How to choose a vise

Most of the vices are usually similar to each other. They have the same design, they differ according to specific criteria. For example, differences can be found in jaw dimensions, stroke length, material used, and the like.

Most of the factors require consideration, since they can be used to understand whether it is worth taking certain vices or not. Let's consider them briefly.

As a rule, the body material is steel or cast iron. Each of the materials is good in its own way. Steel is lighter, cast iron is heavier and more stable. Cast iron is immune to corrosion, while steel is the other way around. In general, material is the first factor to consider.

Body material - the main selection criterion

Attention should also be paid to the purpose of the vice. As a rule, people purchase a universal vice that works with any material, but there are also more narrowly focused options.

The same can be said about the size of the blanks.

Some can work only with small ones, others - with any, no matter what size they are. It is important to know only one thing about the appointment.

If the vise is for metal, then it is better not to fix wooden blanks with them.

The purpose of the vise is an important point to consider

Vise weight and dimensions are another important factor to consider. Understanding how much and how large the vice weighs, you can determine where to put them, how to carry and transport.

As a rule, many vices have additional options, with which work becomes more comfortable, and the capabilities of the tool expand. 360-degree rotation, replaceable jaws and much more can make your job more efficient.

Additional features simplify overall work

Cast iron or steel?

| Material | Dignity | disadvantages |

| Steel | First of all, steel is considered to be a fairly light weight and at the same time a fairly strong material. Tools made from steel are fairly easy to transport, again due to the lightness of the steel itself. In addition, steel is considered to be more adaptable to difficult conditions. And even with a steel vise, processing of small parts is more accurate. | Steel is not very rust resistant material. In addition, this material does not like high humidity. It is also worth noting the high price of steel vise due to the ability to work with small parts, which is not the case with cast iron vise. |

| Cast iron | Firstly, cast iron has always stood out for its hardness and strength on the verge of the possible. Strong shocks and vibrations - all this does not matter to cast iron. In addition, a cast iron vice makes it easier to machine medium to large parts. Another advantage of the cast iron alloy is corrosion resistance, or rather, immunity to it. | Huge dimensions and weight typical of cast iron. In addition, static loads have a negative effect on the cast iron itself. |

Each of the two materials has its own pros and cons.

Types of locksmith vices

In addition to a reliable support, you must clearly understand what types of work you will perform, and correlate the choice of table vise with them. This primarily concerns the material of the case. In the post-Soviet space, it is often cast iron.

This material is hard, wear-resistant, but rather brittle. Therefore, if you are not going to bend thick steel blanks with a sledgehammer without serious preliminary heating them, then feel free to take such a vice, and if you are going to, then it is better to look for steel ones.

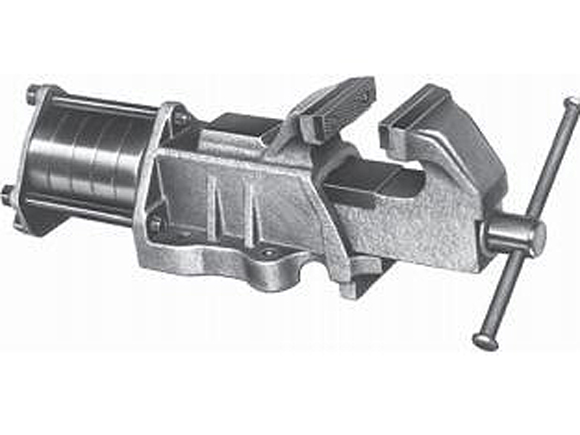

If you need to regularly fasten cylindrical workpieces in such a desktop vice, then it is advisable to make a sponge pad with a triangular cut. And if such operations are quite frequent, then we advise you to consider options for the design of the locksmith's vice, somewhat different from the standard ones.

