Subtleties of choice

Choosing a circular saw in our time is not easy at all. There are many models on sale from a large number of manufacturers.

What you should pay attention to if the saw is purchased for the home

- Work from a network with a voltage of 220 volts.

- The design of the bed: for small jobs, a lightweight, and even a desktop version of the machine is suitable, someone may prefer a manual unit - this factor significantly affects the price of the product.

- Availability and quality of adjusting bars: the more there are, the higher the price.

- The presence (absence) of additional surfaces that increase the size of the machine table top. Machines with such surfaces are somewhat more expensive.

- Engine power. If industrial volumes of work are not expected, then you will have to seriously overpay for a more powerful unit.

A light circular will quickly cease to meet the needs of production and even if it does not fail, you will have to buy a second, more powerful machine.

Device

Stationary saws are installed on a base - a bed, the rigid structure of which, coupled with the power of the engine, allows cutting large workpieces up to logs.

To install such a massive unit, floor preparation is required. As a rule, a concrete foundation is made for the machine.

The polished work surface is also available in steel or cast iron. In lighter versions, the tabletop can also be made of aluminum, in its surface there is a groove that allows the saw blade to rotate freely.

The working surface is equipped with various guides necessary to adjust the width of the workpiece being cut, the inclination of the cut, etc.

An electric motor is located under the tabletop, which transmits torque to a pulley, which serves as a support for the saw blade. On stationary machines, the power of the engine is transmitted to the gearbox and only then to the pulley. A belt drive is used more often, but there are models with a cardan method of transmitting torque.

The disc is covered with a protective cover. On many models, a riving knife is attached to the tabletop immediately behind the disc, which prevents the sawn workpiece from reconnecting under the influence of the elasticity of the wood fibers - this is another element of the tool's safety system.

There are models with a tiltable saw blade that allow you to cut at different fixed angles.

Sometimes additional expanding elements are provided for the main work table to increase the working surface of the machine.

On some models, a redundant safety switch is installed.

Selection Tips

poses a threat to health

Particular attention should be paid to the economic component. When choosing a saw, you should take it in hand, try to understand if it is comfortable enough for you to hold it

Do not think that the same model can be suitable for two people, since each of us has a different body structure, skills and habits. Moreover, it does not even play a big role here, whether a circular saw from a trusted manufacturer is considered or not.

You should also take into account the material from which the protective casing is made. It must be characterized by high strength, the ability to resist deformation in the event of a tool fall.

Test in operation the regulators located on the model body. Set up a few different angles. Find out if they just twist and twist just enough.

Make sure you can easily get to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, as neglecting these points can lead to serious injury in the future.

Design features

The basis of the design of any electrical equipment is an electric motor, by means of which all other mechanisms of the device are set in motion. In the design of the circular saw, the electric motor is located on the machine frame. Its rotary motion is transmitted to the saw blade directly or through a transmission mechanism, depending on the design of the model. The features of such equipment include such elements as:

- the frame - the basis of the structure, is made of metal (steel, cast iron), and this is what determines the significant weight of the models equipped with it;

- table top - a working surface, has a groove for a saw and is also made of metal;

- the gearbox or pulley (depending on the model) is placed under the surface of the tabletop;

- on the working surface are elements to protect the worker from injury, as well as various devices that facilitate the performance of work and expand the functionality of the machine.

