How to choose a technique to create an all-terrain vehicle

As for the type of all-terrain vehicle that can be suitable for creating a snow and swamp vehicle, then almost any option can be chosen. But not all equipment of this type can be easily upgraded. Experts most often use the Neva to create all-terrain vehicles, since these motor-cultivators are the most versatile.

The main thing in a walk-behind tractor is the presence of a cooling system

If you plan to transport goods or people on an all-terrain vehicle, you should pay attention to models with a powerful engine. To create a snowmobile, it is better to take the equipment that is equipped with a four-stroke engine.

The thing is that such engines start much better in any weather. Moreover, the four-stroke power unit will not cause problems even in sub-zero weather, and it is at this time that the snowmobile is planned to be used.

Regarding what exactly the engine should be, it is impossible to say unequivocally. Both gasoline and diesel power units are suitable for working on an all-terrain vehicle. Each case has its own pros and cons. The thing is that gasoline is more expensive. But diesel fuel freezes in freezing temperatures, so it is not suitable for a snowmobile.

Models of equipment for moving on snow or off-road also do not play a big role. Now both reliable Belarusian versions and good Chinese equipment are being sold, which are notable for an affordable price with quite acceptable quality. The main thing is to choose those models that are popular. In this case, if repairs are needed, you will not have to spend a lot of time searching for spare parts.

If you plan to create a tracked all-terrain vehicle, it is best to pay attention to the one-piece frame. The national team will have to work hard to achieve the desired result

Homemade snowmobile on tracks with your own hands: where to start?

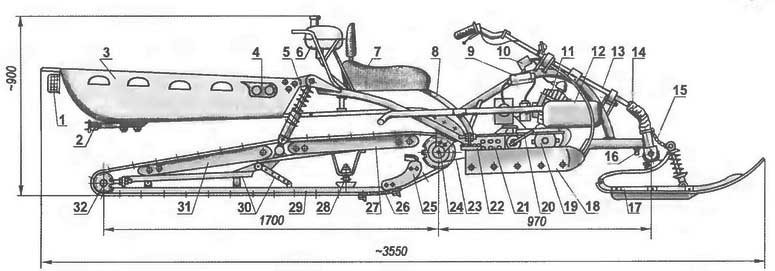

1 - rear light; 2 - hitch; 3 - body (plywood, s16); 4 - side reflectors; 5 - rear shock absorber (from the Dnepr motorcycle, 2 pcs.); 6 - gas tank (from the launcher of the T-150 tractor); 7 - seat; 8 - main frame; 9 - electronic ignition switch (from the Voskhod motorcycle); 10 - ignition coil (from the Voskhod motorcycle); 11 - power plant (from a motorized carriage, 14 hp); 12 - muffler (from motorized carriages); 13 - steering column; 14 - steering joint in a leather case filled with grease (joint from "UAZ"); 15 - limiter for vertical movement of the steering ski (chain); 16 - steering ski turn limiter; 17 - steering ski; 18 - side ski (2 pcs.); 19 - generator; 20 - clutch lever (from a motorized carriage); 21 - drive chain shield; 22 - footboard; 23 - drive shaft drive chain; 24 - the drive shaft of the caterpillar; 25 - lower track chain guide (polyethylene, s10, 2 pcs.); 26 - caterpillar chain (from the header of the forage harvester, 2 pcs.); 27, 31 - upper front and rear chain guides (polyethylene s10, 2 pcs.); 28 - shock absorber of the propeller hinge frame (shortened rear shock absorbers of the Dnepr motorcycle, 2 sets); 29 - support ski; 30 - rear spacer frame; 32 - rear axle.

A drawing of a homemade snowmobile is the most important stage in the preparatory stage of manufacturing. Here, engineering skills will come in handy, and in the absence of such, surface sketches are made, creating a general image of the future mechanism.

Before creating a drawing, it is necessary to determine the list of required components. The basis of the standard configuration of the snowmobile is:

- Frame - depending on the complexity of the design, it can be borrowed from an ATV, motor scooter, scooter, motorcycle, etc.In the absence of them, the part is usually welded from thin-walled metal pipes with a diameter of about 40 mm.

- Seat - given the difficult operating conditions of the equipment, the material of this element must have a high water-repellent ability.

- Engine - is selected with the calculation of the required speed and the total weight of the vehicle. The most commonly used motors are motoblocks, scooters, motorcycles, etc.

- Tank - 10-15 liter metal / plastic container will fully provide carefree trips over relatively long distances and will not take up much space on the unit.

- Skis - in the absence of ready-made options, it is recommended to use nine / ten-layer plywood sheets with a thickness of about 3 mm for self-production.

- Steering wheel - chosen with the calculation of convenience and practicality. Similar to the frame, engine and seat, it is removed from the specified two-wheeled units.

- Drive - a part that transfers rotary motion from the engine to the track. A motorcycle chain performs this function well.

- The caterpillar is the most complex and important element. Their types and methods of self-production will be discussed further.

Algorithm for the execution of parts

There are several proven ways to make a caterpillar with your own hands. They have proven to be the most reliable.

Application of the conveyor belt

It is considered one of the simplest methods. In addition to the conveyor belt, a sleeve roller chain is required. The simplicity in this case lies in the fact that manufacturing does not require a large amount of auxiliary materials and tools. To extend the life of the conveyor belt in the device, you need to circle it around the edges with fishing line

In this case, it is important to ensure a step of 10 mm. To connect the tapes, in this case, a ring is necessary, you need to sew it along the ends or use hinges

Particular attention is paid to the thickness of the conveyor belt. The level of load on the unit directly depends on this.

Optimal will be the selection of a tape with a thickness of at least 7 mm. Among other things, you will have to take care of an additional wheel on each side.

