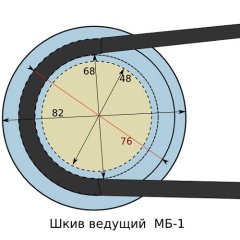

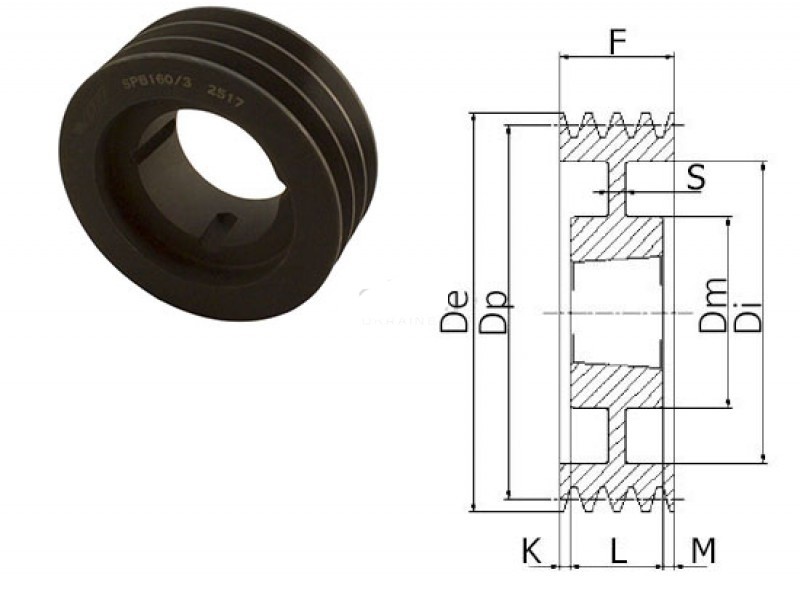

The image of the pulley in the drawings

From the drawing of the product, its structure, dimensions and manufacturing method should be fully understood. For standard products, the designation of the pulleys is mandatory in the drawing.

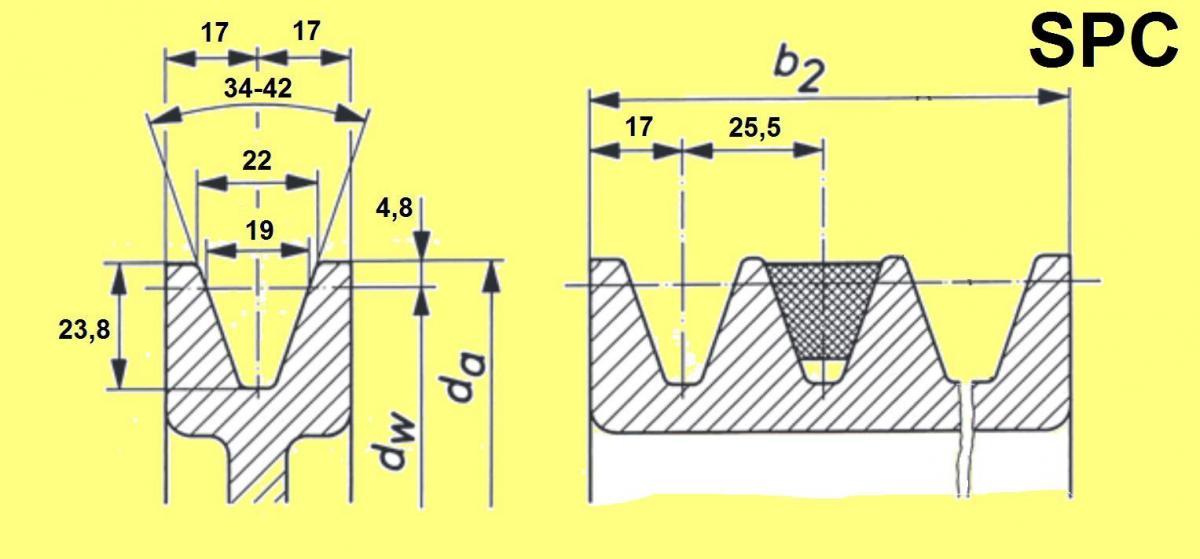

In order to correctly and accurately make a non-standard pulley, its drawing must meet certain requirements. You can choose the correct angle of the pulley groove if you use a standard series of slopes for the drawing.

The pulley is usually shown in the drawings in two forms:

- section with a cutting plane passing through the axis of rotation;

- side view.

