Orbital sander MAKITA BO5031

makita/ .

In the top of the grinder Makita 9404there is a branch pipe for removing dust. Choosing a sander for wood, bosch and makita, sander for. As standard, the sander comes with a dust bag that fits over the nozzle. For better dust removal, of course, connect a vacuum cleaner to the nozzle. A hose with an inner diameter of twenty-eight mm must be used to connect the vacuum cleaner to the sander.

The power button is conveniently located at the bottom of the rear handle. Makita cordless sander makita wood sander. It is similar to oil with a lock that allows you to lock the button in the pressed position for convenience during prolonged use.

An important feature of the Makita 9404 belt sander is the housing design. The machine is designed so that one side can be pressed as close as possible to the wall when sanding the floor

Optionally the model Makita 9404can be turned into a table sander. To this end, Makita manufactures a special tool with part number 193055-3. After assembling the device, the grinder is installed on the table with an abrasive belt upwards, which does not allow not only grinding the workpieces, but giving them different shapes.

The speed of rotation of the tape at the model Makita 9404high enough that the friction between the sole of the sander with a non-abrasive belt will cause the tool to heat up strongly. Grinding machine for wood - buy. To reduce friction, a graphite-coated plate (art. 193201-8) is installed on the sole. The graphite coated plate is used in conjunction with a cork dampening plate (art. 423314-4) which is used to compensate for uneven sanding surfaces.

Another useful tool at work with a powerful grinder Makita 9404- grinding frame Makita 193072-3. As oil is useful in that it limits the depth of grinding uniformly over the entire width of the abrasive belt does not prevent the formation of unnecessary depressions in the workpiece, provides a uniform, not perfect grinding result. Wood sander: which one to choose. Without the use of a sanding frame, there is of course the risk of one side of the abrasive belt going deeper into the material rather than the other side, especially with coarse grit belts.

Which polishing machine is better

When choosing a tool, it is important to pay attention to the build quality: backlash of parts or unreliable fastening of elements is unacceptable. It is also necessary to take into account the power and the number of revolutions, which affect the speed of work execution and productivity in general. The weight of the polisher and the design of the handle will affect the usability

And the availability of additional options and equipment will allow you to use the tool with the proper comfort, also ensuring the safety of the user. Experts suggest paying attention to the following nominees:

The weight of the polisher and the design of the handle will affect usability. And the availability of additional options and equipment will allow you to use the tool with the proper comfort, also ensuring the safety of the user. Experts suggest paying attention to the following nominees:

- So for simple polishing work, for cleaning varnish from wood or metal surfaces, you can consider the Status XPA - an economical and lightweight machine.

- The best vertical machine capable of withstanding significant loads is considered the Bosch GPO, capable of solving any task of polishing and sanding wood, metal or polymer.

- Among the more powerful models, it is worth highlighting the Kolner KPM, which is protected from overloads, has a low price and low weight.

- Patriot AG is suitable for heavy, production workload, with good performance and high working speed. Thanks to the frost-resistant cable, this tool can be used even at low temperatures.

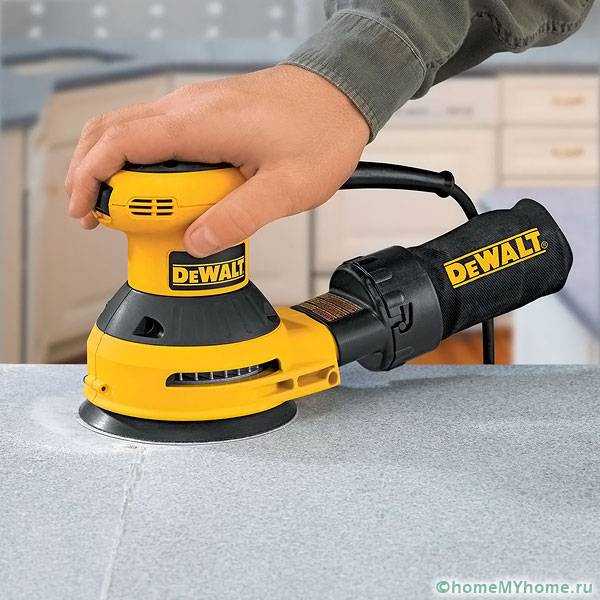

- For production work, the DeWalt machine is also suitable, which has great power and is able to maintain high speeds.

- Diold MP-0.5 - with low power, it has a fairly high speed.

The rest of the nominees in the rating also deserve attention as decent and high-quality tools.

It is important to remember that each model has both advantages and disadvantages, which are presented in the rating reviews.

Which one to choose?

