User manual

In order to react in time to emergency situations, thereby preventing damage to the unit, you need to carefully study the instructions, as well as the methods of promptly stopping the engine. This can help not only save the snow blower, but also prevent possible harm to your health and those around you.

Instructions for use

In general, snow blowers Lynx, Celina, Stiga, Hooter, Kraftsman, MTD have the following instructions, which reflect the main points:

- Persons under the age of 18 must not be allowed to operate the snow blower. The same applies to those who have not studied the safety precautions and a detailed description of the unit design.

- Before starting work, you should carefully inspect the surface from which the snow will be removed. The fact is that there may be various stones and other small objects that, when flying out of the gutter along with snow, can cause significant harm not only to property, but also to human health.

- It is necessary to ensure that there are no people or animals in the direction of the snow flow.

- Wear suitable clothing to operate the snow blower. We are not talking about a specialized jumpsuit or anything like that. It is enough to wear warm clothes that do not let the wind through, as well as shoes that do not slip.

- It is not necessary to immerse the limbs in those parts of the snow blower body where the rotating elements are located. Failure to do so may result in amputation.

- If a foreign object enters the snow blower bucket, immediately turn off the engine until the problem is completely eliminated. The same recommendation applies when the tensioning belt is torn off.

- Persons who have drunk alcohol before are not allowed to operate the snow blower. The same applies to those who are intoxicated, as well as those who take potent drugs that affect consciousness.

Gutter

- There should be no glass or similar surfaces in the direction of the gutter. Stones flying out of the chute can cause significant damage to them.

- There are no headlights in the design, so snow removal should be done only during the daytime. With the onset of dusk, you can simply not notice the people standing nearby.

- It is not recommended to use the snow blower on surfaces where slopes and inclines are clearly visible.

- Periodically it is worth taking breaks in work so that the engine has time to cool down and does not overheat.

- If excessive vibration occurs, which is not typical for normal operation of the snow blower, the engine must be turned off immediately. Vibration is a sure sign of a problem inside the case, so operation cannot continue until the problem is corrected

- Make sure that there are no people in the direction of the snow throwing, or they are standing at a considerable distance from you. The optimal distance is considered to be 20 meters.

If you adhere to these rules described in the instructions, you can significantly increase the life of your mounted snow blower. In addition, knowing and following these guidelines will help you avoid injury or injury at work.

