Tips and rules for choosing glass cutters

curved cutting edge

Choosing a roller type of glass cutting device, the consumer should take into account that there are two types of tools:

- with a movable head design;

- fixed cutting mechanism.

A tool with a rotating head is suitable for inexperienced craftsmen if it is necessary to cut geometrically simple patterns along smooth lines.

More difficult to use with a glass cutter, which is mainly used by experienced craftsmen, is a compass-shaped tool, with which you can cut ovals and circles from glass of different thicknesses. At home, such a tool is practically not used.

Features of cutting glass with a glass cutter

flat and clean surface

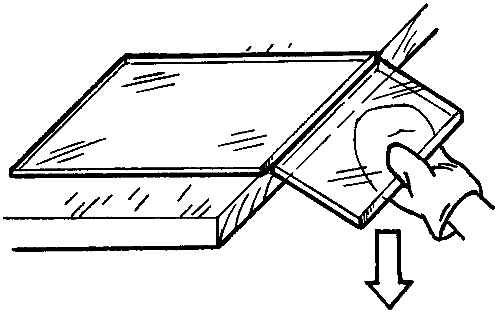

The diamond glass cutter must be placed in the hand like a ballpoint pen, that is, it must be gripped at the base. The cut line is drawn with a clear movement without undue pressure.

If all actions are performed correctly, then a sound with a characteristic crackling sound will be heard. The result of all manipulations should be a slight, barely noticeable scratch on the glass surface.

In the case of using a device with a roller mechanism, a certain pressure must be exerted on it. The result of correct cutting will be a deep, pronounced line along the cutting contour.

But regardless of the tool used, in no case is it permissible to carry out several times along the same line

It is also important to relieve pressure on the cutting mechanism by 5 mm, before reaching the edge of the workpiece.

After getting acquainted with the features of the device and the use of a different type of tool for cutting glass, everyone is able to decide which glass cutter will be the best in a particular case. By choosing a quality tool, even a beginner can cope with glass cutting.

Description of species

Due to the fact that a manual glass cutter is a tool that is quite widely used, and is also popular and in demand among users, there are a large number of varieties of such equipment. For example, there are electric, circular, cutting, round glass cutters, tools with a suction cup, with a ruler, with a compass, units for creating holes in a circle, and many others.

Moreover, each of the types of glass cutters listed above looks different and consists of different parts. Let's give a detailed description of such tools and compare them with each other.

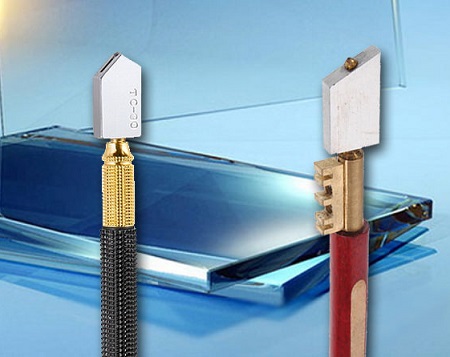

Diamond

Diamond tools are used not only by amateurs, but also by professionals. This is due to the fact that the glass cutter can process glass of any thickness. As you might guess from the name of the tool, it is made from technical diamond grit, and therefore the glass cutter does not require lubrication. As for the distinctive characteristics of the device, they include the fact that with its help the user can carry out an especially thin cut, respectively, the result of your work will be as accurate as possible.

And also diamond glass cutters are sensitive to shock loads (this characteristic is due to the fact that the surfacing of the diamond tip on the steel holder is carried out by soldering with silver solders). If we talk about the appearance of the instrument, then it can be in the form of a pyramid or a cone. At the same time, conical diamond glass cutters are much cheaper than pyramidal ones. And also there are several varieties of the unit, depending on the thickness of the glass on which it will act. The minimum cost of a diamond glass cutter is 250 rubles.

Oil

This type of tool provides for the supply of oil to the working area. Oil is needed to lubricate the cutting disc of the device. Oil glass cutters are made from high-speed steels. In addition, it is often possible to replace the working head (they can be conventional or designed for cutting thick glass). If we talk about the design of the device, then it should be noted the presence of a ball located above or below the roller. Such a ball is designed to evenly distribute the lubricant over the rolling surface of the roller. Accordingly, the cutting force is significantly reduced, and the service life of the glass cutter is also increased.

