Makita 9910 Features and Benefits

This lightweight, small-sized fine sanding tool for wood surfaces is electrically driven and has a power of 650 watts.

Makita design (М-9910) allows grinding horizontal surfaces, as well as vertical and inclined planes. At the same time, it can freely process any surface, for example, the floor, almost close to the wall.

Due to the presence of special brackets in the kit, LShM can act as a stationary grinding machine. In this case, it is no longer the machine that will be attached and move along the surface to be treated, but the product itself.

An annular cloth emery belt with a size of 456 × 76 is used as a grinding attachment. This tape length explains the small overall dimensions of the LShM M-9910.

The machine is quite simple to maintain and operate. For example, you do not need to know the design of the tool to change the belt. It is enough just to pull off the lever that fixes the tape on the rollers, pull it out and insert it onto a new one, and then return the lever to its working position.

When installing the tape, you need to be guided by the arrow, which is drawn on its inner surface. The arrow indicates the mandatory direction of the belt.

The main feature of LShM M-9910 is an automatic sanding belt centering system, which is always in a certain position without additional manual adjustment.

The start button is conveniently located on the handle of the grinder and has a push-button lock. It is used for continuous, long-term work, fixing the start button in the working position. In the event of a sudden power outage, the latch is turned off, which excludes the unauthorized switching on of the tool when the electricity supply to it is restored.

All internal parts of the LShM have a multichannel labyrinth protection against dust that occurs during grinding work. This protection naturally delays wear and tear on the machine parts and extends the life of the tool.

LShM M-9910 is completed with a special dust bag. It is put on the nozzle to collect the dust generated during work.

Specifications

The quality of the processed surface directly depends on 4 parameters of the machine, which include:

Power. This parameter is important when machining a rough surface, when you need to press on the tool under a certain force. The greater the power of the grinding machine, the more it can be pressed against the surface to be treated without fear of overheating of the electric motor.

Speed. Or the number of revolutions of the tape for a certain time. The quality of the processed surface depends on the speed, and the higher it is, the faster the processing will be, but the processing quality will be rougher.

Eccentricity. This is the grinding stroke. The lower its value, the less vibration of the machine will be, which means that the result of grinding will be cleaner and better.

The area of the sole (working surface). The larger it is, the higher the productivity, but the processing accuracy will be lower.

Specifications LShM makita 9910:

- The power of the instrument is 650 W.

- The length and width of the annular emery belt is 457 × 76 mm.

- Belt speed - 270 rpm.

- Working deviation of the tape from the center - 2.5 mm.

- The length of the network cable is 2.5 m.

- Weight - 2.6 kg.

- Dimensions - 130 × 130 × 262 mm.

Equipment:

- Sander.

- A set of sanding belts.

- The bag is a dust collector.

- Steel platform.

- User's Manual.

Advantages of the device:

- You can grind the floor close to the wall.

- The centering of the sanding belt is done automatically.

- Effective dust extraction system. Possibly a direct connection to a vacuum cleaner.

- The belt drive gears are made of aluminum alloy and can withstand high loads.

Popular models

There are a large number of manufacturers that produce different models of grinders. They have their own characteristics, differ from each other in design and some features.

Belt Sanders

Bosch PBS 75 AE

- Power: 0.75 kW

- Belt speed: 350 m / min

- Belt parameters (length and width): 533 mm; 75 mm

- Tool weight: 3.5 kg

Makita 9404

- Power: 1.01 kW

- Belt speed: 440 m / min

- Belt parameters (length and width): 610 mm; 100 mm

- Tool weight: 4.7 kg

Interskol LShM-100 / 1200E

- Power: 1.2 kW

- Belt speed: 400 m / min

- Belt parameters (length and width): 610 mm; 100 mm

- Tool weight: 5.6 kg

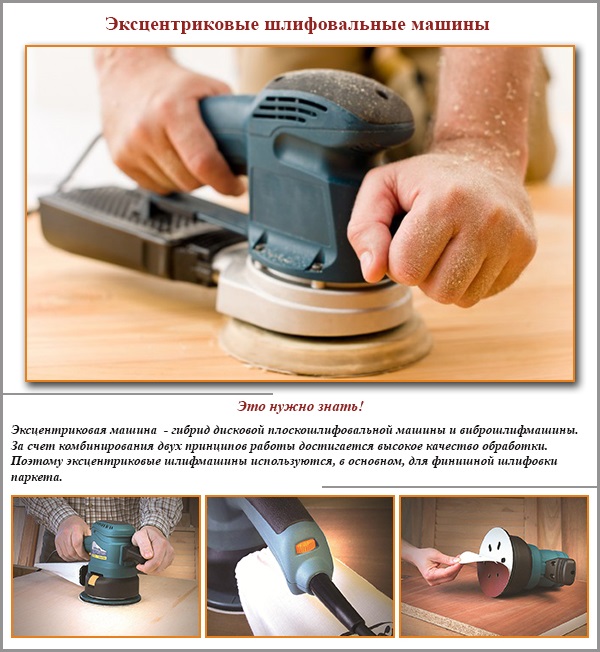

Eccentric (orbital)

