How to make a creeper for a walk-behind tractor with your own hands?

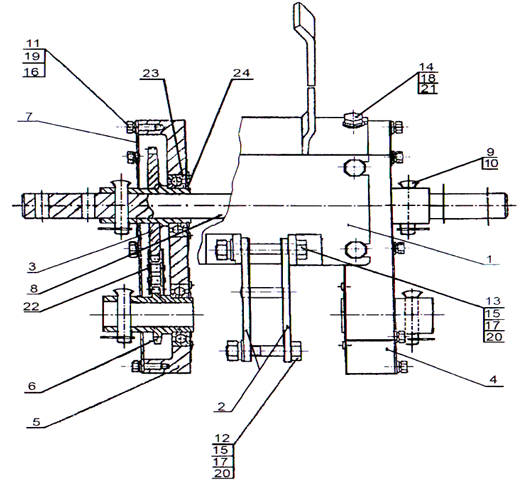

Immediately before making a creeper, you need to decide what type of mechanism you will make

It is also extremely important to choose the gear ratio - this will determine the torque and speed of the output shaft. In addition to all, you need to decide on the mass and size of the future creeper.

Be sure to study the drawings that will tell you the correct procedure for assembling the device.

- driving and driven shaft;

- a set of sprockets with the gear ratio required for work;

- bearings, the size of which is designed for the diameter of the shafts and axles;

- chains through which the boiling moment will be transmitted;

- angle-type profile - it is needed to make the frame and fasten the entire mechanism;

- case - you can buy ready-made or make yourself;

- sheet steel, 5 mm thick.

The algorithm for assembling a creeper on a walk-behind tractor is as follows:

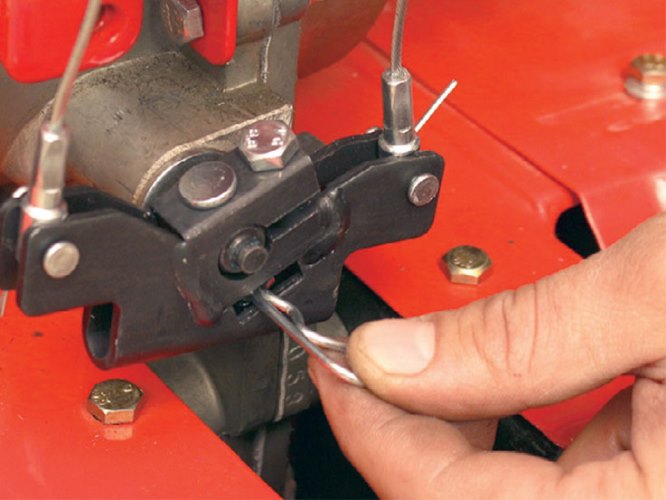

- Install the drive sprockets on the input shaft first. In this case, you can use a flange or keyway. If the mechanism is large enough, then the parts can be fixed by means of spot welding. During installation, make sure that the sprockets do not overheat, as this will lead to their deformation;

- Next, assemble the driven shaft from the two axle shafts. Install the counter flanges on its end parts;

- Fasten the driven sprocket between the flanges, then bolt the sprocket and the axle shafts. If you do not want to equip the mechanism with bolted connections, you can make a one-piece shaft, on which there should be a groove for mounting the key. The disadvantage of such a connection is that, under the influence of the forces of the axes, the sprocket can move in one of two directions;

- The housing for the creeper can be made by yourself, or you can use a ready-made factory design. The latter already provides seats for stuffing box seals and shaft bearings;

