Areas of use

Due to the fact that home-made mini tractors are largely identical to store options, such as Uralets, Kubota, Bulat 120, Uralets 160, Yanmar according to a variety of criteria, their scope of use will also be quite similar.

Application area

Any such equipment is manufactured exclusively for its use in the agricultural sector, where the main requirement is the ergonomics and reliability of the units.

As for home-made mini tractors, then perhaps the most basic type of work that they perform is various tillage for its further use. This area is quite extensive and includes a number of specific works:

- cultivation of the soil, as well as the removal of weeds and other vegetation from the ground;

- the formation of beds;

- planting potatoes using special attachments;

- digging up potato tubers, etc.

As we can see, with the help of home-made mini tractors, you can perform virtually the full range of land work, the main purpose of which is growing and harvesting.

For the village, this is a primary task, because this is the only way to feed oneself in these conditions, hence the indispensability of this technique, which many people note. However, land work is not the only thing that self-made units are capable of.

If you work a little, thinking over the use of additional attachments, then you can significantly expand the scope of application of such equipment:

- mowing grass for the purpose of making hay;

- transportation of various goods, as well as cleaning construction and agricultural waste from the site;

- clearing the territory from snow massifs, etc.

It is important to understand that additional equipment will cost some money, but you can also make it yourself. The same snow blowers and grass mowers have a completely simple design that can be made from handy materials and tools.

In construction

Fortunately, there is a sufficient number of diagrams and drawings on the Internet that make this task easier for the farmer.

Instructions on how to make an all-wheel drive mini tractor with your own hands - drawings and dimensions

Having appreciated all the advantages, many are wondering - how to make a 4x4 mini tractor? In principle, this assembly method is not much different from traditional methods, except, perhaps, the structure of the frame structure.

Basically, the frame is solid, but in the breakdowns, an option with a breaking frame is provided, from which the name itself comes.

Frame

The appearance of the structure may be a little puzzling to an outside observer, but its seeming unpretentiousness should not be misleading. The fact is that everything inside is located so proportionally, if you follow the drawings exactly, that allows the unit to show quite good performance indicators.

Speaking of drawings. This is probably one of the most important stages of the entire assembly, because the success of the entire design depends on the correctness of leaving a detailed drawing and determining the exact dimensions.

The fact is that the specifics of self-assembly involves the adaptation of some parts to the individual characteristics of the frame or power unit. This is understandable, because the components are taken from completely different equipment, which leads to their dimensional mismatch.

The adjustment itself is carried out mainly on a lathe, which in itself presupposes the presence of a detailed drawing. After all, it is much easier to make certain holes or stitching, looking at the drawing, than keeping all this abstraction in your head.

Drawing

So, having made a drawing, we proceed to the assembly process:

- The frame itself will consist of traverses and side members. The spars, in this case, have a three-stage structure. The first stage is made of channel number 10, and the last one is a square steel tube with dimensions of 80 × 80 mm.

- The rear traverse is made of channel number 16, and the front one is made of channel number 12.

- If you are converting a walk-behind tractor into a mini-tractor, then the main power unit will be the engine located on the walk-behind tractor. If not, you will have to purchase the engine separately. In principle, any diesel engine of the required power (at least 12 hp) can be suitable.

- However, experts advise taking a more powerful one - a motor with 40 hp. and water cooled.

Transmission

- The gearbox and power take-off shaft, as well as the clutch, can be taken from the GAZ-53 and GAZ-52 vehicles, respectively. They will not work ready-made, so you will have to modify them a little. To do this, you need to re-make the flywheel of the motor, cutting off a little from the back and drilling one hole in the middle.

- The bridge can be installed in the unit in the desired form without any manipulation. It is attached to the frame structure with four ladders.

- Wheels can be taken from old cars, but 18 inches is considered the optimal diameter. The process of installing the wheels on the hubs itself is quite simple. It is enough to cut a hole of the required diameter from the center of the disk, and the center of the disk from the ZIL-130 is welded to this place.

- The front axle is not so important, because it will not be the driving one. Therefore, you can take the bridge from other equipment.

- The steering is best hydraulically assisted. You can take it from old agricultural equipment, but for its correct operation you need an oil pump.

- By the way, the driver's seat must also be installed correctly, because a person spends not a single hour controlling the unit. The seat must be positioned so that the steering column does not rest on the knees of the person.

In particular, the drum brake will be used in the front wheelbase system, and the steering rack will be borrowed from the cars of the VAZ family.