You can remove it from the old car, but it is important that its diameter coincides with the same parameter for the wheel on the walk-behind tractor

Car tire use

For a walk-behind tractor, they often take tire tracks... Craftsmen claim that the design has high reliability when the specified element is included in it. In order for the resulting walk-behind tractor to be practical, it is imperative to take care of the quality of car tires. They must have the correct tread pattern. In this regard, tires from large cars and tractors are preferable. The tread pattern is of key importance as it acts as a lug.

The manufacturing process can be roughly divided into several stages. Here they are:

- After finding suitable tires, a track for tracks is cut out of them. This is a laborious job that will take a long time.

- Use a well-sharpened knife for cutting. Better to take the one that shoemakers use. From time to time, it must be moistened in a soapy solution. This will make the rubber easier to cut.

- Both sidewalls are cut from the tires. To simplify the process, you can use a jigsaw with fine teeth for this. Remove excess fragments inside the tire, if necessary. If the track is too hard inside, this manipulation can be repeated.

Thanks to this, it is possible to improve the indicators of the reliability of the tracks, which is especially important in conditions of heavy loads. Yet such tracks are of a rather limited length.

It corresponds to a similar parameter for a car tire.

Of chains and belts

Track ATVs are often manufactured using conventional V-belts. They are connected between themselves by means of lugs. The belts are attached with screws or rivets.

An additional way is to use chains of the same size. This material is often found in large quantities in the garage of summer residents. The manufacturing process boils down to the following points:

- Take 2 chains of the same size. The last links are broken, after which they are combined into a closed ring. The links are pinched and welded.

- With lugs, they connect the chains to each other and provide reliable fastening. These fixtures can be made from simple steel plates of suitable thickness. They are connected by means of bolts.

If you don't want to make tracks yourself, you can take such products from old technology. For example, a walk-behind tractor on Buran tracks demonstrates good efficiency. It makes sense to use just the old parts, since the new Buranov tracks are quite expensive.

Engine selection

Gasoline engines are used for motoblocks or sidecars. The engine speed is controlled by the throttle stick placed on the rudder grip. To make a homemade tracked snowmobile with your own hands, the easiest way is to use ready-made small-volume engines for walk-behind tractors with pre-installed:

- Fuel tank.

- Ignition system.

- Reduction gear with a ratio of 1: 2.

- Centrifugal clutch that automatically engages when revving up.

The power of these motors does not exceed 10 horsepower, but they are easy to install: the master does not need to separately assemble the ignition system, supply fuel pipes, adjust the clutch, etc. There are different options on the market:

| Brand | Model | Power, hp with. | Volume, cm3 | Weight, kg | Approximate price, thousand rubles |

| Kipor | KG160S | 4,1 | 163 | 15,5 | 20−25 |

| Sadko | GE- 200 R | 6,5 | 196 | 15,7 | 15−20 |

| Lifan | 168 FD-R | 5,5 | 196 | 18,0 | 15−20 |

| Zongshen | ZS168FB4 | 6,5 | 196 | 16,0 | 10−15 |

| Nomad | NT200R | 6,5 | 196 | 20,1 | 10−15 |

| Brait | BR-177F-2R | 9,0 | 270 | 30,0 | 10−15 |

| Honda | GX - 270 | 9,0 | 270 | 25,0 | 45−50 |

If it is not possible to purchase a ready-made engine from a walk-behind tractor, then you can use an engine from a motorized carriage. Such engines are more powerful by 10-15 horsepower, but require self-assembly. The system includes:

- Engine.

- Clutch.

- Reducer.

- Gas tank (volume 5-10 liters).

- Muffler.

- Generator.

- Switch and electronic ignition coil.

Types of homemade snowmobiles

Even without global modifications, you can get a decent all-terrain vehicle by putting snowmobile wheels on the walk-behind tractor and fixing a small trailer. As for snowmobile wheels, they can be made in the form of tracks or wheels directly.

Crawler

The caterpillar track is constructively considered more difficult to perform. In fact, we are talking about a caterpillar attachment, the operation of which is provided by the main motor. Units of this kind are distinguished by a high level of cross-country ability, reliability and stability. If there is heavy snowfall in your area in winter, this technique will be indispensable.

For making the tracks directly, a conveyor belt, a motorcycle chain and a water pipe are suitable.

The use of a fishing line for sheathing the edges of the tape will significantly extend its operational life. Aim for 10 mm spacing when sewing stitches. It remains to sew the edges so that the tape is closed in the form of a ring. Even if the snow is loose and deep, the self-made self-propelled gun will not slip, but remember that maneuverability will decrease with high cross-country ability, since the weight factor will play a role. The undercarriage of the tracked unit can reach a weight of 30 kg.

Wheel travel

If the snow cover in winter in your area is not too high, it is more advisable and economical to give preference to the wheeled option. All you need is a compact trailer and matching wheels. The maneuverability in this case is much higher, since the specific weight of the rear-mounted wheels is relatively low. The installation of special chains will prevent the equipment from slipping in the loose snow cover. There are two ways to make wheels:

- Truck cameras can be used to craft wheels. Lower them and put them on the wheels of the walk-behind tractor.In the final step, use chains to wind the wheels, fix the ends and only pump them with a pump last.

- Equip the wheels of the trailer and walk-behind tractor with metal hoops. One per wheel is sufficient. When choosing the size of the hoop, be guided by the dimensions of the wheel. The width should be 2-3 times larger than that of the wheel, and the diameter should be slightly smaller. Weld some metal plates on the back of the hoop to increase the level of adhesion to the surface and to ensure the stability of the unit. The optimum plate thickness is 25 mm. This will create a simulated lug. Before putting on the hoop, be sure to lower the cameras, they will be tightly pressed against it after inflation.