Adapter Assembly Tips

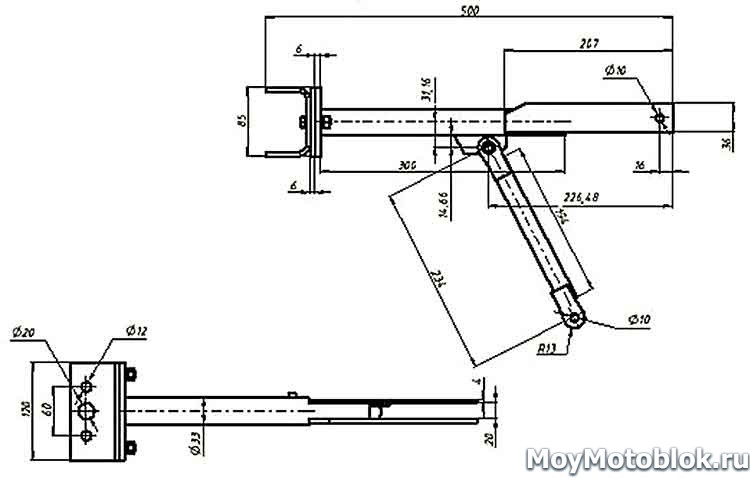

Special equipment for a walk-behind tractor can be easily made by almost any craftsman. To create an adapter, you need to take a tube that has a straight section, its length should be 1.7 m.

Special equipment for a walk-behind tractor can be easily made by almost any craftsman. To create an adapter, you need to take a tube that has a straight section, its length should be 1.7 m.

A pipe will have to be welded perpendicularly to one of the ends, the length of which will be 0.5 m. This part will be the basis for holding the struts under the wheels. The height of the struts from the axle to the upper part will be 0.3 m. At the new stage, the braces must be attached to the central tube and the wheel hub and fixed. The length of the workpiece depends on the slope and angle.

The square frame can be of any size. In our version, the following dimensions will be disassembled: 0.4 × 0.4 m. the structure can be bolted.

In order for you to be able to adjust, it is worth attaching a lever, which should have 3 knees, their length will be as follows: 20, 30 and 50 centimeters, respectively.

In order to increase the applied forces, the lever should be supplemented with a 75 cm lever. The hitch knot can be bought or made by hand.

The duration of the use of our equipment depends on the quality of the hitch. On a metal support, you need to fix the seat, which connects to the central tube. After these completed steps, we can assume that you have managed to create excellent equipment for a walk-behind tractor. Its advantages are its low price and ease of construction.

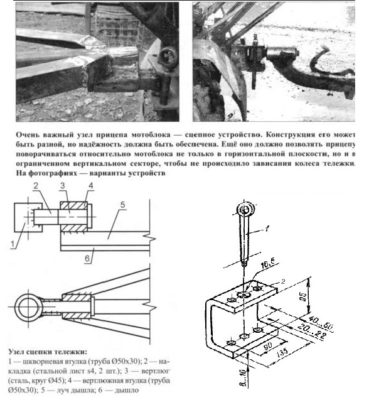

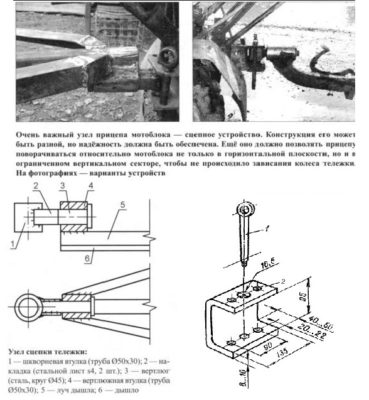

Tips for Creating a Drawbar Assembly

If you want to make this equipment with your own hands, then you should work more with the instructions for creating a coupling assembly. The lightest construction will be a 15-centimeter pin, which is inserted into the hole in the drawbar of the device's towbar. The disadvantage of this possibility is very fast wear, because under the influence of a rotating trailer, holes for the hitch are broken.

Do-it-yourself wheelbarrow for a walk-behind tractor

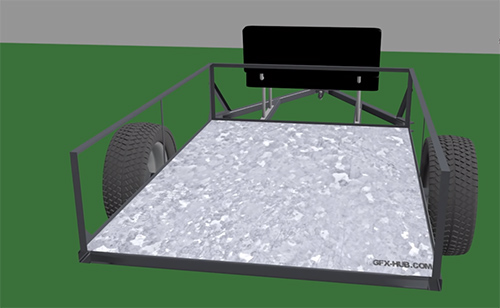

A wheelbarrow for a walk-behind tractor is an irreplaceable assistant in the household. Such a device allows you to transport goods (crops, garbage, building materials, etc.). You can make a trolley for a walk-behind tractor with your own hands from auto parts or from individual materials. In both cases, welding and certain design skills are required. The wheelbarrow assumes the simplest design; any drawing of a trailer for motoblocks is suitable for its creation.

For the Neva mb-2 walk-behind tractor, a mounted wheelbarrow with an H-shaped coupling is suitable. This type of connection is universal and easy to manufacture. The hitching point of the wheelbarrow and the walk-behind tractor is one of the most important units that receives a large load, therefore the materials for its creation must be strong, it is mandatory to check for defects (cracks, rust).

A wheelbarrow for a walk-behind tractor consists of a frame, sides and wheels. If you add a seat and a steering column to it, you get an analogue of a mini-tractor. Any of the options for a wheelbarrow for a walk-behind tractor can be made from improvised means; there are many photos and videos on the Internet with the process of assembling devices.

Do you use trailers, adapters and wheelbarrows for motoblocks?