Makita BO5031

- Power: 0.3 kW

- Shaft speed: 12 thousand rpm

- Oscillation frequency: 24 thousand count / min

- Emery wheel diameter: 125 mm

- Offset range (eccentricity): 2.8m

Metabo SXE 450 TurboTec

- Power: 0.35 kW

- Shaft speed: 13.1 thousand rpm

- Oscillation frequency: 8.5 thousand count / min

- Emery wheel diameter: 150 mm

- Offset range (eccentricity): 6.2mm

Bosch GEX 150 AC

- Power: 0.35 kW

- Shaft speed: 12 thousand rpm

- Oscillation frequency: 24 thousand count / min

- Emery wheel diameter: 150 mm

- Offset range (eccentricity): 4mm

Vibrating hand grinders

Makita BO3711

- Power: 0.19 kW

- Sole vibration frequency: 22 thousand stakes / min

- Sole dimensions: 228 × 93 mm

- Sole travel: 2mm

Bosch PSS 200 AC

- Power: 0.2 kW

- Oscillation frequency of the sole: 24 thousand counts / min

- Sole dimensions: 230 × 93 mm

- Sole travel: 2mm

Interskol PShM-115 / 300E

- Power: 0.3 kW

- Sole vibration frequency: 10.5 thousand counts / min

- Sole dimensions: 230 × 115 mm

- Sole travel: 2mm

Device and principle of operation

In terms of ergonomics, grinders are very convenient, because they allow you to perform operations for a long time without fatiguing the operator. For each type of work, whether it is preliminary cleaning, grinding or polishing with a brush grinder, the design provides the ability to change the attachments. All tools of this type are electric, powered from the mains or rechargeable batteries.

A standard brush grinder has the following basic structural elements:

- The case, usually plastic, on which the handles are installed on top: one is the front guide handle, the second is the push handle, where there is a button to turn on the device.

- A brush-type electric motor is installed inside the grinder housing, from which the torque is supplied through the gearbox to the transverse shaft.

- The front transverse shaft is at the same time the holder of the grinding cylinder, the bearings serve as the support for the shaft.

- On the bottom of the grinder body, there is a wide support roller on one side of the grinding cylinder, at the back; on the other side of the cylinder, in front, is a second adjustable support roller. The rollers allow you to smoothly move the tool along the plane in different directions, adjust the pressing force of the tool to the surface.

- The grinding cylinder is put on the cross shaft of the brush grinder by means of a special mechanism. The cylinder itself is made like a brush, the "pile" of which is made of different materials, such as metal wire, nylon thread and others.

The principle of operation of the brush grinder is very simple: when the engine is turned on, the grinding cylinder begins to rotate rapidly; the tool is applied, leaning on the rollers, to a pre-fixed flat surface that needs to be grinded, and the brush grinder is moved back and forth over the entire plane with methodical movements, visually assessing the quality of processing.

Correct use

High-quality polishing and grinding of a vehicle can be carried out by following these recommendations:

- divide the surface into several sections and process each of them in turn - this will not allow the abrasive or polishing to dry out;

- at the beginning of work, the speed should be minimal, and after the distribution of the abrasive over the surface, it is necessary to turn on increased speed;

- in the process of work, it is necessary to periodically turn off the grinder - this will allow the car body to cool down and prevent it from overheating;

- when processing the body, it is necessary to monitor the uniformity of pressure on the sole area, and the movements should be smooth;

- in the process of manipulation, the grinding wheels are periodically cleaned with a brush;

- if an abnormal sound appears during operation of the instrument, it must be carefully checked, cleaned and lubricated.

Despite the fact that the grinder speeds up and facilitates the repair work, its use still requires accuracy and care, because in the event of improper use of the tool, it may be necessary to completely replace the paintwork of the car.

Gadgets

In addition to the basic functions, many LSHMs are equipped with various options and useful devices that facilitate the operation process and make working with the device much more convenient.

- Smooth start of the tape. Thanks to this option, the abrasive begins to move not in a jerk, but progressively, thus eliminating injury to the operator.

- The additional handle allows for more precise grinding.

- The depth gauge will not allow you to remove extra millimeters beyond what was planned.

- Stationary fasteners make it possible to fix the machine on a hard surface, turning it into a grinding machine.

- The keyless abrasive change option allows you to change the belt with one move of the lever.

- The automatic centering function of the abrasive prevents the belt from sliding sideways during operation.