The side view, as for other parts with axial symmetry, is not shown in full, but in half. For pulleys that have spokes in their design, it is permissible not to depict everything, but to bring a drawing of one part with an indication of their number.

The cut is required to be built so that at least one spoke is in its plane. No hatching is required on the cut. If the part is solid, the cut plane is hatched, as usual in the drawing.

Basic dimensions and parameters, such as:

- rim and hub diameter;

- V-belt profile;

- fillet radii;

- slopes of the groove, etc., are applied on the section.

An additional view of the drawing shows a cross-section of a spoke. If its form is variable, then several additional views of the drawing are made.

An image of the attachment point for a key with dimensions and an indication of the surface quality is also displayed in an additional view of the drawing.

If instead of knitting needles to facilitate the structure, several holes are provided in the body of the part, their number and dimensions are indicated in the section, and it is permissible not to build a side view in the drawing.

Walk-behind tractor pulley: characteristics, manufacture and operation

Auto mechanic specializing in agricultural machinery

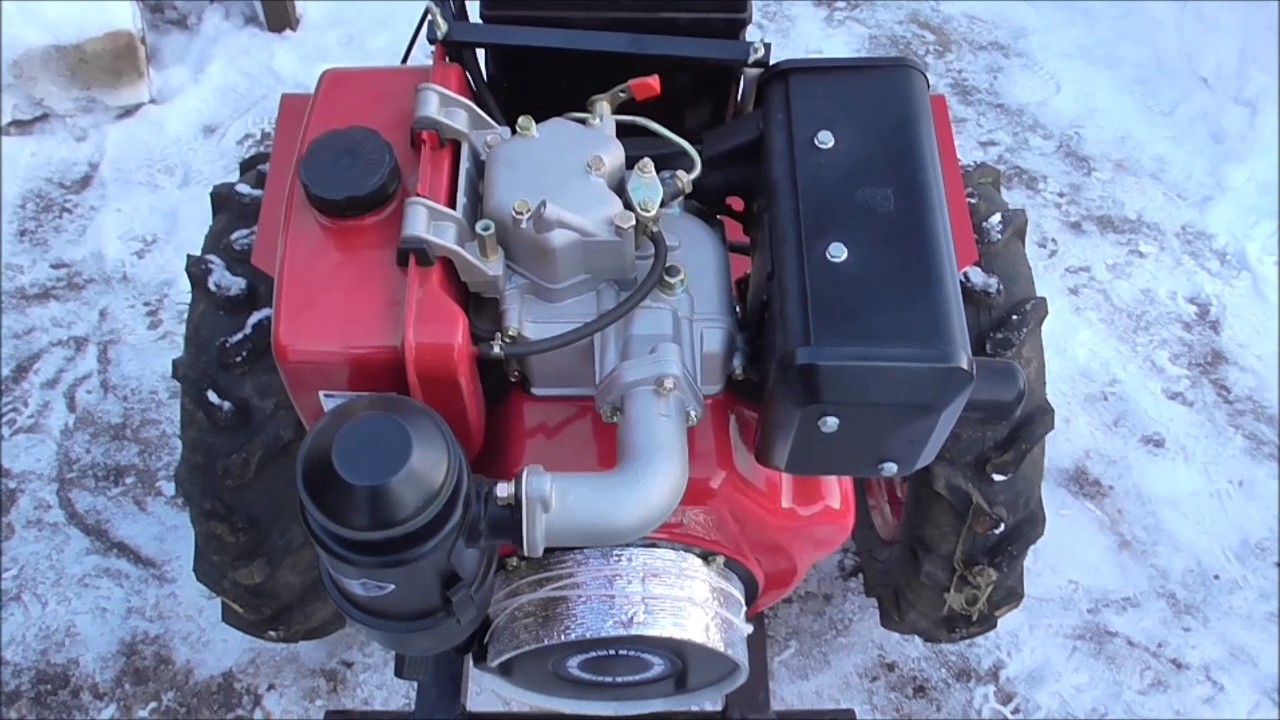

A walk-behind tractor is a uniaxial mechanical device with a motor. Its main functional purpose is to help people in all kinds of agricultural work. Therefore, every lover of gardens and vegetable gardens larger than 10 acres of land is obliged to make friends with this small-sized tractor, since there is no better assistant to find.