Mineral oils of medium viscosity (for example, I-20A) are usually used as a lubricant. The oil can be placed in a dedicated compartment using a conventional disposable syringe. The minimum price for such oil tools is 150 rubles.

Radial (or circular)

Radial glass cutters are characterized by a high price. They are most often used on an industrial scale rather than at home. If we talk about the design of this tool, it should be noted that in appearance, such a glass cutter resembles a compass with a suction cup. And also in the design there is a metal ruler, which is equipped with a cutter.

Professional

In appearance, professional glass cutters resemble window scrapers. As for the structural components of the tool, it should be noted the presence of a ruler, a cutting element, a barrel of oil and a guide rod. This unit is used only in a production environment. It should be noted the high level of comfort and ease of use of this type of glass cutters.

In addition, the device guarantees precise and deep cuts. However, in order to use the unit correctly, you need to have experience and relevant skills.

Types of glass and features of work

In order to understand how glass can be cut, it is advisable to know what kind of glass there are and which ones are to be processed. Each grade of this material suggests a different approach.

The following types of glasses are used in industry and everyday life:

- Hardened is a grade that is practically impossible to cut. If there is a need to cut it, then you need to attend to the fact that the workpiece would acquire the required shape at the early stages of processing. Tempered glass can only be processed on special equipment and this happens in factories for its production.

- Corrugated is a patterned product that is often used to decorate door structures, furniture, and interior items. There is no need for special machines to cut this material. It can be done using an ordinary roller glass cutter, while cutting on the smooth side.

- Plexiglas is a polymer material based on epoxy resins. In order to cut this material, there is no need to use any special tools. You can use an ordinary hacksaw for metal. If the thickness of the sheet does not exceed 2 mm, then it can be cut using both a clerical knife and any sharpened knife.

The main rule that must be observed before cutting glass is the use of personal protective equipment (glasses, apron, gloves). If the volume of work performed is quite large, then it is advisable to use a respirator. Before starting to cut this material, the surface of the table on which the work will be performed is covered with thick paper or cloth.

How to make a choice

To decide for yourself the question of which glass cutter is better, you need to outline the amount of work to be done. Based on this parameter, as well as taking into account the properties of the material that needs to be cut, and it is worth thinking about the upcoming choice of tool.

After you have decided on the model, you need to select the handle of the tool. Wooden handles are the best, they do not slip during operation. Even if you stopped choosing a metal or polymer handle, then it should have a notch or a rough surface to avoid slipping the glass cutter in the palm of your hand.

In any case, remember that the instrument must be tightly held in your hand, this is very important for the upcoming manipulations.

Varieties

Experienced craftsmen recommend using three main types of glass cutters, with which you can easily cut glass to the required size, even at home.

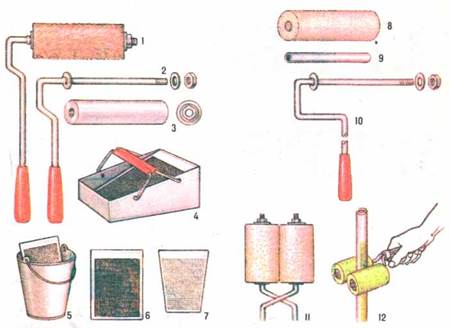

Roller

Quite a popular model that is easy to use. The roller glass cutter is very often chosen by beginners, since it is very convenient in work. In addition, such a tool is cheap because there are no diamond stones in its design.

Structurally, the glass cutter consists of a roller part and a handle. For the manufacture of the roller, special hard alloys are used, the element diameter is 5 mm.

But the working resource of such a tool is limited - it is enough for three and a half - four hundred meters of glass material. But since it costs very much even acceptable, you can buy a new instrument at any time. In addition, the kit comes with several replaceable roller elements, so you won't have to change the purchased tool for a long time.

Diamond

Another common, effective and popular glass cutter is diamond. This option is perfect for both professionals and inexperienced glass cutters.

Let's figure out how to cut glass with a diamond glass cutter. Immediately, we note that in the process of training you will ruin more than a dozen glasses, but all your expectations will come true as soon as you master the technique of using a diamond glass cutter.

