How to choose?

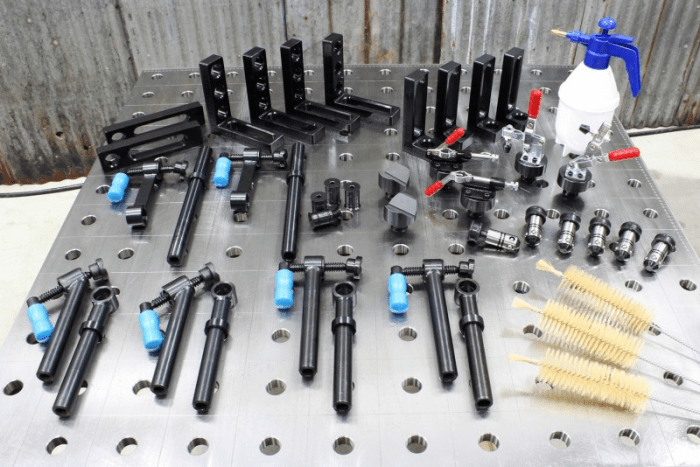

When choosing an assembly and welding table, it is necessary to take into account:

The welding table must have high strength and rigidity;

Have the necessary lifting capacity to work with the planned products;

To perform complex operations with products, a fastening system must be provided for installing accessories and fixing products. The choice of fastening system depends on the diameter of the tool used. The larger the diameter of the tooling, the more reliably the product can be secured.

Determine if plasma nitriding is necessary. If a large amount of work is planned, then plasma nitriding is necessary, otherwise you can buy a regular table, and use a non-stick liquid or a special spray to protect its surface from welding spatter.

Also, the welding table can be additionally equipped with an exhaust system. A welding table with an exhaust hood will allow during work to eliminate contaminated air through the outlet from the working area, thereby protecting the welder and those around him from harmful impurities.

In the MOSSklad company you can order high-quality universal welding tables of various standard sizes based on your needs and production characteristics. We supply professional welding tables TEMPUS (Germany) and assembly tables of domestic production RUBOV.

Clamps

The clamp is considered a universal tool, since it can perform both installation and fixation functions. There is no single type of clamps, but this tool must necessarily be in the arsenal of any welder. Theoretically, welding without the use of clamps is quite possible, but this will have to pay for wasted time, inconvenience and, most importantly, poor quality.

The functionality of the clamp depends on whether the throat size is adjustable. There are quick-clamping devices based on clamping using a cam mechanism. However, one clamp cannot fix absolutely any connection, so the welder must have several types of such tools at once. Welding clamps have one feature - they are made of metal. These carpenter's tools have plastic or wooden elements.

F-shaped

The schematic diagram of the F-shaped clamp device is quite simple, so often homemade products can be found in the welder's arsenal. It consists of a metal frame (tire) to which two jaws are attached. Some of the sponges are movable, while the other is immovable. In some cases, the stationary jaw is designed as an extension of the bed. The movable jaw is driven by a screw with a handle.

A quick-release mechanism is offered as an alternative. It replaces the movable jaw and allows you to more quickly fasten parts. Typically, a relatively high force (up to 10,000 N) can be obtained with F-clamps.

G-shaped

Such clamps are made in the form of a bracket in which both jaws remain stationary. The fixing of the parts is carried out by tightening the screw. This mechanism has one advantage - there is no jaw play. But on the thickness of the fastened parts, G-shaped clamps are very limited.

