Characteristics, types and purpose of the tool

Hammers differ in shape, weight and material. The summarized data on tool modifications are presented in the following table:

| Name | Dimensions (edit) | Average weight | Application |

| Hammer | The height of the hammer in mm depends on the weight of the woman and can be from 1830 mm to 3500 mm | From 0.5 kg to 9 kg, in large forges - from 40 to 100 kg, in steel and iron plants up to 50 tons | For striking when breaking stones, forging metals |

| Locksmith hammer | Standard design | 300-500 gr - for home and household use, more massive - 2 kg | Work with metal products, production of blows on a chopping tool or on a core |

| Carpenter's hammer | Handle length - from 20-30 cm | 250-450 gr | For hammering or removing nails in joinery or carpentry |

| Mallet (wooden hammer) | 130 × 90 × 60mm | 300 g | Assembly, dismantling, molding of materials and structures |

| Sledgehammer | Volumetric tool | 3 to 15 kg | Dismantling and installation work (breaking walls, driving posts and pipes into the ground) |

| Fizdel's Hammer | The striking part of the hammer ends with a steel ball Ø17.5 mm | 250 g | Testing the strength of concrete |

| Kashkarov's hammer | 253 × 40 × 53 mm | 1.5KG | Examination concrete strength by shock compression |

| Rock hammer | 290 mm | 600 g | In rock climbing, mountaineering, caving, for filling and removing rocky hooks, processing the edges of rocky ledges, punching bolts |

| Jackhammer | Medium shank Ø 24 mm, length 70 mm | 3 to 30 kg | Cutting out openings and niches in the walls, dismantling of brick-concrete capital structures, destruction of frozen or heavy soil, removal of the old roadbed |

| Roofing hammers | 300 × 120 × 50 mm | 0.6 - 0.75 kg | For roofing work, alignment and sealing of folds |

Types and purpose

Locksmith hammers are available in different weights. For a locksmith's home workshop, tools weighing 300-500 g are suitable, because their capabilities are quite enough for most household work. However, experts recommend not to be limited to one hammer, but to have several models with different weights, since the purpose of the device depends on this.

Depending on the shape, hammers of several varieties are also distinguished. So, one of the popular options has a rectangular shape and a square striker, the second is slightly convex, the striker is rounded. The first ones have a rather low cost, they are much easier to use, therefore they are widely used among both amateurs and experienced craftsmen. However, in hammers with a rounded firing pin, the striking side has a slight advantage, which increases the accuracy and power of the blow. According to the current GOSTs, tools with a round striker and versions with a spherical toe are also produced, but these models are quite rare on sale.

Hammer construction and basic materials

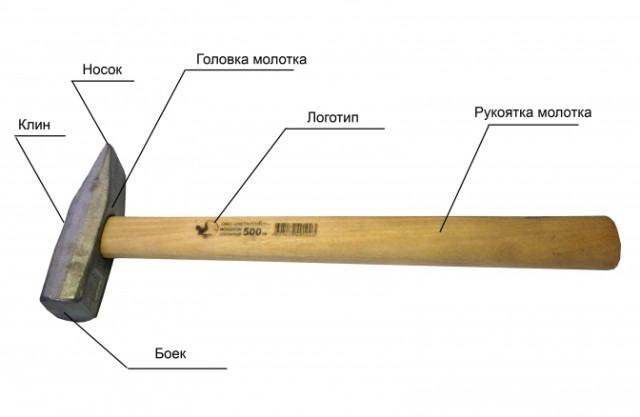

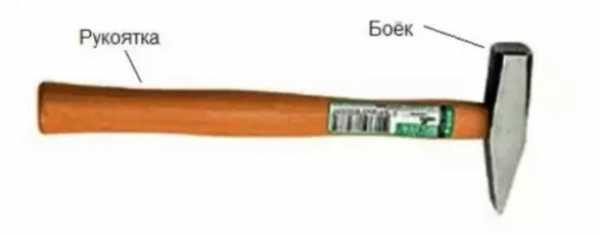

The first hammer appeared a long time ago. We can say that this is the first of the tools that people used for their needs. We have all seen the hammer, held it in our hands many times, and we know that the simplest hammer consists of two main elements: the handle and the head.

Hammer head

In the center of the head there is a special hole for attaching the handle, which is called a sucker. Usually it is made in the form of a round or oval hole, which smoothly turns into a cone. After attaching the head to the handle, the part of it that protrudes from the hole is wedged so that it completely occupies the internal cavity of the seat. This fastening prevents the head from falling off.