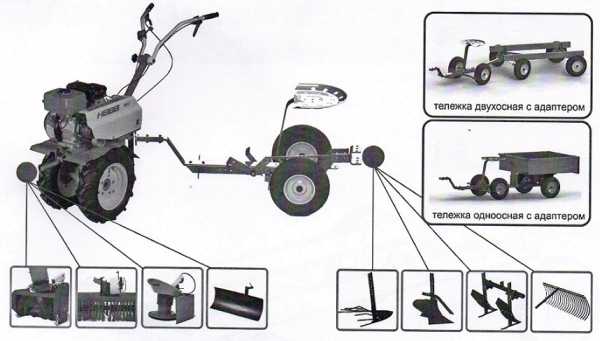

Factory walk-behind tractors and carts

The complete set of the walk-behind tractor can be very diverse:

This is characterized by the carrying capacity of the equipment, weight, power and other indicators. The walk-behind tractor can be medium, light and heavy (professional). A motor-cultivator is considered an analogue of this technique, but it is made to do one job - tillage.Sometimes it can be with an additional feature.

The construction of the carts is not complicated. In the presence of ordinary tools, almost any owner will be able to independently build a cart for a motor cultivator or a Neva walk-behind tractor

An important part of manufacturing is the correct drawing up of a drawing or sketch. The main work should be started, strictly adhering to the intended dimensions.

To simplify the process, you can take a factory model of the cart as a sample. Trailed devices can be of large and small carrying capacity (500 or 100 kg). At the same time, the body also differs in size.

For different types of motoblocks, carts with different technical characteristics are selected:

- For heavy (more than 10 hp), a single-axle or two-axle cart with a body length of up to 1.5 m in width and 3 m in length can be used.

- For medium-sized ones (with a capacity of up to 10 hp), single-axle bogies with a body length of up to 1.5 m and a width of up to 1.4 m are most often used. The carrying capacity of such bogies is approximately 300-500 kg.

- For light (up to 4.8 hp) trailers, single-axle trailers with a body length of about 1.15 m and a width of 1 m are used. The bogies are designed for a load of up to 300 kg.

Standard towing hitch models have a rear center of gravity, which makes it easier to tilt the cart and unload some loads. Only heavy duty models are usually equipped with a hydraulic lift cylinder. Such models should be equipped with brakes, since on steep slopes the inertial force of movement will act and it will not be possible to stop the walk-behind tractor.

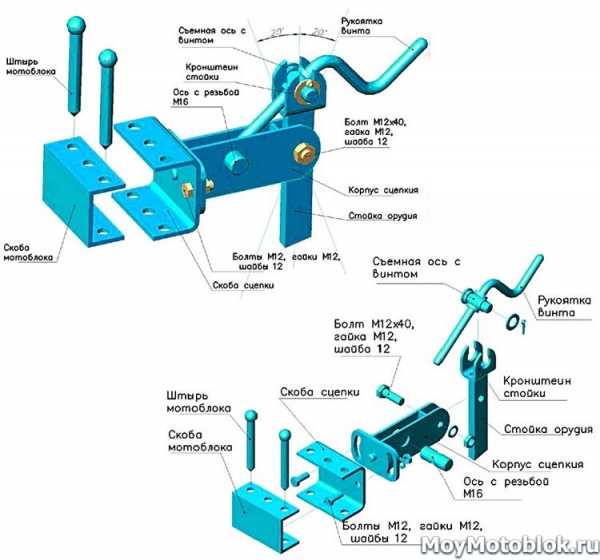

Couplings for motoblocks Neva, their types, what for what

For the operation of any attachments with the Neva walk-behind tractor, it must be connected to the unit. There is a special device for this - a hitch. It can be of several types, let's figure out the features of each of them.

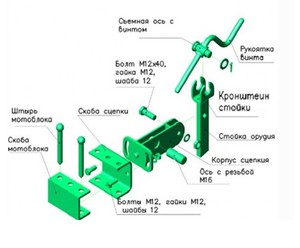

Hitch for the APM adapter (for working with a plow and hillers)

Hitch for the APM adapter (for the Neva, Kaskad, Oka, MB walk-behind tractor)

This hitch is designed to connect a variety of attachments to the adapter. Such as plows, potato diggers and hillers. The design of the hitch allows you to securely fix the equipment to the Neva walk-behind tractors with just three bolts.

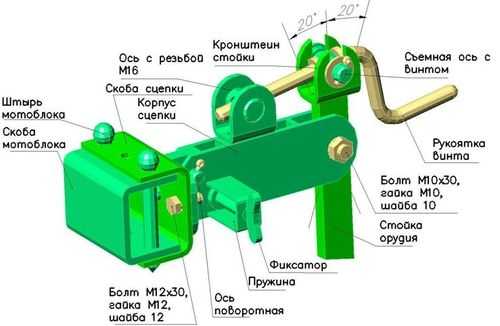

Universal hitch

This type of hitch allows you to adjust the angle of inclination of the attachment using a bolt mechanism. This function allows you to tilt the Neva walk-behind tractor, and the plow will go perpendicular to the ground.

Universal hitch

Since this hitch is mainly intended for the use of plows and hillers, it is possible to install a double or triple hitch so that several working elements can be connected to it at once.