Design features

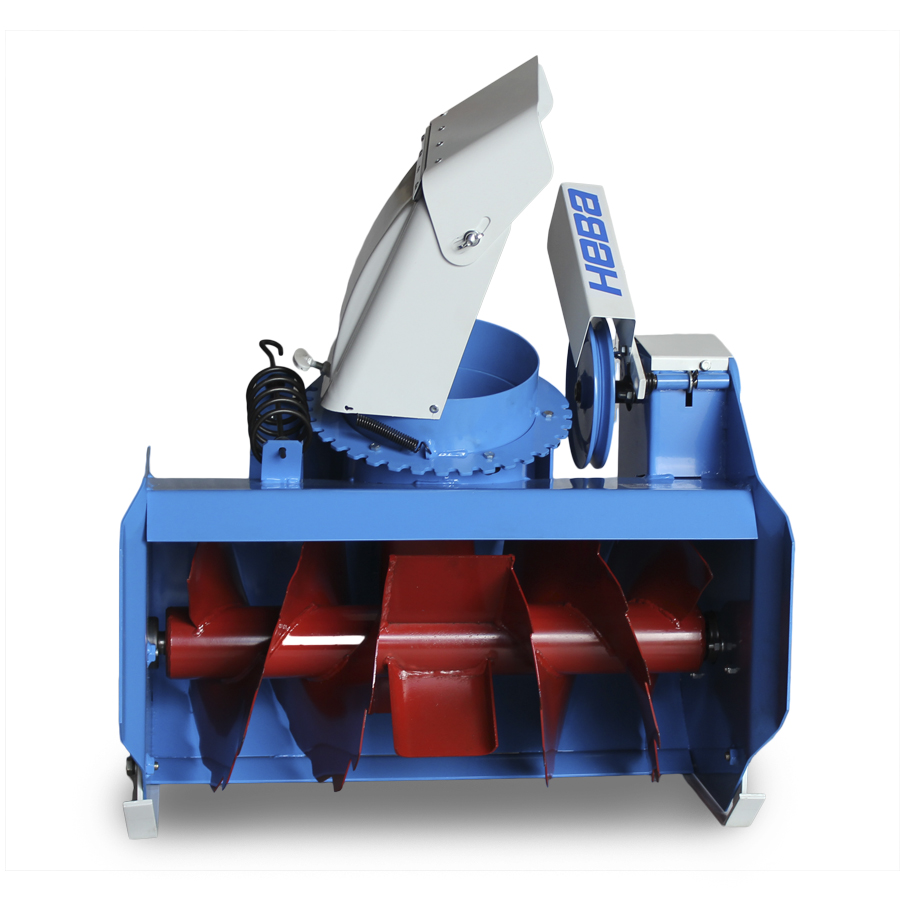

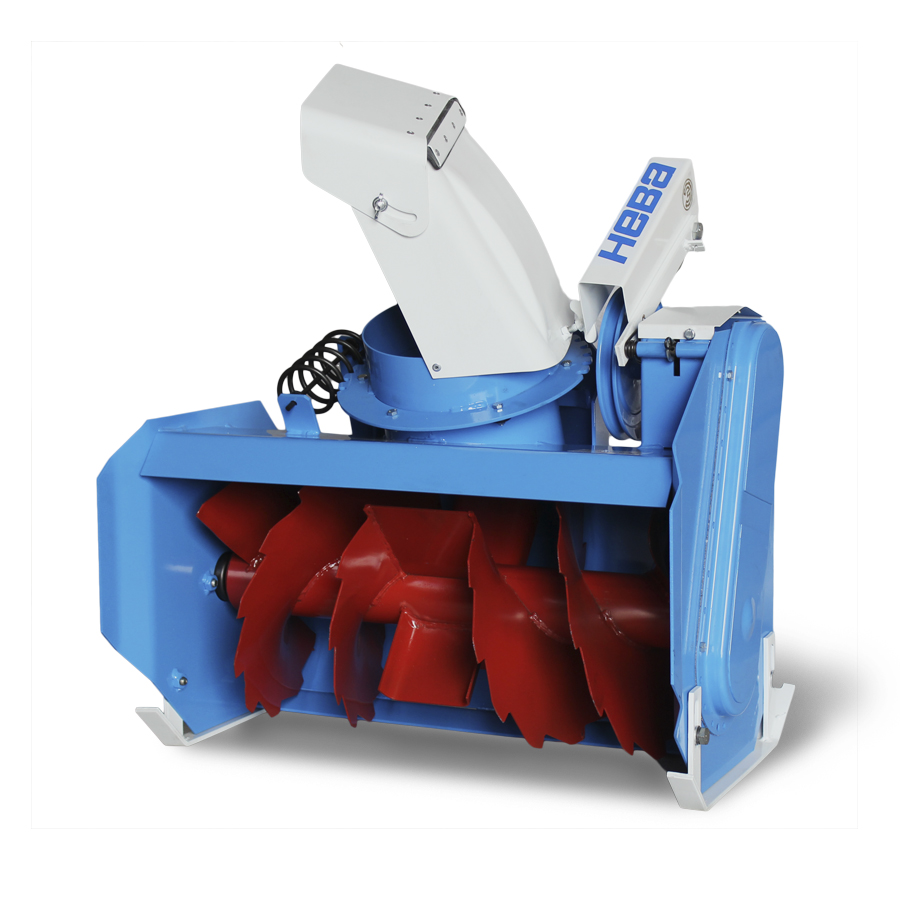

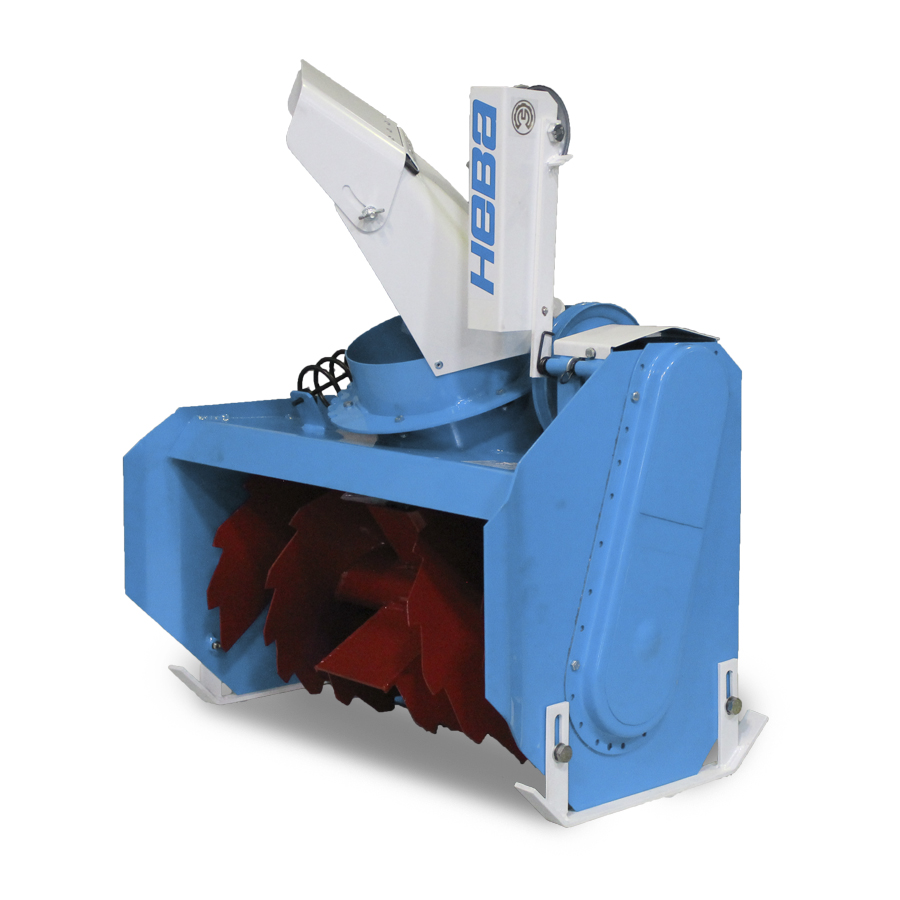

Structurally modifications of snowplows for the Neva unit are identical, differing from each other exclusively in terms of size and technical parameters.

All mounted snow throwers are equipped with an iron body, open from the front. The housing contains a screw conveyor (auger, screw conveyor). A snow outlet is located at the top of the body. On the side of the body, a screw conveyor drive device is mounted. And on the back side of the body, the trailing mechanism is localized.

Now about the structure in more detail. The body is made of sheet iron. In the side walls of the housing there are bearings of the screw conveyor shaft. Below on these walls are small skis to simplify the movement of this equipment on the snow.

On the left side there is a cover of the drive unit. The device itself is chain. The drive sprocket (drive wheel) is located in the upper part and is mated by means of a shaft to the drive friction wheel. The driven wheel of the drive is located in the lower area on the shaft of the screw conveyor.

For individual snow throwers, the drive and driven wheels of the drive are replaceable, which makes it possible to change the rotation speed of the auger conveyor at the snow blower. Next to the body there is a drive belt tensioner, which includes an iron bar, which is fixed to the drive casing with one edge

At the other end is a friction wheel (pulley). The tensioning bar is not rigidly fixed and can move. The actuation of the snow thrower itself is carried out from the friction wheel of the crankshaft of the unit by means of a belt drive.