In order to ensure high strength and durability of the head, it is made of high-strength metal by forging, casting or milling, followed by heat treatment.Special hardening modes allow achieving high surface strength with a tough core. The hardened surface layer reaches 3-5 mm. This structure provides high hardness, but at the same time protects the head fromfragility.To protect the head from corrosion, it is covered with a galvanized coating or special types of paints are used.

Wood has always been the universal material for making hammer handles. It is very durable, does not slip in the hand and has a long service life, and if you break the handle during use, it is very easy to replace or even make yourself

It is very important that the grain of the wood from which the handle is made are perpendicular to the head. In this case, if it breaks down, you will not be injured. The wood species must be of a certain type

For these purposes, beech, birch, ash, oak, hornbeam, maple or mountain ash are well suited. Pine, aspen, alder and spruce are not suitable species.

There are handles made of metal or plastic, and more modern hammers come with fiberglass handles. This is a new material that has proven itself very well in use. It does not slip in the hand and helps to reduce the force of recoil on impact. The metal handles are hollow inside, have the shape of a circle in cross-section, and are covered with rubber for ease of use. The plastic handles are also covered with rubber. Plastic, metal or fiberglass grips have two advantages over wood: they do not dry out over time and they do not swell when in contact with water. Choose depending on what material is more convenient and pleasant for you to work with. The main thing is that the handle is much lighter than the head and has an appropriate length.

Planing tools

Carpentry tools and planing devices include planers, jointers and cycles.

The plane consists of the following parts:

- pads (bodies),

- knife - cutting tool;

- wedge for fixing the knife in the block.

There are planes of the following types:

- Scherhebel for primary wood processing. The blade has a rounded shape, in one pass it removes a three-millimeter layer of wood in the form of a groove. Knife width - 30 - 35 mm, cutting angle - 45 °. The dimensions of the pads are (205 - 240) x (50 - 65) x (40 - 50) mm.

- Single blade planer for leveling wood surfaces. Straight knife, 40 - 50 mm wide, removes 0.5 mm of chips in one pass. The size of the last corresponds to the size of the scherhebel.

- Double blade planer for surface finishing. The surface finish is achieved by supporting the wood fibers with a chipbreaker, a small (0.3 mm) layer of wood to be removed. The dimensions of the knife and block correspond to the characteristics of a single knife planer.

Jointers are used for planing long parts. They differ from planers in the width of the knife (60 - 65 mm) and the size of the block (650 x 70 x 75 - 80 mm). For planing of concave and convex surfaces, as well as for sampling of grooves, planers with curly knives and various configurations of the sole of the shoe are used - humpbacks, kalevki, zenzubels, faltsgobeli, tongue-and-groove, etc.

Cycles are used for planing wooden floors. They are knives attached to the handles at a specific angle.

What it is?

With a hammer, you can not only hammer in nails or break objects, but also bend, level, smooth, and so on. The tool is used in a variety of ways. This is not only construction and repair, but also medicine, welding, shoe making and the like. The hammer combines impact capabilities, depending on the weight of the product and the muscular strength of a person, with a fairly small size. Allows you to amplify the impact while maintaining accuracy. Converts kinetic energy into a concrete result of mechanical work.

The manufacturing technology of the contact surface of the tool from metal provides for different methods of hardening.The side used for blows is hardened in water, for pulling out nails in oil. The former provides strength, the latter provides flexibility. A special coating is applied to reduce the risk of corrosion. The handle must meet the following requirements: strength and lightness combined with the required length. A variety of nails require the use of tools of the appropriate size and weight. The larger the nails, the heavier the tool.

Rating

Each type of hammer has products that can be called the best. When evaluating a tool, technical characteristics, cost and performance are taken into account.

Sledgehammers

KAPRIOL 12301

Easy-to-use steel sledgehammer with fiberglass handle. Product weight 3 kg. The length of the handle is 90 cm. The connection between the head and the handle is epoxy. The KAPRIOL firing pin has a square shape for precise impact. Manufacturer's warranty - 6 months.

Advantages:

The disadvantages include the high price of the tool.

FIT 45232

The Canadian brand has a distinctive yellow and black handle. Manufactured in China. Refers to a professional tool. The length of the fiberglass handle is 800 cm. The striker is made of high strength steel. Has a square shape. Product weight 4 kg.

Advantages:

- Weightiness.

- Reliability.

The main disadvantage is the high cost.

Locksmiths

Inforce 59035

The tool has a very well thought-out design. Product weight - 500 gr. The handle is equipped with a fiberglass cover. Has finger grooves. your coverage. The hardness of the striker is 10% higher than the requirements of the DIN standard. The method of fastening the elements is injection bonding with epoxy resin.