Universal hitch

Universal hitch

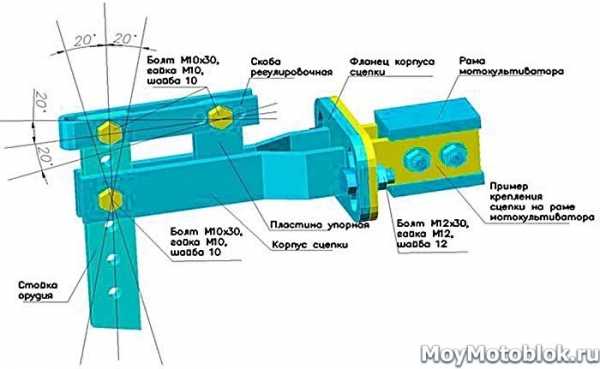

This is a modification of the universal hitch for the Neva walk-behind tractor. Its main difference is that you can not only adjust the diving height, but also change the angle of inclination in all planes. The maximum tilt angle in the horizontal plane is ± 20 °, and in the vertical plane ± 27 °.

MK hitch for working with the OH-2 hiller and the KROT plow

MK hitch for working with the OH-2 hiller and the KROT plow

This coupling is special in itself, since it was produced by the Mobil K plant exclusively for coupling with their equipment OH-2 and Krot. The plant has thought out a separate type of clutch, which is not supplied in the kit, but is purchased separately.

Is it possible to make a do-it-yourself hitch for a walk-behind tractor?

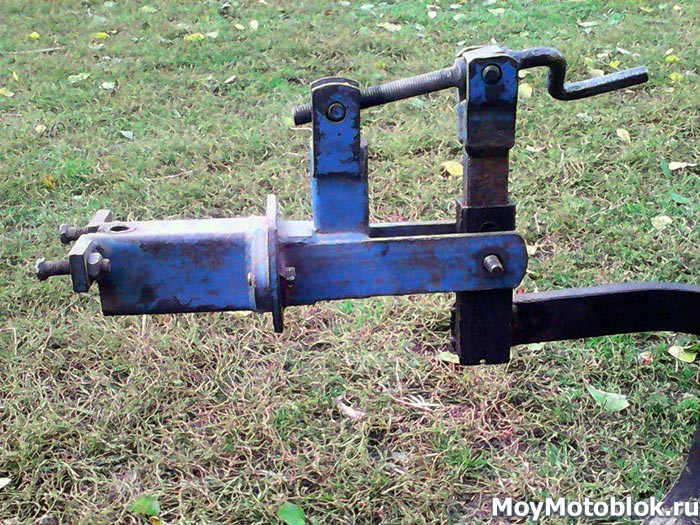

When making a hitch with your own hands, it will be most correct to choose a universal option, since 90% of attachments work with this type of clutch.

It must be taken into account that there will be a lot of pressure on the hitch. Therefore, you should choose extremely strong materials from large sheet metal.

The universal hitch is based on a U-shaped mount.A square channel is best suited for its manufacture; it should be 40x40 mm in size.

Holes are made in this channel, which will serve to fix the hitch with a pin. Therefore, you should initially make the pin from high-quality steel, and then drill holes in the mount to match the pin.

For further installation of the attachment, attach the bracket. The longest part of it should be directed downward or upward so that the connected equipment does not interfere with movement. Do not make it too long to avoid touching the ground.

Here is what people write on the forums about the coupling for the Neva walk-behind tractor:

Stepan writes:

“It took me a long time to choose which hitch to use. After all, their device is similar. I thought about doing it myself, but did not bother and bought a universal coupling N. It seemed to me to be the most effective, versatile and compatible with all the equipment I have. Plus an official guarantee. Since then there have been no complaints at work "

Vasily writes:

“I bought a Krot plow for work. Since it was one of the cheapest options, and I didn't want to overpay. Still, they are similar and functionally the same. What was my surprise when at home I could not connect it to my coupling. The next day I went to the store to find out what the problem was. To which the seller told me that he forgot to mention the special coupling of this plow. I had to buy more additional clutch. Here is the proverb that the miser pays twice visually ... "

Making a homemade trailer for a walk-behind tractor with your own hands

To make a homemade trailer for a walk-behind tractor with your own hands, you should adhere to a certain sequence of actions. We invite you to get to know her.

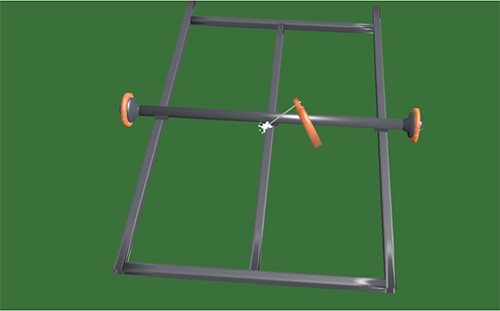

Body frame

Body frame

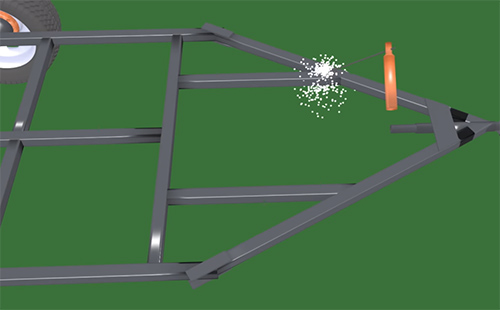

For the manufacture of the frame, rolled metal is taken with a suitable shape and cross-sectional size. The works are performed in the following sequence:

Illustration

Procedure

The rental is cut to size. The number of elements and their parameters depend on the dimensions and carrying capacity of the future body

