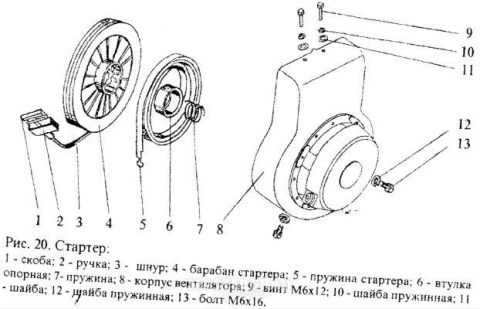

How to assemble a new mower starter?

To assemble the starter, do the following manipulations.

- Pass one end of the cord through the opening at the beginning of the spool and tie it in a knot. The knot must not pass through the hole. Otherwise, you will disassemble the starter again.

- Wind the cord around the spool itself.

- Install the spring into the starter housing, hook one end of it in the groove and wind it. For convenient winding, twist the body counterclockwise.

- Place the ratchet on the spring.

- Hook the return spring to the ratchet itself, secure it to the spool.

- Install the main spring and housing with the assembled ratchet, connect the starter parts together and tighten with the main bolt.

When you have finished assembling the starter, pass the free end of the cord through the hole in the housing for the reel. Re-pass the same end through the hole in the handle that the cord is pulling on. Tie a strong knot on the handle. Check the operation of the starter handbrake.

How to Install a Starter Spring for Gas Cutters

DIY gas drill starter repair, petrol cutters, trimmer

No matter how high-quality gasoline equipment you use, anything can happen to it during the construction process, and at the most inopportune moment for this. Difficulties often arise due to starter failure. It happens that you are going to drill holes for installing fence posts with a gas drill, or mow the grass with a trimmer, you start to start the unit, and only have time to pull the starter handle several times, the rope breaks, and the engine that has already started, famously winding the remains of the cord on the flywheel, breaks the pulley - Run to the store to buy the newest. But these are, of course, extremes.

We will now consider a more widespread case when the breakdown is not so serious and will show how to repair the starter with our own hands, if the cord breaks off without any destructive consequences or does not unwind due to the fact that the spring inside just flew off, out of engagement. At the very least, in the beginning there is a desire to believe in it. But in order to find out whether this is so or not, it will be necessary to disassemble the starter.

Removal and disassembly of the starter, replacement of broken parts

To repair the trimmer starter, you will first need to disassemble it, and then assemble it. This process is not particularly difficult. For work, you need a screwdriver with a tip of the desired shape.

Everything should be done carefully, observing safety precautions, mainly so that the spring does not injure the master in case of an accidental departure.

Disassembly of the starter unit

The launch mechanism is disassembled in order to install new parts instead of broken ones in the following sequence:

- unscrew the screw fixing the pulley with the starter cover with a screwdriver;

- take out the spring and antennae;

- carefully remove the pulley (you need to turn your head away or work, wearing glasses and gloves first);

- determine why the trigger is broken;

- if the spring has collapsed almost completely, then it is replaced;

- when the spring comes out of the hook, it is installed in its original place, bending the antennae in front of this (the photographs show the laying process);

after the spring plate is installed inside the groove, twist it carefully. To change the spring, you must work carefully and carefully: it can accidentally burst under the influence of the force caused by installing it in place.

Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges.

To change the spring, you must work carefully and carefully: it can accidentally burst under the influence of the force caused by installing it in place.

Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges.

It is not always possible to immediately put the spring plate in its original place. It often slips, so attempts must be repeated until the desired result is achieved.

Starter assembly

The assembly of the starter unit is carried out in a number of stages:

the coil is turned over, setting it so that the spring bend fits exactly into the groove of the body, as in the photo below;

- two washers are laid, between which a spring is placed;

- put in place the cup with the antennae;

- tighten the screw (photos below).

When doing the described manipulations, it is imperative to put two washers. If this is not done, then the spring will damage the plastic cup over time, and when it is pulled up, wedging will begin. Because of this, there is a feeling as if the spring has flown off. To eliminate this drawback, you need to install this part of a greater length or an additional washer.

When such parts are not available, you can simply unscrew the screw a little, and the starter unit will start working without wedging. But this option is temporary - it is better to repair it with high quality as soon as possible.

Spring tension

After installing the spring, tighten it. To do this, perform the following actions:

- remove the handle from the starter cord;

- then the rope is inserted into the reel groove;

- tension the spring by rotating the coil in the opposite direction to the clockwise direction (winding);

- make the required number of revolutions specified in the operating instructions for the used trimmer model and corresponding to the length of the cord used;

- at the very end, the rope is threaded into the hole provided for this, located in the starter cover;

- put the handle in place, fixing it with a knot.

If, after repair, the spring continues to fly off, then you can get rid of it in the following ways:

- squeeze a piece of the plate suitable in size into the groove at the location of the spring hook;

- drill holes on both sides of the groove in the coil, into which to insert the spring hook and fix it with a wire.

Replacing a torn cord

The torn rope is replaced in the following sequence:

- the old cord is removed;

- choose a rope that is suitable in size (thickness and length);

- passing it through a special hole in the coil, tie a knot;

- cocking the spring, producing the required number of revolutions;

- fix the handle.

It is better to tighten the spring plate with a partner so that the end of the cord does not reel into the starter mechanism.