Other components can be freely found on the spare parts market, where there are quite a lot of useful things. In addition, on specialized sites there are a sufficient number of advertisements for the sale of parts that can be purchased for mere pennies.

What is a breaking frame

The breakaway (articulated) frame is nothing more than 2 large semi-frames. They are connected using a swivel joint. The technique has a high degree of maneuverability. The advantages of self-made breakable all-wheel drive mini-tractors:

- a significant reduction in the turning radius (while the unit is able to turn a full 360 degrees, being in one place);

- the tractor has good maneuverability in very swampy areas with variable relief;

- the moving frame changes the balance pattern of the machine, which makes it possible to provide reliable, good traction with the soil;

- This tractor has an even load distribution so it delivers maximum power.

In terms of its characteristics, equipment with a breaking frame is significantly superior to light gardening equipment and is in no way inferior to heavy factory tractors. Typically this unit is 4-wheel drive (all-wheel drive). This increases the cross-country ability and stability of the tractors.

Minitractor with break frame

Do-it-yourself mini tractor from a walk-behind tractor. DIY mini tractor from a walk-behind tractor

For the processing of small plots of land, there is no better solution than a do-it-yourself mini-tractor from a walk-behind tractor.Not every site owner can purchase a factory-made model, so you have to look for other solutions. It's easier, for example, to buy a regular walk-behind tractor and remake it only on your own.

Required tools and materials

The first stage of the work consists in drawing up the drawing and preparing the equipment. The scheme of nodes and mechanisms, if you have the appropriate skills, can be developed independently or you can use those what are presented below.

As for the accessories, ready-made factory conversion kits are suitable - in any case, they are cheaper than the mini-tractor itself. But this option is suitable only for those who do not want to save on absolutely everything.

Making a homemade tractor will become impossible without:

- Grinders and disks.

- Fasteners and hardware (bolts and nuts).

- Channels and pipes with a metal base.

- Drill coming with drill sets.

- Welding equipment.

- A set with tools.

You cannot do without two suitable wheels, along with a hinge and a driver's seat, a steering mechanism, pedals, and the walk-behind tractor itself. It must have a sufficient power level.

The heavy class of a walk-behind tractor with diesel fuel is ideal for a homemade mini tractor.

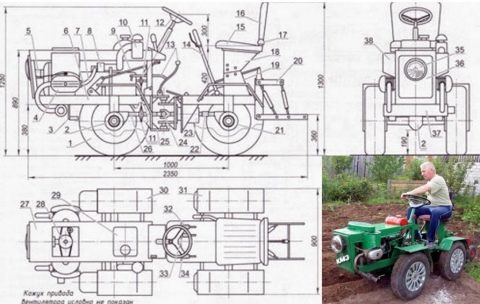

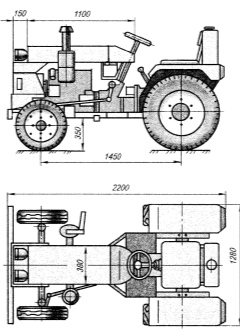

Overall dimensions of the mini-tractor

Layout drawing of the mini-tractor "Ant"

Kinematic diagram of a mini tractor

Choosing a walk-behind tractor

Of the important parameters for these devices, it is worth highlighting:

- Cost and manufacturer.

- The size of the plow (if the mini tractor will be used for plowing the land).

- The type of engine used.

- The weight.

- Power level.

Power. One of the most important parameters, since the performance and power of the mini tractor directly depends on the engine power. The more aggressive and heavier the load on the transport, the more powerful you need to take the walk-behind tractor.

The weight. If a homemade mini tractor is used for plowing the land, then the weight of the walk-behind tractor will be a critical parameter. The defining moment is the type of cultivated land: for hard varieties of soil, you should not choose too light motoblocks, otherwise the mini tractor will not cope with its purpose.

Although gasoline walk-behind tractors work much quieter, the diesel engine wins in terms of the economy of its use: it has stable rpm and increased traction. With heavy soils and large areas, it is the diesel engine that will better cope.

In any case, for any purpose, the heavier the walk-behind tractor, the better the working data of the future mini-tractor.

Price and manufacturer. If possible, it is better to choose products from companies that have been on the market for a long time. If financial opportunities are limited, you can get by with cheaper analogs. Russian products will also be the best option for most.

Chinese walk-behind tractors

These are mainly copies of Russian models. Their cost is lower due to the underestimated resources for production and savings on materials. This has a somewhat negative effect on the final quality of the product.