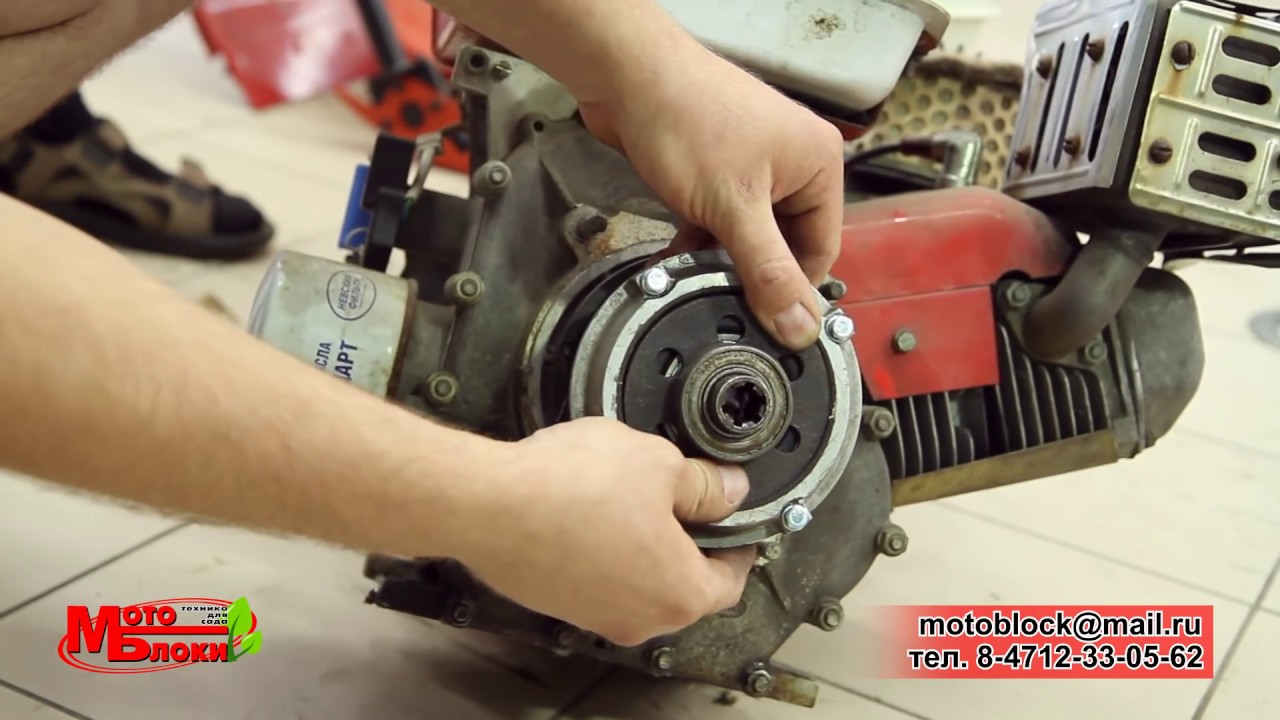

- Install closed ball bearings inside the housing. As a rule, they have a cylindrical shape and are fitted with an interference fit;

- Install and secure the drive shaft between the eccentric bearing assemblies - this will allow the shaft to be adjusted in its seats. In this case, the adjustment limit should be 15 ° from the normal tension of the chain of the mechanism;

- At the end, install a special gasket in the creeper to the walk-behind tractor. The video will tell you more about the manufacture of a creeper for a walk-behind tractor.

The advent of motorized cultivators has greatly simplified the life of every farmer. With their help, land owners were able to plant and harvest crops, take care of plants and perform a number of other works, saving their time and effort.

How to reverse speed on a walk-behind tractor

Consider how to make a reverse speed on a walk-behind tractor. The presence of a reverse depends on the model and dimensions of the mini-equipment. You can cultivate the land with a motor cultivator, a light walk-behind tractor and a heavy machine. It all depends on the goals and objectives set. Usually, when using models weighing up to 30 kg, there is no need for a reverse speed, moreover, it complicates the design of the unit. A heavy machine without this function will make the job more difficult.

Agricultural machinery will not move without a gearbox. It happens:

The task of the bevel gear is to ensure the collision of the transmission with the engine, which affects the power of the gear. The gear is the transmitter between the motor and the wheels.The reduction gear is used to reduce the speed to increase power.

The reverse gear has a clutch located between the gears. They are on the main roller. The main task of this system is to ensure the reverse gear of the equipment. For self-production of this mechanism, the first step is to prepare a case, for which many use a two-inch fitting square.

You can use the generator shaft from the Ural motorcycle. The gears will fit from the Friendship chainsaw. In the shaft, you just need to drill a hole of the appropriate diameter. Mount another pinion shaft with bearings on the opposite side. And already at the weekend, fit a pulley to ensure rotation.