Since quality components are important in technology, everyone who works with it should not only learn their names, but clearly understand their purpose in a complex mechanism and know which of the details is secondary and which takes on the main functions.

Watch the integrity of the Pulley in your walk-behind tractor

Operation and maintenance Neva MB-2

Changing the engine oil

The manufacturer recommends using such well-known brands of engine oil for the walk-behind tractor as LUKOIL - SAE 10W30 API SF / CC standard, as well as RAVENOL SAE 30 API CD / SF.

At temperatures above 4 degrees Celsius, using thickened oils (for example, grade 10W30) will lead to increased consumption of this type of fuel, therefore, in the cold season, it is recommended to check the oil level in the engine more often, not allowing its mark to drop below normal.

An oil change is carried out after the walk-behind tractor has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is completely drained from the tank, and then a new one is added until the oil level reaches a special mark. The drain plug is then screwed on tightly and wiped dry.

The first start-up and running-in of the Neva MB-2 walk-behind tractor

The first start-up must be done according to the following scheme:

- make sure that the walk-behind tractor is in a complete state (the height of the steering rod and handles must correspond to the height of the user);

- you can start the engine only if the walk-behind tractor is located on a flat surface;

- check the oil and fuel level in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- idle time (without load and movement) should be about 10 minutes, then you can move from a place and operate the walk-behind tractor.

The running-in period is the first 20 hours of the walk-behind tractor, after which you need to change the oil

During this period, the most important:

- do not run at full throttle;

- work only on pre-prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that is included in the kit;

- the "Neva" MB-2 walk-behind tractor during the running-in period can be loaded only at ¾ of the power;

- shifting gears in the gearbox can only be done when the rotation of the drive pulley is completely stopped;

after the first 20 hours of operation after the first start, change the engine oil.

Characteristics and fields of application of pulleys for motoblocks

One of the main and very important parts in the walk-behind tractor is the pulley. This spare part is responsible for the direction of the force produced by the motor. By means of the belt, the energy emanating from the engine through the pulley of the walk-behind tractor is transmitted to the hinged mechanisms of the walk-behind tractor, which, in turn, provides control of their rotation and the movement of the entire walk-behind tractor as a whole.

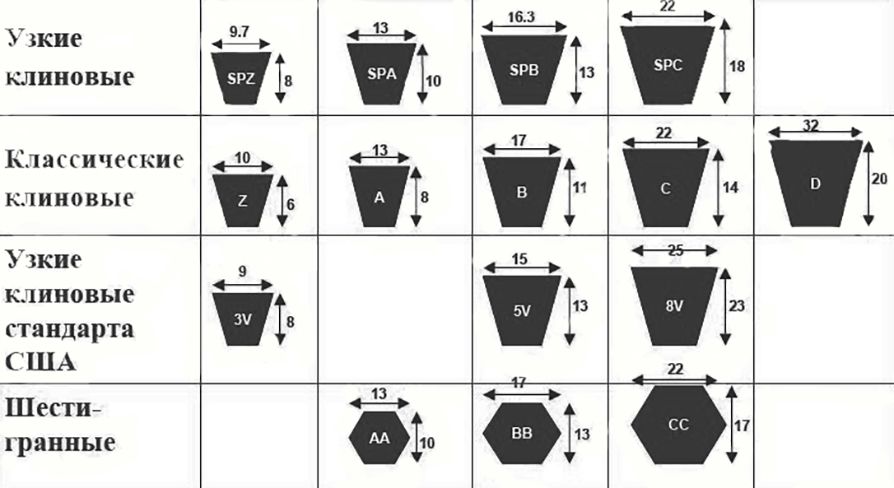

There is a certain classification of these products. They are distinguished:

- by size;

- by the material from which the pulley is made for the walk-behind tractor;

- by the type of manufacture of the part;

- in the shape of the holes for landing on the main shaft of the engine;

- relative to the shaft to which the spare part belongs.

Let's consider each aspect in more detail.

With regard to the material from which such an irreplaceable part as a pulley is made, they often use aluminum, steel, cast iron, stainless steel, duralumin and even plastic. Such options are particularly practical and durable, which significantly extends the service life of the entire walk-behind tractor.

It is very important that a part made of the above materials is very resistant to environmental conditions.

In this video, we will consider a pulley for a walk-behind tractor:

By the type of manufacture of parts, disc, pulleys with spitz and monolithic ones are distinguished, which, in turn, are divided into two- and three-strand (the difference between them in diameters).