When choosing an eccentric sander, you need to carefully study its characteristics indicated in the document. The main parameter is the power of the device. The main range of models has a power from 200 to 600 watts. The more powerful the grinder, the more turns it will be able to make. You can grind objects with a huge area using tools with a power of 300-500 watts.

The next parameter for choosing a grinder is the rotation speed of the disc. In general, the interval varies from 2600 to 24 thousand turns. For furniture factories, car services and "garage" workshops, models are suitable in which the speed of revolutions ranges from 5 to 12 thousand. And also when buying a device, users consider weight and dimensions. Most of the orbital vehicles weigh from 1.5 to 3 kg. There are heavier and lighter grinders.

To select a specific model, you need to decide on the purpose of the device: whether it will be used for woodwork or for car body repair. If the workshop has a pneumatic compressor, then it is better to purchase a pneumatic device. In other cases, it is better to choose models with an electric drive.

When choosing eccentric air grinders, you need to pay attention to air flow, number of revolutions and working pressure. The number of turns directly affects the performance of the equipment and the cleanliness of the processing of the site.

The higher this indicator, the more efficient the operation of the pneumo-orbital machine.

Belt Sanders

These machines are used for sanding straight, flat surfaces of a large area. In domestic conditions, they are used to remove old coatings, leveling putty, and treat metal from rust. The draw frame allows you to quickly and efficiently clean the grinded surface. The grinding part in such tools is a belt closed by a ring, which is attached between two rotating rollers. It is pressed against the surface to be treated using a special plate, which is located between the shafts. As a rule, the rear shaft of the machine is the driving one, and the front one is designed to adjust the tension of the sanding belt.

Household grinders are light enough, but not suitable for long-term use. If the grinding surface is large, it is recommended to switch off the device from time to time to cool down the electric motor. Professional machines have increased weight, power and shaft rotation speed. They can work with a wider sanding belt capable of processing a larger surface in the same period of time. Accordingly, this technique will work for a long time without overheating.

Most often, this type of apparatus is used for roughing the material. They can quickly clean the surface, remove burrs on the boards, level the edge. But to bring the surface to an ideal state, for painting, you will have to use a different type of grinder. If you press this tool too hard against the material being processed or hold it in one place, then deep grooves from the sandpaper will remain on the part.In addition, not all elements are convenient to handle with a tape machine. Due to its rather large mass, this device is difficult to hold on weight for a long time, but it is perfect for working on the floor or table. When working for a long time on soft materials such as wood, the sandpaper becomes clogged and needs to be replaced. This is done very easily. With the help of a special lever located on the side of the machine, the belt tension is reduced, and it can be easily removed from the shafts, and a new one is installed in its place. With the help of the same lever, tension is provided by bringing it to its original position. All grinders of this type are equipped with an additional handle for more convenient use, as well as a dust collector at the back of the machine.

The advantages of these machines are their high productivity, the ability to clean out even deeply ingrained dye and grind large burrs on wood without preliminary processing with a plane.

Varieties

DeWalt currently manufactures various cordless multifunctional grinders.

Vibrating

These models have a flat sole on which an abrasive sandpaper is attached. Typically, these samples are used for delicate and accurate work on flat surfaces.

Vibratory grinders are manufactured together with a special mechanism that makes constant vibrations during the operation of the product.

Vibratory models are also available with sealed ball bearings and convenient switches. They have their own dust extraction system. This type of grinder includes models D26441, D26420 and D26422.

Tape

Most often, such grinders are used to process large rough surfaces. Such devices are perfect for removing a layer of old varnish or paint.

The belt units are characterized by good performance. They are also equipped with a special bounding box. It allows you to adjust the depth of the old layer removed from the surface. These samples also have a special speed control.

These grinders come with dustproof bearings. They are made of heavy-duty steel. These models have a built-in dust extraction system. These samples include devices D26480, DW422, DW433, DW650, DW650E.

Eccentric (orbital)

Such models of DeWalt grinders are considered universal. Like tape specimens, they offer excellent performance. Eccentric devices have an electronic system for maintaining and adjusting the speed. This can significantly improve the quality of work.

Most often, eccentric models are made together with an additional handle. It allows you to make the work with the device as comfortable as possible, and this element also makes it possible to carry out grinding in hard-to-reach places.

These models have a system for removing dirt, which is represented by a small turbine. It is mounted on the transmission shaft. All dust from the device goes into a special built-in dust bag.

The eccentric sander features better balancing and ergonomic design. The models of these devices include D26453, D26410, DW443.

Corner

This type of battery grinder is particularly durable. In addition, these units can operate even in the harshest conditions. Even steel surfaces, concrete, building blocks and tiles can be sanded with angle grinders.

Angle grinders from this manufacturer are equipped with a more advanced dust extraction system.

