Popular manufacturers

It is necessary to consider in more detail the most significant Russian and foreign manufacturers of special footwear for welders.

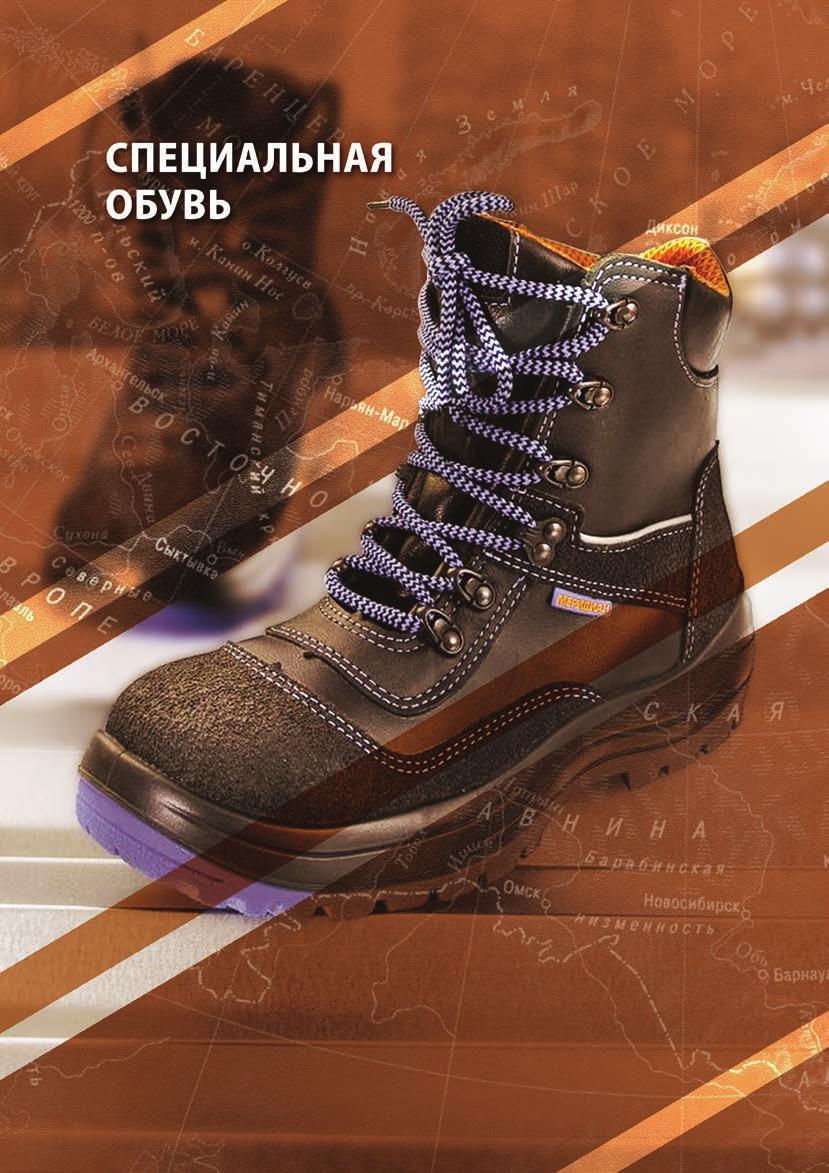

The Vostok-Service company offers a wide range of special footwear and clothing, as well as personal protective equipment. Quality products that meet the standards are produced under several brands: Trail (the Trail Freeze model is shown in the picture), Trail Plus, TOFF, Forveld and other brands.

The Vostok-Service company offers a wide range of special footwear and clothing, as well as personal protective equipment. Quality products that meet the standards are produced under several brands: Trail (the Trail Freeze model is shown in the picture), Trail Plus, TOFF, Forveld and other brands.

Technoavia manufactures a wide range of workwear and footwear, including special ones, designed specifically for welders. Products are manufactured under the brands: Technogard and Neogard.

The TRACT company offers its clients special clothing, footwear and PPE. The products are in high demand, customers appreciate them for their excellent quality and affordable prices.