The screw conveyor includes a shaft on which there are two helical steel strips with the direction of the turns towards the middle. In the center of the shaft there is a wide strip that captures and ejects snow masses through the snow removal.

The snow deflector (sleeve) is also made of sheet steel. On top of it there is a canopy that regulates the angle of discharge of snow masses. The snow thrower is attached to the rod located at the front of the walk-behind tractor.

Method of connecting to a walk-behind tractor

Connecting a snow blower to the unit does not cause difficulties even for those users who are working with a walk-behind tractor for the first time, and takes from 15 to 20 minutes. The process of connecting snow removal equipment consists of several stages.

- On the frame of the walk-behind tractor there is a special hook-on unit made in the form of a metal bracket. In order to secure the snow thrower, the pin located there is taken out of the bracket, the equipment is attached and fixed with two bolts.

- The protective cover is removed from the power take-off shaft of the walk-behind tractor and, by means of a V-belt, its pulley is connected to the pulley of the snowplow. Then, using the adjusting mechanism, the belt tension is set, while controlling so that it does not slip or sag.

- After the adjustment of the belt drive is completed, the pulley protection is put in place and the mechanism is manually turned, thus eliminating the possibility of friction between the rotating elements and the housing.

- In the course of further operation of the snow blower, it is necessary to periodically check the belt tension and prevent it from loosening.

