Popular brands

Today, on the market for mounted snow plow equipment for an ATV, there are 3 groups of sets.

- Chinese.

- American.

- Russian.

Dumps from China

The products of Chinese trade brands are relatively inexpensive, which cannot but draw attention to it. They are equipped with a metal bucket with a metal thickness of up to 2 millimeters and a width of up to 125 cm.

Products from China are famous for their low quality and low practicality. There is no protection against obstacles in the structure of the bucket. Some companies have recently begun to equip their devices with such devices.

Nevertheless, the quality of the plows has not improved, since low-power springs are installed. The list of shortcomings of attachments from the Middle Kingdom also includes the attachment of the blade to the frame. The equipment is fixed at only one point. The affordable price is due to the use of inexpensive materials in the manufacturing process. The bucket components are crude and crude, and the size of the dump is not able to fully satisfy the needs of consumers.

Dumps from America

One of the most recognized Western manufacturers of snow attachments is Warm.

Products of this brand are ranked in the high price segment. However, the price is fully justified by the quality characteristics. The American bucket stands out for its exceptional strength and well thought-out structure. High-quality painting, made according to innovative technological schemes, guarantees a long service life of the attachments.

The collision protection provided in the design is reliable due to the presence of powerful springs. The large width of the shovel should also be highly appreciated, which increases the productivity of cleaning. The blade is attached to the ATV with a quick release attachment. The disadvantage of American products is the high price and a rather small range of buckets available on the Russian market of attachments.

Domestic dumps

The most popular Russian manufacturer of ATV buckets today is Atvstar. Its products are no worse in quality than attachments from America, but their cost at the same time is much lower.

The blade (with quick release) is fixed on the ATV in almost 5-7 minutes using the quick-release platform. In the trade there are both not very large and large-sized, powerful dumps.

The thickness of the steel, depending on the modification, ranges from 2 to 3 millimeters, and the blade width is 125-150 cm. The bucket is adjustable and takes one of 7 available positions. The devices have protection against collisions with obstacles, which folds the blade and, by means of springs, returns it to its initial position. A reliable shock-resistant paint layer contributes to the long-term use of Russian-made attachments.

Blade working video

Well, the video of working with the blade, as you can see, the blade is rowing a lot of snow, and is limited only by the Niva's cross-country ability, so far the tires are ordinary, road studded tires, the Niva is not very passable on it, but this is enough to clear snow from the road.

Further operation of the blade on the Niva

In general, it performs its functions 100%, the height of the shovel itself suits, it is not necessary below, because it will throw snow onto the car, the angle from the car is also normal, but you can increase it a little, put an additional PTF on the roof, because the blade covers the headlights, and they become useless.

There are 100 wadded halogens, how they shine is a separate topic, they shine over the dump onto the road, one closer, the second farther away.

How not to do

Now about why the dump had to be repaired, this nuance should be taken into account by absolutely everyone who wants to make a dump on the Niva with their own hands, the fact is that with short pulls of the dump to the Niva, you run the risk of getting such an embarrassment

Everything is fine with the car, I crumpled my skirt a little. but the dump got it, broke off a long pull. Acceleration was in third gear. on the reduction gear, I wanted to break through a caked pile of snow, in general I suffered from garbage. It turned out this way because the thrust, which is shorter (right), after a small repair (on the same day) was slightly shortened.

The dump successfully served faithfully for several months, then, upon impact, they broke off this left thrust, and welded literally 5 centimeters closer to the car, as a result, a short shoulder, and as a result, the dump went under the car.

In the photo above, this is the minimum shoulder, its size is 60 cm, but it is better to make more, to be sure that the blade does not turn down under the car, with a strong impact.

How to choose?

When choosing a snow thrower, you should pay attention to the material for making the working area. It must be steel at least three millimeters thick.

Now let's move on to the rest of the parameters.

- Height and width of capture. If a complete cleaning of the site is not provided, but only the opportunity to make a path in the snowdrifts from the gate to the garage, from the house to ancillary structures, most of the products sold will do. Most often, you can find a capture span of 50-70 centimeters. In most cases, the technique is capable of functioning in snowdrifts 15-20 centimeters deep, there are devices for 50-centimeter snowdrifts.