The shape is determined by the type of hole for planting - there are products with cylindrical and tapered holes. Both types have eight special grooves, on which the serviceability of the belt directly depends, and therefore, the effectiveness of the robots of the entire walk-behind tractor. Also, in order to protect the walk-behind tractor from breakdowns and damage, before installing the pulley on the gearbox of the walk-behind tractor engine, it is necessary to choose a belt of the ideal size.

With respect to the shaft to which the pulley belongs, drive and driven elements are distinguished. The difference between them is that the slave is installed directly on the crankshaft, while the master is connected to the motor, and, through the energy generated by it, drives the attachment on the walk-behind tractor.

Installing a Chinese engine on a Ural walk-behind tractor

Greetings to dear members of the forum. There is somewhere a similar topic here, more precisely, it is generally about the Urals, and in it the topic of replacing the engine is touched upon without any specific examples (except perhaps a few videos on YouTube, where a specific installation is briefly highlighted without details and with advertising). I learned the essence from it, but some details remained in question. Here I will describe my experience in installation, not without your help, of course. At the moment, there is a Ural walk-behind tractor with an almost inoperative EVP /

Purchased a single-stage reduction gearbox for motors with a shaft of 19.05mm

Ordered a gasoline 4-stroke Green Field GF-170FE engine (with an electric starter, this is the father's requirement, since it is calculated that the walk-behind tractor will be used with a trolley for driving grass for rabbits)))

Now the matter remains with the pulley on the gearbox and belts.But I will buy belts after installing the engine, since there is a plant for the production of rubber products UZEMIK and a company store with it in the city, it will not be a problem to pick up belts. The pulley is not entirely clear. The native pulley from the Urals has a 32mm shaft landing. The shaft of the new gearbox is 15mm. It is not difficult to make a spacer. But ... I found a passport to the Ural walk-behind tractor on this forum, someone from the members of the forum scanned it, for which I am very grateful to him. So, the speed of the gearbox shaft at 1 speed is about 300 rpm, at 2 600 rpm. The speed of the Chinese engine is up to 3600rpm, with a new gearbox of 1800rpm, i.e. somewhere 3-6 times more than necessary (provided that you put your own pulley from the Urals), i.e. change the pulley too. While there are two options - to order a new one, or to fit a Mole from a motor-cultivator, such

unfortunately, I did not measure the dimensions of my own pulley, and I also cannot find the dimensions of the Mole pulley, so while in a creative search. I would be very grateful to everyone for sensible thoughts, or experience, in this homemade product. P.S. the engine will be installed in any case, I will make detailed instructions on what and how I did, so that people do not suffer like me in search of the necessary material ...

Pulley concept

It is designed to transfer torque from the drive shaft to the driven shaft. For the operation of such a drive, both shafts are placed in parallel. A flat wheel is put on and fixed on each shaft, they are placed in the same plane. The wheels are connected by an endless flexible drive belt. When the drive pulley rotates, the frictional force causes the belt to move around part of its surface. This movement is transferred to the driven pulley, causing it to rotate.

Belt transmission is common among household appliances, mechanisms of small and medium-power machine tools, in various internal combustion engines.

It has the following advantages:

- simple device;

- the ability to transmit significant power, modern V-belt pairs transmit up to 400 kW;

- high rotation speed, up to 50 m / s;

- smooth and quiet running;

- damping of vibrations and jerks of the drive shaft during transmission of rotation;

- overload slippage acts as a safety mechanism.

The pulley itself is a disc on a shaft. It consists of two main parts: a rim and a hub. The rim is the outside of the part. It engages with a belt and, depending on the type of drive, can be flat or have a recess in the shape of the belt. The side protrusions above the rim are called cheeks. They keep the belt from slipping. If the drive is wedge-shaped, then the cheeks are made inclined, they have an additional function - they increase the engagement area.

If a gear drive is used, teeth of the corresponding shape are made on the surface of the rim.

If several grooves are used in parallel, several grooves are made on the rim.

The hub is the inner part of the pulley. It has a hole for mounting on the shaft. Often the rim and hub are cast, turned, or milled into a single piece.

To reduce the weight of the product, voids are left in the body of the pulley, forming spokes. When made from wood, the presence of knitting needles was determined by the manufacturing technology.

To ensure the interchangeability of pulleys, their standard sizes, technological requirements, marking are standardized. They are described in GOST 20889-94. "Pulleys for driving V-belts" and in GOST R 50641-94 (ISO 4183-89).

