Seeder for garlic on a walk-behind tractor. Sowing requirements for garlic

Like any garden crop, garlic or tykanka onions cannot be planted in the beds without strict adherence to the recommendations and rules. In order for garlic to grow without problems of shading and mutual oppression by plants, a garlic seeder during planting must provide several basic conditions:

When the seeding unit moves on loosened soil, the most even and rectilinear trajectory should be provided with minimal effort for a person;

The tine dispenser should deliver the seed as evenly as possible and, most importantly, without delays or gaps;

It is especially important that the garlic cloves are planted in the ground to the same depth.

There are many options for seeding machines; in most cases, onion and garlic seeders are made by hand for relatively small areas. It can be a manual seeder for garlic, or designed as an attachment for a walk-behind tractor. With such a device, you can sow up to a hectare of land. For large areas, you will need a tractor garlic planter with a lot of auxiliary equipment, for example, humidifiers and a fertilizer tank.

Important! How accurately the planter is adjusted determines two main performance indicators - the quality of the planting and the force applied to the opener or planting drum. When working with a manual seeder, the quality of laying garlic cloves is easily checked after the fact, since the gardener always sees and controls the operation of the mechanism

For manual seeding, look for a model that is easy to use. Garlic and onions are always planted in moist, highly loosened soil, on which it is difficult to walk, not like rolling a hand seeder

When working with a manual seeder, the quality of laying garlic cloves can be easily checked after the fact, since the gardener always sees and controls the operation of the mechanism. For manual seeding, look for a model that is easy to use. Garlic and onions are always planted in moist, highly loosened soil, on which it is difficult to walk, not like rolling a hand seeder.

You can, of course, remake the device for a walk-behind tractor or a tractor. This will make the job easier, but will require utmost attention to the operation of the device and constant adjustments. Otherwise, you can easily plant twenty acres of garlic with a marriage and not even notice it.

Manual planter. Whip up manual potato planter

In this publication, we will first consider the simplest version of a manual potato planter, which is useful for those who would like to quickly build an affordable tool and not spend money on complex structures.

Gardening tools and other products in this Chinese store.

In the second part, more complex structures are presented that will have to tinker with, but for perfectionists and, at the same time, manual labor enthusiasts, these will be just the most interesting developments.

On the first video the simplest manual potato planter in the form of a wooden handle and a ledge for the leg. According to the author of this mechanism, the potato yield with this method of planting does not suffer at all, but on the contrary, it is higher.

Craftsmen buy inventions at their best

The device, which is presented in this video, does not differ in special or even at least some sophistication. The gardener called it in a simple way "digging stick". But, within the framework of this publication, it will be fair to consider it as a manual potato planter. With the help of it, potatoes are planted without a shovel, practically with their own hands. A similar method is called among gardeners “under the heel”.

The field was pre-plowed with motoblocks.At the beginning, the 70X20 field is marked. Or, the threads are simply pulled at a distance of 70 cm from each other, and during planting of potatoes with the help of a potato planter, 20-30 cm are measured each time.

Every 20 centimeters, holes are made, potatoes and peas are thrown into them. All this is immediately covered with earth. The soil should be moist, because if it dries up, the holes will crumble. Therefore, you need to plant potatoes using this manual potato planter immediately after plowing the field. Peas do not interfere with potatoes, they grow in symbiosis. The fact that holes are being made and at the same time the earth is rammed does not have any consequences for the harvest. On the contrary, it helps to collect moisture after rain. Such a simple mechanism, whipped up, has served for 7 years. In another post about what kind of potatoes to plant.

DIY electronics in

Second development.

When planting a potato, after it has been laid in the furrows, it is necessary to cover it with soil. Many people suffer when working with shovels, rakes or hoes. pre-cut the furrows with a walk-behind tractor with a special device for cutting furrows. Planting material was laid in the furrows and a homemade heel was made in front of the hiller to adjust the constant depth and to make it easier to work. Now we will show how a potato planter works. Thus, the problems with planting potatoes, filling with earth did not become. The planter is also convenient when moving it around the field. You just need to turn it to the top with the working part and move it on the wheel.