- Snow deflector. The removed snow mass is removed by means of a snow deflector. To what extent it will be comfortable to clean snow masses with a walk-behind tractor depends, by and large, on the characteristics of the snow thrower pipe. The snow throw distance and the pivot angle of the snow plow are important. Snow throwers are capable of throwing snow from 5 to 15 meters at an angle of 90-95 degrees to the side, relative to the direction of travel.

- Rotation speed of the screw conveyor. Individual snow throwers have the ability to change the rotation speed of the auger conveyor by adjusting the chain mechanism. This is practical when working with snowdrifts of varying heights and densities.

- The actual speed of the machine. The bulk of snow removal equipment moves at a speed of 2-4 km / h, and this is enough. Clearing snow masses with a walk-behind tractor at a speed of 5-7 km / h is uncomfortable, since the worker gets into the epicenter of the "snow cyclone", the visibility decreases.

Self-production

Manufacturing of items for heavy equipment is only available in the factory. A simpler model for a walk-behind tractor or an SUV is quite capable of being made by a home craftsman of average skill.

It is better to make this element according to ready-made drawings. It is better to cook the frame from a steel pipe, and use sheet steel for the bucket. Remember to reinforce the bucket with stiffeners

And also pay special attention to the installation of protective rubber elements on the bottom of the shovel.

Another interesting way to make a blade is to make it from an unnecessary gas cylinder. You need to cut off the ends from it, then cut it lengthwise and weld reinforcing ribs and an attachment point to it.

Selection Tips

When making a choice between specific models, you should pay attention to the main characteristics of the blade

- Mass - it is on the mass of the element that it mainly depends on which machine it can be used with. Heavy blades cannot be used on walk-behind tractors, and lightweight blades are useless on off-road vehicles and can quickly break down.

- Attachment point - it is imperative to find out whether it is possible to install the selected model on your existing equipment. For snowmobiles and auto dumps, they are mounted on a stretcher, so it is worth choosing this element for your equipment in advance.

- Dimensions, especially width - wide blades are well suited for quickly cleaning large areas and clearing roads, but they should only be used with fairly powerful vehicles. Narrow plows are better at clearing narrow aisles (for example, in home gardens) and require less machine power.

- The installed system of protection against solid obstacles - it is difficult to notice curbs, stones and metal structures under a layer of snow, and hitting them at speed is fraught with breakage of both the blade and the walk-behind tractor or snowplow. Most often, rubber scrapers are used for this, more expensive models are additionally equipped with return springs. If you are purchasing a model with springs, it is worth making sure that the structure is equipped with rebound dampers.

- Rubber used - the choice of rubber is very important both for the safety of the cleaned road surface and in terms of the blade's resistance to wear. The previously popular rubber with metal wire reinforcement has recently been replaced by newer materials reinforced with polyamide or nylon fibers. The use of ordinary rubber without hardeners is fraught with the need for frequent replacement of scrapers.

- Control system - for low-power equipment such as snowmobiles, motoblocks and snowblowers, a blade is enough without adjustment or with the ability to set the angle of attack.

When choosing a spare or replaceable blade for a snow thrower or walk-behind tractor, try first of all to consider the options from the standard equipment of your equipment - you will definitely not have compatibility problems with them.

For information on how to make a do-it-yourself snow plow for an ATV, see below.

Let’s block ads! (Why?)

Selection Tips

When making a choice between specific models, you should pay attention to the main characteristics of the blade

- Mass - it is on the mass of the element that it mainly depends on which machine it can be used with. Heavy blades cannot be put on walk-behind tractors, and lightweight options are useless on off-road vehicles and can quickly break down.

- Attachment point - it is imperative to find out whether it is possible to install the selected model on your existing equipment. For snowmobiles and auto dumps, they are attached to a stretcher, so it is worth choosing this element for your equipment in advance.

- Dimensions, especially width - wide blades are well suited for quickly cleaning large areas and clearing roads, but they should only be used with fairly powerful vehicles. Narrow blades are better at clearing narrow aisles (for example, in home gardens) and require less machine power.

- The installed system of protection against solid obstacles - it is difficult to notice curbs, stones and metal structures under a layer of snow, and hitting them at speed is fraught with breakage of both the blade and the walk-behind tractor or snowplow. Most often, rubber scrapers are used for this, more expensive models are additionally equipped with return springs. If you are purchasing a model with springs, it is worth making sure that the structure is equipped with rebound dampers.

