How to choose and buy a snow blower for a walk-behind tractor

But it also happens that after looking at the instructions and diagrams on how to make a snow blower for a walk-behind tractor with your own hands, you came to the conclusion that such an activity is not for you, and it will be much easier for you to purchase a ready-made device. However, the prices of snow plows for walk-behind tractors, as well as their characteristics, differ markedly from each other. Making the right choice is not always easy. As an example, consider the most popular options that are in greatest demand today.

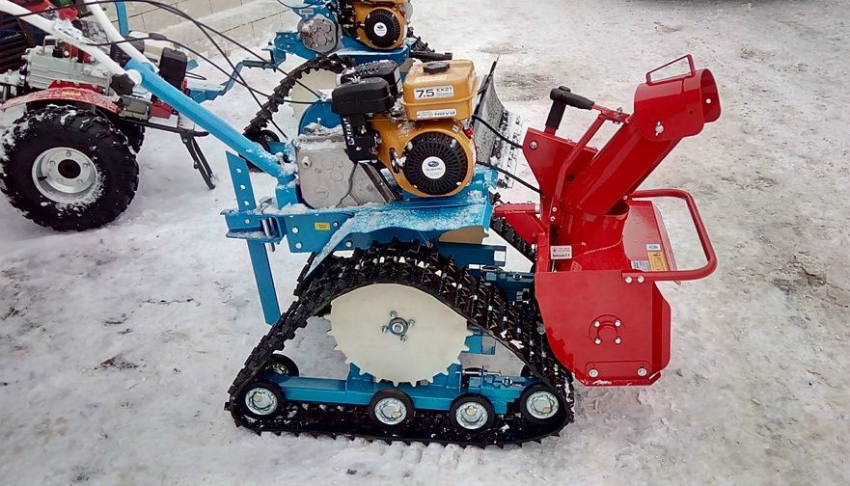

Today's market offers many different designs of mounted snow blowers for walk-behind tractors

Snow blower for the Salute walk-behind tractor: characteristics and features

The snow removal attachment for the Salute walk-behind tractor allows cleaning the surface of the earth from snow at temperatures from -20 to + 5 ° C. It is recommended for use only on flat surfaces, and can be purchased in two different modifications, which differ from each other in the way they are attached to the walk-behind tractor.

Main technical characteristics and parameters:

- dimensions - 600x640x820 mm;

- surface coverage - 500 mm;

- the maximum layer of snow that can be captured is 17 cm;

- screw speed - from 1900 to 2100 rpm;

- weight - 60 kg.

Principle of operation:

- the active part of the structure, the auger, rotating, rakes up snow on its way from the edges to the center;

- special blades located in the center push the snow into the nozzle of the body;

- then the snow is thrown aside.

Snowplow for the Salute walk-behind tractor is recommended for use on flat surfaces

In this model, a lot of adjustments are available, including the range of snow throwing, which can be changed using the visor, as well as the engine speed. In addition, you can change the direction of snow throwing by rotating the screen.

The installation of the snow blower on the Salute walk-behind tractor is carried out as follows: the walk-behind tractor is disconnected, the cotter pin and the footboard attachment axis are removed. On a flat surface, the snow blower is mounted on a walk-behind tractor. To do this, it is necessary to insert the hitch into the frame so that the bolt with the spacer sleeve enters the hitch groove. After that, connect the hitch to the snow blower body using two bolts without tightening them.

After that, it is necessary to put on the snow blower drive belt, having previously removed the protective covering of the power take-off shaft pulley. Moving the hitch along the beam, adjust the interposition of the elements so that the belt engages smoothly, without distortions. Then the bolts can be tightened. Next, the protective cover of the PTO pulley is installed in place and secured.

Mounting scheme for attachments of the Salute walk-behind tractor

Snow blowers MTD: which model is better to choose

Another popular option to avoid making a snow removal nozzle for a walk-behind tractor with your own hands is to purchase special equipment manufactured by MTD. Today it is considered one of the best, and has a fairly wide selection of models, the most popular among which are MTD-M 61, MTD-ME 66, MTD-640 and MTD-M56.

Having familiarized yourself with the technical characteristics, as well as the main tasks that these devices are designed to solve, you can easily decide which of the options is best for you. For example, the M-61 model is great for clearing large flat surfaces, while the ME-66 is more focused on difficult weather conditions and severe icy snowdrifts.

The cost of snow blowers also varies depending on their purpose. So, the most budgetary model is the M-56.Its cost ranges from 35-37 thousand rubles. ME-61 will cost a little more - about 49 thousand rubles. The average option can be considered M-61 - 44 thousand rubles.

Snowblower manufactured by MTD

Varieties

Snow blowers are one of the options for trailed equipment for this motor vehicle. The manufacturer has developed several modifications of snow throwers. All samples of devices for removing snow masses for the "Neva" walk-behind tractor are auger structures with ejection of snow masses from the side (side discharge). The most popular types of this trailed equipment are considered to be several modifications.