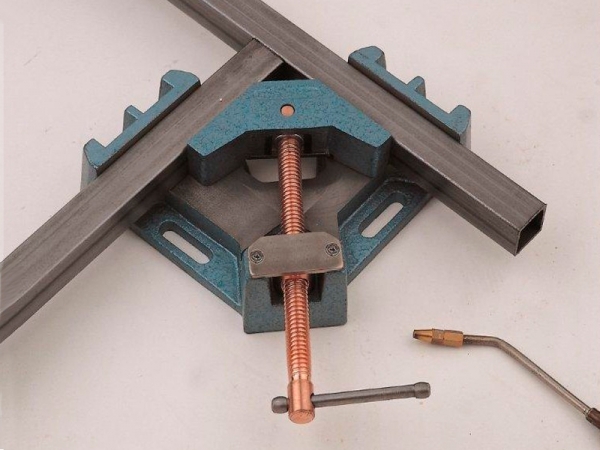

Corner

If necessary, fix the parts at right angles, use corner clamps. More sophisticated devices allow you to adjust the angle of fixation. The constituent parts of such clamps are the body and the clamp. The clamp can be single-screw or two-screw. The compression heels come into direct contact with the product.

End

Such devices are designed to fix the welded element to the end of the part. In appearance, they vaguely resemble G-shaped clamps, however, they differ in two additional clamping screws.

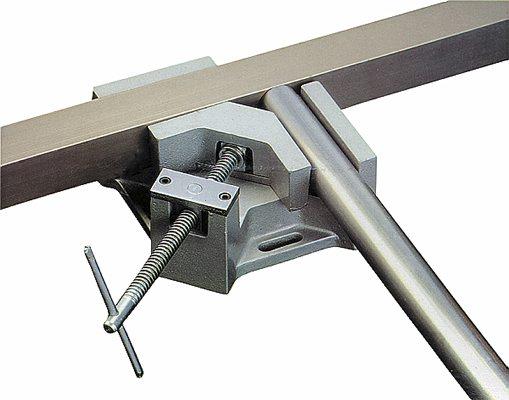

Corner clamps

This is a series of highly specialized clamps. With their help, it is possible to precisely join shaped steel at right angles. Such clamps are indispensable in the manufacture of frames and frames. The angle clamp allows you to weld the ends of pipes, angles, channels, etc.

There are mobile and stationary clamps. Clamps of the mobile type can be used locally, that is, directly on the metal structure itself. Stationary clamps are rigidly attached to the tabletop of a locksmith's workbench or assembly / welding table. Stationary clamps allow joining rolled products in one place, which positively affects the accuracy of the manufactured structures. Stationary devices have proven themselves well in the serial and mass production of metal structures.

Classic angle clamps fix workpieces with clamping jaws. In more modern models, the fixation of the rolled metal is realized due to magnetic forces. It is enough just to place the workpieces on the guides, the rolled metal itself "sticks" to the clamp. Magnetic clamps are simple and reliable in design.

The weak point of magnetic angle clamps is the ability to work only with metal workpieces that exhibit magnetic properties. Clamps with clamping jaws can dock aluminum, alloy steel, copper and all kinds of alloys that do not react to a magnet.

Universal fittings for assembly for welding

General purpose assembly tools are usually simple and portable. They do not always provide the required accuracy and are designed to check the correct assembly and installation dimensions.

Portable clamps are designed to fix the relative position of the parts to be welded. Clamping devices can be used when welding certain parts, as well as in the manufacture of assemblies and structures. In this case, they are equipped with stands, racks and other auxiliary equipment. They are made in the form of clamps and bolt clamps, allowing you to assemble parts of any profile.

Wedge and clamping brackets are used to assemble products from sheet metal for welding. Spring clamps are used to fix thin sheets and short parts made of profiled steel.

| wedge bracket | clip | spring clip |

Tongs are used mainly for the installation of large structures. Individual elements of the clamps are temporarily welded to the assembled parts, and removed after welding. The clamps are rigid and adjustable.

Ties are used to bring the edges of the parts to be welded closer to the specified dimensions. The most widespread are the screw ties.

Tie with bolt and welded elbows for welding large sheet metal structures.

Clamping device with welded temporary elbows for assembling pipes. It is used to a limited extent and only on carbon steel pipes.

Screw tie for assembling structures and parts from sheet, strip and profile products.

Lever-screw coupler.

For the assembly of pipe joints, clamping screw devices of the clamp type are most used, which do not create a rigid fastening of the abutting elements.