- Rubber used - the choice of rubber is very important both for the safety of the cleaned road surface and in terms of the blade's resistance to wear. The previously popular rubber with metal wire reinforcement has recently been replaced by newer materials reinforced with polyamide or nylon fibers. The use of ordinary rubber without hardeners is fraught with the need for frequent replacement of scrapers.

- Control system - for low-power equipment such as snowmobiles, motoblocks and snowblowers, a blade is enough without adjustment or with the ability to set the angle of attack.

When choosing a spare or replaceable blade for a snow thrower or walk-behind tractor, try first of all to consider the options from the standard equipment of your equipment - you will definitely not have compatibility problems with them.

For information on how to make a snow plow with your own hands, see below.

Material selection

At this stage, the choice always remains with the performer, you can only advise or suggest where it is easiest to find suitable parts. Two-hundred-liter barrels have proven themselves well as material for a moldboard shovel, but given the planned dimensions, 2 barrels or additional structural reinforcement will be required. Square or rectangular pipes can be used as guiding and reinforcing ribs, it is also possible to use a rolling angle, a thin channel or I-beams.

For adjusting the angle of inclination of the blade of the jumpers, you can use lanyards or pipes of different diameters with holes for fixing fingers. When using a winch to control the lift of the blade, additional material will be required to equip the platform for the winch itself and the block system, if necessary.

How to do it yourself

To make a blade, you need the tools and equipment that every home workshop has.

For work you will need:

- welding machine;

- Bulgarian;

- electric drill;

- roulette;

- square;

- durable knife;

- adjustable wrench;

- core;

- sandpaper;

- paint brush.

Necessary materials:

- steel barrel 200 l;

- 2 springs from UAZ or GAZ;

- profile pipe 20x40 mm;

- iron corners 30x30 mm;

- hardware (bolts, washers, nuts);

- car tire;

- acrylic paint.

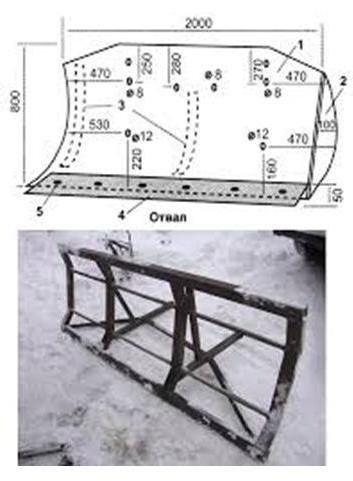

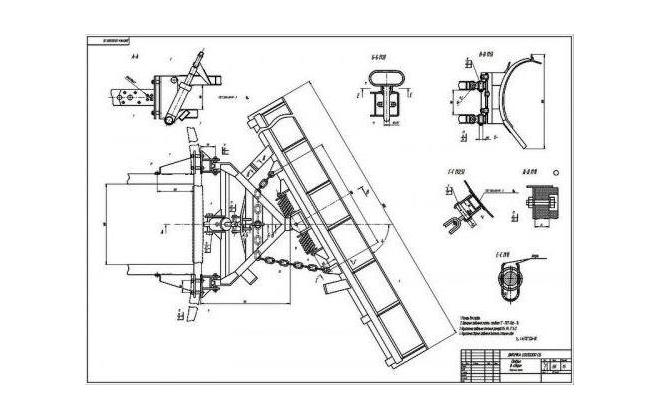

To make a do-it-yourself blade on a UAZ, the drawings should be prepared for 4 nodes of this product: an installation device, a stretcher, a knife and a lifting mechanism.

The sequence of work is as follows:

- Shovel making. It is cut out of the barrel, half or a third of it is used. Along the perimeter and in the middle, the workpiece is reinforced with a steel corner, which is welded or screwed to it. The width of the shovel can be in the range of 100-200 cm, and the height - 40-80 cm. A knife from a steel strip of 100x20 mm or a cut tire is installed on the lower part.

- Installation kit. It can be of the central or frontal type. It is preferable to choose the second type, which is more durable and reliable, allows you to evenly distribute the load over the shovel frame. 2 brackets are made from a profile pipe with lugs for fastening. A turning mechanism is provided.

- Stretcher. Made of durable metal. Constructions are made of a removable or stationary type. Removable mounts are fixed to the bumper, and stationary mounts are rigidly screwed to the car frame.

- Lift. A standard or separately purchased electric winch is used to adjust the height above the ground. A simpler solution is a hand winch, but you have to get out of the cab to lift it. The easiest option is to attach steel skis with level adjustment to the shovel.