Assembling the starter on the trimmer and winding the spring is not difficult, you just need to do it carefully and with care. For different models of petrol cutters, the breakdowns of the triggering mechanisms are the same, so they are repaired in the same way.

At the same time, there are some nuances associated with their design features.

how to repair the trimmer starter

The video clearly shows how to make a quick repair of a starter trimmer.

How to install the spring in the recoil starter for the petrol trimmer? It is possible to do this at home. To me.

this is how I wind the springs of the starter of the petrol meters, but the springs of the starters of the saws and motoblocks are wound along.

We repair a broken gasoline-meter starter spring. The model and brand of the trimmer are not indicated as the starter.

A step-by-step description of the assembly process for a sarter, brushcutter, walk-behind tractor.

how to independently assemble the trimmer starter, bend and wind the spring, as well as wind the starting rope.

A detailed description of the repair of the trimmer starter using the example of a hammerflex.

How to make a starter on a chainsaw yourself? How to bend the spring on the chainsaw starter? How to wind a spring.

Starter for petrol pumps.

How to replace the trigger mechanism on a petrol cutter SUBSCRIBE TO LIKE SUPPLY CHANNEL.

Sometimes it is necessary to disassemble the trimmer starter, for example, for cleaning or repairs, in this video we will show.

Repair of starter petrol cutters.

P.S. During operation, the cover may fly off

It will not kill, of course, but you must be careful. New starter (not

Starter for petrol trimmers: Starter assembly soft start 4 hooks.

The video shows in detail and tells how to replace the rope in the starter on a baby two-stroke motorcycle.

Link to my channel: -g? View_as = subscriber.

Principle know the brushcutter, if it was mowing, then the motor was hit hard and it was jammed. So yak dvigun bouv.

Determining the causes of the malfunction

If the trimmer motor does not start or stalls immediately after starting, when the gearbox overheats or during the operation of the device, extraneous noises are heard and vibration is clearly felt, it is important to visually inspect and identify a non-working unit

To optimize the preparatory measures before repairs, you should carry out a simple diagnosis and check step by step:

- the presence of fuel in the tank and lubrication in the main units;

- serviceability of the spark plug and its performance;

- the cleanliness of the fuel and air filter of the brushcutter;

- clogging of the outlet channel and breather of the device;

- the quality of the fuels and lubricants used.

To determine the functional performance of the petrol cutter ignition, it is necessary to determine whether the spark plug is working by testing the appearance of a spark when it comes into contact with the body of the functional device.

The spark plug itself can be replaced with a new one, having previously dried the candle channel, if necessary, the old element is also dried, cleaned with special devices and returned to its place.