Spacers and jacks are used for fixing products with a closed profile from the inside, for leveling the edges of cylindrical products, for removing dents, etc. When welding cylindrical products, spacers are used in combination with clamping rings. If the diameter of the shells is small, spacer rings are used, and for large diameters, screw spacers or jacks are used. The forces in the struts and jacks are generated by mechanical, hydraulic or pneumatic drives.

Centralizers are intended for fixing individual pipes or similar products, so that they do not have a shift and rotation in the directions of three coordinate axes. They allow you to combine the cylindrical surfaces of abutting products (pipes, pipe sections, etc.) for welding. Depending on the position of the centralizers relative to the mounting surfaces, the centralizers are divided into external (grasping) and internal (spacer) ones. External centralizers are used when assembling pipes in sections for welding on blank bases or in the area of construction sites. Although the design of the external centralizers is different, they perform the same operation to ensure the alignment and alignment of the end edges of the pipes (see the figure below).

| Pliers for pipes with a diameter of up to 40 mm | Screw clamping device for pipes up to Ø 60 mm |

Centralizers for assembling large diameter pipes can be equipped with a hydraulic power cylinder in place of the clamping screw. The external hydraulic centralizer is a double-row lamellar chain, pulled together at the ends of the pipes to be joined by a jack placed inside the bracket. The jack is driven by a hydraulic pumping station.

External hydraulic centralizer TsNG-1220

1 - chain; 2 - thrust roller; 3 - staples; 4 - end link; 5 - jack; 6 - screw.

Internal centralizers provide the highest quality pipe assembly due to a more accurate alignment of their edges. When centering, the joint is open from the outside, which provides free access to the welding site. The use of internal centralizers makes it possible to increase the productivity and the degree of mechanization of the assembly for welding both rotary and non-rotary joints of pipelines.

Convenient 90 ° welding

Welding magnets allow you to hold the work piece to be welded at an angle of 90 °.

In order to make pipe welding not too troublesome and do without an assistant, they came up with welding magnets that hold pipes at an angle of 90 °. Previously, devices for this kind of work were made without the use of magnets.

This will require the following materials:

- metal square with a side of 20-25 cm;

- a piece of a square pipe;

- 3 small bolts and nuts for them;

- a thick bolt with a diameter of 4 cm and a nut 35;

- drill, drill;

- a small metal cylinder with a diameter of a ballpoint pen;

- the holder for the cylinder, in fact, its handle;

- welding machine.

Pipes 20 and 15 cm long are welded onto the square, on replaceable sides, in the very corners, so that the ends of the pipes are on opposite sides of the square.

Craft two accessory parts. Weld a U-shaped figure from the same pipes, about 10 cm long. Using the same pipes, weld the second in the form of an isosceles trapezoid with bases of 11.5 cm and 5.4 cm.

Calculations must be performed more accurately, the angle formed at the intersection of the side parts should be 90 °, so the lengths of the bases will exactly depend on the width of the pipes.

On the sides of the square at the corner where the pipes are not welded, make an isosceles triangular cut. Weld a U-shaped figure to it, having previously drilled a hole in the center of the upper rectangle for a small bolt. A 4 cm wide bolt with a nut should be placed in the gap between the square and the figure.

Attach a handle to the bolt; as it, you can use a nut with a hole in which a thin rod moves freely.

In a small cylinder with a length of the smaller base of the trapezium, thread for the taken small bolts. Thread along the tip of the large bolt, centering it.

At the point of intersection of the trapezoid diagonals, make a hole in both such parts. A cylindrical part will be inserted between them, in which a thread was previously made and a hole was drilled in the center.For further assembly of the device, it is necessary to prepare a 35 nut for a bolt 4 cm wide, for this, make a through thread on one side of it, without affecting the opposite faces.

corner connection

All further assembly consists in the correct sequence of attachment of parts. On the bolt with the handle already attached, put a threaded nut, turning until almost to the base. Attach a cylindrical part to the end of the bolt, with a drilled hole to the female thread, and fasten it with a small bolt. Next, we fix the trapezoidal figure with the help of bolts, one of which is recessed in the thread of the cylindrical part, the second fixes the configuration from above, through the thread of the same cylindrical figure. A bolt with a prepared part at its top is pulled under the U-shaped support, adjusting a threaded nut under it. Fasten the bolt with a bolt that passes through the center of the U-shaped figure and is screwed into the special thread of a special nut. The device is, in fact, ready to use. By rotating the handle of the bolt, it can be loosened. By inserting the pipes at right angles, fixing the fixture, you can weld.