After the production of individual units, they are assembled and installed on the machine.

Varieties

The main division of snow blowers is carried out according to the type of work cycle:

- single-stage, with a combined working cycle, that is, both the breakdown of snow masses and their transfer is carried out by the same unit;

- two-stage, with a divided cycle of work - the snowplow has two separate working mechanisms responsible for the development of snow debris and their clearing by throwing the snow mass.

Advantages of one-stage snow blowers:

- compactness and increased maneuverability of the apparatus;

- higher travel speed.

The disadvantage of such machines is their relatively low performance.

Single stage

The single-stage type of snowblowers includes plow-rotary and milling snowplows. The former are usually used to clear snow drifts from roads. In cities, they can be used to clean sidewalks and small streets. With an increased density of snow debris, they are considered ineffective.

Milling or milling-plow snow blowers were popular in the sixties of the XX century. The principle of their operation was slightly different from the plow-rotary counterparts: the throwing rotor was replaced by a milling cutter, which, thanks to the torque moment, cut the snow mass and transmitted it to the bell. But numerous shortcomings of this type of technology quickly reduced the popularity of such machines and they "went out of the way."

Two-stage

The two-stage type of snowplow includes auger and rotary milling units. The main difference between them lies in the design of the feeding mechanism, which is engaged in cutting the snow mass and feeding it into the snow thrower.

Rotary auger snow blowers are currently very popular in Russia. They are hung on cars and trucks, tractors and special chassis. They are designed to rake snow shafts left by other types of snow plows, and load the snow mass into trucks using a special chute. They are used to clear snow both within the city, on highways, and on the runways of airports and airfields.

Advantages of auger snow blowers:

- high efficiency when working with deep and dense snow cover;

- large throwing distance of treated snow.

But this type has its disadvantages:

- high price;

- large dimensions and weight;

- slow movement;

- operation only in winter seasons.

Rotary auger snow blowers are divided into single-engine and twin-engine. In single-engine models, both travel and operation of the snow blower attachments are powered by a single engine. In the second case, an additional motor is installed to power the snowplow.

The main disadvantages of the twin-engine design of auger snow blowers include the following points.

- Irrational use of the main chassis motor power. When used as intended, the efficiency is less than 10%, for a long time the speed is less than the nominal. This leads to clogging of the combustion chamber, injectors and valves with the products of combustion of the fuel mixture, which, in turn, leads to excessive consumption of fuel and accelerated wear of the engine.

- Cross arrangement of motor drives. The motor that drives the snow blower mechanism in front of the cab is located at the rear of the machine, and the main motor that drives the equipment is at the front.

- Significant loads on the front axle in travel mode. This can lead to a breakdown of the bridge, to prevent such malfunctions for auger rotor machines, a speed limit of up to 40 km / h is set.

Product characteristics

There are a huge number of different snow removal equipment on the market today.

For example, the Impulse SR1730 model made in Russia has a working width of 173 cm for clearing snow, with a mass of 243 kg. And Impulse SR1850 is capable of cleaning a strip 185 cm wide at approximately 200 m3 / h, the weight of the device is already 330 kg. The mounted rotary milling unit SFR-360 captures a width of 285 cm with a capacity of up to 3500 m3 / h and is capable of throwing the processed snow mass at a distance of up to 50 m.

If we take a screw-rotor mechanism made in Slovakia, the KOVACO brand, then the cleaning width varies from 180 to 240 cm. The weight of the unit is from 410 to 750 kg, depending on the configuration. Spent snow throwing distance - up to 15 m.

The KFS 1250 rotary milling snow blower has a weight of 2,700-2,900 kg, while the snow capture width varies from 270 to 300 cm.It is capable of throwing snow at a distance of up to 50 m.

Gf gordini tn and the GF Gordini TNX clear an area of 125 cm and 210 cm, respectively, throwing snow at a distance of 12/18 m.

The rotary milling mechanism "SU-2.1" made in Belarus is capable of processing up to 600 cubic meters of snow per hour, while the width of the working strip is 210 cm.The throw range ranges from 2 to 25 m, as does the cleaning speed - from 1.9 to 25.3 km / h.