Advantages:

- Comfortable rubberized handle.

- Increased reliability.

The main disadvantage is insufficient weight for some types of work.

Case Technics 315100 DT / 24/6

Weighted hammer with which you can hammer nails very quickly. For the manufacture of the striker, steel 45 is used. The handle has a rubberized construction. This ensures safe work.

Advantages:

- Low cost.

- Reliability of construction.

No shortcomings identified.

Pickaxes

BISON MASTER 2015-05_z01

The hammer cannot be called a full-fledged pickaxe due to its low weight. Product weight 500 gr. The striker has increased strength. Made of steel 55. The handle is made of wood, which is considered a disadvantage of the product.

Advantages:

The disadvantage is the material for making the handle.

Sturm 1010-05-600

The hammer is equipped with a striker made of high strength steel. Pickaxe weight 600 gr. The handle is two-component. The surface of the steel base is covered with a fiberglass plate. There are three notches for the fingers. This improves safety and makes the handle more comfortable.

Advantages:

- Comfortable handle.

- Long service life.

The disadvantage is the high cost.

Carpentry

Stanley FMHT1-51276

The hammer head is shaped like a straight nail. It is equipped with a surface hardened striker and a protective coating. Tool vibration during work is mitigated by a special pad on the handle.

Advantages:

The disadvantage of the tool is its high cost.

NEO 25-000

The hammer is made of a monolithic steel billet. This provides the structure with increased strength. Product weight 450 gr. The handle is two-component. The sliding of the hand is prevented by a special covering.

Advantages:

- Long service life.

- Low weight.

- Convenience in work.

- Increased strength.

Poorly adjusted instrument balancing is considered a disadvantage.

Straightening

ONNESWAY M10110

The hammer is very popular with car mechanics. The tool head has a rounded striker. The second side is in the form of a lance. The handle is elongated. The design allows you to perform a wide range of works.

Advantages:

The main disadvantage is the high price.

KING TONY 7842-28

Multifunctional model. The hammer is used not only by bodyworkers, but also by installers, locksmiths and carpenters.For the manufacture of the handle, a walnut tree is used. The tool is lightweight.

Advantages:

- Convenience in work.

- Wide functionality.

A big disadvantage is the rapid wear of the striker.

Optional equipment

To work with wood, you need a workbench. It is equipped with stops, bumpers, tool recesses, and clamping carpentry tools. To install the stops, through holes are drilled in the working board.

At the edges of the workbench, two vices are attached to fix long parts. Clamps serve as an additional tool for fastening wooden products. They are used for gluing, simultaneous drilling of several parts.

The ax is considered the main tool of the carpenter. They carry out the primary processing of wood. To drive nails, you need a hammer and a doboiner - a metal rod, one end of which is sharpened on a truncated cone. To connect the details "thorn in the groove" use a mallet - a massive wooden hammer. A sharpener for sharpening axes, knives, chisels will be useful in a carpentry workshop.

Over the centuries, man has invented many devices for processing wood. A carpenter's equipment can consist of several dozen tools and is constantly updated with new devices.

Sledgehammer

the largest type of hammer.

The head of this tool is made of high-strength steel by forging with subsequent heat treatment in the form of hardening to the required hardness and can be in the form of a parallelepiped or a conventional hammer. By the way, the depth of the hardened layer after hardening reaches 30 mm. The handle has a larger diameter and length compared to previous models, which means two-handed operation.

The length of the handle is directly proportional to the weight of the working part of the sledgehammer: the higher it is, the longer the handle can reach 120 cm, but usually it is in the range of 80-90 cm. The cheapest sledgehammers have a wooden handle, but they can also be all-metal.

The hole into which the handle is inserted is tapered, and the handle itself is inserted from above and does not need to be wedged. This assembly method completely prevents the massive head from sliding off. When working with a sledgehammer, you must be extremely careful, because it is considered a traumatic tool. There are several types of sledgehammer, but the most used is a blunt-nosed sledgehammer weighing 2-16 kg, longitudinal sludge with sharp-nosed transverse, which weigh from 3 to 8 kg. The preferred version of the handle is rubberized, it is more expensive than a wooden one, but the tool will be securely held in your hands and dampen vibration during impacts.

Bushhammer

Construction for construction installation work paving slabs

The striking part of the hammer has two different surfaces. One is a square smooth firing pin, and the opposite has a flat pointed nose. The material for making the head is tool steel, which is very strong, hard and practically not subject to deformation or destruction. The handle of such a hammer can be made of wood, which is the cheapest option, all-metal handles are less common, and more and more often, tools with fiberglass handles are being produced.