At the same time, the functionality does not differ from Russian motoblocks. Recently, products of acceptable quality have appeared, although they are still far from analogues from Russia. Popular Chinese walk-behind tractors include the Bison, Farmer, Centaur, Forte, Aurora, Zirka and others.

Russian products

The optimal solution with a reasonable price. Popularity among buyers has gained motoblocks with a belt drive or with a transmission with the ability to transfer torque to, or. In any case, the process is not complete without the participation of a special belt.

A feature of our developments is a simple device of the clutch system. From the maintenance procedures, only the replacement of the belt remains. Even Soviet engineers designed a gearbox, which is recognized as one of the most successful on the market. Professional motors of foreign manufacturers are used. The units are functional and reliable.

Homemade mini tractor with an engine from Oka

This tractor was built by the craftsman Ivan, let's take a closer look at its design.

An internal combustion engine and a gearbox from the Oka, a transfer case from the Niva are installed on the homemade product. Number of gears: forward 4 + 4 reduced; back 1 + 1 reduced. The bridges were taken from Moskvich-412, shortened, only I did not weld the axle shafts, cutting off the standard one, cut the splines (when asked if we could do this to me at our plant, they said, like a finger on the asphalt), so I made not welded but solid ones (700 mm track) ...

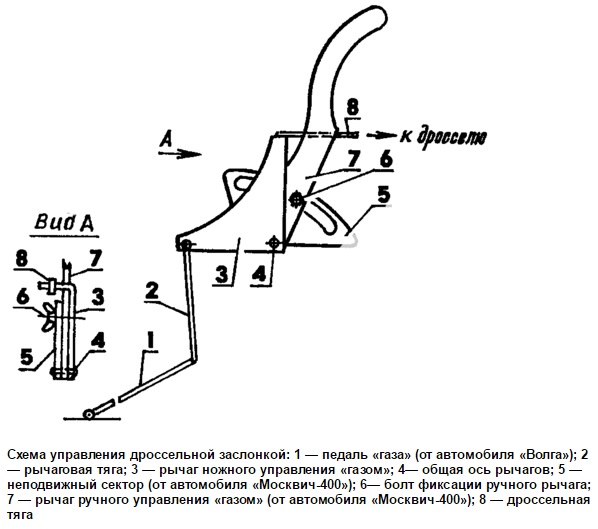

An additional crankshaft pulley from a Volga, Gazelle car (from a generator for two belts) so far, one stream for a belt is free - a pump for pumping water is planned.

Disassembled gearbox "Oka" took out the gear with the assembly of the satellites from the gearbox and weld the gears of the satellites together (but not with the casing, it is cast iron, and the gears are steel).

As a pump, I used what was in the possession in excess (a power steering pump from BMW) a ZF petal pump, max. pressure 115bar (plus I opened it and plugged the pressure reducing valve, so I think now it is capable of more.)

The pulley from the motor to the pump is about 1k3. Hydraulic distributor P80-2-022 (with floating position).

A muffler from a Chinese scooter (for obvious reasons, I chose the lightest one).

Wheels also from BMW525 E28 (14 inches) become after slight revision like native ones (narrowed from 6 inches to 4.5 inches).

Crosspiece in the swivel unit from the front Nivov cardan (the extreme flanges were taken and slightly sharpened for a larger bend angle).

The gearshift mechanism is made on the ball-and-socket joints of the front stabilizer bar BMW730 E32.

The hydraulic system is all new, except for the pump, the front cylinder is from MTZ-80, the rear one is from the combine. I selected new hoses of suitable length. The valve is two-section with a floating position. Hydraulic tank from BMW 528 E28 (1.2L).

Self-made blade - sheet metal 4 mm.

Start off in any gear (min speed about 1 km / h at idle; maximum about 35 km / h). All-wheel brakes.

The mini tractor has overall dimensions:

- Length 2500 mm (with blade but without plow yet).

- Width 900 mm.

Next, a couple of videos about a homemade mini tractor:

Mini tractor with an engine from Oka: stages of work

All homemade mini tractors are assembled according to the same principle and order.

-

- Frame construction.

You will need 2 spars (right, left) and 2 traverses (rear, front). The spars are made of channels No. 10, and the traverses are made of channels No. 12 and No. 16. The metal beam may well be made of a crossbeam. - Engine.

The motor should be chosen according to the torque and power indicators. The ideal option would be a 40 hp water-cooled diesel 4-cylinder engine. If you are going to make a 4x4 mini tractor, then you will need to increase the transmission ratio. - Bridge.