The standard marking includes the following parameters:

- number of streams;

- the profile of the drive belt used;

- diameter (calculated along the cord);

- sleeve designation.

So, the marking 8 SPC 500 denotes an eight-ribbed pulley for SPC profile with a diameter of 500 mm.

The rules for depicting pulleys in the drawing are also standardized. The drawing must be constructed in such a way that the product can be manufactured precisely in shape and size.

Pulley application

Wedge drives are among the most widely used in a wide variety of high torque and angular speed applications.First of all, these are internal combustion engines. In addition, V-belt pairs are used in areas such as:

- fans and air conditioners;

- compressor units, both piston and screw;

- transport systems of buildings: elevators, escalators, travelators;

- agricultural machinery;

- road construction equipment;

- mining machines;

- industrial technological installations;

- machine tools;

- Appliances;

- hand power tools;

and in many other industries.

Gear drives are used when it is required to transmit significant torque without slipping. The toothed belt drive does not require strong tension for good grip. It has a significantly lower radial axle load than other belt drives.

Such drives are used in:

- automobile engines, for the gas distribution mechanism;

- power drives of machine tools and industrial mechanisms;

- in technological installations of the food, pharmaceutical, chemical industry.

V-ribbed pulleys do an excellent job in the so-called serpentine gears, when one drive supplies rotational energy to many consumers, and at the same time follows a very winding path. V-ribbed gears allow you to transfer significant moments and reach high speeds without increasing the size.

They are used both in heavy engineering and in the production of household appliances.

Variable speed drive wheels are used wherever it is necessary to smoothly change the speed and torque without stopping rotation and removing the load. They are popular in areas such as:

- transmissions of cars, motorcycles, other wheeled vehicles;

- conveyors;

- precision machine tools for processing metal, wood and other materials;

- agricultural machinery.

The modern CVT is superior in performance to both manual and hydraulic transmissions.

Plane-belt drives are used where it is required to transmit rotation over considerable distances (up to 7-9 m) and to absorb shocks, shocks and other dynamic loads transmitted from the drive shaft to the driven shaft (or in the opposite direction). They are applied:

- in pressing and other forging equipment;

- in sawmill drives;

- in the technological equipment of the textile industry;

- in powerful centrifugal pumps.

Round belt drives are used for lightly loaded gears in precision instruments, consumer electronics and engineering.

They also cross easily and, with the help of additional passive pulleys, allow connecting the driven and driving shafts located in different planes and at an angle to each other, as well as changing the direction of rotation.

Description

In walk-behind tractors, designers use a belt drive, which consists of two pulleys, a belt and a tensioner.

Advantages:

- high speed of work;

- overheating protection of drive units;

- simplicity;

- reliability;

- low cost;

- lack of noise.

Disadvantages:

- frequent belt replacement;

- pressure on shafts and bearings.

The pulley is the main part of the gearbox, which is located on the central shaft of the engine. The appearance of the part resembles the shape of a wheel, interacts with other elements through a special belt.

You can buy these devices in different sizes from specialized stores. Most of the parts are made of aluminum, steel, cast iron and duralumin, they have high strength and reliability. To reduce the cost of goods, some manufacturers use plastic, plywood and textolite for production.

The main criterion when choosing a part is the size of the belt. The size of the pulley depends on it.

Technical requirements for belts:

- strength;

- wear resistance;

- minimum bending stiffness;

- maximum index of friction on the surface of the pulley.

Types of belts:

- flat - have a small thickness and cross-section, during the manufacturing process they are glued from separate parts of the fabric;

- woven - have a thickness of up to 1 cm and are made of nylon fabrics, which are impregnated with polyamide and rubber;

- rubberized - made of anid cord and have a thickness of 10 mm;

- synthetic - have a thickness of up to 3 mm and a glued joint.

And there are also round and V-belts.

Care

To extend the life of the walk-behind tractor, experts recommend knowing and applying several basic rules for caring for a pulley:

- regular checking and cleaning of the protective casing from stones, dust particles, earth and other debris;

- constant verification of the reliability of fastening the part to the axle to prevent thread wear;

- compliance with all rules and regulations for the operation of an electrical device;

- alignment check with a laser level;

- checking the device for mechanical damage, as well as cracks and scratches.

To prevent the development of corrosive processes after operation, it is necessary to put the walk-behind tractor in a dry and ventilated room, protected from the ingress of various precipitations.