Varieties of snow removal attachments

All commercially available nozzles for a walk-behind tractor can be conditionally divided according to the method of attachment, shape, principle of operation. Depending on the design of the walk-behind tractor, the methods of attaching the attachment can be as follows:

- through the power take-off shaft (PTO);

- by means of a homemade or industrially manufactured hitch;

- belt drive;

- using adapter and hitch;

- through the track attachment.

Types of attachments for cleaning snow

According to the principle of action, the nozzles are subdivided into the following forms:

- Blade-shovels (snow plow) - for clearing snow drifts. The design is a scraper bucket with a sharpened bottom edge. The knife (pointed bottom) is set at a certain angle and lowered.When driving, snow masses are directed into the bucket, and part of the snow is shifted to the side of the road, which does not interfere with the movement of equipment.

- Communal brushes - for removing freshly fallen snow, for collecting dust, sand and foliage. The pile is made of polypropylene or metal. Before starting work, the angle of inclination of the brush and pressure are set. When rotating, the structure brushes away snow, providing a gentle cleaning of the surface.

- The screw-rotor attachment (snow rotor) - copes with caked or freshly fallen snow, ice, ice crust. The rotor spins, the blades capture the snow cover and transfer it to the impeller. Rotating at high speeds, the impeller crushes snow, ice and clods, after which the snow is thrown out through a special pipe in a certain direction.

According to the constructive type, a walk-behind tractor for cleaning snow happens:

- rotary;

- screw (single-stage);

- mixed type.

Attract and the principle of robotics

Compact bybutov_ snow blowers are petrol and electric. Smells come from oneself only in the way of grabbing: first, it is produced from gasoline, others are from electricity. Read the article about electric snow blowers.

The principle of robots The essence of robotics is in the offensive: for the help, special spinning of the attachment is for picking up the snig in itself, and then for the help of the vypusky zholob with the force of vyshtovhuvati yogo in a given direct on the required distance.

The running machines are divided into one-stage and two-stage parts. The first for vyshtovhuvannya snig vikoristovuyut only strength, like opening the auger, wrapped with great shvidk_styu. The design of the other transmissions has a special rotor, which stands at the inlets of the discharge gutter, і, wrapped, vishtovhuє snig.

This allows the auger to spin with less speed, which will cause a lot of wear and tear and part of breakage when stones or solid objects hit.

The auger is a pristіy, a kind of podrіbnyu sіg and "throwing away" yogo in the middle of sіgopribirach. It is located in the front part of the car, at the bottom and at the top and at the sides with a bucket body, and then directly into the snow blower. The auger will start making metal.

Win is a monolithic cutting machine, which is similar to a drilling rig for cutting a gwent in a larger version. Wrap yourself around your axis, grind the snig and give it to you in the middle of the snig-picker.

One-stage snow blower Yakshcho the speed of the wrapping is great (yak in one-stage types), then the use of a solid object in the auger is the cause of the breakdown. Tom, in such machines, they cover the top with humi (in some cases, they store up with humi).

Tsya specialty is allowed, when in contact with solid earth, the trocha is oversaturated with self-reliance. In two-stage machines, the auger is wrapped with a small speed, which is not the fault of the wikidah of a large country, but the rotor.

Such snow blowers can not only clean out fresh snow, but cope with compressed and cold notes. The surface of the metal auger can be either smooth or notched.

Besides, snigopribirach maє dvigun, vypuskny zholob. How to regulate directly and the distance of the tracker, wheels (in the form of caterpillars), handles for oversupply of the tracker, and in the most popular models - the control panel.

Bilsh ate a report. Snegopribrachі marvel at the guided video:

Snow pickers go on self-employed and non-self-employed. For the first one, oversubstantiated, go for the help of the dvigun (report - here), for the other - for the help of the people themselves (div. Forte QI-JY-50).

We have posted a rating of the biggest bulldozers in the world. Read the article about them here.

The increase in the productivity of the bulldozer, in the fallowness in the soil and in the technical characteristics of the bulldozer, is in addition to the statute.

And from the list of statistics, you learn about the special features of the B10M bulldozer, which is ready to go to the Chelyabinsk plant.

Lugs

Special attachments in the form of lugs are used to enable deep entry into the ground. Such devices are metal wheels with special teeth. Motoblock Neva is compatible with KMS wheels, the weight of one of them is 12 kg.