Also shown is another development, which is sometimes called Tykalka.

Seeder for walk-behind tractor with own hands

Nowadays, seeders occupy a worthy place among the used equipment among farmers. Using the seeders, they produce row planting of grain crops: oats, rye, barley, wheat. Also, grain seeders are used for sowing leguminous crops: peas, soybeans, beans, lupines, lentils and chickpeas. In addition, sowing equipment is used to plant crops close to grain in size and seeding characteristics: sorghum, buckwheat and millet.

It will be appropriate to use a manual seeder in small areas. If the site is quite large, then a seeder for a walk-behind tractor (made by hand) is used. But any of them will help speed up the seed sowing process and increase the evenness in the placement of the plants as they grow.

Grain seeders are divided into three groups, depending on the crops sown: Combined seeders are equipped with special devices that apply mineral fertilizers to the soil along with the seeds.

- Universal seeders are used for planting almost any crop.

- Special drills are needed to plant certain types of crops.

- Each grain seeder, you can buy, or you can do it yourself.

Consider several options for making a do-it-yourself seeder for a walk-behind tractor

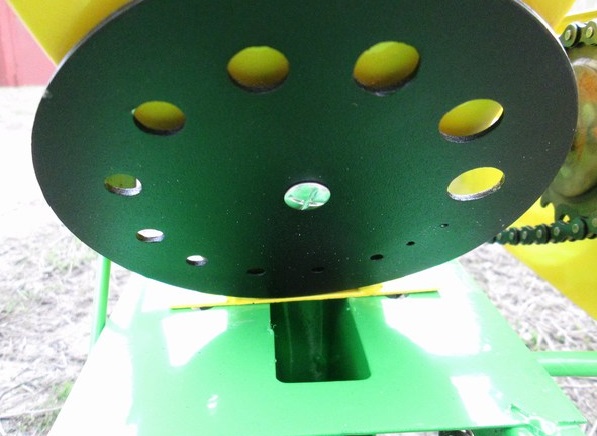

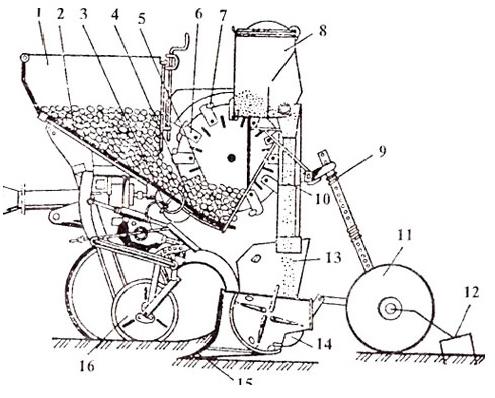

Vertical identical discs (3 pcs) are mounted on the axle at an equal distance. Seed nests are drilled in the rim of any of them, in the amount of 12 pcs. When the drill is moving, the seed disc goes into the top-mounted hopper where the seed is located. There, the grain is captured and transferred to the furrows, which are mounted in front of the seeder discs. A horizontal grab bar is installed to the frame of the tool for planting seeds. The diameter of the disks and wheels and the distance between them are determined by the manufacturer.

The homemade seeder is mounted on three wheels. The front wheel is taken from a baby stroller, the rear wheel is from a child's bike. The frame, bent in the shape of the letter P, is made of strip iron, 11.5 cm wide and 52.5 cm long. seed hopper, which is a box made of plywood.

Then the hopper is tightened with bolts. A sowing device is installed inside, on two plain bearings.He himself is a shaft made of birch and varnished, the shape of which vaguely resembles a spool of thread.