Diamond glass cutter

The tool consists of a handle and a working head with a diamond element, which can be pyramidal or beveled. It is necessary to know everything about such a feature, since the shape differences of the heads affect the principle of operation. For example, cutting a glass with a pyramid-shaped head is much more difficult - this requires a developed, practically "musical" ear. Let's see how to properly cut glass with such a glass cutter. During operation, the diamond moves across the glass surface and emits a sound of a certain frequency. When the sound is "wrong", it confirms that the movement of the diamond element is not correct, and the glass chip is likely to be defective. To cut the desired shape correctly, beginners use a glass cutter with a beveled head.

In such a tool, the stone can be artificial or real, and this difference affects the cost. But here there is one more feature - with a real diamond you will cut the glass of a centimeter thickness, and the artificial one is enough only for 5 mm. And the operational period of such samples is different - a real diamond will cut from ten to fifteen kilometers of glass, while an artificial one will end its operation after the fifth kilometer.

Oil

This version of the glass cutter is a modification of the tool with a roller head. A small reservoir is arranged in the handle, into which the lubricant is poured. During the cutting process, it is constantly fed to the roller and glass surface, significantly reducing friction and improving the quality of the lines being scratched, ensuring long tool life. Ultimately, the operating period of an oil glass cutter, in comparison with a simple roller cutter, is fifteen times longer.

Oil glass cutter

In addition to the listed models, there are circular glass cutters, with which you can easily cut round holes on the glass.Such a tool is somewhat different structurally, more like a compass than a handle with a cutting element. In addition to circles, such a glass cutter can cut holes in the shape of an ellipse.

Popular models

The range of oil glass cutters is very large. Even more popular brands that produce this tool:

Fit (Canada) presents its model of a cutting device. This device has one monolithic roller, therefore it is resistant to cutting material up to 8 mm in size. The comfortable handle is made of a composite material in the form of a flask, filled with grease using a measuring container. The cutting angle of the roller ranges from 110 to 135 degrees.

The glass cutter is very practical, excellent for many operations, maintains its working condition for a long time, the monolithic roller holds the sharpening well and ensures a uniform cut. The comfortable handle follows the contours of your hand exactly. This advanced design sets it apart from other models. At the same time, the cost is very low, especially considering that the appliance used in everyday life has a service life of more than a year.

This model is characterized by high wear resistance of the working rollers - up to 8000 m. If the tool is purchased for use in everyday life, you will not need to replace it for a long time. The kit includes a practical dispenser for filling the instrument with grease. Most glaziers agree that the device is ergonomic and practical to use. The only negative caveat is the fragile plastic handle.

The hard alloy (tungsten carbide) of which the roller is made ensures a long service life, makes it easier to cut even thick glass and a uniform cut. All this, combined with an affordable price, makes the model an excellent option for general home use.

In order for a glass cutter to cut glass at any angle, a special head shape is required. This tool uses a form that expands the range of use of this unit. Chinese manufacturers have managed to achieve the maximum balance of price and quality when developing this glass cutter.

How to cut a glass bottle

To apply it, you have to prepare some materials:

- A bottle to be cut;

- Natural rope made of wool, cotton or linen;

- Flammable liquid (kerosene, gasoline or alcohol);

- Matches or lighter;

- A container with cold water (bottle, glass).

First, a line is drawn on the glass, which determines the required size and shape of the future object. Then the string is thoroughly impregnated with a flammable liquid, placed on the bottle over the markings and set on fire. When the fire is completely extinguished, you can start pouring water from the vessel in a thin stream along the marked line. The glass should crack on its own, it remains only to break it slightly with your hands, and then sand it with sandpaper.

If the crack still does not appear on the glass, you will have to repeat the whole process again. You can lay out the twine figured, then you end up with pieces of glass of a bizarre shape. In the same way, you can make holes in the bottle.

All of these methods make it possible to successfully cope with glass cutting, even for a person without special training. There is no need to be afraid to experiment, this work is not as difficult as it seems at first glance. The main thing is to believe in yourself and use your wit.

Output

And the answer suggests itself: you must first of all decide how many and what tasks are required to complete.

If you want to cut one small thin glass, it is enough to limit yourself to a roller-type carbide glass cutter.

If you're going to be cutting glass more than once, a diamond tipped tool is the right solution.

If you have a professional attitude to work, then it is difficult to imagine better than an oil glass cutter. Its service life will delight you for a very long time.

And, of course, for all glass and tile cutting tools, buy them in specialized stores so as not to be disappointed and not to run to the store for the next.

The choice of professional equipment requires a balanced analysis and is the prerogative of specialists competent in this area, taking into account all the economic and technical nuances of large-scale production.