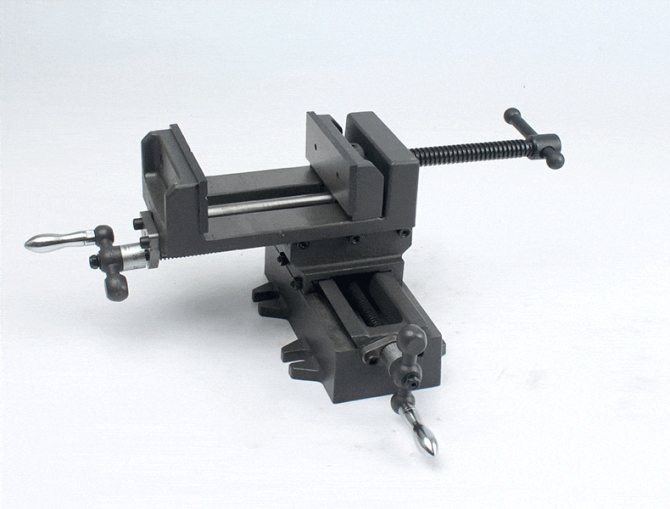

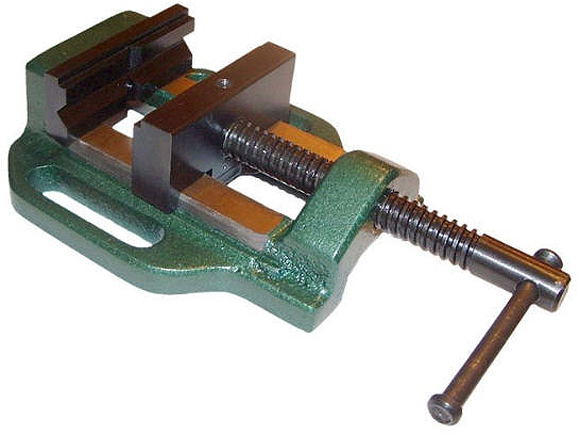

In general, if we talk about the functionality of a locksmith's vice, then first of all it is worth thinking about the size.If you know for sure that you do not have to work with dimensional parts, then do not pay for extra metal, and perhaps even consider a compact machine vice.

Or vice versa - it is possible to work with large-sized parts, but without much effort when processing them. Then you can consider the option of a vise with the possibility of pre-expanding the jaws without using a lead screw.

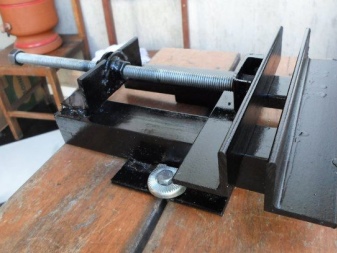

If you do not have a workbench, and there are also more operations in the list of works that do not require the application of brute physical force to the parts being processed, then the option with a table vise fixed with various clamps is yours.

True, the latter are minitisks, it is better to have them on the farm as additional ones. Large parts cannot be clamped in them, and you cannot apply serious efforts to the workpiece being processed - there are not enough efforts to press the clamp to hold the vise themselves, but making a key from the lock according to the sample is the very thing.

In addition, such vise is sometimes indispensable if you need to unscrew a stuck nut, when you can use them as a hand tool. Despite the miniature size, the clamping of the sponges is very good.

It is also worth mentioning a small vice on a ball joint, which serve for the convenience of processing very small parts of a complex configuration, allowing processing of various surfaces of the part from one fixture.

It is clear that the clamping force of the ball joint is not enough for serious physical activity, so such a vice is suitable for quite specific types of work. The same, in our opinion, not very serious, will be vise with a suction cup attachment.

For their more or less reliable fixing, either a well-polished surface or glass is needed. On other surfaces, they are unlikely to be securely fixed. And their functionality is also small.

For all types of locksmith vices, you will obviously need additional pads to secure parts made of soft materials.

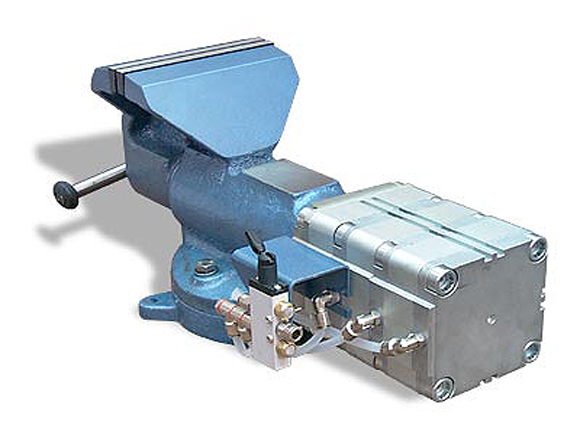

Some bench vices have a pneumatic drive, which greatly facilitates the process of clamping the workpiece.

But if you do not have a mini locksmith production at home, then such a vice is unlikely to be useful to you.

What else is important to know when choosing a locksmith vise? Quite a lot of complaints from users about Chinese vices with cast-iron bodies, equipped with clamps for fastening, often break off, so if you want cheap vices from the Middle Kingdom, then choose from steel. Choose a vise that has the least play between body parts with the jaws spread as wide as possible.