When the homemade seeder moves over the plowed area, the spool of the seeding unit rotates, thanks to the tensioned bicycle chain. The cell of the belt grabs the seeds in the hopper and drops them into the specially attached funnel of the seed tube.

A more modern version of a homemade seeder for a walk-behind tractor

A homemade seeder is made for a walk-behind tractor of three main parts: two running wheels, a seeding roller, a seed box, two bearings, two brackets for attaching the opener and a handle with a bracket.

The seed box is made using wood planks, 15 mm thick. To close them from below, use two steel overhead bottoms, 1 mm thick. The transverse and longitudinal walls are connected with self-tapping screws, spikes and steel corners. At the bottom of the box walls, on screws or nails, wooden overlays are installed, the thickness of which is 15 mm.

To mount the seeding roller, semicircular cutouts have been made in the linings and walls. For the same purpose, fastening brackets are screwed to the linings with screws. In order for the seeds to be dropped from the cells, rubber plates are installed in the inclined bottoms.

The planter wheels have a diameter of 200 mm, and the hubs are 60 mm. The hubs have holes that are the same as the diameter of the seeding roller. The coulter is attached to brackets and is made of 1.5 mm steel sheet. Several holes are made in the bracket. The depth to which the seeds will be planted can be adjusted by re-fastening the opener in the holes. A bracket is attached to the rear wall of the seed box, through which the connection to the walk-behind tractor goes.

Instructions

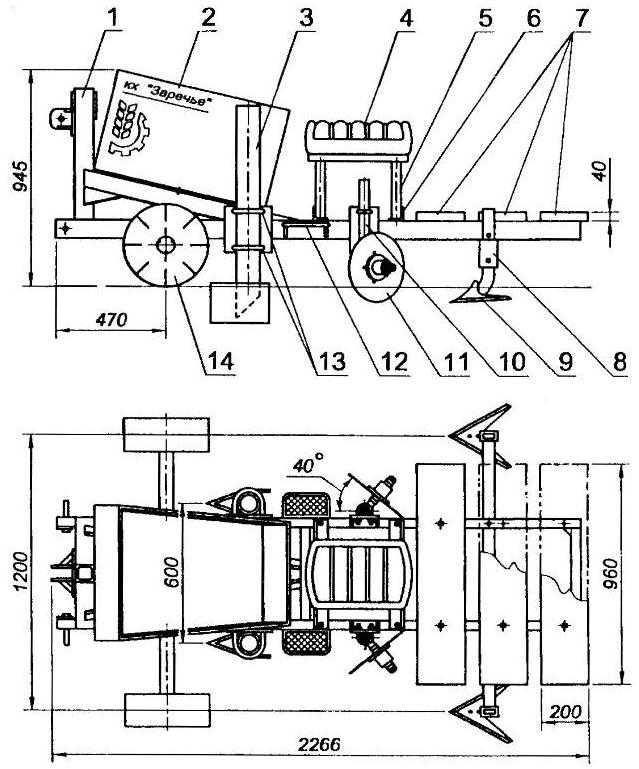

Many people ask themselves the question - how to make a potato planter with their own hands, the drawings of which are on the Internet? Indeed, the network has enough recommendations with a detailed description and dimensions, following which, you can make a fairly efficient unit.

The algorithm of actions, in this case, will be approximately as follows:

- Of course, you need to start with the manufacture of a frame structure, on which the rest of the components will be attached. To do this, we need channels number 8, of which two longitudinal spars are welded, connected to each other by three transverse steel strips.

- In front of the structure, you need to weld an arch with fastening forks going to the central link.

- The frame can be reinforced with two inclined steel beams, which must be fixed with the second side to the middle of the arch. Next, you need to fix the seatpost support made of a 5x5x0.5 cm corner. We attach it to the side member with our own hands.

- A plastic type bracket must be welded to the inclined beams. It is to these beams that the potato tank will be connected.

- For the tank, we need regular plywood, which will be about 12 mm thick.