Devices of this kind are a good substitute for welded magnets, which can be too expensive for simple household use.

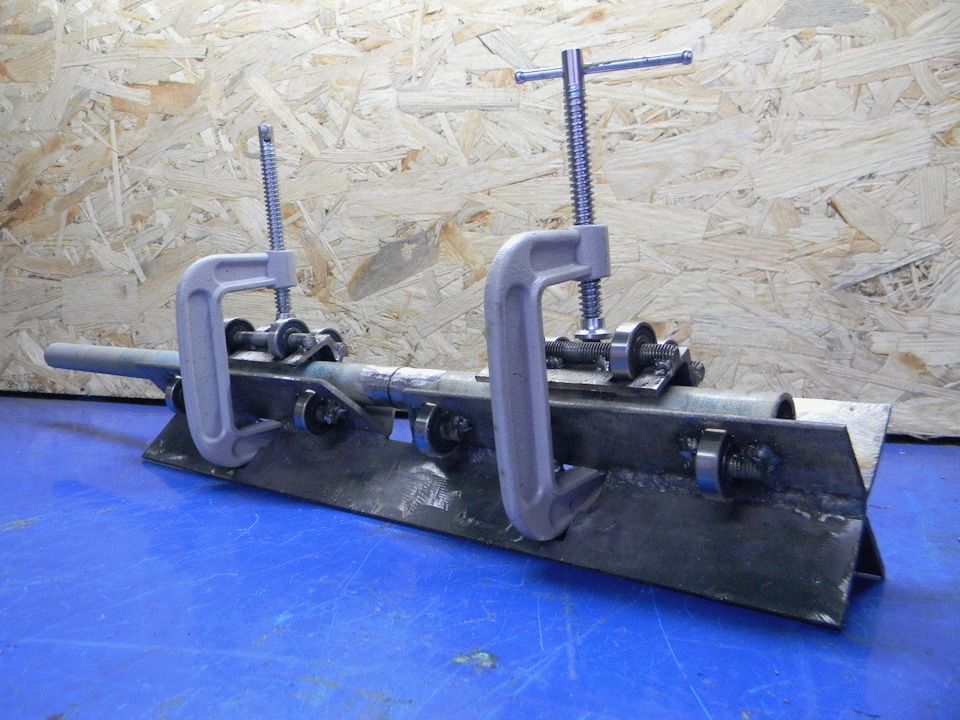

Pipe clamp

Welding metal pipes end-to-end is a complex operation. Welding the pipe to the finished system is considered simpler. The structure for such cases is made of a metal corner and steel plates. The halves of such a device should be fixed using the traditional method, namely with threaded studs. As a result, a sufficiently simple and effective design can be obtained, which will greatly facilitate the work when welding pipes with various designs.

Welding metal pipes end-to-end is a complex operation. Welding the pipe to the finished system is considered simpler. The structure for such cases is made of a metal corner and steel plates. The halves of such a device should be fixed using the traditional method, namely with threaded studs. As a result, a sufficiently simple and effective design can be obtained, which will greatly facilitate the work when welding pipes with various designs.

Other types of designs are available, such as cam gears, straps and wire clamps, which can be useful for working with specific designs, including particularly fragile and thin ones. However, their manufacture is the subject of separate master classes and articles on specialized resources.

Homemade clamps are indispensable helpers for any craftsman working with metal and wood parts and products. Making them is quite simple and very exciting.

