Range

The Elitech range of snowblowers is represented by a number of models. Let's consider them in more detail.

Elitech CM 6

This unit belongs to the category of reliable and inexpensive devices that can operate smoothly for quite a long time. The model is suitable for clearing snow from small areas. The cost of the car is 29,601 rubles.

Distinctive features:

- power - 6 horsepower;

- engine type - OHV, 1 cylinder, 4 strokes, runs on gasoline, there is air cooling;

- LONCIN G160 engine (S);

- volume - 163 cm³;

- 6 speeds (4 of them are front, and 2 are rear);

- capture width - 56 centimeters, height - 42 centimeters;

- throwing distance - 10-15 meters;

- the angle of rotation of the outlet chute - 190 degrees;

- wheels - 33 by 13 inches;

- auger - 240 millimeters;

- oil sump - 600 milliliters;

- fuel tank - 3.6 liters;

- consumption - 0.8 l / h;

- weight - 70 kilograms;

- dimensions - 840 by 620 by 630 mm.

Elitech CM 7E Elitech CM 6U2

This snow blower is designed for intensive and frequent work, so if you plan to use the device quite rarely, then this machine will not suit you (the power and price are too high). The cost of the model is 46,157 rubles. She is known and popular not only in Russia, but also far beyond the borders of our country. Here the manufacturer entered the international level.

Peculiarities:

- power - 6 horsepower;

- gasoline engine with 1 cylinder and 4 strokes (model and volume are the same with the previous unit);

- 6 speeds;

- capture: width - 56 centimeters, height - 42 centimeters;

- throw length - up to 15 meters;

- the angle of rotation of the outlet chute - 190 degrees;

- auger - 2.4 centimeters;

- oil sump volume - 0.6 liters, fuel tank volume - 3.6 liters;

- weight - 70 kilograms;

- dimensions - 840 by 620 by 630 mm.

Elitech CM 12E

A distinctive feature of this model is the ability to clean not only fresh, just fallen snow, but also stale precipitation (for example, crust or ice formations). The price of this option is 71,955 rubles.

Options:

- engine characteristics: 12 horsepower, air-cooled, volume - 375 cm³;

- increased number of speeds - 8 (2 of them are rear);

- capture 71 centimeters wide and 54.5 centimeters long;

- wheels - 38 by 15 inches;

- auger - 3 centimeters;

- fuel tank - 5.5 liters (its consumption is 1.2 l / h);

- weight - 118 kilograms.

Elitech SM 12EG

This snow blower is designed for clearing fairly large areas, so it is often used on an industrial and production scale. Price - 86 405 rubles.

Options:

- engine power - 12 horsepower, its volume - 375 cm³;

- 1-inch track wheels;

- capture area - 71 centimeters;

- capture height - 54.5 centimeters;

- discharge - up to 15 meters;

- rotation angle - 190 degrees;

- wheel size - 120 by 710 mm;

- weight - 120 kilograms;

- dimensions -1180 by 755 by 740 mm.

Advantages and disadvantages

Like any other product, Elitech snow blowers have proven advantages:

- the chute rotates 190 degrees;

- there is a protection designed for the muffler;

- there is a handle for control;

- 6-8 speeds, including back.

At the same time, many users also note disadvantages:

- unreliable fastening of shear bolts;

- short service life of candles;

- the possibility of freezing the torso of rotation of the auger;

- insufficient permeability of wheels.

However, despite the presence of some drawbacks, products from Elitech are considered an example of high quality units. Due to its democratic price and domestic origin, the technique is popular among buyers.

You will learn about the intricacies of working with the Elitech CM6 snow blower below.

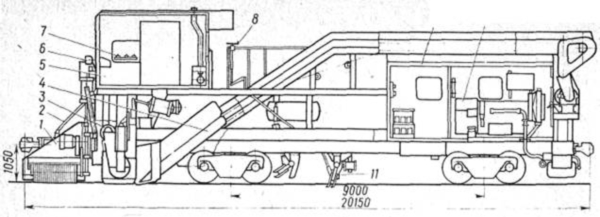

Device

Let's start with the head carriage. It is based on a sturdy frame on two bogies with two axles each. This frame was specially made elongated in order to place the harvesting mechanisms in front.These are hinged side wings and a brush feed rotor, controlled by separate lift and swing air cylinders, and a scoring knife. There are three ice-breaking devices (side and center) in the central front part of the frame. They are also controlled by separate cylinders.

Also on the front car there is a conveyor equipped with an electric motor and a device for lifting the bow (for which a special cylinder is used). On the sides of the frame are two brushes that sweep away debris or snow from the surface between the tracks. When the car goes in reverse, they throw this mass onto the road. In the working position, they are lowered and rotated 45 degrees relative to the travel direction. They are raised and lowered by a pneumatic cylinder, and kept on chains.