We cut out all sides of the bunker, and then fasten them together with steel corners. By the way, it will not be superfluous to treat the box with linseed oil to protect it from moisture.

Rubber sheets can be installed inside the tank so that the potatoes do not get damaged against its walls while moving. Next, we attach the hopper to the bracket using two bolts.

Next, you need to fix the wheel axle and the ripper to the bottom of the frame. In principle, you can see the drawings of a DIY potato planter for greater clarity.

The wheel axle is a structure made of various parts. As a basis, you can take an ordinary steel pipe, at the ends of which you need to install trunnions. It is difficult to give the exact dimensions here, depending on what pipe diameter you are using.

Therefore, the trunnions must be adjusted to these dimensions on a lathe.

In the steel pipe, you need to drill holes into which special pins with spikes will be installed. At the end, they must be brewed.

The wheel axle must be secured with steel clamps, using 4 M16 bolts.

Wheels from old agricultural machinery can be used as a wheelbase. If there are none, then you need to work a little in this regard.

Hubs need to be welded onto the wheels, on which then you need to put on a pair of bearings. Next, we put the bearings on the spikes, protect them with a felt gasket so that they do not become unnecessarily dirty.

The part holding the rippers is represented as a square of steel rods welded together. At the ends of the square, you need to weld clips of 6 mm sheet steel. Cultivator blade stands will be located inside them.

The seeder for this unit is made of a steel pipe with a diameter of 100 mm. At the same time, the wall thickness of the pipe must be at least 3 mm so that the structure does not bend during operation.

A furrow cutter made of 6 mm thick sheet steel is welded to the bottom of the pipe.

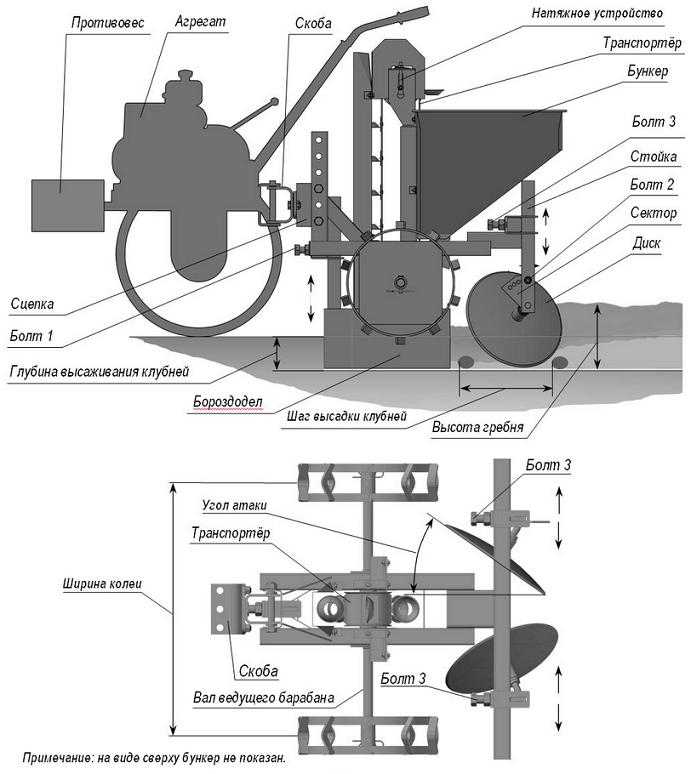

Potato planter for walk-behind tractor drawings and dimensions

In order to make such a technique, you must first prepare properly. Calculating all the values and making a drawing of the structure are the most important actions that will help to avoid mistakes in the future.

Any mechanism, for whatever it is intended, is based on a frame, to which all working parts are attached in one way or another. In our case, the frame is made from pieces of steel channel, from which the semblance of two longitudinal spars is made, they are fastened together by three pieces of steel strip. At the front of these side members, a steel arch is welded with a central link fork, and two rings for lower link fastening are also attached to the structure.