The Italian F90STi snow blower also belongs to the rotary-milling type, the weight of the device is 13 tons. Differs in high productivity - up to 5 thousand cubic meters per hour with cleaning speed up to 40 km / h. The width of the processing strip is 250 cm. It is used for clearing the runways of airfields.

The Belarusian SNT-2500 snowplow weighs 490 kg and is capable of handling up to 200 cubic meters of snow mass per hour with a coverage width of 2.5 m. Waste snow is thrown at a distance of up to 25 m.

The LARUE D25 model snow blower also belongs to high-performance devices - it is capable of processing up to 1100 m3 / h with a working area width of 251 cm. The weight of the device is 1750 kg, the snow throwing distance is adjustable from 1 to 23 m.

These technical characteristics are for informational purposes only, and at any time can be changed at the request of the manufacturer, therefore, when choosing a model of a snow blower, carefully read the instructions and technical characteristics of the intended purchase.

Buy or do it yourself?

For snow removal to be carried out quickly and easily, all attachment parts must be of high quality and durable. Some ATV owners prefer to make do-it-yourself dumps, but it is more advisable to purchase additional equipment for several reasons.

A commercially available dump bucket is usually made from steel sheet with a thickness of about 2-2.5 mm or more. At home, it will be difficult to bend such material correctly. The metal is covered with a protective layer of paint, which is baked at high temperatures. It adheres firmly to the surface, without collapsing under the influence of mechanical and other unfavorable influences. A layer of paint reliably protects the metal from corrosion.

At home, it is impossible to paint the metal of the bucket with such high quality. Therefore, it will be permanently damaged during snow removal work. It will need to be painted again at least once a season to avoid corrosion.

Purchased attachments are manufactured in accordance with applicable standards and have a number of additional functions, therefore, they have a significant operational resource. If you create such products with your own hands, you will not be able to achieve the same high quality. For this reason, it is better to opt for a reliable commercial blade made by a trusted manufacturer.

We make the blade ourselves

Making a blade for clearing snow with your own hands is not difficult if you have a welding machine, a drill, a tape measure and a grinder on your farm.

Here is one simple design for ATV owners. You will not have to look for a suitable metal for a long time, since an ordinary 200-liter steel barrel is quite suitable for this. Carefully cutting it into 3 pieces, we get curved segments for the shovel. Weld two of them along the contour, and the resulting 3 mm metal thickness will be quite enough for rigidity.

The bottom of the blade must be reinforced with a knife. This requires a 5 mm thick steel strip with a length equal to the width of the scraper. It is necessary to pre-drill holes in the knife with a diameter of 5-6 mm and a pitch of 10-12 cm for attaching a safety rubber strip.

The most difficult and critical parts of the entire structure are the attachment frame and subframe that connect the blade to the ATV. Therefore, it is better to buy them so as not to engage in painstaking shooting of the installation dimensions under the car. It is much easier to adapt a self-made snow plow to the factory fasteners and this work can be done "on site".

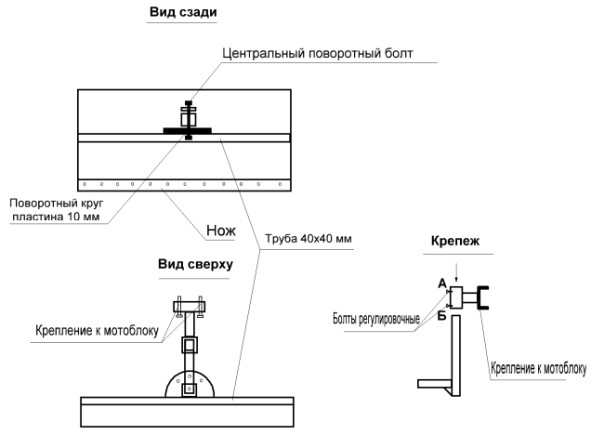

For a walk-behind tractor, the fastener design is much simpler and may well be made in a home workshop. To do this, a 40x40 mm square pipe must be welded to the blade welded from two halves of the barrel for reinforcement.Then a semicircle of thick steel with three holes is welded to the pipe, which are necessary to fix the angle of rotation of the shovel.

After that, an L-shaped holder is welded from the same pipe, one side of which is inserted into the mount on the blade, and the other is attached with bolts to the frame of the walk-behind tractor. To adjust the height of the shovel, two bolts A and B are used. They are screwed into the holes drilled in a piece of square pipe welded to the hitch and put on the L-shaped holder.