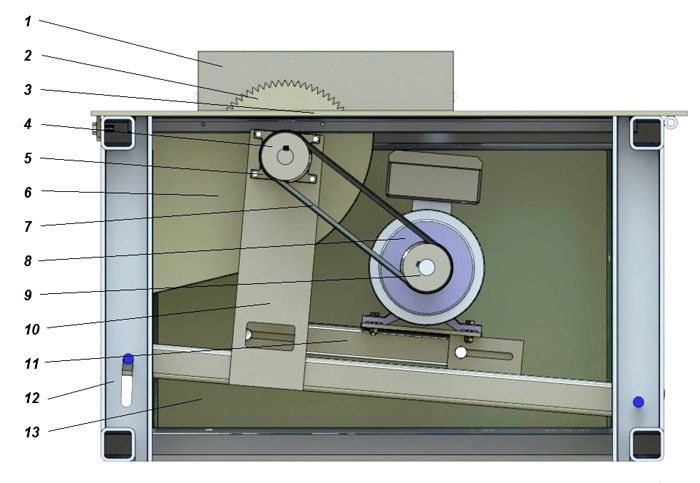

Diagram of the device of one of the variants of the layout of a stationary circular saw: 1 - a thrust plate, by means of which the width of the cut-off part is adjusted; 2 - saw blade; 3 - work surface (table top); 4 - saw blade drive shaft pulley; 5 - saw blade drive shaft with bearing assembly; 6 - a casing that ensures the removal of sawdust generated during the use of the machine; 7 - belt used to transmit the rotational motion of the motor shaft to the saw blade drive shaft; 8 - electric motor; 9 - a pulley mounted on the shaft of an electric motor; 10 - movable bed; 11 - unit for attaching the electric motor to the machine body; 12 - machine base - fixed bed; 13 - a structural element serving to close the internal space of the machine (protective panel).

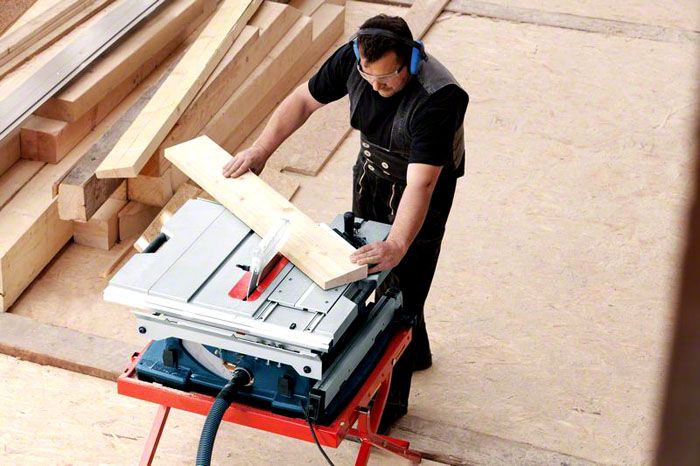

Circular is convenient and functional enough when used

Making a stationary machine with your own hands from a hand-held circular saw

There are situations when a hand-held circular saw is available, and a stationary structure is required to perform work, which is caused by the need for processing long workpieces or a large volume of operations of the same type. In this case, you can independently make a table on which to place an existing hand-held electric tool, and then use it as a permanently installed equipment. All work can be divided into several stages: preparation, manufacturing and installation, performance check.

Preparatory stage

At this stage of the production of work, the material is prepared from which the working surface (table) of the machine being manufactured will be made, as well as its basis, a sketch is developed. A hand-held circular saw is being prepared, as well as other elements: wires and cables, a button or an automatic machine for turning the circular saw into operation.

Hand-held circular saw "Bosch PKS 55"

Manufacturing and installation

After the tool and materials are prepared, and a drawing (sketch) of the assembled structure has been drawn up, you can begin to manufacture it.

The manufacturing sequence from wood blanks and plywood is shown in the following table.

| Illustration | Description of actions |

|---|---|

|

Using thick plywood 12-15 mm thick, a circular saw table is made according to the developed drawing. Holes are made in the side wall to ensure air circulation in the inner space of the table. |

|

On the working surface of the table (tabletop), a hole is cut to accommodate a hand-held circular saw, corresponding to its geometric dimensions. Its installation is in progress. |

|

The table top is attached to the table by means of door hinges, which allows it to be moved horizontally. |

|

To fix the circular saw, fastening elements are used, allowing, if necessary, to disassemble the structure. |

|

An electrical outlet is mounted inside the table body, and the wires are fixed with mounting clamps. |

|

An electrical switch is installed on the outer wall of the table, which ensures the operation of the assembled structure. |

This structure can be installed separately or placed on any horizontal surface. Its geometric dimensions depend on the dimensions of the hand tool, as well as the needs of the user.