Moderam is one of the leading companies in the design, manufacture and sale of work footwear and special clothing. The products meet the quality standards of recognized world market leaders.

The Ursus company (Ursus) is a developer and manufacturer of workwear and work footwear. The products are actively used by specialists in many fields of activity. The company maintains a leading position in the Russian market due to a wide range and high quality of equipment, flexible pricing policy.

ESAB (Sweden) is one of the leading and oldest companies producing a huge range of equipment, accessories, components, materials, special footwear for welding.

ESAB (Sweden) is one of the leading and oldest companies producing a huge range of equipment, accessories, components, materials, special footwear for welding.

Special footwear from Jalas is one of the best solutions for welding professionals. The products of the Swedish manufacturer are distinguished by the maximum degree of protection of the foot from damage, increased comfort, natural, wear-resistant and modern materials.

The French company "Delta Plus" (formerly "Panoply") is engaged in the production of special clothing and footwear, the leader of the European market. The company offers quality products recognized by many customers. The “Delta Plus” brand belongs to the middle price segment.

Safety Jogger is a Belgian work footwear brand created in 2001 by Cortina. Models are made of polyvinyl chloride and meet the most stringent safety requirements.

Will any work?

On the market for the production and sale of special footwear, there is a large variety of universal working models that are suitable for use by specialists in various fields of activity. Some of them can also be used in welding.

However, when choosing shoes from the general assortment, you should pay attention to the following aspects:

1. Material. It is recommended to choose shoes made of genuine leather with threads soaked in special substances against the negative effects of high temperatures, oils, and petroleum products. In addition, a combination of natural and artificial leather will become an acceptable option for working in mild climatic conditions.

1. Material. It is recommended to choose shoes made of genuine leather with threads soaked in special substances against the negative effects of high temperatures, oils, and petroleum products. In addition, a combination of natural and artificial leather will become an acceptable option for working in mild climatic conditions.

For low temperatures, you should choose felted or insulated with natural fur shoe models. Buying shoes made of materials that are not intended for use during welding can lead to the fact that the shoes quickly deteriorate, and burns from splashes of hot metal will appear. The worst option would be to harm the health of the performer.

2. Toe cap.It is desirable to have a metal toe cap that will protect your fingers from bumps and bruises. The industry also produces toes made of advanced composite materials such as Kevlar.

3. Fittings. Laces or zippers are used as a fastener. The first option is preferred as the zipper can get hot and often jam.

Important! Regardless of the type of fastener, it is better to select models with a protective flap (overlay).

In addition, the lacing must be made of heat-resistant materials and have a fire-resistant impregnation. Otherwise, it will burn. And the zipper should only be metal.

4. Outsole. An economical option is thermopolyurethane, which can withstand short-term exposure to temperatures up to + 195 ° C. The best solution would be to purchase shoes with nitrile rubber soles (up to + 300 ° C). The injection-molded method of attaching the sole to the upper of the shoe is the most reliable

It is recommended to pay attention to models with an anti-puncture insole, which serves as additional protection for the feet. Choosing shoes with the wrong soles can lead to premature wear of the model.

Important! In addition to the use of special footwear, welding must be carried out in special clothing.

Models

Let's characterize some models of work shoes.

Salomon Quest Winter GTX

High-quality winter model, the basis of which is the technology of mountaineering shoes. Thanks to the GORE-TEX membrane, these boots are resistant to all weather conditions, protecting your feet from moisture, wind and cold. The microporous surface combines properties such as strength, reliability and durability.

Another advantage is the availability of Ice Grip and Contra Grip technologies. Both of them provide high-quality grip of the sole with the surface, only the first is designed for work on slippery and icy surfaces, and the second is designed for use in nature.

The rubber bumper at the toe provides protection against physical damage and various impacts, while the Mudguard technology makes the upper surface of the boot more resistant to dirt. The sole is made of durable rubber, there are water-repellent and antibacterial impregnation, weight 550 g.

New reno s2

Summer work boots that have all the necessary characteristics. The upper is made of natural water-repellent leather that protects the feet from moisture in rainy weather.