You can purchase a ready-made gearbox, only when buying it is better to give preference to more expensive mechanisms, since they are more reliable and last longer.

If you increase the speed of the cultivator, then you need to take into account that wear will occur much faster. When doing land work, I want to quickly cope with the task. To increase or decrease the speed of movement, you can try the throttle stick. If the work is hard, then when the gas decreases, the engine will stall.

The first speed is used when plowing the land when more power is required from the machine. Faster work reduces the depth of cultivation.

How to increase the speed of MTZ

The article will tell you about what characteristics a conventional walk-behind tractor has, as well as what needs to be done if there is a need to resolve the issue of how ... Rating is available when the video has been rented. ... What wheels are better to take on a trailer to a walk-behind tractor so that it travels faster? Same way…

More and more gardeners today are wondering: how to tune a walk-behind tractor with your own hands?

After all, if you turn to specialists in this matter, this can entail large financial costs. Ultimately, reworking a walk-behind tractor can even cost significantly more than buying a new unit.

Equipment for the Neva

In today's market, there is a wide range of attachments for the Neva walk-behind tractor. It can be either designed specifically for this unit model, or universal. There is always such an option as the use of homemade attachments for a walk-behind tractor. In this case, having independently developed a drawing of attachments (if the master has sufficient skill), you can make equipment that optimally meets specific requirements.

The set with the Neva walk-behind tractor comes with a pair of plowing cutters, and the rest of the attachments are purchased separately.

Using a very necessary attachment device for planting potatoes, a potato planter, you can finish planting work much faster, thereby freeing up a lot of time for more interesting things.

Such an attachment for the Neva walk-behind tractor, like a hiller, will help in caring for root crops, allowing all the work to be carried out as efficiently as possible. It is designed as single-row and double-row. Such attachments can also be homemade.

The weeder will also make life easier for the gardener. With this attachment, there is no need to manually remove weeds between crop rows. After a couple of seasons of working with a walk-behind tractor with such attachments, the growth of weeds is significantly reduced.

Combines with the Neva MB 2 walk-behind tractor and attachments such as a potato digger. With its help, it will be possible to harvest most root crops without damaging them as when using a shovel. If you watch a video about the operation of the Neva walk-behind tractor and its attachments, you can see the process of harvesting root crops.

Lugs also belong to the attachments for the walk-behind tractor. They improve the flotation of the machine and give it extra power when working on soft, sticky soil.This attachment for the Neva walk-behind tractor has a more than affordable price, and it is better not to refuse to purchase it.

The necessary attachments for the Neva MB walk-behind tractor will also be a trolley for transporting goods. In this case, in addition to helping in gardening work, the car will also become a vehicle. If desired, using the drawing of attachments for the walk-behind tractor, the cart can be made with your own hands.

Motoblock Neva 2 is also compatible with other attachments - a lawn mower. Using it, it will be possible not only to prepare the grass for drying hay, but also to tidy up the lawn.

Using attachments on the Neva walk-behind tractor, it is turned into a very versatile device. To reduce costs, you can find drawings of attachments and make it yourself. If you have no desire to tinker, you can purchase used attachments.

Chopping branches with a walk-behind tractor

Often, branches from trees are thrown away and not even considered as fuel. But if you look at this issue from a more practical point of view, everything on the farm can be used with benefit.

An excellent helper will be wood shredder

, or a chipper, which also goes as attachments to walk-behind tractors. The shredder is suitable for recycling garden scraps, tree crowns, wood waste.

With the help of this unit, you can harvest firewood without great physical costs.

The recycled branches are used for the manufacture of pallets - fuel pellets from wood waste used for heating.

Often, branch shredders are installed on heavy walk-behind tractors. It is driven by one or two belts that connect to the front PTO on the engine.

Some models of such hinges have special tables and cones for chopping wood. The cutting tool is a knife system.

Fastest models

First, let's find out which walk-behind tractors are considered the fastest? Are there any advantages for domestic manufacturers or does the palm unconditionally belong to foreign competitors?

By the way, it is quite difficult to determine the unconditional winner in terms of maximum speed, because not only are there simply a great many models of walk-behind tractors from different manufacturers, and independent modernization of this multifunctional agricultural unit is possible.