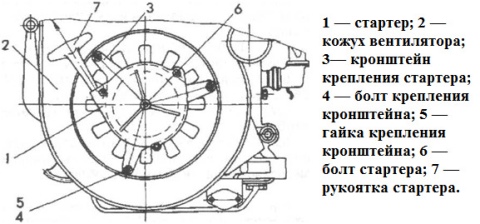

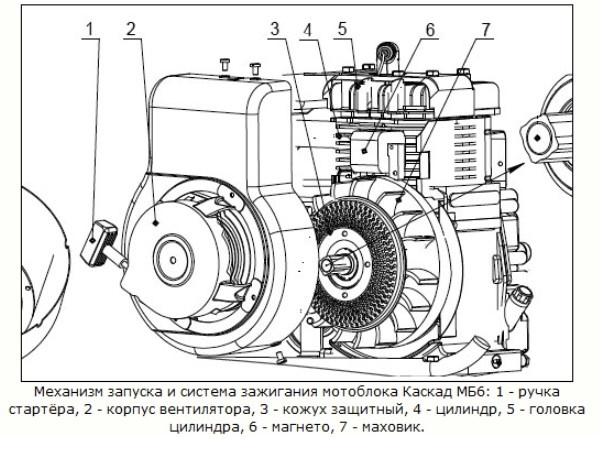

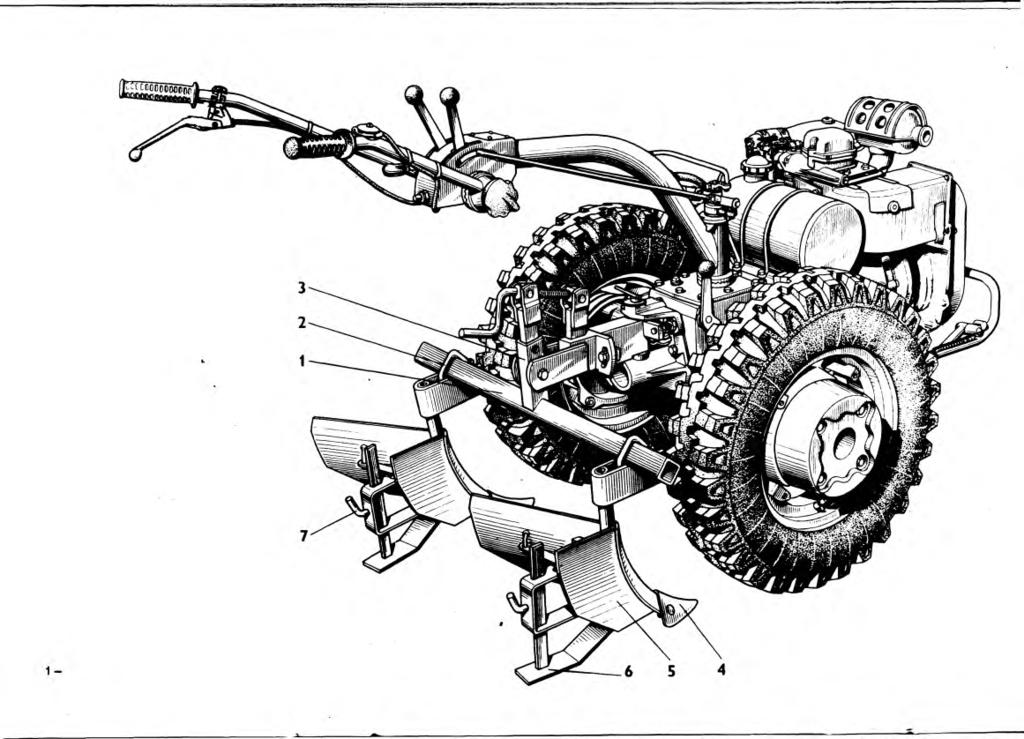

How to put a starter on a walk-behind tractor - the correct procedure

Even a beginner can remove the electric starter from the walk-behind tractor in order to further repair the broken mechanism. However, many novice farmers, as a rule, have problems with re-installing the starter on the unit with their own hands. Due to improper installation, the starter does not start the walk-behind tractor engine even after several strong jerks. In order to prevent typical mistakes, you should study the algorithm for installing a starter on a walk-behind tractor in more detail.

The starter must be installed in the following order:

- First you need to remove the flywheel - this will be required for mounting and fixing the crown on it. To dismantle the flywheel, you need to dismantle the air filter, which will give free access directly to the internal structure of the walk-behind tractor available on the farm;

- Then you will need to remove the protective cover and unscrew the screws that secure the starter mechanism basket, flywheel and its nut. Removing the flywheel, as a rule, causes certain difficulties, and therefore many experts advise to purchase a removable key immediately before repairing the walk-behind tractor. As soon as the flywheel is dismantled, you should unscrew the key, which is located immediately behind the flywheel;

- Then the generator should be installed. The existing wiring must be pushed through the hole located in the metal wall of the engine. Then the generator will need to be fixed in place on the motor wall;

- Further, the generator magnets must be installed inside the existing flywheel. In this case, all the holes in the flywheel and generator must match. Both elements will need to be connected with fasteners, after which they will install the crown of the used walk-behind tractor.Immediately before mounting the crown, it must be heated with a spray burner;

- The assembled mechanism must be installed on the motor-block motor, at the same time screwing in the nut and flywheel key;

- Next, you need to screw in the starter basket, fix the casing and motionlessly install the standard air purification filter in its original place;

- Then you need to remove the plug and put the starter itself on the engine;

- Next, you need to connect the generator wiring to the charging relay;

- At the final stage, the starter terminals must be connected to the battery of the walk-behind tractor and the unit must be started.

Installing a starter on an existing walk-behind tractor is not as difficult as it seems at first glance. The most important thing is to be as careful as possible and adhere to the correct assembly algorithm.

All of the above methods of starter repair are suitable for owners of Neva, Cascade and Agro walk-behind tractors. The procedure for removing and reassembling the mechanism will be the same for agricultural machines of all listed equipment manufacturers.

Caring for a starter and walk-behind tractor

During the first year of using the starter, you can start the walk-behind tractor with one jerk, but after this period - 2-3 or more (with regular use). To extend the life of the device, you need to carefully look after it - do not throw the walk-behind tractor on the street, it should be in a relatively clean, preferably not very dusty room. Periodically (1 time 2-4 starts), it is necessary to lubricate the starter, so you slow down the damage to the semi-automatic spring.

Important! If the handle does not stretch well, it seems to you that its stroke is somehow wrong, that is, you feel some kind of interference - do not pull with all your strength. Most likely, there is already some kind of breakdown, and if the starter is new, an incorrect installation or a factory defect was made.

Try to find out the cause of the malfunction, do not act simply by brute force, it will not lead to anything good.

Other works

Sometimes on "Cascade" walk-behind tractors it is necessary to replace the reverse belts. Usually they resort to it if it is impossible to adjust the tension due to severe wear or complete rupture.

Important: only belts that are adapted to a specific model are suitable for replacement. If unsuitable components are supplied, they will quickly become worn out.

Before replacing, turn off the motor, putting it in zero gear.

Remove the insulating casing. Worn belts are removed, and if they are extremely stretched, they are cut off. After removing the outer pulley, pull the belt over the pulley remaining inside. Return the part to its place. Check carefully that the belt is not twisted. Put back the casing.

Very often you have to disassemble the trigger mechanism in order to get rid of its malfunctions. It is not necessary to replace the problem springs. Sometimes the tip of the part is simply annealed with burners. Then the desired contour is reproduced with a file. Then the attachment of the spring and drum assembly is normal. It is wound on a drum, a free edge is placed in a slot on the fan housing, and the starter drum is centered.

They bend the "antennae", cock the drum counterclockwise, release the fully cocked spring.

Align the holes of the fan and the drum. Insert a starting cord with a handle, tie a knot on the drum; the tension of the released drum is held by the handle. The starting cord is changed in the same way

Important: all these works are easier to do together.