Functional check

When the structure is assembled, it must be checked in operation, for which it is connected to an electrical network corresponding to the voltage class of the circular saw used. When the performance has been verified, it is possible to complete the manufactured product with the necessary accessories (stops, clamps, etc.) and devices that facilitate use during operation.

Circular device with stationary installation

circular Baikal fixed on the table

circular Baikal fixed on the table

The circular saw is designed for cross and longitudinal cutting of relatively soft materials: wood, wood-based panels, plastics, non-ferrous alloys. Hand tools work quickly and accurately, therefore they are widely used in various carpentry works, as well as in:

- roofing works;

- flooring;

- making furniture.

By replacing the blade on the hand circular, you can cut soft metals and profiles. And having installed it on a workbench using a special device, turn it into a machine.

The main elements of the circular saw:

- electric motor;

- gearbox in the housing;

- guide;

- platform;

- protective box;

- stationary mount.

The body of the tool is made of durable plastic and only a few models are made of metal. Since the work produces a lot of dust and chips, manufacturers provide for a chip removal system. As a rule, this is an outlet for connecting an industrial vacuum cleaner. There are models with a built-in dust container - a convenient solution for one-off work.

On modern hand-held models, only 750 - 2500 W collector motors are installed. This indicator determines the number of revolutions of the disc and the capabilities of the tool. The most powerful models have a speed of up to 5000. A powerful motor requires cooling, which is provided by the ventilation system of the case.

The platform is of great importance when choosing. She may be:

- stamped - cheaper, suitable for the amateur;

- cast aluminum - does not deform, strong and stable.

Often, a graduated scale is applied to the platform to help cut workpieces more accurately.

Guide rail - serves for performing an even cut. Some manufacturers equip their tool with a guide rail. But this is not always the case.

Additional accessories

A laser pointer is a convenient option that allows you to cut a part with markings covered with sawdust. Increases the cost of equipment, but is welcomed by professionals.

Disc replacement - modern models are equipped with a spindle lock, which allows you to quickly and easily remove the disc for replacement. Otherwise, the disk is removed with two keys - a long and inconvenient procedure.

Saw wheel compatibility

Saw blades differ in the number, shape and size of teeth, material, bore and outer diameter. Discs for 32 cannot be fitted to a 30 mm chuck. A large disc with a diameter of 200 mm does not fit into every low-power circular.

The number of teeth on the wheel determines the possibilities and quality of work. So, with more teeth, a better cut is obtained. For cutting pressed panels, 36 - 48 teeth discs are optimal. To work with the board, 20 - 24 teeth are enough.More durable discs with carbide surfacing, they are able to cut even a nail accidentally hammered into the board.

By the shape of the teeth, the discs are divided into active (sharpened at a positive angle) and passive (sharpened at a negative angle). The setting of the teeth in the direction of the saw wheel is characteristic for a positive sharpening angle... Rear wiring is for negative. Solid materials are sawn with passive (metal alloys, tin), and wood and plastic - with active discs. If you cut wood in a circle with a negative sharpening, the cut will turn out to be torn, with protruding fibers.

Videos about the device and modernization of the manual circular Baikal 514:

Popular models of stationary circular saws

On the domestic market of woodworking equipment, there are models of stationary circular saws produced in different countries of the world. Among them, in accordance with the reviews of real users, the most popular brands are: Bosch and Metabo (Germany), Makita and Hitachi (Japan), Interskol (Russia) and JET (Switzerland). Consider the characteristics of the most popular models.