At motoblocks MTZ-05, MTZ-12

4 speeds are provided when moving forward and 2 - backward. The minimum speeds correspond to the first gear, when shifting to the next speed it increases. For the above models, the minimum speed for moving forward is 2.15 km / h, for reverse movement - 2.5 km / h; the maximum with the forward movement is 9.6 km / h, with the rear - 4.46 km / h.

At the walk-behind tractor "Mobile-K G85 D CH395" / Grillo

the maximum speed of forward movement is 11 km / h, reverse - 3 km / h. At the same time, the gearbox provides the ability to switch between three forward and two reverse speeds. Keep in mind that all of these metrics are true for unimproved models.

MTZ-05

MTZ-12

Mobile-K G85 D CH395 "/ Grillo

"Mobile-K Ghepard CH395"

- a Russian-made walk-behind tractor, has a 4 + 1 gearbox, can accelerate to 12 km / h.

Ukrainian walk-behind tractor "Motor Sich MB-6D"

can reach a speed of 16 km / h, six-speed gearbox (4 + 2).

Unit "Centaur MB 1081D"

Russian, but produced in Chinese factories. It is considered the fastest walk-behind tractor in the heavy class. The maximum speed of its movement is as much as 25 km / h! Refers to diesel motoblocks, unlike the models listed above - they run on gasoline.

Mobile-K Ghepard CH395

Motor Sich MB-6D

Centaur MB 1081D

How do I adjust the speed?

Sometimes it turns out that you want to change the speed of movement of your walk-behind tractor: increase or, which happens quite rarely, decrease it.

To increase the speed of movement of motoblock units, one of the following two methods is usually used:

- replacement of wheels with large ones;

- replacement of a pair of gears of the reducer.

The usual wheel diameter of almost all motoblocks is 570 mm. Most often, when replacing, tires are selected with a diameter that is approximately 1.25 times larger than this - 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows for larger tires, you can try increasing the speed gain.

The gear pair installed in the wheel reducer usually consists of two gears with 12 teeth for a small one and 61 for a large one. You can change this indicator by 18 and 55, respectively (only for specialists in agricultural machinery service centers), then the speed gain will be approximately 1.7 times

Do not try to carry out the operation to replace the gears yourself: it is very important here to select not only high-quality parts with minimal errors, but also the appropriate pulley. The gearbox shaft retaining plate also plays an important role.

A possible solution to increasing the speed is to adjust the throttle switch: when the machine is turned on, move it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change the speed downward, special reducers are not needed - it is enough not to switch to high gears.

Also possible solutions to the problem of increasing the speed of the walk-behind tractor are replacing the motor with a more powerful one and upgrading or installing a clutch system (in some outdated models it is not provided).

It can help to increase the speed (especially on uneven terrain or heavy soils, where slippage of the equipment is frequent due to insufficient weight of the unit) and the installation of weights. They can be made with your own hands from metal parts. Weighting structures are installed on the walk-behind tractor frame and wheels. For the frame, you will need metal corners, from which a self-made removable structure is formed, that is, you can easily remove it if not needed. Additional ballast weights are attached to this removable additional frame. The wheels need discs made of steel and solid iron blanks with a cross-section in the form of a hexagon. These parts are welded and inserted into the hubs. For reliable fixation, cotter pins are used, which are installed in specially prepared holes.

Of course, if there are no round steel elements at hand, you can replace them with almost any available material: reinforced concrete products or even flattened round plastic flasks, inside which sand is poured.

To speed up a walk-behind tractor with a trolley in bad weather conditions - snow, slush, soil sour from torrential rains - you can put caterpillars (if the design allows). This method requires the installation of an additional wheelset and the purchase of rubber tracks of a rather large width. On the inner side of the tracked track, limiters are attached to securely fix the rubber and prevent it from jumping off the wheel pair.

Also for this purpose, you can replace the native gearbox with a similar device with a low gear - to facilitate overcoming obstacles.

If you take good care of the unit, follow all the recommendations for operating the device, carry out regular preventive maintenance, then the walk-behind tractor will give out the maximum of its capabilities in terms of speed and performance.

For adjusting the speed of the tiller of the walk-behind tractor, see the video below.