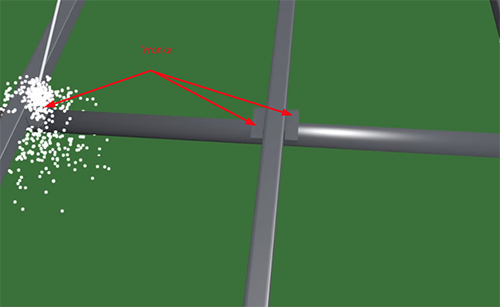

The prepared segments are welded together, forming a frame with crossbars. Their spatial position is carefully controlled

Particular attention is paid to the corners at which adjacent elements are located

The assembled frame is additionally welded around the perimeter, which ensures sufficient strength of the finished structure

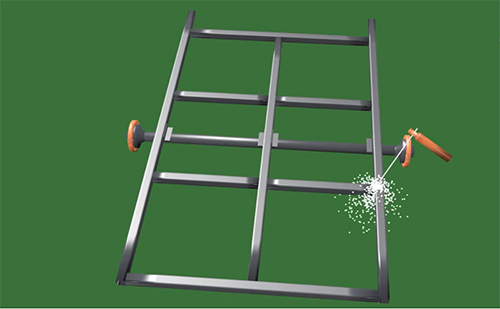

Chassis

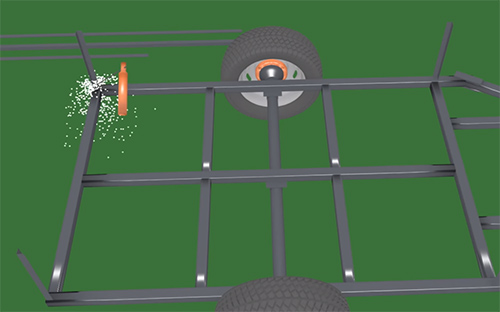

Assembly work for the manufacture of the chassis of a homemade trailer is performed in the following sequence:

| Illustration | Procedure |

|

When making do-it-yourself axles for a trailer, half-shafts from "Zhiguli" are welded into the pipe. Channels are welded along the edges and in the center of the pipe, to which the frame will be attached |

|

The frame is welded to the beam. For this, the structure is turned over and a welding seam is formed on the reverse side. |

|

The structure is turned over. At the points of contact of the frame with the axis, the elements are welded together, having previously installed the corners |

|

To further strengthen the frame, the cross members are welded. They are located in accordance with the drawing. |

|

Install the wheels. Check their parallelism. Its structure is welded correctly, the wheels will fit correctly |

|

The drawbar is welded, if it has not been done earlier |

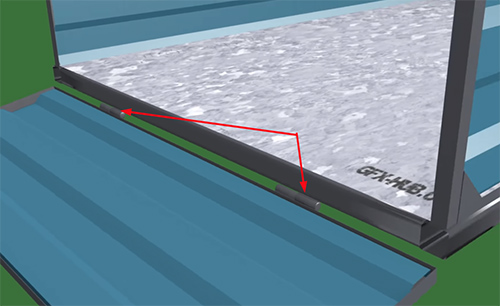

Body, frame lining

Body shaping is performed in the following sequence:

| Illustration | Procedure |

|

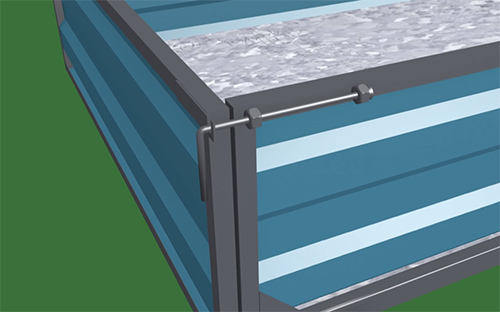

Vertical posts are welded to the frame. Their height depends on the volume of the manufactured trailer for the walk-behind tractor. On average, their height is 42 cm |

|

Vertical posts are interconnected by horizontal elements. The spatial position of each is carefully controlled. If necessary, the seat is welded. The structure is installed assembled |

|

Additional elements are welded to the frame to fasten the skin. Provides horizontal and vertical details |

|

The pallet is attached.Sheet metal up to 2 mm thick can be used. First, the pallet is grabbed, and then carefully welded around the entire perimeter |

|

The sides are installed. For their manufacture, sheet metal or metal profiles are used. |

|

The tailgate hinges are welded to the frame. The counterpart is welded to the tailgate itself. The element is installed in place |

|

A structure is welded to fix the tailgate while driving |

Do-it-yourself brakes on a trailer for a walk-behind tractor: manufacturing procedure

So that the trailer to the walk-behind tractor does not accidentally roll, you should think in time how to make the brakes. If they are available, the safety of the trailed structure will be significantly increased. To make brakes on a trailer to a walk-behind tractor with your own hands, you need to have a traction, cable and drum available. The work is carried out in the following sequence:

- we attach the drum to the hub of one of the wheels;

- weld a piece of pipe to the brake disc;

- we put the mechanism on the axis;

- on the axle we fix the brake pads with a cable. We stretch the latter to the lever, which we install next to the driver's seat.

We offer you to watch a video that tells how to make brakes on a trailer for a walk-behind tractor with your own hands:

Other details

In addition to the listed elements, it is possible to install additional parts that will expand the functionality of the trailer for the walk-behind tractor. When making a trailing device with your own hands, you can provide for the installation:

- folding benches. It is attached to the front side of the body using the side parts as support;

- spare wheel, which may be required when doing work outside the home. Most often, for its placement, a side board or the lower part of the pallet is chosen. To exclude its displacement, special fasteners are used;

- small boxes or special bags located near the driver's seat. They are used to store small tools that may be required when performing repair work.