EVANIT insole evenly distributes the load over the entire foot. The outsole is made of dual density polyurethane, so the Reno S2 is shock, oil and gas resistant and has good traction. Thanks to the design with a 200 Joule metal toe cap, the feet are protected from various injuries to the toes. Weight - 640 g.

Scorpion Premium

Domestic footwear that meets all the requirements for work in the industry. The upper of the boot is made of genuine leather with various finishing materials, which provides high durability and lightness. The two-layer outsole is resistant to the negative effects of oil, gasoline, acid and alkaline substances.

The polyurethane layer provides shock absorption and dampens vibrations, and the forefoot with toe cap will protect against loads of up to 200 Joules. The blind valve prevents moisture and dust from entering.

The running layer, made of thermoplastic polyurethane, prevents deformation, abrasion, and promotes good adhesion to various surfaces.

Metal toe shoes

Work shoes with an iron toecap - strong safety boots made of tanned leather, less often of leatherette or rubber, with a reinforced iron toe that protects the toes from falling dangerous objects. The sole is also often reinforced with iron inserts for the foot, on the option, if a person steps on a sharp object, for example, on a nail. Reinforced boots are work shoes.

Wearing such boots is weighty on construction sites, in engineering, foundry and many other industries.In accordance with the legislation on labor protection and safety technology, as well as insurance claims, the wearing of reinforced boots (as well as other workwear) in many versions is considered integral, and certain certification claims are presented to the boots personally. Often the certification symbol must be located specifically on the boot: for example, in Canada, boots certified by the Canadian Standards Association have a green triangle.

Reinforced boots are produced today in a variety of improvements and styles: repeating the type of shoes, sports sneakers or sneakers, clogs. Some refer to workwear only de jure - these will be adopted by the supervising engineers and managers. In the Russian Federation, the requirements for protective boots are described by GOST.

On sale there are also simple boots, stylized as boots with an iron toe (English Steel toe boots), otherwise referred to as motorboots.

In the absence of a similar insert, the foot would “just” be crushed. Man.go footwear withstands a load of up to 6 tons, which excludes the destruction of an iron toe in almost all dangerous situations. Such safety shoes are required to protect against falling heavy objects, and are strongly recommended to everyone employed in traumatic industries.

Views

Special footwear, however, is not always designed for use in particularly harmful and dangerous conditions. Even during normal office activities, specific problems arise, from which the legs must be protected.

With the help of shoes and sandals, this problem is solved:

-

in office buildings;

-

in cafes and restaurants;

-

in kitchens;

-

at textile factories and other light industry facilities.

In the catering industry, you sometimes have to spend many hours on your feet. Therefore, orthopedic characteristics and the quality of ventilation, moisture removal are of great importance.

It is equally important to maintain a pleasant appearance of employees, because they will be judged on the whole company as a whole. Many options for shoes for the kitchen and similar objects are made of high quality leather or yuft

Leather safety shoes have the widest profile

But it is important to understand that it also has a number of restrictions on its use. Only a few leather pieces are sewn entirely at once

Usually, the leather is placed on top, and the bottom is made of rubber and other materials. All-leather safety shoes are needed mainly where explosives are constantly present.

Summer

This type of equipment involves the use of a metal or synthetic toe cap. Composite materials are most often used. Since operation at elevated air temperatures is envisaged, heat dissipation and micro-ventilation are very important.

Even a sudden blow must be successfully repelled.

Antistatic properties and resistance to moisture ingress are still relevant. The difference between specific types of summer safety shoes may also be related to its size. A wide range of sizes is now produced, especially for men. For women are intended:

-

shoes;

-

sandals;

-

boots.

Winter

In this segment, cold resistance and the ability to contain moisture are already at the forefront. But winter conditions also impose other requirements, first of all, stability on slippery surfaces and easy passage on loose snow. For relatively mild weather conditions, it is sometimes limited to sneakers or ankle boots. However, for severe frosts, you already need:

-

felt boots;

-

insulated boots (with fur or with thick membranes);

-

high fur boots;

-

multi-layer rubber footwear, combined with other materials and with an increased level of protection against extreme cold.

