Materials (edit)

Eye safety is especially important when a person is performing work in difficult conditions. Glasses protect from chemicals, debris, glass. Such means of protection are irreplaceable in the woodworking industry and construction.

Safety glasses can be tinted or clear. You can choose the color of the lens based on your own comfort. If you have to work in the bright sun or with welding, then it is better to choose dark glasses.

Products can be in plastic or metal frames.

Each model offered on the market has its own place in the safety rating. This rating means that the lenses have been tested for their ability to withstand impact. The more expensive the glasses, the more mechanical impact their lenses can withstand.

On the market, you can find models with adjustable straps or anti-fog lenses.

The described means of protection are of several types:

- glass;

- plastic;

- plexiglass;

- polycarbonate.

Scratches do not remain on the glass over time, but the problem is that users often complain that the material is heavy and causes discomfort. Glass is also prone to fogging.

Plastic is lighter when compared to glass. It is also less prone to fogging. The problem is that scratches quickly appear on it, as a result of which visibility is reduced.

Plexiglass is widely used in medicine and aviation. It owes its popularity to its high strength. If it is destroyed, then without fragments. The disadvantages include poor resistance to solvents and other chemicals.

Polycarbonate is another option for goggles. It does not fog, scratches and is lightweight. These glasses are more durable than the other two options, but they also cost more.

How to choose?

When choosing such a product for work, it is important to consider the scope of use of protective glasses, since they must cope with the tasks assigned and protect the eyes from possible injury. All the necessary information can be found in the marking, the main thing is to know how it is deciphered

All the necessary information can be found in the marking, the main thing is to know how it is deciphered.

Experts also recommend taking into account the ergonomics of the product. In practice, if such glasses do not fit well, then it becomes inconvenient to work in them, and sometimes they cease to meet safety requirements due to the available free gaps.

If you need a tight fit, then you should pay attention to the models where the manufacturer has provided arms with the ability to adjust the length. It is desirable that the straps have a thickness of 1 cm

Before buying, you should pay attention to the jumpers and nose pads. They should not have sharp edges and, moreover, no burrs.

As a nice addition, there will be a model with removable lenses. If one breaks, you just need to replace the glasses, not buy new glasses.

For an overview of protective glasses, see the following video.

Views

There are several types of goggles on sale: with direct and indirect ventilation. Ventilation slots located around the perimeter of the frame or on the sides prevent fogging.

But it is important to take into account that goggles designed for working with toxic substances, designed to protect against fine dust, must be sealed. The presence of ventilation holes eliminates this property

For the manufacture of lenses and sealed eyeglass frames, materials are used that can withstand aggressive influences. Such accessories exclude direct eye contact with paints and primers, as well as with their vapors. Safety glasses are needed when using hammer drills, grinders and other tools. They prevent metal shavings, sawdust and dust from getting into the eyes. Such models are equipped with shockproof lenses.

The main purpose of welding goggles is to protect the eyes from strong glow. Accessories from this series are resistant to high temperatures and mechanical influences.

Transparent closed models are easy to use. On sale are models with a rubber rim - a coating that prevents the lenses from fogging. They are recommended for use when performing work on a construction site, when painting and varnishing. The ventilated and double lens models are recommended for use when operating a lathe.

Comfort

| Red laser beam | Working with measuring laser devices in intense lighting conditions | Open glasses | Special light filters on the lenses, side protection |

| Dust, wind | Outdoor work | Closed glasses | Indirect ventilation |

| Glare | — | Open glasses | Dark Polaroid Lenses |

| Twilight light | — | Open glasses | Yellow lenses |

| Heat | — | Open glasses | Anti-fog lenses, dark lenses |

| Dirt | — | Closed glasses, protective masks | Side protection, scratch resistant |

| Cold | — | Closed glasses | Soft seal, compatible with warm balaclava masks |

As already mentioned, the main reason for ignoring safety glasses when performing construction work is discomfort - the glasses do not fit well, they have limited visibility, they rub the bridge of the nose, and so on. Let's try to figure this out.

The ergonomics of modern eye protection have been brought to perfection. Let's start with the term "pantological system". This is nothing more than a variable length of the temples. Despite the seeming simplicity, the function is very useful - with a little effort, the glasses sit like a glove, do not slip or fall off.