How to make a mower from a walk-behind tractor, choose attachments

In the summer, one of the important tasks for farmers and land owners is mowing the grass. If you do this manually, then it takes a lot of time and effort. Therefore, the attachment to motoblocks in the form of a mower is an almost irreplaceable tool.

It makes work easier and significantly reduces time spent. For example, mowers for motoblocks will help you quickly prepare mows for cattle.

When choosing a mower for a walk-behind tractor, you need to assess the landscape of the site on which it will be used. In each territory, crops grow, different in height, density and composition of grasses. Therefore, two types of mowers have been developed

:

- disk (rotary);

- finger (segmental).

Disc or rotary mounted mower

It is used for mowing vegetation up to 1 cm in diameter, dense grasses and low bushes. Such a model is used on flat terrain with slopes of no more than 15-20 °, with a lateral slope of no more than 8 °.

The grass cut by the rotary mower is laid in rows.

The disadvantage of such devices is the high probability of injury, and when working with them, stones must be avoided, as this will lead to breakage. The advantage of a mounted mower - simple design, respectively, and a low level of breakdowns (except for the possibility of falling stones).

Important!

Safety rules must be observed when working with the mower. In particular, every two hours of operation of the unit, the fastening of the nuts and the tension of the belt should be checked, and all maintenance operations should be carried out with the motor of the walk-behind tractor turned off.

Before starting work, it is also worth checking the strength of all connections, and during the work itself, you should not be in front of the cutter bar.

Segment mowers

By design, the segment mower has cutting blades that move progressively under the influence of the motor shaft. They are not afraid of thick branches and stones. The belt drive is hidden in a special casing. The quick-coupling mechanism allows you to quickly dismantle and reinstall the mower on the walk-behind tractor.

Today, walk-behind tractors are perhaps the most common type of mini-equipment for agricultural purposes. It so happens that users of some models no longer satisfy the speed and performance of the unit. Buying a new model is quite expensive. In this case, you can try to upgrade your device.

How do I adjust the speed?

Sometimes it turns out that you want to change the speed of movement of your walk-behind tractor: increase or, which happens quite rarely, decrease it.

To increase the speed of movement of motoblock units, one of the following two methods is usually used:

- replacement of wheels with large ones;

- replacement of a pair of gears of the reducer.

The usual wheel diameter of almost all motoblocks is 570 mm. Most often, when replacing, tires are selected with a diameter that is approximately 1.25 times larger than this, - 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows for larger tires, you can try increasing the speed gain.

The gear pair installed in the wheel reducer usually consists of two gears with 12 teeth for a small one and 61 for a large one. You can change this indicator by 18 and 55, respectively (only for specialists in agricultural machinery service centers), then the speed gain will be approximately 1.7 times

Do not try to carry out the operation to replace the gears yourself: it is very important here to select not only high-quality parts with minimal errors, but also the appropriate pulley. The gearbox shaft retaining plate also plays an important role.

A possible solution to increasing the speed is to adjust the throttle switch: when the machine is turned on, move it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change the speed downward, you do not need special reducers - it is enough not to switch to high gears.

Also possible solutions to the problem of increasing the speed of the walk-behind tractor are replacing the motor with a more powerful one and upgrading or installing a clutch system (in some outdated models it is not provided).

It can help to increase the speed (especially on uneven terrain or heavy soils, where slippage of the equipment is frequent due to insufficient weight of the unit) and the installation of weights. They can be made with your own hands from metal parts. Weighting structures are installed on the walk-behind tractor frame and wheels. For the frame, you will need metal corners, from which a self-made removable structure is formed, that is, you can easily remove it if not needed. Additional ballast weights are attached to this removable additional frame. The wheels need discs made of steel and solid iron blanks with a hexagon-shaped cross-section. These parts are welded and inserted into the hubs. For reliable fixation, cotter pins are used, which are installed in specially prepared holes.

Of course, if there are no round steel elements at hand, you can replace them with almost any available material: reinforced concrete products or even flattened round plastic flasks, inside which sand is poured.