The spare wheel can be secured in different ways

The spare wheel can be secured in different ways

Transport trailers

The widespread use of semi-trailers and trailers is due to the additional convenience when transporting heavy loads. The vehicle carries only part of the load, which extends its service life. When unloading, you can save valuable time by unhitching the wagon and leaving it in place, and unloading at a convenient time. This option is convenient and is used for the delivery of goods between workshops of one enterprise located at a certain distance.

All towing devices are conventionally divided into two groups:

- Special purpose trailers allow you to take into account the needs of working with various loads, and there are quite a few universal machines for such work. Common types include semi-trailers, heavy trucks, timber trucks, panel trucks, cement trucks and other types of trailers.

- General transport equipment includes flatbed, curtainsider and other trailers of various sizes, designed to transport heavy loads of any kind.

Varieties depending on load distribution

In the design of trailed equipment, different steering wheel control systems are used in order to improve the maneuverability and speed of regulation of the road train. Couplings are standard in most cases. If the trailer has an active wheel drive from a car engine, then such carts are called active car trains.

In the design of trailed equipment, different steering wheel control systems are used in order to improve the maneuverability and speed of regulation of the road train. Couplings are standard in most cases. If the trailer has an active wheel drive from a car engine, then such carts are called active car trains.

To drive such an active drive in motion, a mechanical transmission is used by means of a coupling device or a hydraulic drive is used.

Depending on the distribution of the load between the trailer and the tractor, trailers are divided into several types:

Requirements for transport devices

A person who independently wants to make a transport vehicle for the movement of goods should study the requirements for car trailers. These standards are contained in GOST 37 .001.220-1980, which is called "Trailers for passenger cars." A selection of these requirements include the following:

Features of using carts

Trailers are used only in accordance with their intended purpose, as this is due to similar tires and wheels with the main machine, track width, travel in certain dimensions of the ground clearance. This rule does not apply to heavy trucks and dismantling trailers. All breakdowns that occur during operation are similar to malfunctions of the brake system and the chassis of the main machine.

Trailers are used only in accordance with their intended purpose, as this is due to similar tires and wheels with the main machine, track width, travel in certain dimensions of the ground clearance. This rule does not apply to heavy trucks and dismantling trailers. All breakdowns that occur during operation are similar to malfunctions of the brake system and the chassis of the main machine.

To delay the repair of these systems, you need to carry out regular inspection of the trailer. Since the operation of the device is associated with constant shaking and impacts due to uneven movement on the roads, it is required from time to time to tighten the fasteners and align the bent parts. Before operation, you need to check the health of the springs, brakes, lighting, tire pressure, the presence of a spare wheel, the health of the side and body locks.

The towing of carts is carried out according to the rules, exceeding the speed is unacceptable, as well as sharp braking and uneven distribution of the load. Increasing the speed while driving will cause the trailer to wobble on the sides. Harsh braking causes the vehicle and trailer to collapse

This is also aided by motor-assisted braking. Uneven storage of the transported materials compromises stability and the trailer may tip over.

Harrows

The harrow is intended for mixing the topsoil (for uniform fertilization, moistening or aeration of the soil) and bringing it into a uniform state (removes the crust on the ground, breaks lumps, removes weeds). One official harrow model is presented on the official website of the Neva motoblock manufacturer.

Harrow BD 850M (cultivator)

The harrow breaks large pieces (lumps) of soil into smaller ones, thanks to which the soil additionally absorbs moisture and oxygen. These two factors are indispensable for growing crops.

Harrow BD 850M

BD 850 is a disc harrow and is recommended for use in small or medium fields. At the same time, the working width can be adjusted from 70 to 96 cm.

The harrow is equipped with 8 stainless steel discs. They are replaceable and, if desired, the old ones can be easily exchanged for new ones. The discs are sharpened at the factory using a special technology, thanks to which they do not become dull over a long period of operation.

The discs are mounted on the axle. These axles are mounted on heavy-duty Teflon bearings.

The furrow angle can be changed depending on the conditions:

- A 10 ° slope is used for aggressive furrowing;

- A 15 ° slope is used for standard furrowing;

- A 20 ° slope is used for soft furrowing.

If hard rock is being processed and the discs slip, then a weighting agent can be used to immerse them in the ground. For this, there is a specially thought-out platform on top.

To achieve maximum furrow results, two furrows connected in series can be used. In this case, the first unit dumps the earth inward, and the second outward.

It is also recommended to replace regular wheels with lugs.

Installation of the BD 850M Harrow on the Neva walk-behind tractor

Is it possible to make a harrow with your own hands?

If desired, the harrow can be assembled independently, there is nothing complicated in this design.

The easiest way to make a tine harrow. It is slightly less efficient than disk, but much simpler in the device.

All you need is a square tube, teeth and bolts.

It is necessary to cut the pipes and connect them to each other at an angle of approximately 30 °. And at the place of their connection, insert the teeth and fasten them with bolts.

To connect to the walk-behind tractor, you can use a regular chain or make a clutch device using an ordinary metal pipe.

But only this structure will often jump out of the ground, it needs to be additionally weighted with something. The ideal solution to the problem would be cinder blocks or any heavy metal structures. But do not overdo it, since the connecting elements must support the weight of the entire structure.

Video review

The video demonstrates the manufacturing process of such a harrow:

And here is a video of the harrow in action and the result of the work done:

What the owners say

And here are a few opinions of people who have already worked with harrows on Neva walk-behind tractors.