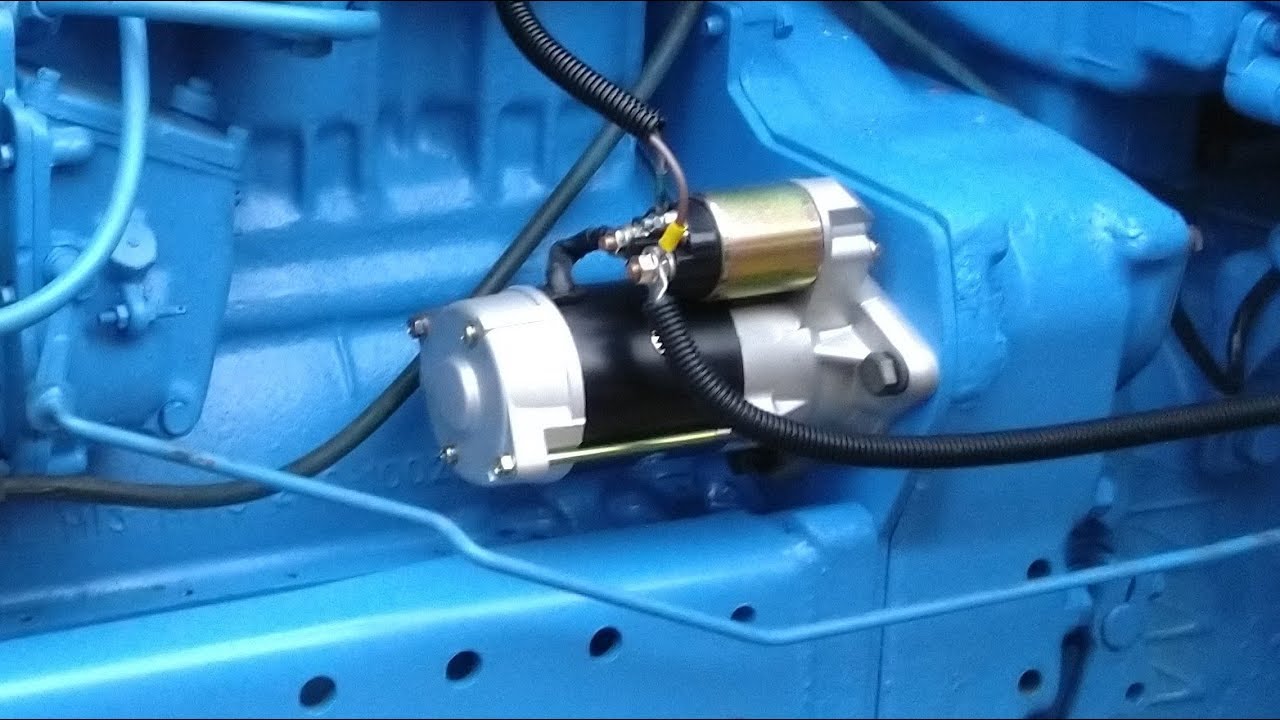

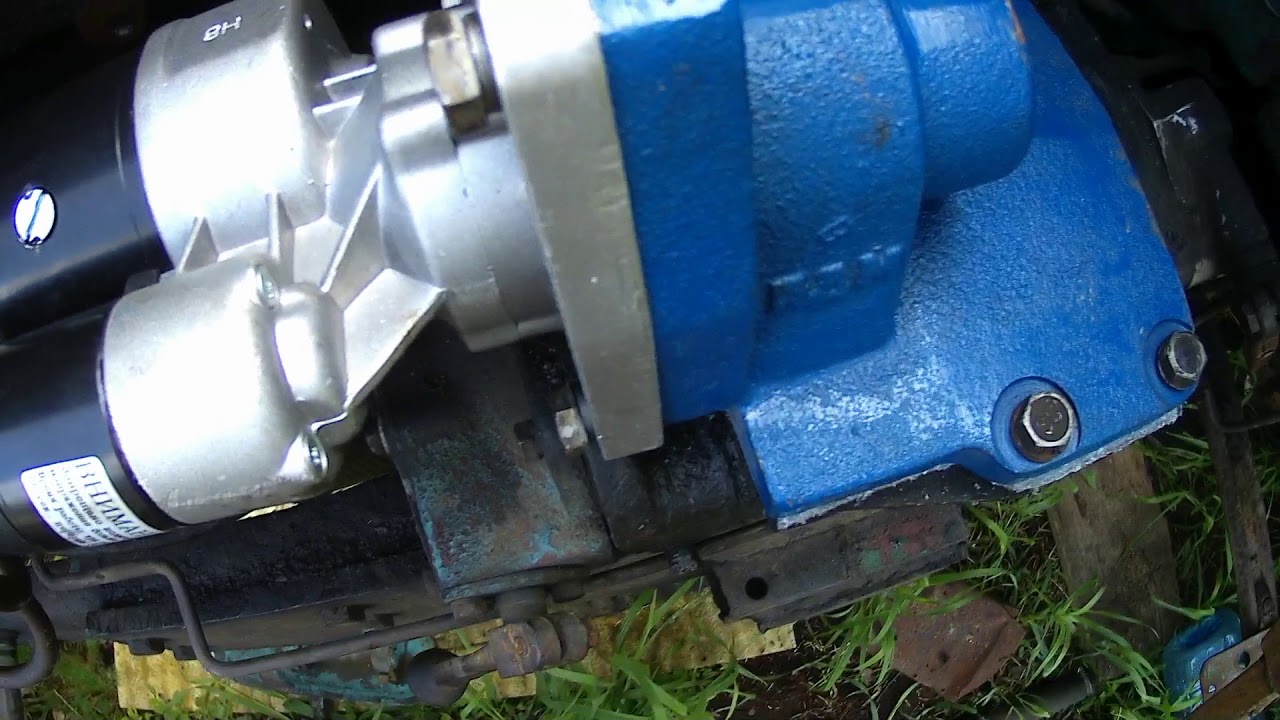

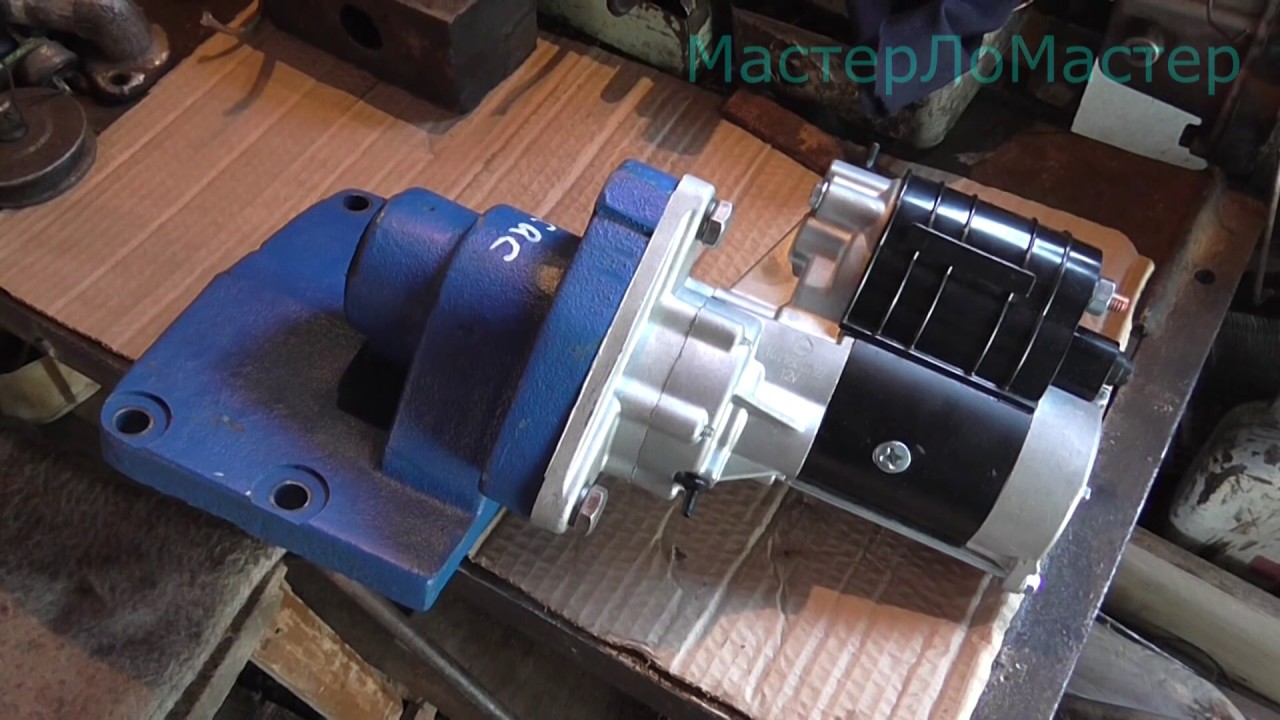

Starter installation sequence

All operations of this stage should be carried out carefully and carefully in accordance with the sequence given below.

To correctly install an electrical element in its rightful place, you need to do the following:

- Before installation, you must carefully inspect the starter, familiarize yourself with its complete set, check the build quality and the presence of a guide sleeve;

- The starter must be placed at the bottom of the vehicle in its place and fastened first with a long bolt, and then screw in the remaining mounting bolts, tighten;

- Install the wire terminals and tighten the nuts securely;

- Install and secure the wiring harness holder;

- Screw on the battery support;

- Place the battery in its usual place;

- Connect the battery terminals, close it with a protective cover;

- Perform a functional check of the electrical system and install an engine mudguard.

By performing these operations, you can successfully install the starter, but the process can be easily facilitated by performing certain steps. For example, on a carburetor engine, it is more convenient to work with the air filter removed. When the motor is an injector, it is better to first turn off the extension of the branch pipe, and it will be more convenient to do all the operations.

Typical malfunctions

The most common tool breakdowns include the following:

- problems in the ignition system;

- stopping the chainsaw in the process of cutting;

- loss of power during operation;

- wear of some structural elements of the chainsaw (brake band, drive sprockets, anti-vibration parts);

- problems in the fuel supply system;

- malfunctions associated with the starter.

In addition, it is necessary to carry out a visual inspection of the chainsaw before starting work and preventive measures. These include chain lubrication, control of the amount of fuel mixture, and the availability of the required amount of oil.

Unscrew the spark plug to check its condition.