Types and models

The classification applied to safety shoes, of course, is also suitable for its summer version:

- boots;

- boots with an elongated bootleg;

- boots;

- low shoes;

- shoes;

- galoshes;

- shoe covers;

- sandals,

- sneakers,

- slippers.

The summer version of protective boots is represented by lightweight models that protect not only the foot, but also part of the thigh due to a sufficiently long bootleg.

Boots with a metal toe are widely used for loading, skidding or construction work. The so-called tarpaulin boots, which combine lightness, cheapness and functionality, have proven themselves perfectly.

In some cases, boots are more comfortable. Due to the lacing, they can be adjusted in accordance with the anatomical features

In addition, in the summer, such shoes leave the foot more open, which is very important when working in conditions of high natural ambient temperatures, while the foot remains reliably protected.

An even more open version is represented by low shoes, and then shoes, the lightest working sandals close this row of shoes with reliable soles. Galoshes and shoe covers represent a separate line of special footwear, their main function is to protect the legs from a wet or aggressive environment, however, they can save from mechanical influences very mediocre.

Clogs, sneakers and slippers represent another specific group of work shoes. This is the lightest type of special shoe.

Types of work safety footwear

In the modern bazaar, a huge assortment of special shoes is presented, which is difficult to classify.

Shoes can be divided according to purpose:

- specialized medical shoes (shoes for doctors)

- construction shoes,

- footwear for workers of the security service and other warranty services (footwear for law enforcement agencies), as a rule, these are boots with high ankle boots.

- for workers in the food industry.

- chemical companies and the like.

There is a classification of work safety footwear according to the form of performance:

- boots,

- boots with an elongated bootleg,

- boots with a shortened bootleg,

- ankle boots,

- boots,

- low shoes,

- shoes,

- shoe covers,

- galoshes,

- bots,

- slippers (sandals).

Also, shoes can be divided according to their protective properties.

Requirements for work footwear. Work shoes are made according to the officially accepted stereotypes of the property. So, in the European Union, a stereotype has been adopted for the methods of testing working safety footwear ISO 20344: 2004. The analogue of this standard in the Russian Federation is GOST 12.4.127-83 SSBT “Special footwear. Nomenclature of property attributes. " Special-purpose footwear must protect: from mechanical actions (blows, cuts, punctures, abrasion, pulsation), from slipping, from high temperatures, from low temperatures, from radioactive contamination, from electric current, from water, from poisonous drugs, from joint industrial pollution, from harmful bio-moments, from static loads.

The safety footwear is designed to protect the worker's feet from various mechanical influences, aggressive environments and industrial pollution, exposure to low or high temperatures and a whole range of possible dangers. In this regard, shoes can be divided into different items:

- Shoes from general industrial pollution (HMO)

- Heat Resistant Shoes (Boots or boots with heat-resistant soles, boots for casters, welders, etc.)

- Water Resistant Shoes... This includes boots made of rubber, PVC (fishing), as well as semi-overalls (wading),

- Insulated or winter shoes... It can also be said as a shoe against low temperatures. This includes felt boots, leather boots, warmed with fur, woolen cloth. It can also include boots or ankle boots to protect against HMO, but a warming stocking (chuni) is used as a heater.

- Men's work shoes... It is believed by many that men's work shoes start from 39, 40 sizes and up to 47 sizes. And women's shoes start from 35, 36 sizes and up to 40

- Women's work shoes.

- Work shoes with molded soles... This is a shoe in which the sole is attached by the injection method.

- Safety shoes with metal toe... Boots or boots in the nose of which a metal or thermoplastic toe is inserted. Prevents amputation or crushing of the toes.

- Shoes with increased requirements for cleanliness... Various slippers, clogs, sandals for laboratory work.

On the Internet, people very often look for shoes for workers for the following queries: safety shoes, work shoes, work shoes, safety work shoes, safety shoes, work shoes, or even work boots, tarpaulin boots, tarpaulin boots, work boots, etc. etc. etc.

Due to the specific requirements, in the production of work shoes, special attention is paid to the quality and reliability of the sole. It must be resistant to acid, oil and petrol (MBS), as well as heat-resistant and antistatic properties and puncture protection.