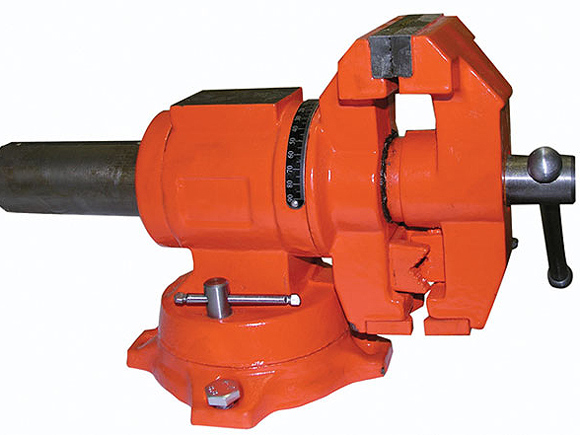

Also, if you do not need a rotary mechanism at the base of the vise for work, choose a model without it: you will save money and the rigidity of the structure is higher.

Choose a vise that has the smallest play between the body parts with the jaws set as wide as possible. Also, if you do not need a rotary mechanism at the base of the vise for work, choose a model without it: you will save money and the rigidity of the structure is higher.

Precautions for use

Despite its diminutive size, if handled carelessly, the hand vise can cause injury to your hands. Therefore, before you start using the tool, it is advisable to familiarize yourself with the safety rules.

- Thus, most hand held specimens are not designed for gripping incandescent parts. This is due to the fact that the hot metal changes the physical parameters of the jaws, due to which the fixation can weaken and the workpiece will fly out of the vice. This must be taken into account and, if it is necessary to work with red-hot workpieces, purchase models made of an alloy with special additives that increase the heat resistance of the material.

- In addition, it is necessary to coordinate your movements and try to avoid pinching the skin of your hands when installing miniature parts in the working gap.Tweezers are recommended for placing particularly small items (eg jewelry).

- When fixing workpieces made of soft and brittle materials, do not pinch the jaws, as this can lead to breakage of the part and the formation of fragments.

- The vice should not be used as an adjustable wrench on live electrical equipment. This requirement is due to the absence of an insulating braid on the handle of most models, which, when working with metal parts of electrical installations, can lead to electric shock. For such purposes, special pliers with a dielectric handle should be used.

Which one to choose for a garage?

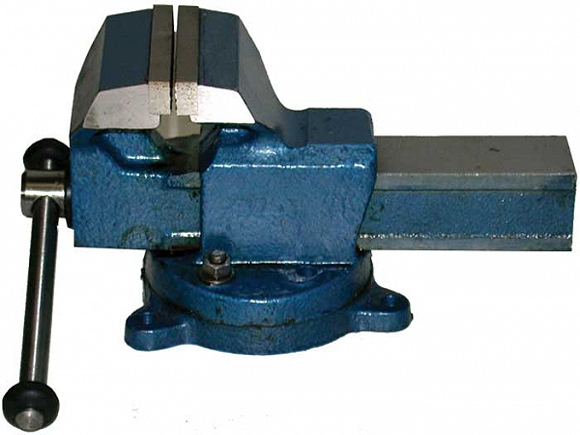

If you have a garage or workshop, it becomes necessary to purchase a locksmith vice. For small garage locksmith work (for example, assembling auto parts), the best option would be models of classic parallel rotary vise

When choosing a tool, you should pay attention to the following parameters

The size of the sponges. It is determined by the dimensions of the parts to be processed. To work in a garage, the size of the jaws should be from 100 to 150 mm, since these are the parameters that are most optimal for performing car repairs.

Manufacturing material. Cast iron models with steel jaws are considered the best option.

Installation method. To install the tool in a permanent room (garage), a vise with a stationary attachment to the workbench should be preferred. If a vice is necessary for rare use when necessary, then it is better to choose a model with a screw clamping mechanism.

The versatility of the model. If it is necessary to work with products made of materials of varying degrees of hardness or different shapes (flat or round), a vice with replaceable jaws is required.

Vise dimensions. If you intend to change the installation location of the tool, then you should choose lighter, more compact options.

Product quality

When buying, you need to pay attention to the appearance of the model. The tool must be free of visible defects, burrs, sharp edges, distortions, have a finished shape with straight lines

With a curved configuration, the transition of the lines should be smooth. Threaded areas must be coated with grease, moving parts move smoothly, without jamming.

The cost is determined by the features of operation: for professional intensive work, it is better to purchase a more expensive model, and for use at home, budget options are also suitable.

What are they made of?