Each of the faults is eliminated according to its own technology. So, for example, repairing the fuel system of a chainsaw should begin with an inspection of the corresponding filter. Electric lawn mower starting faults. After that, they check the correctness of the carburetor regulation, which is carried out with the help of screws. Clearances must be set in strict accordance with the manufacturer's instructions, which must be included with the chainsaw. The repair of the ignition system includes inspections of the spark plugs. This element must be replaced if heavy carbon deposits, a change in the gap or other visible damage are found.

Starter for chainsaws and trimmers. Terms of use. Typical mistakes.

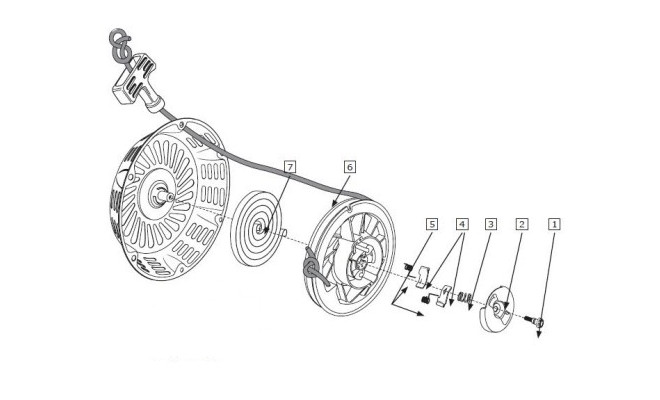

How it works.

In order for the engine to start, it is necessary to give the crankshaft and flywheel initial rotation. This is achieved by transmitting torque from the starter pulley, driven by a person by pulling on the cord.

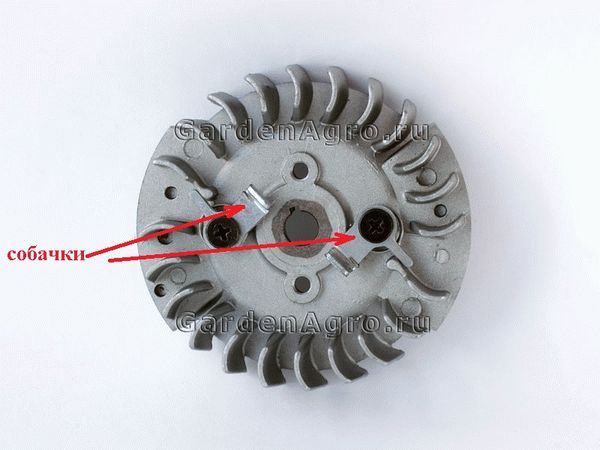

There are special hooks on the starter pulley (one, two or four, depending on the design). When you begin to pull on the cord, the pulley turns and the toothed teeth engage with the flywheel pawls. Next, together with the pulley, you rotate the flywheel and crankshaft. When the engine starts, the flywheel pawls will disengage from the pulley.

After you release the starter handle, the cord is wound back onto the pulley with a special return spring. It is located under the pulley between it and the starter housing.

How does a "soft" or "light" start starter work?

To facilitate the starting procedure, special modifications of the starter such as "soft start" or, in other words, "erogostart", "easy start" are produced. The purpose of this modification is to eliminate the need for a sharp force movement. "Smoothness" is achieved by installing an additional spring already inside the pulley itself.

This is how it works schematically. The pulley is divided into two parts: one part contains the fangs-hooks, the second drum part is wound with a cord with a handle, which you usually pull on. Both parts are connected to each other by a spring.

When you begin to pull on the cord, the flywheel pawls engage with the claw teeth on the starter pulley.Then the additional internal spring is compressed: on the one hand, the spring is held by the compression force of the engine through the engagement of the dogs with the fangs, and on the other end you pull, pulling the starter cord. In this case, part of the pulley with teeth remains stationary, and the drum part, on the contrary, rotates. Due to this, the spring is compressed. As soon as the spring force becomes greater than the compression force, it begins to expand and rotate the engine crankshaft.

Immediately important conclusions: firstly, in a starter with a soft start, it does not matter how strongly and sharply to pull the cord. The saw will not start until the spring is properly compressed. It can be compressed slowly, but you can quickly - the result will be the same. Secondly, in order for the spring to give its compression energy to the crankshaft, it is necessary that it unwind from one end. Therefore, after you have pulled out the cord, you need to hold it at the top point for a few moments.

Rules for the use of starters.

The starter is made of plastic. It's easy to break it. To prevent this from happening, you must follow simple rules and read the operating instructions.

- Place the tool on the ground. Do not start the engine by hanging it. You will break the starter so. Especially important for chainsaws: at the moment of starting the clutch can "pick up" the drive sprocket and the chain will start rotating unexpectedly for you. You run the risk of sawing off your leg or eggs. Read the operating instructions for the tool in the safety section.

- Select "idle" run. Grasping the handle, gently pull the cord until you feel the beginning of resistance from the compression side of the engine. It is from this point that an effort must be made. By doing so, you will make the engagement of the flywheel dogs and the pulley hooks smooth, avoiding shock loads on these parts. Otherwise, you risk breaking pawls and holds. The results of such actions are in the photo.

- Do not pull out the cord completely or use excessive force. As can be seen below in the photo of the breakdown, the cord was pulled out completely, then excessive force led to a breakdown of the pulley attachment axis, displacement of the pulley and breakdown of the cooling grilles.

For starters with "easy" starting.

Remember, the engine is spring-started. You only squeeze it.

- Don't overdo it.