On the sides of the frame, plate-type supports are mounted, which serve to fasten the seed tubes and discs for sealing the furrows.

After these operations, it is worth strengthening the frame and reinforcing it with steel strips.

The arch also needs reinforcement, we perform this action using overlays and kerchiefs made of sheet steel, cut in the form of a right-angled triangle, for reinforcement.

The hopper (container for planting material) is fixed to the plate-shaped bracket with two bolts.

Hopper assembly

For its manufacture, plywood is required, its thickness should be from 0.8 to 1.2 mm. We cut out the parts according to the template with an electric jigsaw, after that we process the structural elements with linseed oil or other compositions suitable for their properties and assemble them into steel corners. The finished product can be painted with water-resistant paint that withstands atmospheric and mechanical stress. A rubber lining is made inside the hopper to avoid injury to the tubers.

After these actions, it is necessary to attach the holder of the loosening paws and the axle for the wheels of the unit to the frame of the future planter using bolts.

The axis consists of a pipe (steel or cast iron), necessarily thick-walled, because it has a very considerable load, spike-shaped inserts or metal trunnions made on the machine and held by pins. After the final assembly of the entire mechanism, the pins must be welded. The wheel axle is fastened using strong steel clamps and corresponding bolts.

Wheels, rippers and their holders. Sowing device

Wheels can be used both ready-made from medium-sized agricultural machinery, and home-made. For the manufacture of the latter, steel sheets are required. Self-made wheels are preferable because they are designed as cylinders wide enough to minimize soil compaction due to wheel crushing.

The wheel hubs are connected by a welding machine and mounted on two ball bearings.The wheel bearings are put on the spikes of the axle, to prevent sweat from getting inside the bearings of dirt, dust and parts of plants and roots, you can use oil seals or build cuffs.

Holders for loosening paws need to assemble a square bar using welded work, this will require metal corners 500x500x50 millimeters. An ordinary square of a welded type can deform during the work process, so it is more reliable to use the corners.

On both sides of the resulting bar, you need to attach clips, into which the racks of the cultivating parts of the potato planter will subsequently be inserted. In carrying out this work, it is necessary to observe accuracy - the gap between the material of the cage and the stand should not be more than one millimeter.

The planting device itself will require a steel pipe with a cross section of 100 millimeters to be manufactured, the pipe must be thick-walled to avoid bending it from contact with the soil. From the bottom, from the front, a furrow opener is attached to the pipe. This element must be adjustable to control seed penetration. Basically, the regulation of its position is carried out by loosening the stepladders and vertical movements of the seeder pipe.

Discs for filling furrows and forming a furrow ridge for this planter can be taken from the SO-4,2 seeder, but in this case they will need to be slightly modified. It will be necessary to bore or ream the hub bores and replace the bearings, because as standard these discs have only one ball bearing marked 203. Bearing 160503 fits perfectly into the bore holes, which is much better suited to the requirements.

Varieties of potato planters

There are several types of potato planters on the market, differing in shape and size, functionality. The range of prices for such devices is also different. You can buy both expensive multifunctional models and inexpensive budget devices.

Small-sized

Small-sized potato planters are used for planting seed potatoes in the home garden or in the country garden.

Small-sized potato planters are used for planting seed potatoes in the home garden or in the country garden.

The design of the device is equipped with a regulator of the planting depth of potato tubers and a regulator of the height of the earthen ridge formed by raising the soil.

Small-sized potato planters are suitable for motoblocks of both domestic and foreign manufacturers.

The average weight of the device is about 20-25 kg. The hopper volume is up to 34 liters. With its help, you can process rows with a width of 60 to 75 cm and plant 6-7 potatoes per meter. The planting rate is 0.2 ha / hour.

Average

These planters have a capacious 44-liter tank. These are rather large heavy planters, their weight is 41 kg, and the productivity is 0.2-0.25 ha / h. Such planters are aggregated with medium and heavy walk-behind tractors.