In order to remove the pulley and correct the beating of the starter, you must first reduce the stroke, reduce the speed, and then completely stop the apparatus.

Before starting the process of performing the planned work, it is imperative to check the serviceability of all elements of the walk-behind tractor to prevent the occurrence of unpleasant situations that can lead to breakdown of the entire walk-behind tractor.

The main activities of a comprehensive technical inspection:

- regular cleaning of all working units;

- checking air filters;

- regular replacement of deformed parts;

- checking spark plugs;

- oil change;

- lubrication of parts of the control system;

- clutch adjustment;

- muffler change;

- belt tension adjustment.

A walk-behind tractor is a universal device that is used not only by farmers, but also by ordinary residents who have personal plots. This unit is a multifunctional device that makes it possible to remove snow, mow grass and lawns, transport goods, pump water and clean streets. To perform various types of work, it is enough just to change attachments. This process takes a short period of time and has a simple technology. The stable operation of the device is ensured by a large number of different parts. One of the most important elements in a walk-behind tractor is the pulley. A simple round-shaped part is the link between the motor and the moving parts. The whole process of performing work depends on the work of the pulley.

How to replace the pulley of the gearbox and front hitch on the "Neva" MB-2 walk-behind tractor, see the video below.

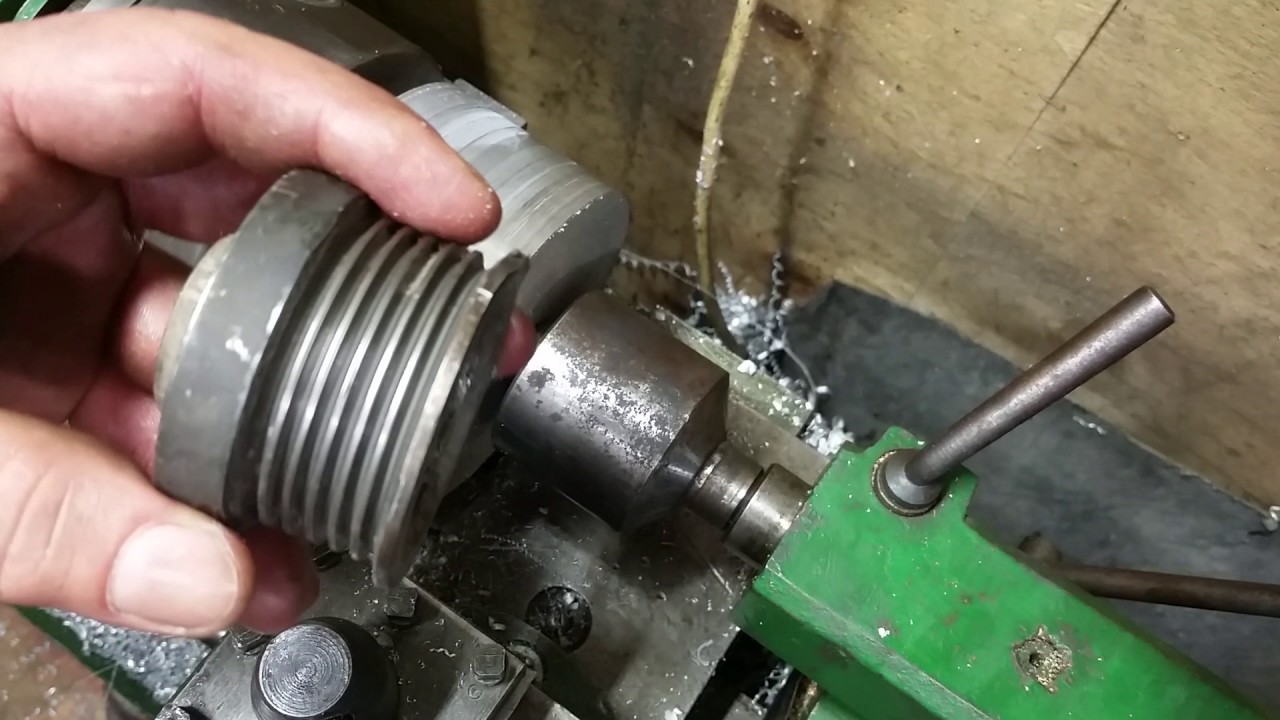

Self-production

If it is impossible to purchase a finished pulley, professional craftsmen advise you to make this part yourself.