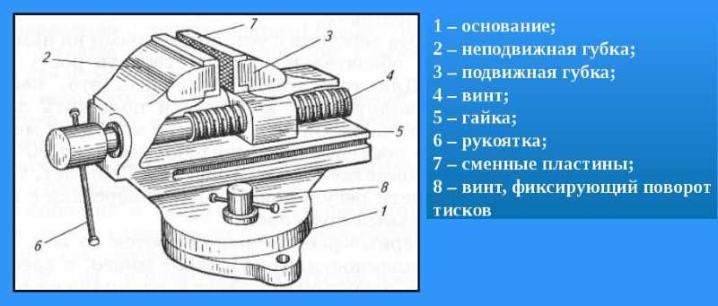

Regardless of the type, model and shape of the locksmith's vice, they all have a standard device in accordance with the requirements of GOST 4045-75, which regulates the necessary design parameters and the nomenclature of parts. All models are arranged according to a certain scheme and consist of the following structural parts:

- stationary stable body-base;

- 2 jaw plates - movable and fixed (fixed jaw can have an anvil);

- clamping trolley, consisting of a screw and a nut;

- a rotary knob that rotates the screw clamp;

- spring and bushing;

- fixing mechanism to the desktop.

The vise kit also includes such spare parts as removable grooved pads for the jaws, which provide a more reliable fixation of the workpieces. Some expensive vise models can be equipped with a pneumatic drive, and they are most often used in the factory.

The vise is fixed to the tabletop of the workbench with bolts or a special screw is used to fix the structure like a clamp. Communication between the 2 jaws takes place by means of a screw clamp, which is set in motion when the rotary knob is turned.

How to choose a quality vise

The vise design has remained unchanged for decades. The main components of the clamping device are two jaws, a base plate, a lead screw.One of the jaws is fixedly fixed on the base, and the second is moved using a special mechanism with a handle.

Most often, the vice is made from cast iron, steel, or a combination of both. It is rare to find wooden devices in carpentry workshops. Each of the materials has its own pros and cons.

All vices can be grouped according to their intended purpose. Locksmith models must securely hold solid metal while maintaining integrity. Carpentry is more gentle with wood pieces without destroying soft fibers. A vice is made especially for machine tools, which is fixed on the bed. With their help, the part is precisely fed into the processing zone. It is more convenient to work with pipes if you hold the workpiece in a pipe vise. They have special jaws that adhere to the surface of the part from several sides.

Vices are seriously different in overall dimensions and weight. If the device is installed motionlessly on a workbench, then the mass is not decisive, it is more important to pay attention to the method of fixation. And with constant movement, lightweight and compact models will be more convenient. Although users are confident that the heavier the vice, the stronger and more reliable it is.

For ease of use, there are many additional functions. The locksmith's vice is equipped with a rotary mechanism (180 or 360 degrees). Folding legs and clip plates are mounted to the carpentry models. For machine tools, movable parts are made, thanks to which it is possible to bring (withdraw) the part into the processing zone by rotating the handles

The quick-clamping screw speeds up the fixing of the part, which is especially important in production conditions.

Our review includes 11 of the best vices. When compiling the rating, the opinion of the expert community and feedback from domestic consumers were taken into account.

Care advice

In order for the instrument to last as long as possible, you need to take care of it:

- Keep parts, especially those with threads, clean. To do this, you need to wipe the vice with a soft cloth, cleaning it from dust.

- Lubricate periodically with special oil. It is applied to the screw part and to the thread of the plates, and to all moving parts of the vice. After that, they need to be closed and opened again.

- Remove rust stains. When it forms, machine oil is applied to the spots and left for several hours. Then the rust is cleaned with a metal sponge, washed off and wiped dry with a soft cloth.

- Types of vise and their application

- How to make a workbench in the garage yourself

- How to make a workbench correctly

- How to make a wooden workbench with your own hands

Construction details

Such locksmith tools come in different shapes and sizes, depending on their functionality. It is used both in the home workshop and in the workshops of factories and plants.

Regardless of the size and place of operation of this mechanism, all its varieties include similar design details:

- base (base plate);

- static sponge;

- movable sponge;

- undercarriage screw;

- nut;

- handle;

- replaceable notched plates;

- spring;

- sleeve;

- fastening for holding a vice.

Various versions of the vice can include many other parts and elements, depending on the functional purpose.

Locksmith's vice is a pretty heavy tool. It is made from a material as strong as steel or cast iron. In order to hold it on the table surface, a special fastener is provided in the design of this mechanism, which also supports the vice in an upright position. With its help, the static (stationary) sponge of the device is fixed. A movable sponge is attached to it in a special way.

The movable jaw is removed and approaches the fixed jaw by means of a threaded screw. It is set in motion by means of a retractable handle. By turning the handle of the vise, you can adjust the distance between the plates, setting the desired width.

Common to all locksmith vices is that the size of the part held between the plates determines the length of the maximum distance between them.

Plates and other mechanisms are made of durable steel, as they bear the maximum load during operation, especially when the vise is used as an anvil. Other structural parts are also distinguished by their special strength and reliability, a high degree of wear resistance, which allows them to easily withstand mechanical loads.