| Image | Model | Specifications |

|---|---|---|

|

"Metabo TS 254" | Power - 2 kW; Saw blade diameter - 254 mm; Weight - 33.4 kg; Additional options - soft start. |

| Image | Model | Specifications |

|---|---|---|

|

"Bosch PTS 10" | Power - 1.4 kW; Saw blade diameter - 254 mm; Weight - 26 kg; Additional options - soft start. |

| Image | Model | Specifications |

|---|---|---|

|

"Makita 2704" | Power - 1.65 kW; Saw blade diameter - 255 mm; Weight - 30 kg; Additional options - soft start. |

| Image | Model | Specifications |

|---|---|---|

|

Hitachi C10RD | Power - 1.6 kW; Saw blade diameter - 250 mm; Weight - 24.6 kg. |

| Image | Model | Specifications |

|---|---|---|

|

"Interskol DPN-250 / 1500P" | Power - 1.5 kW; Saw blade diameter - 254 mm; Weight - 37 kg. |

| Image | Model | Specifications |

|---|---|---|

|

"JET JBTS-10" | Power - 1.7 kW; Saw blade diameter - 254 mm; Weight - 35 kg. |

Power tool care tips

deal with a dangerous tool

It is necessary to work with a circular saw only in protective clothing, gloves and goggles.

Make sure the saw is off before plugging in the saw.

If you need to turn the saw on or off, it is advisable to do it at idle speed. If this is done under load conditions, it can lead to a reduction in tool life.

Make sure that the load does not exceed the permissible level. To do this, it is recommended to take breaks after every 15-20 minutes of work. This will prevent overheating of the engine.

Make sure the workpiece is securely fastened before operation. It is unacceptable for it to dangle and bend. Otherwise, it can be fraught with serious consequences for you.

Keep the area free of moisture.

How to choose a stationary circular saw for your home - our editorial advice

Choosing a circular saw for your home is not so easy as it might seem at first glance, and there are several reasons for this:

- a large number of models that are similar in technical characteristics and in a wide range of price indicators;

- novice users have no experience with such equipment.

In this case, sales consultants at the point of sale and specialists with experience in woodworking machines come to the rescue.

The convenience of working on it and its mobility depends on the size of the circular saw.

The convenience of working on it and its mobility depends on the size of the circular saw.

Our editorial office has its own consultants in this area of technology, and here is what you should pay attention to first of all:

- Technical characteristics determine the cost of the model, therefore, you should initially decide on the purpose of the equipment and its potential load.

- When choosing a model with a powerful electric motor, you must make sure that it is possible to connect the machine to the existing electrical network.

- When choosing a low-power model, one should initially understand that it will be impossible to perform large-scale work on such equipment.

- The larger the working surface, the more convenient the machine is in work, and, accordingly, with greater accuracy, you can process workpieces.

- Mobile models are more suitable for one-time work, and bed-mounted models are more suitable for industrial use.

- The presence of additional options and a combination with other types of equipment increases the cost of the model, therefore, when choosing it, you should evaluate the feasibility of such additions.

- The reliability of the equipment depends on the manufacturer's brand, and the efficiency depends on the electrical power of the engine used.

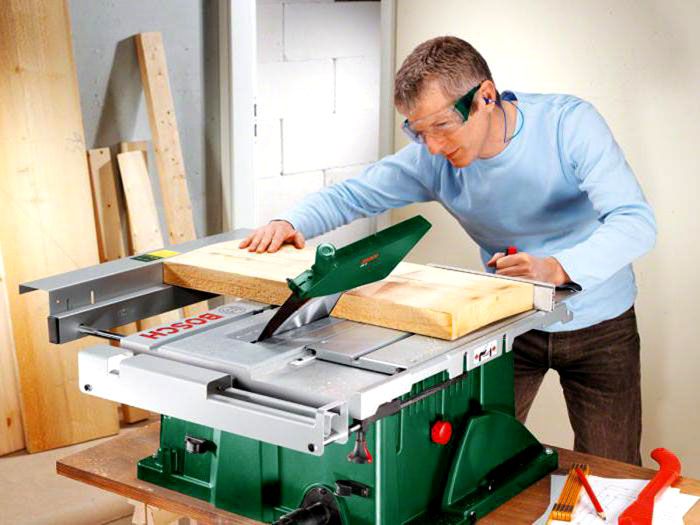

The Bosch PTS 10 woodworking machine is small and very functional

Circular disc

The very first criteria for choosing a stationary circular saw are the cutting blades. Their diameter, shape and material determine the type of work for which the equipment is suitable.