The sole should be made of a material with increased resistance to mechanical stress (especially to the effects of bending, breaking and twisting).

In accordance with the requirements of the norms for issuing shoes, the employee is provided with one pair of work shoes per year if his production duties are associated with the risk of injury to his feet.

Marking

This point is especially relevant already because in Russia since 2018 (more precisely, from July 1), all manufacturers and suppliers must take care of the labeling. It applies not only to special shoes, by the way. The basic designations must correspond to the two-dimensional code according to the Data Matrix standard. Additionally, a special sequence of letters and numbers with a total length of 31 characters is used.

Marking must be done on sale prior to final shipment from the manufacturing facility. If shoes are imported from the EU, then they must have special designations at the time of crossing the border of the Russian Federation. The main properties are indicated by additional letter combinations:

-

Мп - protection against punctures and cuts;

-

Ma - vibration resistance;

-

Moon (number) - force of impact to the forefoot in KJ;

-

Mut (number) - the force of the blow to the back;

-

Mule and Moob - strikes to the ankle and shin, respectively;

-

Сж - reduced sliding on fat;

-

SL - small glide on ice;

-

Cm - minimum sliding on wet, dirty and other surfaces;

-

Тн - protection against negative temperatures;

-

Yazh - resistance to liquid toxic substances;

-

Oa - isolation from organic solvents;

-

Нт - for contact with solid petroleum products.

Norms and requirements

Overalls and PPE, other components of the protection of company personnel should be purchased at the expense of the companies themselves. Ultimately, it is the companies that are interested in their employees staying productive longer and ensuring the fulfillment of the assigned tasks. Therefore, you should definitely be guided by the official standards when choosing special footwear of any type and purpose.

It is, of course, carefully sized. But it's not only that.

Special standards have also been introduced for transportation, storage in warehouses, acceptance and marking.

Standardized:

-

the thickness of the top and bottom parts;

-

adhesion strength of the heel;

-

tensile strength;

-

the strength of the seams on the workpieces;

-

hygiene indicators;

-

weight of packing places;

-

service life of work shoes;

-

silhouette;

-

the temperature of the skin on the foot;

-

interior finishing characteristics;

-

external appearance.

To comply with labor protection standards, shoe personal protective equipment is classified according to resistance to:

-

abrasion;

-

puncture force;

-

vibration effects;

-

slip;

-

intense heat;

-

thermal radiation;

-

open fire;

-

sparks;

-

drops and splashes of molten metal;

-

low temperatures;

-

contact with electric current;

-

electromagnetic fields;

-

toxic particles and environments.

Materials (edit)

The outer parts of special shoes are usually leather or made of leatherette. In this case, there may be fur inside, some kind of synthetic or natural fabric. In theory, the continuous application of leather wherever possible would improve the quality of the shoe to the maximum. But for financial reasons, no one will do that. Therefore, fabric linings are most often used.

PPE based on yuft (combined tanned leather) are widespread. This material is mechanically strong and completely safe in terms of the environment. However, it can hardly be considered a particularly aesthetic solution. Therefore, yuft is usually used for footwear designed for aggressive environments. And somewhat less often it is needed for outdoor work.

Chrome skin is much more attractive in appearance, and in terms of basic characteristics it is not bad. There is only one minus - this material is significantly more expensive than leather. Due to the attractiveness of the price, splitting is becoming more and more widespread. It can be used (depending on the specific variety) for both the internal and the front surface. If the lowest cost is important, artificial leather is used, but its protective properties are relatively low.

The sole is most often made on the basis of:

-

nitrile;

-

polyurethane;

-

thermoplastic elastomer;

-

PVC.

For work in winter, the most attractive solution is natural fur lining. But its widespread use is hampered by the relatively high price. Therefore, products with artificial fur or even with composite insulation are becoming more widespread. Since the technological problems have been generally resolved, the use of these materials does not cause any particular risks. And their rejection has a lot to do with the force of habit.

In places with high humidity, it makes sense to use rubber PPE. But you need to understand that the standard options for such shoes create a bad microclimate for the foot.

The difference between shoe options can also be related to the way the sole is attached to the upper. The glue method is appreciated for its extraordinary high strength and stability, even under adverse conditions.

