the acquisition stage.

- A gray tint with a steel sheen indicates that the steel was not hardened during the manufacture of the drill. This will lead to a decrease in the strength of the drill and its rapid breakage.

- The black color indicates that the steel was treated with hot steam during the production process, which increases its strength.

- A golden hue means that quality metal was used in the manufacture, in which residual stresses have been eliminated. Such products are distinguished by their durability.

Any cutting tool has a marking indicating the type of steel and used additives

Any cutting tool has a marking indicating the type of steel and used additives

Marking

All products on the market have special markings that determine the type of steel used in the production of a particular product. Experts consider the instrument with the HSS marker to be among the highest quality samples. These drills are designed specifically for processing materials at high speeds without deforming the nozzle itself when the temperature rises. Additionally, in the marker, the letter designations of the alloy composition are affixed. (Co - cobalt, Ti - titanium, N - nitrogen, M - molybdenum).

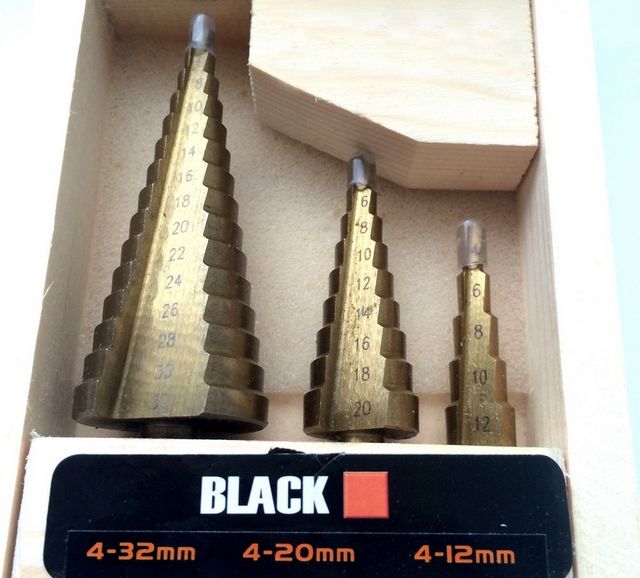

The purchase of a set of attachments will diversify the scope of use

The purchase of a set of attachments will diversify the scope of use

The size

Before buying, you should decide which holes will have to be drilled, since the size of the purchased nozzle will depend on this. You can determine the diameter that can be obtained with a specific drill from the name. For example, the indication on the label "Step drill bit for metal 4-32 mm" will mean that using this bit it will be possible to drill a hole from 4 to 32 mm, respectively.

The manufacturer informs about the possibility of sharpening on the packaging

The manufacturer informs about the possibility of sharpening on the packaging

Sharpening capability

Another characteristic that determines the cost of the final product is the possibility of self-sharpening. Such products have a longer service life, but cost, on average, a third more expensive than conventional ones.

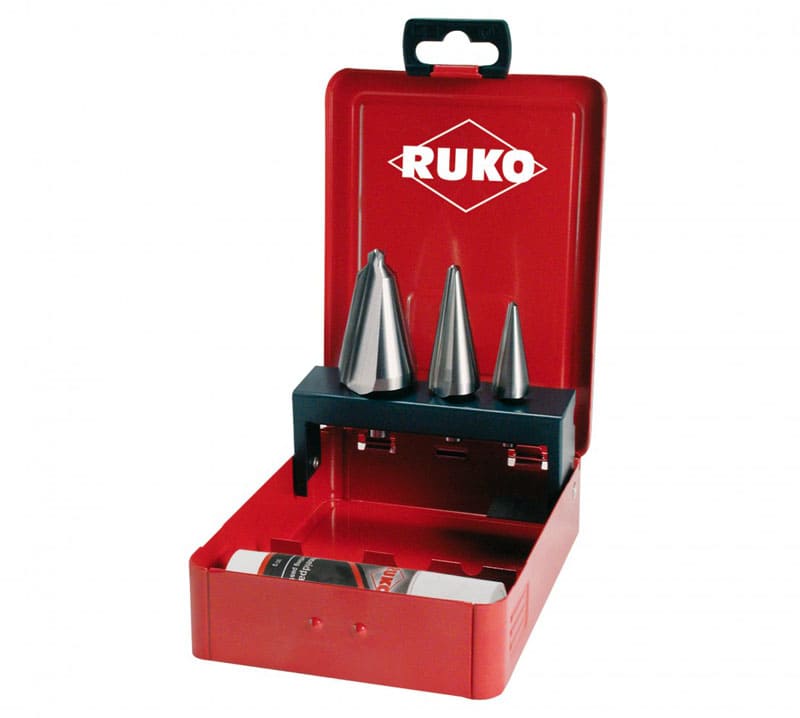

Buying products from a well-known brand is a guarantee of quality

Buying products from a well-known brand is a guarantee of quality

How to choose?

There are several characteristics and tips to help determine quality:

- Model designation of letters and numbers. The first three numbers indicate the starting and ending diameter, as well as its pitch. Then the letters indicate the grade of steel from which the nozzle is made. The latest figures show Rockwell strength;

- Metal color is one of the important quality indicators:

- Steel with a gray tint. Unambiguously speaks of low strength without heat treatment

- Black color. Steam hardened steel. Strength is higher than in the first version

- Golden tint. Speaks about the high quality of the metal. He was relieved of his inner tension

- Bright golden hue. High strength steel drill bit with titanium nitrate added. Refers to a premium tool with a long service life

- Overall and working length. The scope of the tool depends on this parameter;

- The diameter of the working part. There are two of them. The first indicates the minimum hole size, and the second indicates the maximum;

- Trademark. Quality and price depend on it;

- Quality certificate for compliance with the declared technical characteristics and GOSTs;

- Sharpening capability. If the drill is sharpened, it will increase its service life.

Tool sharpening and maintenance

Subject to the observance of the requirements of operation, the cutting edge retains its properties for a long time. However, sooner or later there will be a need for sharpening. For this procedure, you will need a sharpener and coolant.

Sharpening is carried out with a rigid fixation of the drill, using fine-grained abrasives.

Please note that the distance between the cutting corner and the opposite flank must be the same at each step. The stepped drill is an excellent tool for making high quality holes in thin sheet materials

Have you used this tool? Some craftsmen find that using a stepped drill with a drill quickly wears out the sharpening of the edges. What do you think? Share your opinion in the comment block

The stepped drill is an excellent tool for making high quality holes in thin sheet materials. Have you used this tool? Some craftsmen find that using a stepped drill with a drill quickly wears out the sharpening of the edges. What do you think? Share your opinion in the comment block.