It integrates without any modification and is attached to the frame with 4 ladders. You can also take a composite propeller shaft from any car. - Transmission.

The gearbox is mounted on the frame. But in order to ensure synchronization of the clutch with the engine, you need to make a new clutch basket by welding. The basket also needs to be adjusted to the correct size. In the flywheel of the motor, you will need to shorten the back plane, as well as make a hole in the center.

- Frame construction.

- Steering.

Of course, hydraulics need an oil pump to supply pressure. The pump is located at the drive shaft. The best option would be if the control of each wheel of the drive shaft is carried out using a gearbox. It's better to borrow the hydraulics. - Rear axle.

You can take this mechanism from the car. Only he will need to reduce the axle shafts.

- Wheels.

When choosing wheels for a mini tractor, consider the purposes for which you will use the unit. If you need such a technique for transporting various goods, then the discs should definitely have a radius of 13 - 16 inches.If you aim to carry out agricultural work, then set the wheels with a radius within 18 - 24.

The process of making a minitractor from Oka will consist of the following steps:

- We make the frame. To do this, you can take channel # 10 or sheet metal. As a result, you should get a standard rectangular structure welded from metal corners.

- The UAZ fist can be used as an interframe hinge.

- We solder the front and rear axles on the basis of the constituent parts of the Oka car.

- The layout of the structure with the engine from the Oka. The half engine from this passenger car is quite suitable for creating a minitractor. But still, be sure to take into account a few nuances: for better cross-country ability, increase the wheel clearance; develop a scheme for attaching the mechanism for the hitch; Reinforce the front and rear side members.

- If you decide to use a powerful engine from UD2, then you will additionally give your unit more power and thus be able not only to process the site, but also to transport goods.

- The clutch device consists of 2 V-belts that transfer the rotation to the pulley. The pulley is located on the gearbox shaft.

- The gearbox can also be borrowed from OKA. During installation, it must be deployed towards the driver.

- We mount the steering components.

- And finally, we install the fuel tank, brake system and electrical parts.

It is worth noting that such a home-made unit pays off completely in 1 season. Therefore, the popularity of breaking a mini-tractor with an OKA internal combustion engine with your own hands is increasing every year. Use the drawings below to create a homemade mini tractor.

The main stages of the assembly of the structure

To assemble a tractor with your own hands from the Oka, you will have to create drawings yourself. Having considered the location of the structural units, it will be possible to calculate the required frame dimensions. When making a base, it is necessary to make welded seams to get a strong frame. And also you need to make a mount for the attachment, which is placed on the rear traverse.

In the future, it is necessary:

- Mount the undercarriage using tracks or wheels.

- Install the engine and clutch.

- Assemble the steering and braking systems.

- Secure the driver's seat.

Working with wheels begins with installing the axle shafts. For them, you need to weld racks using a corner. For homemade mini tractors, the same type of rear and front axles are suitable. If you have to replace the discs with options with a large diameter, you will have to change the hubs. It is permissible instead to cut the circle with the fastener and weld it to the hole in the disc.

To create the front axle, steel rods are taken, no thinner than 5 cm. A joint from hinges is attached to the center, and ears for the hubs are installed at the ends. The clutch and brakes are usually of the standard type. The engine is located in the front, but to reduce the size of a homemade minitractor, it can be placed under the driver's seat.

Engines used

For homemade equipment, several types of power units are used.

Zid 4 5

Petrol, 1-cylinder, 4-stroke engine with 4.5 HP, air-cooled. The power unit is installed on self-propelled agricultural machinery and various agricultural equipment. Starting is done with a cord wound on a pulley.

Several types of power plants are produced, each type is designed for different equipment.

When buying a unit, the manufacturer gives a warranty period for the engines - 2000 motorcycle hours per year, provided that it is stored and used correctly.

Lifan 6 5

The most common engine for mini-tractors is the Lifan 1-cylinder, 4-stroke 6.5 hp petrol engine. It is used for motoblocks, snow blowers, motor pumps, generators and other agricultural equipment.

The motor has a tapered shaft output and a built-in reduction gear.Some models are equipped with an electric starter and an oil sensor, which stops the engine when there is a lack of oil.

Lifan 6 5 is made in China, but it has a high-quality assembly. Upon purchase, the manufacturer gives a 2-year warranty.

Other options

Another engine option for a homemade mini-tractor is a gasoline, 2-cylinder power unit UD-25, with a volume of 0.42 liters, with a capacity of 12 hp. The motor has been discontinued, but many variants of this model can be found on the Web.