The pneumatic equipment includes: taps, an air line, a check valve, shut-off devices for tanks with air, as well as control devices (pressure gauges). In addition, there are air cylinders - for each working body its own.

The set of the diesel power plant includes an internal combustion engine with a capacity of 300 horsepower, as well as a 200 kW generator.

Intermediate cars are simple. Conveyors (driven by separate electric motors) move inside them, transferring the snow further. In the final car there is a receiving conveyor of the unloading type, as well as accumulating and feeding conveyors, differing in different speeds. They are all equipped with separate electric motors.

Technical features

So, the speed and functionality of this snow blower are determined by the gasoline four-stroke single-cylinder ZongShen 188FE OHV engine with a capacity of 13 liters. with.

The abbreviation OHV refers to the overhead valve arrangement in the motor. This results in low noise and vibration levels, resulting in more economical fuel consumption and longer machine life.

Starting the power unit can be done either manually or using an electric starter operating from a voltage of 12 V. The presence of the latter option greatly facilitates the operation of this model even in severe frosts.

The motor is endowed with throttle and air valve controls that operate in separate, unrelated modes. The volume of the fuel tank is 6.1 liters, refueling is carried out with gasoline of the 92 brand.

In addition to the powerful engine, another important feature of the self-propelled snow blower in question is the tracked drive. The special triangular shape of this structural element guarantees excellent flotation of the machine even on slopes and icy areas, providing excellent traction.

The special triangular shape of this structural element guarantees excellent flotation of the machine even on slopes and icy areas, providing excellent traction.

The number of gears in this unit is 8: forward gear has 6 speeds, reverse - 2.

The two-stage metal toothed auger system is responsible for excellent snow removal results.

The width of the captured layer of snow is 106 cm, the height is 61 cm. These parameters are optimal for performing large-scale work in an extremely short time.

The width of the captured layer of snow is 106 cm, the height is 61 cm. These parameters are optimal for performing large-scale work in an extremely short time.

The presence of the function of trimming snowdrifts significantly increases the effectiveness of using the described snow blower.

The steel snow discharge chute is adjustable, the maximum throwing distance is 15 m. The mechanism for setting the distance at which it is possible to throw the waste mass is located on the control panel.

For the increased maneuverability of the SM-10613E, the differential lock present in its design is responsible, which makes it possible to make turns even in a confined space. By locking one side of the machine, turning is easy and very fast.

The weight of the unit is 170 kg, which is ideal for working in difficult conditions, when an impressive mass affects the best cross-country ability and stability of the machine.

The properties of its mobility and the characteristics of the course are compared by many of the consumers who have already tested this special equipment in practice with the capabilities of a mini-tank.

The additional grip heating option, also present here, can be very useful in long-term continuous use. The presence of a halogen headlight allows the use of the snowblower even in the dark.

The design of the model under consideration also includes double-sided skids, with the help of which it is possible to adjust the clearance between the ground and the auger itself of the machine.

This snow blower is an excellent example of professional special equipment, sold at a more than affordable cost and with an increased working resource.

This machine is ideal for solving problems faced by both utilities and owners of large land plots, sports complexes with ice cover, etc.

Principle of operation

During the movement of the CM 2 snowblower, a brush-type drum begins to rotate, which has a transverse position with respect to the rails. It throws snow onto the loading conveyor, from where the mass moves further, going to the accumulating apron conveyor, the movement of which is ten times slower than the loading one. Due to this difference, the average carriages are gradually filled with snow to a great height - up to two meters.

If the snow is dense or there is too much of it, then the drum is raised by lowering the scoring knife. The feed rotor is lowered again only when it is necessary to throw the cut mass onto the conveyor. The ice is removed in two or three passes - during the first of them, a cleaver is used by raising the rotor. Then the brush drum works again.

The side fenders, equipped with wheel arch liners, increase the retracted space from 2.45 to 5.1 meters. During transport, they are lifted and stacked parallel to the frame. They are also folded so as not to accidentally damage when the line ends and the station is visible nearby.

Snow or debris accumulated in the intermediate cars is ultimately unloaded at a specific location. This starts the discharge conveyor mechanism, which can be configured to throw snow to the left or right. By the way, it is possible to do this not only in the parking lot, but also during the course of the train.

What you need to know when purchasing a track cleaner

Choosing a petrol crawler snow blower, the consumer should proceed primarily from practical considerations.

Such special equipment should be purchased only if there is a need to care for large areas.

Such special equipment should be purchased only if there is a need to care for large areas.

It is completely unreasonable to spend money on buying such a powerful tool for dealing with snow drifts if the machine will be used to clear paths to the house.