Glasses of the American brand Wiley X with adjustable temples (can be replaced with a strap), highly ergonomic and very reliable in all respects. They are used both in the construction industry and for outdoor activities. Due to their high performance, they are recommended by the US Pentagon for wearing in military units. The only drawback is the relatively high price - 5,000 - 11,000 rubles.

The temples are also a very important detail. Soft, deformable, they firmly and discreetly hold glasses on any head

The same positive changes affected the nose pads and the bridge. The weight of the correct glasses is kept to a minimum while maximizing strength. In general, all this allows you to work almost without noticing that you are doing it with glasses.

A serious manufacturer pays special attention to lenses. When purchasing high-quality glasses, you can count on the fact that their transparency will be perfect, they will not fog up and distort

There are more than ten different systems of their execution, which guarantee comfortable use in any conditions. In addition to the fact that lenses in advanced models can be easily changed by replacing the desired color, depending on the lighting, lenses are offered for consideration that change shade themselves, for example, when the specifics of work involves frequent movement from the sun to the shade or from the street to the room.

Photo of safety glasses

We also recommend viewing:

- What are aluminum rivets

- Best screwdriver bits

- Which polyurethane foam is better

- Choosing a blade for a hacksaw for metal

- Overview of drills and drills for rock drill

- Overview of diamond core bits for concrete

- The best concrete drills for drills and hammer drills

- How to choose a good diamond blade for concrete

- Which abrasive disc is better to choose

- Wood milling cutters for hand router

- How to find the right grinding wheel

- Which drill chuck is better

- Choosing good wood drills

- Types and sizes of staples for the stapler

- Why do you need a unipack

- Metal brush for grinder and drill

- What and how to choose a line for a trimmer

- Which drills for metal are better

- Which chainsaw oil to choose

- Cut-off wheels for grinders

- Metal pipe clamps

- How to choose a galvanized bucket

- How to choose a circular saw blade

- Types of jigsaw files

- Varieties of petal circles

- What is tow

- Nylon ties

- Types and application of electrical tape

- Choosing a light plastic bucket

- Why do you need masking tape

Help the site, share on social networks

Species overview

Among the wide range of models, you can find sealed anti-fog, locksmith, heat-resistant with a light filter and with indirect ventilation, glasses, backlit options, mesh and even goggles.

Despite the possible equipment, all models are divided into two large groups: open and closed.

Open

These products are sold at attractive prices. There are anti-fog and panoramic models.

For such professional products, the structure does not fit the face, hence the excellent ventilation. Glasses with direct ventilation rarely fog up, which in some areas is an indispensable quality for protective equipment.

However, because from the sides, dust and particles can enter the eyes with the wind, they do not have a sufficient level of protection when we are talking about working with a grinder.

In the professional field, open-type safety goggles are used with the ability to adjust the temples.

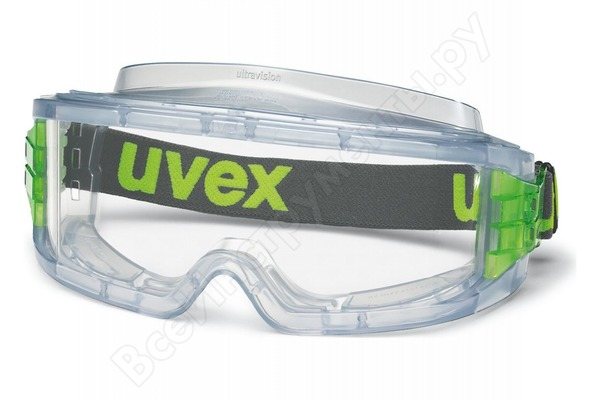

Closed

The greatest degree of protection is ensured through the use of goggles. They should be used when sparks, material particles or glass shards fly away during operation.

Closed glasses are equipped with an elastic band and a device for adjusting the temples. They are very similar to the masks used by divers or snowboarders.

There are products on the market that are completely made of silicone, and those in the design of which only a silicone seal is present.

Despite such a number of advantages, this type of glasses also has its drawback - they fog up a lot. Some manufacturers were able to solve this problem by making small holes on the sides, but with the advent of ventilation and the degree of protection decreased.

Glasses of this type are easy to clean - you just need to remove the ventilation inserts, rinse them with water, wipe them and dry them with a hairdryer.

When working with chemicals, goggles are also used, but MH.