Large

They are used for processing large areas. They have a large-sized bunker, into which potatoes are filled with a dump truck. Attaches to the tractor. These are powerful, expensive units used in agriculture and farming.

Cost of devices

The cost of different potato planters depends on factors:

- Hopper volume. The powerful large potato planters have a large hopper. They are convenient to use, since you do not need to often pour tubers into the bunker and stop the walk-behind tractor for these purposes. For a small suburban area, you can purchase cheaper models of devices with a smaller tank volume, which is quite sufficient for processing small areas.

- Possibility of picking with different types of walk-behind tractors. The more clutch options are provided, the easier it is to choose a planter, and the more expensive its cost will be. With limited funds, you can purchase an inexpensive potato planter and adapters to it, which also allow you to complete it with any walk-behind tractor.

Description

In large state farms and agricultural enterprises, sowing has long been carried out with the help of special equipment, but our summer residents for many years had to loosen the land, form furrows and scatter seeds by hand. Of course, if you are the owner of three beds, then such work will not be difficult, but if you have a plot of 6 or more acres, it makes sense to "entrust" part of your work to little assistants - seeders for walk-behind tractors.

These powered attachments are multifunctional multi-shed implements. Thanks to the use of a seeder, almost all sowing operations are significantly accelerated, while their quality meets all agrotechnical standards, and very little energy, like fuel, is consumed. Such equipment is designed for clutching with medium and heavy motoblocks, the performance parameters of which are 6 or more horsepower.

How to make a potato planter for a walk-behind tractor with your own hands: manufacturing technology

If you can't buy a potato planter for a walk-behind tractor, you can do it yourself. We offer you to understand the intricacies of the technological process so that you can start assembling such a useful device.

A DIY fixture can be very functional.

A DIY fixture can be very functional.

How to prepare with your own hands a drawing of a device for planting potatoes: useful tips

To make such a useful device for planting potatoes with your own hands, you must first develop a drawing. When developing it, you should decide on the principle of operation of the device, overall dimensions, method of attachment to the unit. If you have not previously had to assemble such structures, you can use the ready-made documentation.

When developing a drawing, the principle of operation of the device is selected

When developing a drawing, the principle of operation of the device is selected

Making a frame and a hopper for a homemade potato planter for a walk-behind tractor

So let's get started. The work process will be shown in the photo instructions.

| Illustration | Description of action |

|

We weld the frame for a homemade potato planter for a walk-behind tractor from a profile square pipe 40 by 40 mm. We additionally weld bearing seats to the frame, in which the lower axle with a leading sprocket of the chain drive mounted on it will rotate, and vertical posts designed to install the upper axle with a driven sprocket. The racks are made from a 20 x 40 mm pipe. |

|

A bunker for potatoes can be welded from metal sheets or made from scrap materials. Many people use tanks from old washing machines and other similar containers. |

DIY potato planter rippers and holders

A metal bar is used to make the ripper holder. The clips holding the paw racks are attached to it. For the manufacture of the rod, a corner or a square pipe 50 by 50 mm is used. The holder is bolted to the frame.

Rippers for potato planters can be made by hand from rebar

Rippers for potato planters can be made by hand from rebar

Seats and wheels of a homemade potato planter for a walk-behind tractor

To plant potatoes comfortably, it is worth taking care of a seat and suitable wheels. The latter, together with ball bearings, are mounted on the axle and mounted on the frame. For protection, wide locknuts or collars can be provided.

Wheels must have a suitable diameter

Wheels must have a suitable diameter

The seat can be made of boards, and then covered with foam rubber and any material that is comfortable for sitting.

We also offer you to watch a video that describes in detail the process of assembling a homemade potato planter with your own hands:

What types are there

Before choosing a garlic planter, a farmer must understand the rather complex classification of these mechanisms. They can differ from each other by a variety of parameters - according to the method of sowing, the number of rows and the type of work.