This element defines the depth of the cut. Engine power directly depends on it. The larger the diameter of the cutting disc, the more complex the principle of the equipment systems. For larger cutting elements, a more sophisticated stabilization system is used.

This affects the weight and cost of the tool. For professional processing of materials, it is necessary to purchase circulars with a disc diameter of 165-240 mm. For home use, products of 140-150 mm are quite suitable. Discs 150-165 mm are considered universal. They are suitable for almost all types of work.

Fixed mount for circular

This simple device slightly increases the cost of the saw, but significantly expands its functionality. This is especially true for powerful heavy devices. The stationary mount is:

- a pair of clamps that fix the mechanism on the workbench;

- a pair of legs;

- plate fixing the protection;

- clip for the start button (the button is clamped in the "ON" position).

Holes are provided in the upper part of the tool body for fasteners. After installation, three points of support are formed, which securely and firmly hold the saw upward with the cutting teeth. It turns out a mini-circular machine with a working surface equal to the platform. It is very convenient for cutting a large number of small parts.

Installing the saw on a stationary mount

- We attach the legs: we take out the plug-bolts and instead of them we screw in the bolts to fix the legs.

- We attach the plate securing the protection. The guard must be pressed into the body and pressed down with a plate.

- With the help of clamps, we attach the tool to the workbench by inserting the hooks into the special holes.

clamps for fastening

clamps for fastening

Only specially designed models are installed "upside down"! Otherwise, the tool may be overloaded or the disc will jam, resulting in costly repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. For information on this, see the operating instructions.

There are few models on the market with the possibility of stationary installation. These are mainly domestic products. Distinctive properties - large circle diameter and powerful electric motor.

| Soyuz TsPS-50200 | Caliber EPD - 2100 + St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope DP-2000 | |

| Power, W | 2500 | 2100 | 220 | 1500\1800 | 2150 | 2000 |

| Idling speed, rpm | 6000 | 4800 | 5500 | 3700\4100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Inclination angle, degrees | up to 45 | up to 45 | — | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6,6 | — | 5,7 | 6,7 | 7,8 |

Table 1. Characteristics of some models of table-mounted circular saws on the domestic market

Types of circular saws

There are several features on the basis of which circular saws can be classified.

By scope

- Standard circular saw. It can be used to cut wood with a density ranging from 0 to 85 mm.

- Mini circular saw. It has a high power rating of 400-800 watts. This saw has a saw blade with a size of about 65 mm.The model is distinguished by its small dimensions and weight, which is about 2 kg. The cut created with its help has a depth of about 16 mm. Based on the above, it can be concluded that this tool is suitable for cutting thin materials.

- Cordless circular saw. It has a lot in common with the standard version, except that the battery is the power source for it. This explains why the saw is less powerful and is offered at a higher price, although this is all compensated for by higher mobility. Such a tool is ideal for owners of suburban areas who are planning to build a summer cottage.

- Plunge saw. Most of it is used to cut material from the middle. It will bring the greatest efficiency when a task arises of cutting holes inside a material or making blanks from any material. To cope with such tasks, it allows the plunge mechanism, thanks to which the saw blade can move in a vertical plane.

- Diamond circular saw. The main working element is a diamond saw blade. With its help, you can cut any kind of artificial and natural stone, as well as ceramics and tiles. The possibility of a water supply increases the productivity of the tool. This saw can cut to a depth of 50 mm and can also cut material at an angle.

Depending on the class:

- household;

- professional.

The difference between these models lies in their power. For household models, this parameter is in the range of 1100-1800 watts. Against the background of small dimensions, the weight of this saw is about 4-5 kg. It can work with material of normal thickness - 50-55 mm. The saw blade used in such modifications has a diameter of 160-200 mm.

The power displayed by professional saws ranges from 1800 watts and above. They differ in a rather significant weight, which is 8 kg or more. With their help, you can saw a bar, the thickness of which does not exceed 70-85 mm. Equipped with discs up to 250 mm. The quality demonstrated by these saws also determines their higher price.