To make a spline pulley at home, you need a lathe and a metal workpiece. For help, you can turn to turning workshops, where professional turners will definitely help you turn the necessary part.

If it is impossible to get a metal blank, experts advise using a piece of plywood.

Required tools:

- electric jigsaw;

- milling cutter;

- compass;

- electric drill.

Manufacturing steps:

- purchase of the necessary workpiece;

- drawing a circle of the required diameter;

- drilling a central hole;

- cutting a circle with a jigsaw strictly along the marked line with an indent from the line by 20-25 mm;

- grinding the resulting workpiece with fine sandpaper;

- cutting a groove for the belt using a cutter of the required size;

- installation of the finished product in the walk-behind tractor;

- elimination of all defects and inaccuracies.

This plywood part has a short lifespan and requires constant inspection and replacement if necessary.

It is possible to install homemade parts only on those walk-behind tractors in which this manipulation is provided by the developers.

To extend the life of the walk-behind tractor, experts recommend knowing and applying several basic rules for caring for a pulley:

- regular checking and cleaning of the protective casing from stones, dust particles, earth and other debris;

- constant verification of the reliability of fastening the part to the axle to prevent thread wear;

- compliance with all rules and regulations for the operation of an electrical device;

- alignment check with a laser level;

- checking the device for mechanical damage, as well as cracks and scratches.

User manual

To protect your equipment from premature breakdowns, thereby avoiding unforeseen expenses, both from a financial point of view and from the point of view of temporary resources, it is worth following just a few simple rules for care and operation:

the technique cannot be eternal only because most of it consists of durable steel, therefore, protect the walk-behind tractor from sudden temperature changes, the influence of excessive moisture and dampness;

regularly clean the top of the pulley from dust and other contaminants to avoid foreign particles getting into the inside of the part;

make sure that the pulley is correctly attached to the engine axis, since the slightest vibration or loose fastening will lead to inevitable damage;

if you notice the slightest scratch or crack on one of the parts - pay due attention to it. Thus, you will be able to protect the equipment from serious breakdowns and provide yourself with comfort and safety during its operation.

Making a pulley with your own hands

There are several methods that allow you to independently make a spline pulley for a walk-behind tractor. The easiest way is to grind the part. To do this, select a suitable workpiece and machine it on a lathe. If you do not have a specialized machine at your disposal, then the manufacture of a part can be ordered from a lathe. However, it should be borne in mind that the pulley for the walk-behind tractor is a rather large element, so it will be quite difficult for the master to find a suitable blank for turning the element. V in this case the pulley you can make it yourself, and order a flange for it from the workshop.

The second method is more difficult to execute. For work, you need to prepare in advance a sheet of plywood, an electric jigsaw, a drill and a hand router. The procedure is as follows:

- First of all, cut out a workpiece of a suitable diameter from plywood;

- Take a compass and draw a circle on the workpiece. Make a hole in the center of it;

- Use an electric jigsaw to cut out the disc. In this case, the distance from the edge of the disc to the extreme line of the plywood should be approximately 2–3 cm;

- To give the cut out disk a perfectly round shape, fix a drill in its central hole with a bolt previously put on the drill, and grind the workpiece with fine-grained sandpaper;

- Next, form a place where the belt will stretch. This is very easy to do with a hand router. Securely fix the disc on the workbench using self-tapping screws, and select the groove for the belt, having previously selected a cutter suitable for the work;

- After making the pulley, measure its seat on the motor shaft and drill a hole of the required diameter inside the part.

The finished part can be installed on the walk-behind tractor. When operating the unit, remember that a plywood pulley will not last long, so check it regularly for damage or deformation. If the first defects appear, immediately replace the pulley with a new element.

What is PTO on a walk-behind tractor - description and functions

The power take-off shaft is an element that is necessary for installing various types of attachments on a walk-behind tractor.Motoblocks with a power take-off shaft allow the use of such types of attachments as mulchers, seeders, harrows, stump grinders, mounted-type mowers, as well as attachments installed directly into trailers used for work.

The main function of the PTO is to receive and transmit rotational forces from the engine to the attachment. In most cases, this important element is located at the back of the walk-behind tractor, which allows you to connect almost all known types of attachments to it.

Among the main advantages of the power take-off shaft, one should highlight its versatility, high strength and reliability. In addition to the advantages, the PTO has several significant disadvantages, which are the large weight of the element and the need to use an additional gearbox with it.