To begin with, it is worth noting that the designs of seeders are somewhat different, depending on which crops they are used for planting. There are cereal, vegetable and multipurpose models. Seeders with a hopper system are used for seeding beans, sunflowers and corn. In some cases, a vacuum system is used instead of a hopper system.

As for, in fact, garlic planters, then, among other things, they are divided into two categories, depending on the size of the planting material:

- small teeth, whose size does not exceed 2.5 centimeters;

- large denticles ranging in size from 2.5 to 3.5 centimeters.

The design of the trailed unit also plays an important role. Depending on its availability and type, seeders are divided into:

- manual;

- for a walk-behind tractor or mini-tractor with a one-point knot;

- for a mini-tractor with a three-point hinged unit.

As you can see from this list, garlic planters can be either manual or attached to a mini-tractor or walk-behind tractor. This also significantly affects the number of rows that the device can process at a time: from one to five. The choice depends on the size of the site.

A manual garlic planter is the simplest version of the device, but it is activated by the physical effort of a person. Not only is it manually transported and moved in this way during sowing, it is also adjustable. Among all models, handheld devices are the cheapest and are suitable for small plots of land, summer cottages and vegetable gardens.

The trailed garlic planter is used on medium and large plots, since it can be hung on a walk-behind tractor or mini-tractor of any design and any production. Due to the presence of this unit, the need for the use of manual labor is noticeably reduced. At the same time, the constant need for refueling is considered a disadvantage.

In addition, the planters differ depending on the row spacing to be created. They are 20 cm and 58 cm.

An important parameter that is considered when choosing a device is the type of seeding and its accuracy. It is classified according to the following sowing methods:

- nesting;

- square-nested;

- private;

- dotted;

- scattered.

The error with which the mechanism works is always indicated on its case. The farmer should check his needs and learn the characteristics of the planter before purchasing it. In many cases, maximum seeding accuracy is an essential parameter.

The choice of the number of rows also depends entirely on the needs of the grower of garlic and onions. Their standard number varies from one to five. There are some particularly large models with more. Modern planters can have removable containers that allow you to change the number of rows as you like.

The seeding type is different for each device

The seeding type is different for each device

The number of rows is the most important parameter affecting the productivity of the mechanism. The more of them, the more at a time he will be able to sow and the faster to process the selected area. Most of the models on the market are:

- one-;

- two-;

- three-;

- four-;

- five-;

- six-row.

But the row is not the only indicator that they are guided by when purchasing a planter for garlic and onions. Weight and dimensions are equally important. Since it is made of metal, the mass is impressive, exceeding 70 kilograms. Especially on 6 or 5 in-line models.

The choice of a manufacturer in our time is especially difficult. Both domestic and foreign models are presented on the market. The price depends on the country of production. Some craftsmen make garlic planters with their own hands, thereby significantly reducing their cost.

This is interesting: the mowing machine for the Neva walk-behind tractor.

Planting potatoes

Thus, heavy manual labor is excluded when using mechanized devices. In this case, potatoes are planted several times faster.A tiller with a trailed planter makes a furrow, potatoes automatically fall into it, and then the hiller fills the holes. It turns out that seeds are planted and the earth is tamped in one pass. Time is spent only turning the machine in the opposite direction. Therefore, if there is a large plot of land, it is an irreplaceable assistant. It is only necessary to monitor it and carry out maintenance in a timely manner.

In addition to trailed automatic potato planters, manual planting devices are also widely used. This is the most popular crow's beak. When planting, the point is pierced into the soil, then potatoes are thrown into the cavity of the "beak". Further, the cuttings close, the "beak" opens, and the potato remains in the ground.

Potatoes are harvested in early September. And while it is ripe, craftsmen can work all summer on the manufacture of a potato digger and other useful devices. For example, a self-made potato peeler will be great helpers in the kitchen.

Originally posted 2018-03-28 15:01:11.