There is also another model of lugs - metal wheels KUM, designed for deep hilling of the earth. Compared to KMS, they are thinner - their thickness is only 10 cm, but their diameter is 70 cm. The KUM wheels weigh 15 kg each. Choosing the right device is necessary based on the specifics of the work that you need to perform.

How to assemble a snow blower

DIY snow blower assembly sequence:

Assembly

- First, a box of iron sheets is taken, the ends of which are bent like skis. To make a shaft, you need to get a pipe with a thickness of at least 5 cm. A grip made of two welded bent plates in a U-shape is welded into the box. Both plates should be rotated 180 degrees in relation to each other.

- The auger can be made by hand using a conveyor belt (1.5 m in length and 10 mm in thickness). It is possible to cut 4 rings from the tape using a jigsaw (28 cm in diameter). In the absence of such a device, it can be replaced with a special board, which is used like a compass (rotations in a circle). With this manufacturing method, high-quality rings are obtained.

- In a casing made of galvanized iron, you need to make a hole, and then install a pipe in it, which will serve as an ejection of snow. The holders on both sides of the spreader are welded to it.

- A gear or pulley must be installed on the auger drive shaft (the choice depends on the drive). The rings on one side are cut and welded to the beginning of the other end. One side of the workpiece is welded to the gripping blade, and the other end, reinforced with a strip of steel, is welded to the shaft at a distance of 5-10 cm from the free end.

- Next, you need to prepare the auger drive. It can be either chain or belt. A belt drive should be used when the engine has a pulley, and if the auger jams during operation, the belt will slip safely. The size of the grab body should be 2-3 centimeters larger than the pulley. In this case, the pulley will not cling to the body, there will be a gap between them.

- To prevent the auger from breaking, it must be equipped with a spare pin that breaks off in the event of a jammed auger. A round hole is made behind the gripper, into which a bent pipe of the required gauge is inserted and welded.

- After carrying out all the work, you must carefully check that the distance between the gripper blades and the rear wall of the box is minimal.

- The glasses should be fixed on the sides of the box. It is better to create glasses from AMgb aluminum and fasten them to the machine using MB bolts (be sure to tighten them with nuts). The shaft rotates in bearings located in glasses. He should look out of the box at a distance of 5-10 cm.

- The swivel gutter can be made from a sewer pipe (diameter 160 mm). A gutter is attached to this pipe, which sets the direction for the snow. The diameter of the chute should be larger than the width of the auger plate, which is responsible for the discharge of the snow mass.

- An asterisk is welded to the end of the shaft to change speeds. The sprocket and shaft are connected to the walk-behind tractor using a chain.

- The rotor is connected to the front wall of the body by means of rivets with a diameter of 4 mm. If skis are installed on the unit, then wooden blocks can be attached under them or plastic strips can be screwed on.

- Make a frame from steel corners (50 * 50 cm). Angles measuring 25 * 25 mm are attached to the transversely installed corners. The power unit is attached to them.

- The handle of the machine is bolted to the longitudinal corners.

Snow blower for walk-behind tractor Neva

After the assembly is completed, the walk-behind tractor can be spray painted.

In addition to the main technical parameters and characteristics that affect the quality and performance of snow blowers, you should consider some additional devices that can make the operator's work more comfortable. The standard equipment of models of snow removal equipment can be supplemented with a number of additional functions, for example, a heating system for the handles of the machine, an electric starter, a headlight for operation at night, etc.

Note! When using this device, observe the safety regulations. In conclusion, it should be noted that the snow blower makes it possible to adjust the direction of snow throwing using the screen rotation, but the snow throwing distance is adjusted by rotating the device motor

In conclusion, it should be noted that the snow blower makes it possible to adjust the direction of snow throw using the screen rotation, but the snow throwing range is adjusted by rotating the device motor.

vote

Article Rating

Safety during work

There is nothing complicated in working with a snow plow attachment. However, you need to adhere to a number of rules, more aimed at observing personal safety:

- Before starting the engine of the Neva, it is necessary to check all important components. These include the hitch, drive, auger. There should be no loose bolts or loose parts. The auger must be turned by hand. If he walks easily and does not rub anything anywhere, you can start the engine.

- The movement begins smoothly at a speed of about 2 km / h. On flat and long sections, you can accelerate to 4 km / h, but no more.

- Snow is ejected through the discharge arm with great force. The guide visor must be correctly adjusted so that the flying mass does not harm passers-by and the windows of buildings.