Alexey writes:

“I decided to make the harrow myself, as its design was intuitive to me. Therefore, having worked a little with my brains, and having collected information on the forums, I was able to do it without any problems. All that was needed were pins and pipes to attach them. Simplicity is the key to success) "

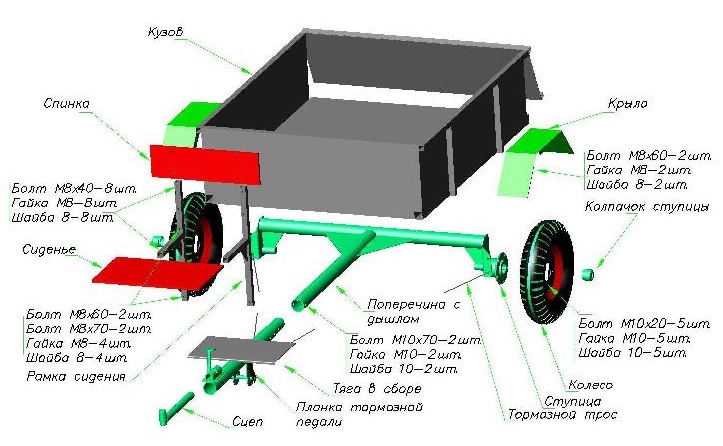

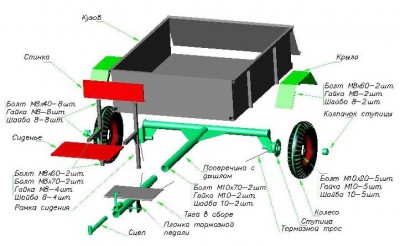

The main parts of the cart

A typical design of a trolley for a motor cultivator consists of a certain set of elements, but it is not difficult to alter it to suit your needs. For example, the owner of a walk-behind tractor may decide that additional components are needed. The main details will be as follows:

Suspension. It can be of axial or gantry type. Installation with a shock absorber is allowed, but with them the carrying capacity will decrease, and the whole structure will be more complex. Elastic elements are not required if the owner plans to drive at a low speed, while the tires of the wheels have a fairly high profile.

Frame. It is welded from a piece of profiled pipe.

Body. Options: with folding or fixed sides. Materials: sheet steel, wood or plywood. Metal is connected by welding, wood - with a metal corner. The steel cart looks solid, it is more reliable. The disadvantage is a lot of weight.

Drawer. This component connects the walk-behind tractor and the hitch. The length should be selected so that it is convenient to turn.

Seat. It is fixed to a cart or hitch.

Steering wheel

The most important thing in developing this mechanism is to ensure that there is no risk of deformation on uneven terrain and there are no increased torsional loads. The task of the steering gear is to provide a horizontal articulation with two degrees of freedom.

How to make a homemade hitch for a walk-behind tractor

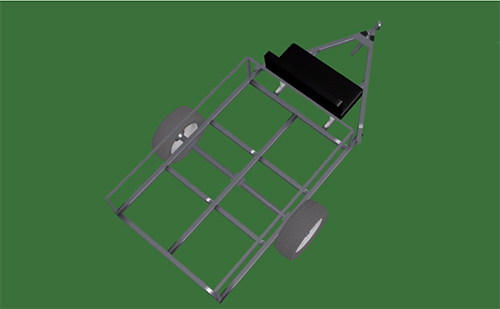

If you decide to make a homemade hitch for a walk-behind tractor, then let's get down to implementation. To manufacture this trailer, you will have to spend several days of work. The carrying capacity of the trailer was calculated for the weight of the transported cargo of 400-450 kg. When tested, the trailer easily held 6-7 sacks of potatoes.

There were no overload problems. The trailer was designed for the transportation of goods in bags, therefore, folding sides are not provided.

We think over the constructive part of the project in advance. The trailer will consist of a fairly strong carrier, a body, a frame made of steel corners and reliable wheels.

- Bracket for mounted implements of the walk-behind tractor;

- Console;

- Trailer device;

- The footboard, we use the s20 board;

- Driver's seat, use s20 board;

- Frame;

- Body, we use s20 board;

- Support beam, we use three beams 50x50;

- Bolt М8;

- The ring is persistent, we use a pipe 58x4;

- Two wheels removed from the SZD motorized carriage.

The hitch for the trailer walk-behind tractor consists of several parts. We connect different parts by welding. The junction of the drawbar and the swivel part is the most loaded, therefore we reinforce this place with additional stiffeners.

For the manufacture of the frame, we use cuts of pipes of round and rectangular sections, and steel corners. The design will turn out to be slightly intricate, but with an additional margin of safety. The reason was the difficult terrain and difficult operating conditions of the trailer.

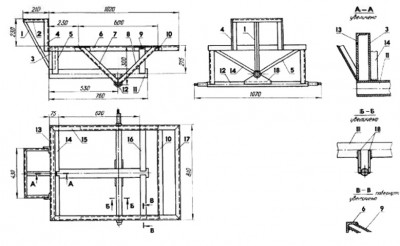

1.For the brace, we use a corner 21x21x3;

2. The frame for the seat is also made from a corner 21x21x3;

3. The riser is made of pipe 50x25x4;

4. We make the seat racks from a 40x40x4 corner;

5 and 14. For the front struts, we use a 50x25 pipe;

6 and 15. For longitudinal side members we use a 40x40x4 corner;

7 and 8. The right bearings of the wheel axle are made from a corner 32x32x4;

9 and 16. We make the rear struts from a 50x25 pipe;

10. For the manufacture of a reinforcing cross member, we use a corner 40x40x4;

11. The body of the longitudinal hinge is made of 58x4 pipe;

12. For the manufacture of the wheel axle, we use a rod with a diameter of 30 mm;

13 and 17. For the transverse spars we use a 40x40x4 corner;

18. To make a scarf, we use metal s4.

If heavy loads on the trailer are not planned, a simpler option can be made.