To speed up a walk-behind tractor with a trolley in bad weather conditions - snow, slush, soil sour from torrential rains - you can put caterpillars (if the design allows). This method requires the installation of an additional wheelset and the purchase of rubber tracks of a rather large width. On the inner side of the tracked track, limiters are attached to securely fix the rubber and prevent it from jumping off the wheel pair.

Also for this purpose, you can replace the native gearbox with a similar device with a low gear - to facilitate overcoming obstacles.

If you take good care of the unit, follow all the recommendations for operating the device, carry out regular preventive maintenance, then the walk-behind tractor will give the maximum of its capabilities in terms of speed and performance.

For adjusting the speed of the tiller of the walk-behind tractor, see the video below.

Many farmers are interested in how to increase the speed of the walk-behind tractor. The most common agricultural technique is the walk-behind tractor. With its help, the performance of work on land and personal plots is greatly simplified. Let's consider how you can increase the speed on this technique. The increased speed will increase the productivity and cross-country ability of the mini-car, which can be used in any season and weather.

Preparatory work

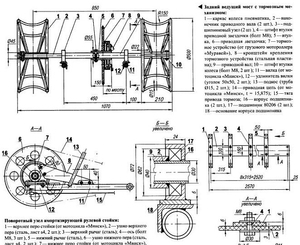

To make a minitractor out of a walk-behind tractor, you must first prepare drawings and kinematic diagrams. Thanks to the drawings, you can better imagine what kind of unit will turn out in the end, as well as decide on the necessary material.

To make a minitractor out of a walk-behind tractor, you must first prepare drawings and kinematic diagrams. Thanks to the drawings, you can better imagine what kind of unit will turn out in the end, as well as decide on the necessary material.

The diagrams are needed in order to correctly calculate the load on the frame, as well as the tractive effort that will be required to perform work on the personal plot.

The location of the engine also plays an important role. It is best if the power unit is located in the back, immediately behind the driver's seat.

This creates better traction between the drive wheels and the ground, and the driver adds weight to the front driven axle. As a result, the mini tractor will not be able to tip over backwards when plowing on firm ground.

Required materials and tools

The work will require the following materials:

- Motoblock Neva.It represents the basis for the entire future design.

- A pair of additional wheels together with an axle. The choice of wheels must be very careful. If they are too small, the machine can tip over, and too large can negatively affect handling. The optimum wheel radius is 14-18 inches. The ideal option would be tires from an old-style Volga passenger car.

- Bearings for mounting the steering column and wheels.

- The metal to create the frame. It is recommended to use a pipe, channel or angle.

- Fasteners: nuts, bolts and washers.

- Consumables: grinder discs, drills, electrodes.

- Lubricant: lithol or solid oil.

To make a mini-tractor from a walk-behind tractor, you will need the following tools:

- Welding machine.

- Drill.

- Bulgarian.

- Set of wrenches.

How to increase the speed of the walk-behind tractor

There are two ways to increase the speed of the walk-behind tractor:

- installation of large wheels;

- replacement of the gear pair.

Let us first consider how changing the wheels helps to increase the speed of the cultivator. The standard wheel size of almost all mini-unit models is 57 cm. When changing, you can install tires that are 1.2 times larger in diameter. Usually, wheels of 70.4 cm are used. Despite the small difference, the speed of the walk-behind tractor increases markedly. If the arches into which the tires are inserted will allow the insertion of wheels with a larger diameter, then you can try adding centimeters.

When using a walk-behind tractor, lugs are used to cultivate the land. These are wheels with iron plates that grip freely on the ground or snow. They can be purchased in specialized stores, or you can make them yourself. Their size also affects the speed of movement of the unit.

Let's consider how to increase the speed on a walk-behind tractor in the second way. Like any technique, the cultivator has several speeds, which are controlled by gears. Usually cultivators move at a speed of 2 to 15 km / h, while the large gear has 61 teeth, and the small gear has 12. To increase the speed, the gear pairs of the reducer are replaced. We increase the number of teeth, thus the maximum speed of the walk-behind tractor is achieved.

It is recommended that the replacement be carried out by professionals and preferably in specialized centers, since parts turned with a minimum error will affect the operation of the motor. It is not only the replacement of the gear that is important, but also the correct selection of the pulley.