- If a stone or a large block of ice accidentally falls into the bucket, the auger may jam. In this case, the unit should be stopped, the engine should be turned off and the mechanism should be cleaned.

User manual

In order for the operation of the snow blower to be convenient and safe, a number of simple rules must be followed.

- Before starting the engine of the walk-behind tractor, you should check the condition of the main components and assemblies, stretch all the threaded connections and check the belt tension. Then you need to manually turn the auger. Only after making sure that nothing interferes with it, you can start the engine.

- You need to start moving at a speed of no more than 2 km / h, gradually increasing it to the recommended speed.

- In the process of work, it is necessary to adjust the direction of the canopy on the snow deflector so that the escaping snow masses do not fall into people, animals and windows.

- A sudden jamming of the auger indicates that a large piece of ice or stone has entered the mechanism. In this case, it is necessary to muffle the walk-behind tractor and try to remove the foreign object.

- Due to the fact that snow blowers are not equipped with headlights, it is prohibited to operate them at night.

When clearing large areas, it is necessary to take breaks and allow the equipment to cool down.

When working on inclined surfaces, you need to be extremely careful not to allow the equipment to roll and overturn.

The chain tension must be adjusted every 5 hours of operation. It is carried out using an adjusting bolt located on the body of the snow thrower

The amount of deflection should be no more than 10-15 mm with manual pressure.

When working with snowplowing equipment, personal precautions must be taken, and exposed body areas and eyes must be protected.

For cleaning large areas, it is advisable to attach an adapter. This will allow the operator to work in a seated position and significantly reduce the stress on the spine.

An overview of the SMB "Neva" snow blower is shown in the next video.

Operation and maintenance

When choosing a motor-cultivator, one should proceed from the size of the cultivated area and the quality of the soil, light models will not be able to cope with heavy soil and work effectively with additional devices. Therefore, any discrepancy between the real capabilities of the equipment can lead to breakdowns.

Of the disadvantages of Patriot cultivators, the owners single out the small diameter of the wheels, which complicates the operation of the machines. For some less popular models, it can be difficult to find spare parts. The most problematic moments include the complex structural design of the unit. Without instructions, its assembly, running-in, the first start can cause certain difficulties.

Instruction for cultivators Patriot Alaska, Arizona - download.

Possible malfunctions

The technique must be looked after. Such concern should be manifested in regular equipment diagnostics and timely oil changes.

It is important to carefully study the operating instructions for the motor cultivator, where recommendations for the maintenance of equipment, practical advice on eliminating breakdowns and defects on our own are indicated in an accessible form

The design of the Patriot cultivator consists of a fuel system, an ignition system, a starter, a gas distribution system, and a cooling system. A correct understanding of the device of technology helps to diagnose the causes of malfunctions in a timely manner and eliminate them.

Many startup problems arise for the simplest reasons associated with basic maintenance shortcomings:

- clogged air filter

- airing the fuel supply system

- clogging of the gas supply channel

- damage to carburetor

- closed fuel tank.

Carrying out a routine inspection in accordance with the work schedule will protect your cultivator from premature breakdowns.

At the end of field work, before storing the unit for the winter, you should perform the following steps:

- Clean and wash the unit.

- Wipe dry, or air dry.

- Lubricate the rubbing parts with oil and grease.

Running in

To extend the service life of Patriot cultivators, the machine should be run-in. At the beginning of the running-in procedure, the engine should idle, then gradually start to work in a gentle mode - up to 50% of the load for 10-13 hours, it is allowed to perform various types of soil cultivation.

At the stage of running-in, the main units and mechanisms of the machine are run-in, therefore, attention should be paid to their functioning: the clarity of gear shifting, the condition of the moving parts of the structure, chassis, wheels, the presence of noise. At the end of the running-in, change the oil, once again carry out a technical inspection of the cultivator

Patriot Tesla electric cultivator at work:

Oil, fuel

The manufacturer recommends completely replacing the engine oil (class SE, SF, SG) after 5 hours of operation of the Patriot cultivator during running-in, then after 25 or 50 operating hours, depending on the mode of operation of the equipment, or every season.

Motor-cultivators Patriot run on fuel of a certain brand - AI-92 gasoline, the equipment is sensitive to the quality of gasoline. Some light models consume a mixture of gasoline and oil, so it is advisable to use the correct fuels and lubricants for your cultivator.