- Hold your hand for a moment at the top point so that the spring unwinds from the side of the crankshaft.

- Do not tug on the starter often. Often "jerking" for the starter, you do not spin the crankshaft. You are only breaking the spring. Read what is written above about the latency at the top point.

In winter, Chinese grease in the springs may freeze. To prevent this from happening. WITHOUT DISASSEMBLING THE PULLEYS, put a few drops of engine oil under the springs. It will slightly dissolve the Chinese grease and freezing will not occur.

The breakdowns shown in the photo are solely caused by improper use. This has nothing to do with the quality of materials and the manufacture of starters. These are purely operational errors. THESE ARE NOT WARRANTY CASES.

PHOTOS OF TYPICAL STARTER BREAKS.

How do I replace or replace the starter spring?

If everything is in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a ribbon spring, coiled into a roll. Certain steps must be taken to change the spring.

- Remove the starter from the brushcutter.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and spring, the ribbon spring is almost fully extended or coiled into larger rings.

- Hold it in advance.

- Check if the spring is intact (rusty streaks, fractures, etc. may be present). If the hooks at its ends are broken, it will not be possible to bend new ones - high-carbon steel breaks when you try to bend it. Loose hooks are suitable for slight bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil body from being punctured by the ends of the main spring. If the washers and the spring are broken, and there are no new ones available, do not tighten the coil bolt tightly, but watch it - it can unscrew and get lost.

- If the main (flat) spring is damaged, insert the same new one. Place the hook on the end of the spring in place and bend it, inserting coil by coil into the space it should be.

The rewinding of the spring takes a minute. Dexterity in this action is acquired quickly.

How to replace or replace the starter spring, see the next video.

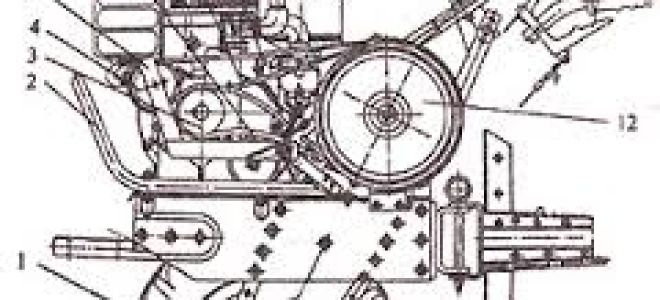

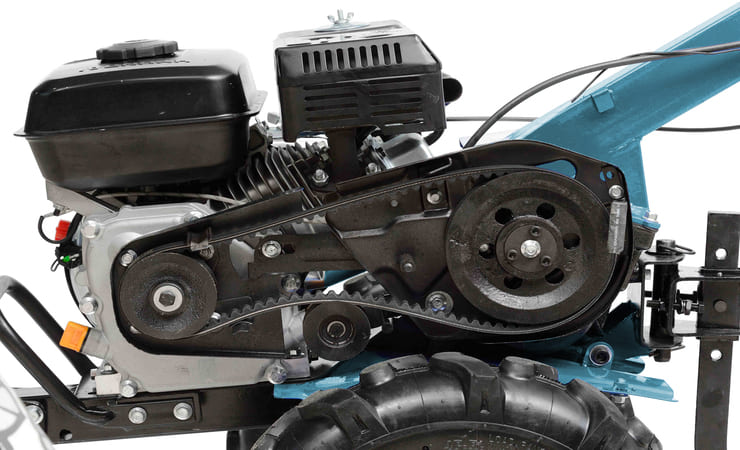

How to make a generator on a walk-behind tractor - just about the complicated

Making a generator for a walk-behind tractor with your own hands is quite simple if you follow the correct procedure. For work, an electric motor is required, which must be installed on an agricultural machine. The generator manufacturing algorithm is as follows:

- First you need to install an electric motor on the walk-behind tractor frame. It is best to use a pre-made frame for this, screwed to the unit frame with screws. Place and fix the electric motor in the frame so that its shaft and shaft and the shaft of the standard motor of the walk-behind tractor are located strictly parallel to each other;

- Next, you need to install 2 pulleys - install one of them on the shaft of the gasoline motor of the walk-behind tractor, and the second on the shaft of the electric motor used. An important role for the proper operation of the entire system is played by the correctly selected diameter of the used pulleys - the speed of the electric motor depends on these dimensions. In order for the generator to work without malfunction, the diameter of the pulleys must be equal to the nominal diameter, which is indicated on the packaging of these parts. It is even better if the real diameter of the pulleys is 10% larger than the nominal one;

- Having finished the mechanical assembly of the generator, you can proceed to connecting it to the walk-behind tractor. To do this, use the wiring diagram above.

A homemade generator from an electric motor does not require special care. However, to extend the life of the device, a number of rules should be followed.

When operating a walk-behind tractor, pay attention to the following nuances:

- if you find that the electric motor installed on the walk-behind tractor has become very hot, then replace the standard motor capacitors with elements with a lower capacity;

- the voltage of the capacitors installed in the electric motor is of great importance. The best option for work is considered to be capacitors with a voltage of at least 400 volts. If this indicator is lower for standard electric motor capacitors, then replace them with suitable elements;

- try to operate the walk-behind tractor with an installed generator in dry weather, as moisture that can get into the electric motor will inevitably lead to a short circuit inside the electrical system.

By adhering to the listed rules, you will prevent damage to your homemade generator and significantly extend its life.