To ensure comfort during work, the angle machines are equipped with a comfortable two-position handle. The switch of the device is produced together with a special system that protects against accidental activation. Corner models include DC 411 KL, D28132C, D28498, DWE4151, DWE4051.

How to choose a vibratory sander

The vibration sander is suitable for removing old paint or rust from steel products, leveling building structures, finishing wood, plastic, stone or metal. It is more compact, lighter and cheaper than belt or eccentric type devices, therefore it is highly popular.

Consider the features of the equipment and technical characteristics that you should pay attention to when buying

What you need to know about power and vibration amplitude

All sanders are equipped with an eccentric-type electric motor that vibrates the soleplate to which the abrasive or polishing points are attached. Oscillations are characterized by frequency and amplitude. The higher they are, the more productive the tool is and the more energy is required for its normal operation.

For rough and fast surface treatment, grinders with an amplitude of up to 5 mm are used. At the same time, the engine power of such devices reaches 400-600 watts. For more accurate work, it is more convenient to use models with a swing of no more than 1 mm. For them, 150-250 watts are enough. A less powerful tool is always cheaper, but you need to have some margin to avoid overheating and engine damage.

Why is the amount of vibration important?

The vibration frequency is related to the intensity of the surface treatment. The higher it is, the faster the required result is achieved, but one cannot thoughtlessly work only at maximum speed. The frictional force can strongly heat the part being cleaned and thereby damage its internal structure. Therefore, plastics and varnished parts are sanded at the minimum speed, non-ferrous metals at medium, and wood, metal and stone at the maximum. Universal machines are equipped with a frequency regulator for ease of use.

What does the sole size affect?

The larger the sole of the sander, the more area it treats, the more powerful the motor must be installed on it. However, one should not blindly chase the limiting dimensions. Experience shows that with equal power, a unit with a smaller platform turns out to be more productive, and it is much easier to manage such a tool.

How to choose the shape of the sole

Vibration soles come in a variety of configurations. Let's name the most common options.

Rectangular outsole

The rectangular platform has gained maximum distribution. When moving with the wide side forward, you can capture a large area of the processed surface, and the narrow one is convenient to work in confined spaces.

Rectangular outsole.

Square sole

The square base lacks the advantage of swath width selection, but these machines are usually lighter and lighter.

Square sole.

Deltoid outsole

The deltoid or triangular shape is better than others for cleaning inside corners and complex structures. The disadvantage of such a sole is considered to be the limitation of the choice of the method of attaching the sanding sheet, for which only Velcro is usually used.

Deltoid outsole.

Which fastening of the sanding sheet is preferable

The most versatile method of attaching an abrasive sheet is a mechanical clamp. It is suitable for all substrates, including the cheapest and most reliable paper skin. This is the only way to fix special sanding nets used for leveling walls and ceilings.

Fastening the sanding cloth with clamps.

For curved platforms, only lindens can be used, which reliably hold sanding sheets on a special fabric base. They are more expensive, and it is not so easy to find them taking into account the uniqueness of the form.

Attaching the sanding cloth with Velcro.

Where is it used?

The vibration surface grinding machine is used in the workshop or during repairs, restoration of surfaces.In the course of its operation, the movable platform contacts the material, removing the top layer from it. The tool grinds materials with different indicators of hardness and strength. Artificial and natural stones, polymers, wood, metal are susceptible to action, ensuring the removal of plaque, impurities (carbon deposits, rust, scale). On the farm, the use of vibration PSHM is quite diverse.

With their help, you can perform the following actions:

to achieve the desired evenness and smoothness of the wooden surface during the restoration, repair of furniture;

This is just a small part of the work that modern grinding tools successfully cope with.

AEG FS 280

7 185

The AEG FS 280 sander falls roughly between the amateur and professional segment: by itself, it is reliable enough for constant use, only the platform and the clamps on it require attention, and at the same time, its price is already quite elevated for a home craftsman who needs to work with extensive planes. And this model, equipped with a 440-watt motor and a 114x226 mm platform, is really well suited for such use.

In terms of dimensions and weight, it is close to the Makita, but due to its lower power and operating characteristics, it is more modest: the platform travel is exactly two times less, although the vibration frequency is as much higher. Hence the increased vibration level in comparison, therefore, unlike the Makita, a soft pad was installed on the rear handle as well.

The platform does not have Velcro - we will not call this a serious drawback, because Velcro sandpaper, although fastened more conveniently and fits better, is more expensive. The only problem is the inevitable wear of the clamps.

Main pluses:

- Good performance

- Anti-vibration pads

Minuses:

Fastening only to clips that wear out over time.

9.4 / 10 Rating

9.4 / 10 Rating

Reviews: A good sander for the home, as I bought it, and I still use it.