Having established themselves in the decision to become the owner of a crawler-mounted snow blower, each potential owner becomes the owner of truly reliable equipment

First of all, you need to pay attention to the characteristics of the power unit.

The increased power of the engine, designed not only to drive a machine weighing about 200 kg, but also to perfectly cope with snowdrifts of varying degrees of density, in this case is of the most importance. Thus, the ratio of the indicator in 13 liters

with. with a working width of more than 1 m, the SM-10613E is optimal

Thus, the ratio of the indicator in 13 liters. with. with a working width of more than 1 m, the SM-10613E is optimal.

It is the combination of such parameters that ensures a productive workflow in the minimum amount of time allotted for clearing snow. This is where the price of the just mentioned snow blower comes to the fore as the main competitive factor.

Models of such snow blowers from recognized foreign brands, which have functions identical to those of Tselina, in their cost are based on the figures of 100,000 rubles.

The trend of the growing popularity of domestic snow blowers of the described category is becoming clear. Moreover, overseas deliveries of units on tracks are associated with some difficulties, which ultimately affects their final cost.

This kind of problem is absent in the production and sale of Tselina special equipment.

Customers are also attracted by the warranty that the manufacturer extends to their products and the excellent maintainability of these machines.

If necessary, there is always the opportunity to contact the official service centers, where any required technical assistance will be provided.

And, of course, it is important to follow all the recommendations provided by the manufacturer. for the care and operation of snow blowersto maximize the life of the equipment. After all, various problems in the operation of these machines appear in most cases due to inattentive attitude and ignorance of the elementary rules prescribed in the instructions for use.

After all, various problems in the operation of these machines appear in most cases due to inattentive attitude and ignorance of the elementary rules prescribed in the instructions for use.

Domestic snow blower "Celina SM-10613E" is an excellent solution for a prudent owner. Owning such a unit, you can count on durability, excellent performance and operational payback.

Snowblower SM-2

The snow train (it is called that way for short) has been produced since 1958. The main manufacturer is OJSC Transmash, located in the city of Engels, Saratov Region, and created back in 1893. Until 1984, among the manufacturers was also the plant of heavy track machines from Tikhoretsk.

The device consists of four cars that cannot move on their own - a locomotive is required (which can be contacted by an internal phone). The first car is the head car, it contains all the equipment for clearing snow and breaking ice. The conveyor begins here, transferring the snow mass to the conveyors with which all the cars are equipped. The end of the last conveyor is equipped with a special mechanism for lateral unloading of snow. It spreads a mass of up to 6 meters.

The head carriage is equipped with a diesel power plant that supplies power to several engines. It also has a compressor that feeds the pneumatic cylinders of the working mechanisms. The controls are also located in the first and last carriages. According to the rules, a team of three people should serve the train. This is a mechanic, road master and diesel operator.

In winter, the machine is used to remove snow and ice from rails, switch joints and station tracks. This is necessary for the normal functioning of rail transport, as well as for the ability to work track fitters, checking fastenings and troubleshooting.

However, in the summer, the snow plow train also does not stand idle. With its help, you can clear the railway from debris and the resulting dirt. During the movement of the snow train, its speed depends on the thickness of the removed mass - it can vary from 0.6 to 10 kilometers per hour.

Device and principle of operation

The SM-5 machine is distinguished by its compact dimensions and high mobility. It is equipped with special fenders and side brushes. Due to the presence of these elements, weeds and snow are fed into the material cutting area. The latter ensures the flow of the snow mass into the storage container. The unloading process is carried out thanks to the presence of an ejection rotor. During operation, it rotates around an axis, as a result of which the snow is thrown to the side by 20-30 meters.

A brush drum is located at the front of the snow blower. The latter is installed transversely relative to the path. During harvesting, the snow is initially fed to the loading conveyor, and from there to the lamellar accumulator. The loading and accumulating conveyors are equipped with belts that move at different speeds. Thanks to this difference, the thickness of the snow mass on the container storage can be up to two meters.

Snow removal equipment SM-5 also produces ice and compacted snow masses. This is made possible by special devices installed in the middle of the machine.

Fenders at the front of the machine increase the working width. They are attached in a hinged manner and ensure the movement of snow from the tracks into the track. The fenders can be lifted up and folded along the frame. This option makes it easier to transport the machine. The maximum cleaning performance is achieved by installing side brushes. They are located at an acute angle relative to the railroad tracks.

A blade ripper is installed at the rear of the CM-5 snowblower. Here, one more belt conveyor is additionally mounted, but already of a rotary type. During operation, it can change its location. Thus, during track cleaning, the ripper is placed directly under the machine truss. To ensure high-quality unloading of the snow mass, it can turn perpendicular to the farm. The ripper rotates to supply snow to the conveyor belt. Subsequently, the mass is thrown to the side.