"MB2"

Many people believe that this is what snow throwers are called. In fact, "MB2" is a walk-behind tractor brand. The snowplow is used as a nozzle. "MB2" goes for other motor vehicles "Neva". The structure of the compact packing is elementary. A screw conveyor is enclosed in the body of the iron body. Welded spiral strips are used as knives. The discharge of the snow mass to the side is carried out by means of a sleeve (snow plow). The sweep of the capture of the snow layer is equal to 70 centimeters with a thickness of 20 centimeters. The throw distance is 8 meters. The weight of the device is no more than 55 kilograms.

"SM-0.6"

It differs from "MB2" by the device of the screw conveyor. Here it is made in the form of a set of blades, similar to the fan wheels assembled in a pile. The toothed screw conveyor handles hard snow and ice crust effortlessly. In terms of size, this unit is more small-sized than the brand "MB2", but its productivity has not decreased from this.

The discharge of the snow mass is also carried out by means of a snow deflector to the side at a distance of up to 5 meters. The range of capture of the snow layer is 56 centimeters, and its maximum thickness is 17 centimeters. The mass of the device is at most 55 kilograms. When working with a snow thrower, the Neva unit moves at a speed of 2-4 km / h.

"SMB-1" and "SMB-1M"

These snow-clearing sheds differ in the structure of the working device. The SMB-1 brand is equipped with a screw conveyor with a spiral strip. The sweep of the grip is 70 centimeters, the height of the snow cover is 20 centimeters. The discharge of the snow mass through the snow deflector is carried out at a distance of 5 meters. The weight of the device is 60 kilograms.

The SMB-1M attachment is equipped with a toothed screw conveyor. The gripping span is 66 centimeters and the height is 25 centimeters. The discharge of the snow mass through the sleeve is also carried out at a distance of 5 meters. Equipment weight - 42 kilograms.

How to make a snow blower from a walk-behind tractor

Before you take on the independent manufacture of a snow blower, you need to sensibly assess your skills, since the task will require effort. At the heart of the most common home-made is the Neva, Honda walk-behind tractor. The attachment can be made in three versions:

- The nozzle, like a bulldozer, is attached to the walk-behind tractor by means of a special adapter. The layer of snow is cut off with a knife - a metal sheet with a sharp edge.

- There is a more complex way that requires a blueprint. Design - a rotary nozzle consisting of a box, auger and a pipe that ejects snow. This is the most efficient two-stage system.

- Another tricky way is to make a fan blower. With the necessary skills and time, a fan is made, the blades of which scoop up the snow and throw it through the pipe.

You can make a snow blower for a walk-behind tractor from scrap materials. To make a snow shovel for a walk-behind tractor, you need tools: a tape measure, a drill, a grinder, a welding machine. You will need an unnecessary large diameter pipe or barrel.

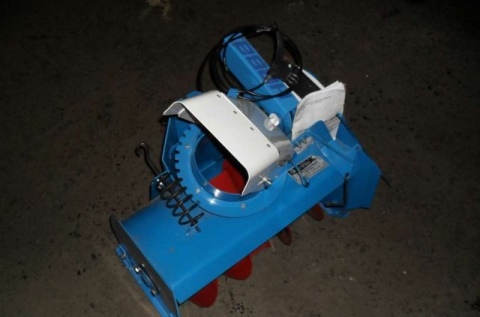

Self-made snow blower

Cut out the dump of the desired depth from 2 halves of the barrel, you can use a curved sheet of metal with a thickness of 2 mm or more. They are scalded with a rigid frame, and internal struts are made to ensure rigidity.A steel semicircle with three holes is welded to adjust the direction of rotation. Fastening to the walk-behind tractor is made of a rod and brackets, the holder is fixed in the center of the blade.

Note! If you plan to make a more complex option, then the whole difficulty lies in the manufacture of an auger located inside the box. You can take an old auger from any equipment

The auger is made from a pipe, with holders on the sides. The working part is made of metal blades of the same size, between which equal gaps are left

You can take an old auger from any technique. The auger is made from a pipe, with holders on the sides. The working part is made of metal blades of the same size, between which equal gaps are left.

For the manufacture of a screw auger, 8 large and 4 slightly smaller disks are cut out of metal sheets. They are put on the shaft. It is necessary to monitor the rigidity of fastening structural parts, counting on intensive use. The rotor is made from an aluminum boiler with a volume of 20 liters. For fixation on the front wall of the auger, rivets (4 mm) are used.

A snow plow in the form of a pipe with a socket is welded in the central upper part of the box. The work is carried out using the rotating shaft of the cultivator. To transmit torque, adapters are required, for example, a flexible belt hitch (A-100 belt).

The purchase of mounted snow-clearing equipment makes the walk-behind tractor a universal assistant on the farm. It is better to buy in specialized stores with guaranteed product quality.

vote

Article Rating