Additional accessories

Motoblocks are on sale with a minimum number of components. However, a milling cutter and a standard plow are not enough for all agricultural work. How to improve a motor cultivator using the materials at hand? With the help of the tools that are in every home, you can expand the capabilities of the walk-behind tractor.

Equipment that you can make yourself:

- Installation of a rake on a walk-behind tractor for cleaning garbage, leaves, hay. Such a simple device will speed up the autumn field work, and will allow you to clear large areas of debris in a matter of minutes. To make a rake, you will need: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. The armature is cut into pieces 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase maneuverability, the rake can be equipped with roller wheels.

- A trailer and a cart will help you to transport oversized cargo. The trolley can be made from scrap materials - a channel and old wheels from a car, a metal profile and boards. The clutch is made standard for both tractors and cars.

- If desired, you can make a potato digger, hiller and harrows, which will not be inferior in quality to the purchased ones.

Plows for motoblocks

Another device for cultivating the soil using a walk-behind tractor is a plow.

The following types of plows are distinguished:

- The easiest to use is the single-body, also known as the Zykov plow.

- Reversible plow for walk-behind tractor: swivel or reversible. Upper part with curved feather, which turns the ground during the plowing process. A versatile tool that easily handles plowing heavy soils. Quickly copes with the processing of areas with clay and swampy soil.

- The rotary plow for the walk-behind tractor has a complex design. Depending on the number of plowshares, there are two-piece and three-piece models. Active plowshares throw the soil in one direction only, while passive plowshares compare the beds and raise them. Tilling the land with such a plow has a number of advantages: the soil is saturated with oxygen as much as possible; reduced tire wear and fuel consumption; after processing, no large clods of soil remain.

- A rotary plow for a walk-behind tractor gives unlimited possibilities. During operation, the axis turns, and with it the layers of soil. It easily plows even very hard soil at a depth of about 30 centimeters. A distinction is made between paddle plows, drum plows, paddle plows and auger plows. Devices of the first type are equipped with a rigid pusher, they can consist of a spring plate or be combined. Units of the second type are equipped with a disc with blades rotating during operation. A plow with a disc knife for a walk-behind tractor is suitable for work in early spring, it copes well with wet soil.

Any of the above plows can be made independently, taking into account the design features and following the instructions and diagrams. You can also improve an already purchased plow.

Thanks to the expansion of the capabilities, the walk-behind tractor becomes universal. It can be used to solve a variety of tasks from field work to snow removal in winter.

How to make weights yourself

To make weights for the wheels of a walk-behind tractor, a desire is enough, a minimum of material and time. There are no particular difficulties here. It is necessary to prepare the future details of this device:

- 2 five-kilogram weights,

- 2 ten-kilogram pancakes,

- 2 clutch baskets from Zhiguli,

- hexagonal solid profile (piece),

- motoblock cotter pins (2 pcs.).

All this can be overlooked at the collection point for old scrap. You cannot do without a welding machine with electrodes, a grinder with a cut wheel, a drill with drills. Well, in order to give an aesthetic look to the device, you should stock up on paint.

2 pieces are cut from the hexagonal profile, about 5 cm in size. Holes for the cotter pins will need to be drilled in them. Then this segment is attached to the pancake from the bar. The hexagon is inserted into the neck hole and welded.

Then you will need to attach the clutch basket to the pancake. For this, welding is used - it is scalded around the circumference of the flywheel.

Motoblock - indispensable equipment for the gardener

A walk-behind tractor by its design is a tractor, but with one axle. This is a must-have device for soil cultivation. The term walk-behind tractor began to be used more often in the 80s, earlier this technique was called a pedestrian tractor or a single-axle tractor. It greatly facilitates the monotonous manual work of loosening the soil for planting various horticultural crops. In addition, the walk-behind tractor can perform several functions at its low cost. The work on this equipment takes place in this way: a person follows the walk-behind tractor, controlling the steering wheel.

Motoblocks are divided into wheeled and motorized cultivators. They are distinguished by the way they are aggregated. The first is included in the operating mode when the wheeled chassis is moving. In the second, the wheel part is replaced by a milling cutter.

This technique has a gasoline or diesel engine, which drives the unit, and a wheelset. For field work, you may need other accessories that are connected via the towing device of the walk-behind tractor.