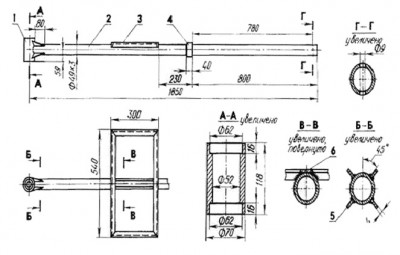

- Swivel body;

- For the drawbar, we use the pipe 49x3, L1820;

- For the frame of the footboard, we use a corner 25x25x4;

- For an emphasis, we use a 58x4 pipe;

- For the stiffener we use s4 steel;

- For the overlay, we use a 25X4 strip.

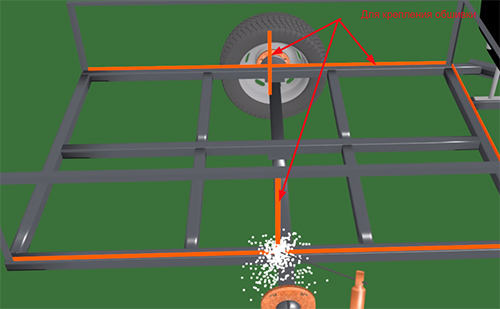

Wheel axle for a trailer to a walk-behind tractor

For the manufacture of the wheel axle, we use a steel rod with a diameter of 30 mm. We weld it to the spars and the body of the longitudinal hinge using corner gussets and supports. The wheels should not protrude beyond the dimensions of the body, so we choose the right axle size.

The body is hammered by 20 mm boards and reinforced with a steel corner. Further, it is attached to the frame with three strong, support beams of the 50x50 beam ties.

The center of gravity of the transported load must be closer to the front, as is customary for single-axle trailers.

The wheels are taken from the SZD motorized carriage. They were used assembled with the hub, and the ends of the axle rod were turned in accordance with the diameter of the hub bearings.

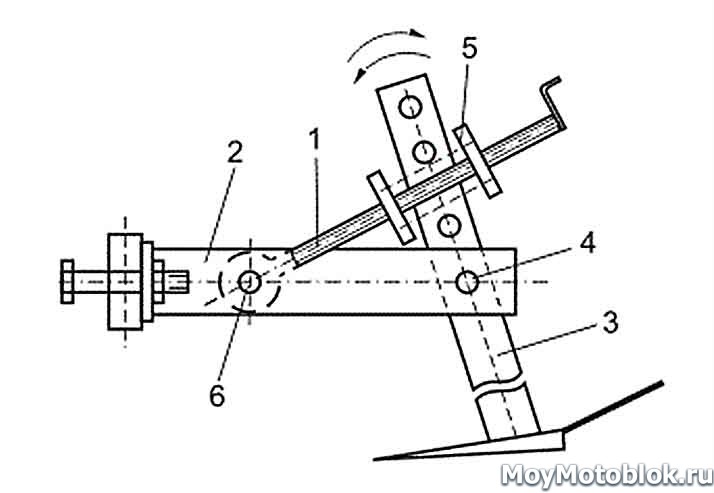

Tow hitch for trailer

To connect the trailer with the walk-behind tractor, a trailing device is made. The shape of the upper part of the console is taken from the hiller holder, since the standard attachment bracket will be used for fastening. Around the axle in the lower part, a swivel assembly of the tow hitch is fixed. The remaining space between the angular contact bearings must be filled with grease and covered with anthers.

The connection of the hitch and the trailer is made articulated, depending on the complexity of the trailer operation. The drawbar must be inserted into the tubular body of the longitudinal joint and fixed. This solution will allow the trailer to be independent from the wheels of the walk-behind tractor, which greatly simplifies the control of the trailer on strong bumps.

The components of the carrier swivel unit are:

- hitch (1),

- anthers (2),

- bearings 36206 (3.6),

- case (4),

- spacer bush (5)

- remote (7),

- washer (8),

- nut м20х2.5 (9),

- oiler (10)

- drawbar (11).

For the driver, a seat is made in the front of the body. It is done with a very soft base. So that the driver can rest, a step is made on the drawbar. In other words, the driver uses the control levers with his hands, and rests his legs on a special footrest.