The above methods are suitable for manufacturing and installation generators for walk-behind tractors Neva brands, as well as agricultural machines of other domestic and foreign equipment manufacturing companies.

This is interesting: Varieties of rakes for a walk-behind tractor and is it possible to do it yourself - we describe in detail

DIY repair

In this case, it is required to consider the main options for malfunctions, as well as the available ways to eliminate them:

- The brushes on the cam mechanism are worn out (replacement is required, since the drive does not reach the shafts).

- Internal components of the drive mechanism are damaged (they must be replaced with new ones).

- Open circuit (power is not supplied, you need to find an open and replace the wiring).

- The coil spins without transmitting torque to the shafts (most likely, the transmission mechanism has fallen off, you need to install it in place).

In most cases, these are the main breakdowns that are inherent in such a mechanism. To eliminate them, it is required to completely disconnect the element, dismantle the casing and carry out restoration work. Also, if the drive cord is out of order, it must be replaced. In all other cases, it is recommended to completely replace the device.

Problems in the ignition system

If there is no spark, as mentioned, the battery should be checked carefully. When everything is in order with him, the contacts and the quality of isolation are examined. In many cases, the absence of sparks is due to a clogged ignition system. If everything is clean there, they look at the contact connecting the main electrode and the candle cap. And then the electrodes are checked sequentially, assessing whether there is a gap between them.

A special feeler gauge will allow you to determine if this gap corresponds to the recommended value.

(0.8 mm). Remove carbon deposits accumulated on the insulator and metal parts. Check the candle for oil stains. All of them must be removed. Pulling out the starter cable, dry the cylinder. If all these steps did not help, you will have to change the candles.

Chainsaw starter - device, DIY spring replacement

In the design of the chainsaw, the starter is responsible for the proper starting of the engine of the tool.

Over time, owners of chainsaws are faced with the need to repair this important unit. And, the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

The device and principle of operation of the chainsaw starter

Most of the well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which the cord is passed.

When the handle is suddenly lifted, the cord is pulled out, which engages the drum, which is in the ratchet mechanism. This drives the spitz drum, which is located on the shaft.

During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. On the contrary, when the handle is lowered, the ratchet and pins lose their contact, which leads to a stop of the shaft.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In such a case, the number of jerks of the starter cord must be increased to start the engine.

Leading brands are using other methods to make it easier to start a chainsaw:

- Pre-enrichment of the fuel mixture using a separate flap;

- Installation of an automatic decompression valve, which reduces the pressure inside the cylinder of the chainsaw;

- Installing a primer designed to pump fuel before starting the engine.

The use of one of these technologies greatly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

Typical breakdowns and repairs of the chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start the chainsaw. The most common starter breakdowns include:

- The starter pulley is completely burst or cracked;

- The spring has burst;

- The starter cable is torn.

To fix each of these faults with your own hands, you will need certain tools. You must have a set of screwdrivers and a spare cable with you. It is necessary to remove and inspect the starter for the chainsaw in the following order:

- To find the cause of the breakdown, the starter will need to be removed from the chainsaw.To do this, unscrew the screws with a screwdriver, with which the protective cover is held with the starter attached to it;

- After removing the cover, you must carefully unscrew the screw by means of which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter - for this, remove the spring and clamps from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical malfunctions. These include:

- Various damage to the pulley in the form of ruptures or cracks, mainly in the rear of the part - they interfere with the normal operation of the entire starter;

- Damage to the starter spring of the lightweight start - in such cases, not only the spring itself can be faulty, but also the place of its fixation - this is the most vulnerable part of the spring;

- Damaged starter flywheel dog.

In any case, any defective part must be completely replaced with a new part.

How to replace the chainsaw starter spring?

In order to replace the old spring in the disassembled starter, you must proceed in the following order:

Before installing the chainsaw starter spring, you will need to remove the mechanism holder - this should be done very carefully so as not to break the part;

Then you need to look inside the clip - in it you will see a spring wrapped around a C-shaped element. To pull out the spring, fix its upper part with your finger and pull the starter handle slightly to the side;

After removing the old spring, you need to wind a new part

At the same time, try to avoid kinking and twisting of the new spring element;

To collect the chainsaw starter spring, you will need to act as carefully as possible, otherwise one wrong movement can lead to unwinding of the part;

After you have managed to fully insert the spring into the starter, you must carefully secure the clip.

At the last stage, all that remains is to assemble the chainsaw starter and try to start the tool. It is quite possible that you will have to do 10 to 20 jerks - this is necessary in order for the spring to finally fall into place.

Chainsaw starter: device, breakdowns and DIY repair Link to the main publication

What is the bottom line

So, as you can see, replacing a faulty solenoid relay is not so difficult.

On the other hand, it is necessary to do everything very carefully and thoroughly here, otherwise there is a high probability of damage to the engine starting system, or serious injury.

Thus, if you are worried about whether you can carry out repairs yourself, it is better to seek help from professionals - they will help you quickly restore the operation of this unit.

Video review of repairing the starter retractor relay yourself:

How to replace the starter retractor relay - it happens that the starter "does not turn" when trying to start the car, there are no characteristic sounds before starting the "engine", there is an unusual "hum". Most likely, the solenoid relay has become faulty. Let's try to change it ourselves. To perform this operation, you must initially remove the starter.