It is important to follow the manufacturing technology, find the best instructions and videos. You can buy clamps, but they may not fit in the end due to the specificity of the blanks or work

That is why you should make your own clamps. Successful work with various blanks and making homemade quick-clamping clamps!

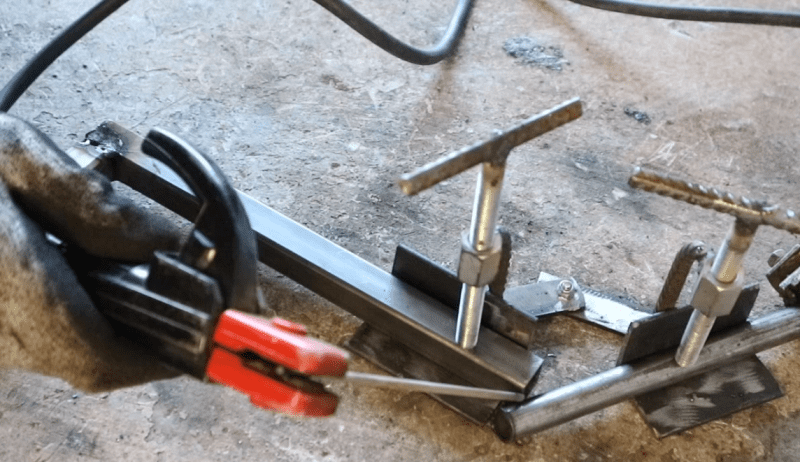

Step 6: angle clamp in action

The homemade corner clamp can be used both outside and inside. This is why all the welds are made on the underside. The photo shows examples of use, if I were going to weld these pipes, I would additionally secure them with ordinary clamps. The last photo shows an example of adding a vertical element. This also explains why the gap between the arms should not be too large - otherwise the vertical pipe would slip through the hole.

Be careful when welding pipes externally - the inner bend radius of the angle can interfere with the pipe clamp. Be sure to check this point before proceeding with pipe welding.

I'll tell you how to do something with step-by-step photos and video instructions.

Welding area maintenance equipment

Convenience of the position of the welder when working on large-sized products is provided by cradles, ladders, as well as special platforms. The platforms are designed to accommodate welders and welding equipment, as well as to move them to the welding area.They are made for one or more welders and can be mobile (self-propelled or non-self-propelled), portable and stationary. The figure shows a universal platform that can move along the workpiece to be welded, rise and fall depending on the level of the weld, and move in the direction of the workpiece.

How to choose?

Before buying a clamp, you need to understand that there is no single (universal) type of clamping mechanism that is suitable for all occasions in life. Each of the varieties of these devices is designed for specific tasks.

- If you need to weld 2 pieces at a 90 degree angle, and you only have G-clamps at hand, it will be very difficult to solve the problem with their help, especially if you are welding round pipes.

- An angle clamp will also not help if you need to weld 2 sheets of metal together in the same plane.

Therefore, the performance of certain welding work must be approached responsibly, knowing exactly what type of auxiliary tool will be needed in a particular case.

Pay attention to the area and thickness of the clamping jaws: the wider and thicker they are, the more clamping force they can withstand (and the area will also provide a secure grip of the workpiece). These are very important parameters that should not be underestimated, because during welding, the metal very often drags away from overheating, and unscrupulous clamps will allow the parts to be welded to move.

This will inevitably lead to scrap or to further tension of the workpiece for subsequent welding.

It is necessary to pay attention to the thread and the design of the screw connections. As mentioned earlier, it is desirable that they are depleted - this is the best solution

And also look at the existing thread pitch - the larger it is, the more clamping force the nut can withstand. It is best to choose the maximum step, since such a product will last much longer.

The size of the clamp is equally important in choosing the perfect tool. Everything is individual here, so the expression "more" in this case does not mean "better" at all. Too large a clamp cannot be used in a small structure, and a small one, probably, may not be enough to clamp the dimensional element. That is why the size of the clamp to be purchased should be based on the maximum width of the two parts to be welded (plus a small gap).

For an overview of Bessey clamps, see below.