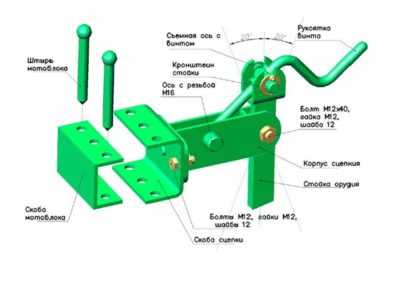

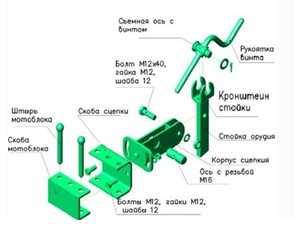

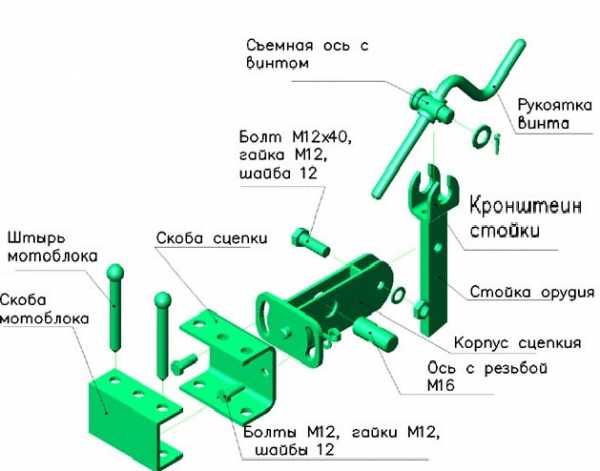

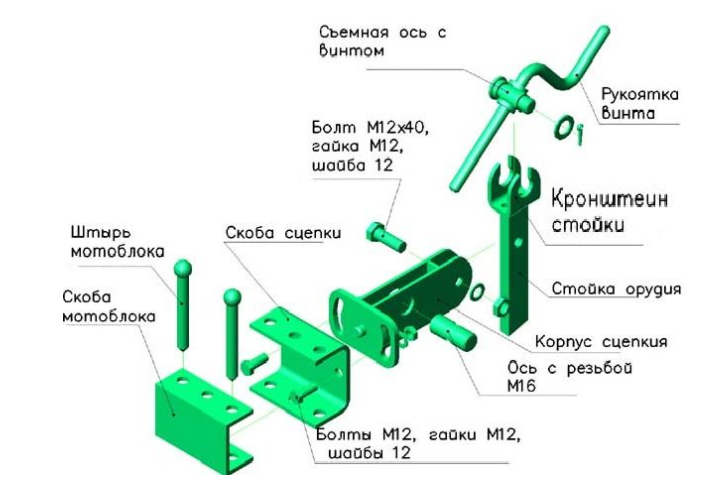

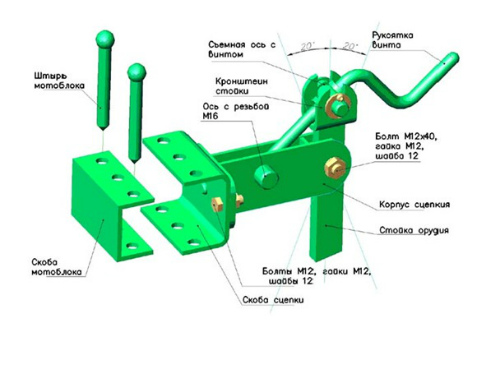

Universal Coupling - Assembly Sequence

After preparing the necessary equipment, you should begin to study the diagrams. The drawings should indicate the exact dimensions of the parts and their place in the overall design of the coupler.

The correct order when assembling the hitch is as follows:

First you need to take two identical U-shaped staples, and carefully make small holes in them with a drill. In the first bracket, 6 holes must be made, and in the second - 8 holes for M12 bolts;

The body is one of the most difficult parts of the hitch. To make it as reliable as possible, it should be welded from several parts.

It is very important to make the correct holes in the existing housing. It also has to be made 2 threads - one M16 and one M12;

Inside the case, you will need to place a mechanism designed to adjust the position of the hitch

For the manufacture of the mechanism, a screw connected to the bracket and the handle should be used;

The most complex structural element is the handle, which consists of several small parts.

How to make a universal joint?

The universal design of the hitch will adjust the attachment to the walk-behind tractor without backlash and free play.This, in turn, facilitates the work on the walk-behind tractor. It does not take much time and excessive effort to make such a coupler with your own hands.

Using this device, you can attach to the walk-behind tractor:

- plow;

- potato planter;

- mower;

- hiller;

- harrow.

To create a quality product for your walk-behind tractor, durable metal is used. You can also use channels, they have a sufficient margin of safety, made according to factory technology. You need to make a few additional holes, the homemade hitch is almost ready.

Double universal hitch to the walk-behind tractor

The fixture can be made of durable cast iron or steel. But such materials require special processing equipment, so it is better to buy industrial blanks.

If special workbenches are available, you can make a steel blank of the desired shape. A good hitch for a walk-behind tractor trailer can come from a car cardan. to the menu

Tools and materials

The device consists of several complex parts. Before starting work, you need drawings that are suitable for creating a node. They must be tested and working.

Materials required for assembly:

- bolts and steel pins are the main fasteners, they create movable and fixed connections;

- adjustment element - a lever that will help to change the position of the device;

- metal blanks - channels from which the main part will be welded.

Drawing of the hitch to the walk-behind tractor

To assemble the equipment you will need:

- drill for metal to create holes;

- ruler for measuring;

- metal welding;

- a set of wrenches to tighten the screw connections.

to the menu

How to connect a walk-behind tractor with a trailer?

The device is attached to the walk-behind tractor with pins. They must be made of solid steel. Studs and pins are threaded through the holes. The connection node is located either under the steering wheel or behind the main unit. If there are any connection features, they are indicated by the manufacturer of the trailer or walk-behind tractor.

A self-made connection can be useful not only for attaching a plow, trailer and other similar devices, but also used for rural equipment or mini-tractors.

Before starting work, you need to check the reliability of the unit, turn all the nuts and screws.

After agricultural work is completed, the threaded connections must be cleaned and lubricated to prevent corrosion and breakage. to the menu

Hitch selection

Any trailed or attachment for motor vehicles, be it a trailer-trailer, a mower, a hiller, a harrow or any other equipment is fixed by means of a hitch. If the basic element does not fit, the owner has a choice - to buy a suitable one or to make a coupler for the unit with his own hands.

Be that as it may, when deciding which of the mechanism options is capable of meeting the functions that the unit performs to the maximum, it is necessary to take into account a number of factors, in the list of which:

distinctive features of a cultivator or walk-behind tractor;

- the scope of use of the unit - the duties that it performs;

- equipment that will integrate with it;

- loads;