We mentioned the advantages of this material in the first paragraph. In order to protect the impact part of the hammer from corrosion, it is coated with special varnishes or paints, or a protective galvanic coating is performed. To give it increased hardness, a special heat treatment is carried out, which consists in quenching followed by tempering. This allows maintaining a high hardness index and relieving the internal stress of the metal, thereby reducing its brittleness. These hammers are lightweight and affordable.

The automatic bricklayer's hammer has been developed especially for the convenience of making masonry.It has not yet gained sufficient popularity, but it has very significant advantages. The design of the automatic hammer consists of two laser levels, a pneumatic element that creates an impact moment and a laser receiver that is able to "understand" and receive signals from other laser beams. The use of such a tool is very simple but effective.

Let's say you have completed a piece of brickwork, but doubt that its main parameter has been observed - strict perpendicularity to the base. It is for leveling the masonry and bringing it to the ideal that the automatic mason's hammer serves. It is installed directly on the last row of bricks, its laser levels create a mark on which you need to orient yourself, then each brick is knocked under one level. Very simple, understandable, and most importantly, really functional.

If earlier the quality of the masonry was determined by the skills of the employee, and one had only to rely on his consciousness and qualifications, now such a complex work can be done independently. Moreover, labor productivity when using this tool increases almost 5 times, and its high cost will pay off after a couple of months of use.

Roofer hammer

In addition to the roofing hammer, a sharp-toothed hammer, a fang, a sharp-nosed hammer also received popular names.

This hammer has collected in itself the functionality necessary for carrying out generally accepted roofing work.

It has a serrated firing pin that prevents slipping when hitting a nail.

The end part of the hammer head on the side of the striker is equipped with a groove for inserting a nail, which is convenient when it is not possible to hold the nail with the other hand:

The groove is designed to bait the nail without holding it with the other hand. It has the contours of a nail and has a magnet that prevents the nail from falling out.

There is a sharp nose on the side of the nailer - this is an element from the classic slate hammer.

The weight of the hammer is 500-700 grams, which is suitable for hammering nails with a size of 35-150 mm.

Sax

Another type of roof hammer.

This hammer belongs to a specific type of tool and is used only for specialized work.

This hammer has been designed and used specifically for the installation of slate roofs, shingles and slate.

The sharp nose of the hammer serves as a punch. There is also a nailer on the hammer. The hammer handle is rounded, which allows you to conveniently use all the functionality of the hammer.

Slate Roofing Hammer

A hammer designed to work with slate roofing. On one side of the hammer head is a serrated firing pin, and on the other, a hatchet with a nail puller:

A hatchet on a hammer is needed for cutting the edges of slate tiles, which must be done according to technology, to eliminate traces of factory processing of slate.

A hatchet on a hammer is needed for cutting the edges of slate tiles, which must be done according to technology, to eliminate traces of factory processing of slate.

Slate roofing hammers come in a wide variety of shapes and sizes.

Mallets

Mallets are often wooden and rubber hammers, which are used in cases where damage to the surface of the material with which work is being carried out must be excluded.

The range of these hammers is huge. The variety in size and type of material is very large.

Mallets are used when working with fragile materials, as well as in order to avoid damage on the surface of a part, product or tool in contact with the striker.

Professional wooden mallets are made from larch.

The rubber hammer is mainly used in paving slabs and car body repairs.

Straightening hammer

Also, in narrow circles of professionals, this hammer is called a blooper.

This is a special professional tool for working with sheet metal and sheet metal.

Lyapoks come in different sizes and shapes. They are selected for specific tasks.

Lyapoks come in different sizes and shapes. They are selected for specific tasks.

Pick

The pickaxe is considered the hammer of masons.

A brick is knocked out with a punch when laying, and with the opposite side in the form of a spatula, a brick is chopped to fit the required dimensions.

A brick is knocked out with a punch when laying, and with the opposite side in the form of a spatula, a brick is chopped to fit the required dimensions.

It is also widely used for removing plaster and cleaning used bricks.

Sledgehammer

The sledgehammer is a heavyweight hammer. It is needed where punching power and brute force are required.

Has popular names mashka and balda.

Compared to other hammers, the sledgehammer has a large body weight of up to 2.5 kg.

Compared to other hammers, the sledgehammer has a large body weight of up to 2.5 kg.

The range of work carried out with a sledgehammer is very large. It is used for dismantling works, for driving reinforcement, stakes or iron supports.