The inner element is attached to the welt on a special sewing machine. The outer parts are glued with a special glue. To make the connections stronger, a nylon seam is additionally used, which is almost impossible to break. The glue-stitching technique involves first gluing the sole to the edge of the workpiece. After that, the shoes go to a high-class sewing machine, where the plantar sides are sewn with reinforced lavsan thread.

This approach involves the penetration of polyurethane (its permeation) into both the bottom and the top of the shoe. Such a solution allows to increase the resistance to moisture and aggressive substances. The multiple increase in the contact area ensures exceptional solidity.

Importantly, this does not compromise the flexibility of the finished structure. But the technological process is simplified - no need to additionally use glue or threads

But shoes with a metal toecap are used where increased mechanical loads are created, where there are many sharp objects and cutting surfaces. A slight increase in price allows the overall service life to be increased several times. In most models, an extra thick tread with increased shock absorption properties is used.

Popular manufacturers

Quite a few companies in different countries are engaged in the production of special shoes. But still, there are clear leaders among them in terms of quality and variety of products. In our country, this is the firm "Tract". Its goods are actively shipped abroad. A number of shoe models are made using nitrile rubber, non-metallic puncture-resistant insoles.

You can find options:

-

for welders;

-

for working with petroleum products;

-

for staying in a particularly aggressive environment;

-

for work with energized communications.

But in Russia there is also another top-class manufacturer - the Tekhnoavia company.

The range includes winter, summer, demi-season PPE for legs.

The official catalog also widely includes:

-

footwear for medical needs;

-

footwear for people with large feet;

-

white equipment;

-

products with composite inner socks;

-

leather shoes for men and women;

-

boots and boots with fur lining (and this is just a small part of the range).

Finnish factories also produce excellent safety footwear.

Among them, Sievi deserves special attention. The brand appeared in 1951 and has managed to become a solidly leading manufacturer of foot-operated PPE in northern Europe.

The enterprises employ about 500 people, and significant production volumes are achieved through the use of automation. The company has a laboratory for the production of the most complex tests.

Summer and demi-season segment is represented by:

-

sandals;

-

low shoes;

-

work shoes with and without a metal toe cap;

-

models with anti-puncture insole;

-

models with a metal insole (and all of these options are resistant to oil, gasoline).

American safety shoes are also quite widespread. Thus, Frye brand products have been on the market since 1863. Of course, during this time, a lot has changed in technology. However, the presence of a thick leather upper and a durable rubber base has proven itself for decades. Such products do not look very presentable, but they will work for a long time.

The Thorogood brand has made a name for itself with work boots and boots. The reviews note the convenience of landing a leg

The focus is also on the slip resistance of the outsole.

Many people still choose products:

-

Chippewa (USA);

-

Cofra (France);

-

Pezzol (Italy);

-

Reis (Poland);

-

Ahiless Safety (Russia);

-

Ewest (Republic of Korea).

Safety footwear production

The modern production of work footwear has made a significant step forward today. The nail, glue and welt-stitching methods are becoming a thing of the past, becoming obsolete, and the shoes of the injection method of attaching the soles are gaining more and more fans. This is not unusual, just over time we find more practical solutions, including for the production of special footwear.

The production of better quality and more practical products requires shoe makers to use modern machinery and equipment: injection molding machines, presses, where almost all processes are automated and controlled by electronic control systems. Even the tops of shoes, which are the least subject to significant changes, are sewn today using semi-automatic lines.

Production of safety footwear

Modern technologies for the manufacture of special footwear have made it possible to exclude such methods of making shoes as a nail, glue or welted method, which are a thing of the past.

Today, the injection-molded method of attaching the sole has become the most innovative method. Shoes with polyurethane soles have taken the leading position in the market, they have excellent protective performance. Its main indicators are good thermal insulation, wear resistance and resistance to aggressive media.

In the manufacture of such products for work in low temperatures, a second layer of heat-resistant polyurethane is applied to the sole.

Each type of work footwear has its own wear period, after which it must be replaced. Shoes are also replaced if, during the process of wearing, they become unusable.