In the manufacture of homemade equipment, engines from passenger cars are often used. The most common one is from the Oka car, with a volume of 0.649 liters, with a capacity of 29 hp. The unit is characterized by low fuel consumption and high efficiency.

A tractor with a Zhiguli engine will cope with any agricultural work.

Pros and cons of such a tractor

The advantages of homemade equipment include:

- good cross-country ability and endurance thanks to the all-wheel drive from the UAZ;

- a wide selection of attachments suitable for use;

- dimensions of a homemade tractor, allowing you to work the soil in small areas;

- the ability to repair equipment with your own hands at minimal cost;

- low fuel consumption;

- the ability to replace the power unit with a more powerful one.

The disadvantages of homemade products include a long, complex and painstaking assembly process, which not everyone can complete. If a self-made part breaks down, it will be difficult to find a suitable one.

To drive a tractor on the road, a special permit is required, which must be obtained from the nearest traffic police department. Otherwise, a fine will be imposed.

Instructions

Having appreciated all the advantages, many are wondering - how to make a 4x4 mini tractor? In principle, this assembly method is not much different from traditional methods, except, perhaps, the structure of the frame structure.

Basically, the frame is solid, but in the breakdowns, an option with a breaking frame is provided, from which the name itself comes.

Frame

The appearance of the structure may be a little puzzling to an outside observer, but its seeming unpretentiousness should not be misleading. The fact is that everything inside is located so proportionally, if you follow the drawings exactly, that allows the unit to show quite good performance indicators.

Speaking of drawings. This is probably one of the most important stages of the entire assembly, because the success of the entire design depends on the correctness of leaving a detailed drawing and determining the exact dimensions.

The fact is that the specifics of self-assembly involves the adaptation of some parts to the individual characteristics of the frame or power unit. This is understandable, because the components are taken from completely different equipment, which leads to their dimensional mismatch.

The adjustment itself is carried out mainly on a lathe, which in itself presupposes the presence of a detailed drawing. After all, it is much easier to make certain holes or stitching, looking at the drawing, than keeping all this abstraction in your head.

Drawing

So, having made a drawing, we proceed to the assembly process:

- The frame itself will consist of traverses and side members. The spars, in this case, have a three-stage structure. The first stage is made of channel number 10, and the last one is a square steel tube with dimensions of 80 × 80 mm.

- The rear traverse is made of channel number 16, and the front one is made of channel number 12.

- If you are converting a walk-behind tractor into a mini-tractor, then the main power unit will be the engine located on the walk-behind tractor. If not, you will have to purchase the engine separately. In principle, any diesel engine of the required power (at least 12 hp) can be suitable.

- However, experts advise taking a more powerful one - a motor with 40 hp. and water cooled.

Transmission

- The gearbox and power take-off shaft, as well as the clutch, can be taken from the GAZ-53 and GAZ-52 vehicles, respectively.They will not work ready-made, so you will have to modify them a little. To do this, you need to re-make the flywheel of the motor, cutting off a little from the back and drilling one hole in the middle.

- The bridge can be installed in the unit in the desired form without any manipulation. It is attached to the frame structure with four ladders.

- Wheels can be taken from old cars, but 18 inches is considered the optimal diameter. The process of installing the wheels on the hubs itself is quite simple. It is enough to cut a hole of the required diameter from the center of the disk, and the center of the disk from the ZIL-130 is welded to this place.

- The front axle is not so important, because it will not be the driving one. Therefore, you can take the bridge from other equipment.

- The steering is best hydraulically assisted. You can take it from old agricultural equipment, but for its correct operation you need an oil pump.

- By the way, the driver's seat must also be installed correctly, because a person spends not a single hour controlling the unit. The seat must be positioned so that the steering column does not rest on the knees of the person.

In particular, the drum brake will be used in the front wheelbase system, and the steering rack will be borrowed from the cars of the VAZ family.

Other components can be freely found on the spare parts market, where there are quite a lot of useful things. In addition, on specialized sites there are a sufficient number of advertisements for the sale of parts that can be purchased for mere pennies.

It is interesting: Advantages and disadvantages of the kmz-012 mini-tractor: it is useful to know

Increased comfort

Mini tractor seat with increased comfort

Homemade mini tractors based on this Oka car are usually assembled without spring. As a result, while driving, the driver strongly feels all the shocks. In the case of prolonged work on such a technique, vibrations negatively affect the condition of the spine. To alleviate this detrimental effect, it is worth installing soft springs under the seat.

If you have to use the car at night, then you need to tackle the issue of creating electrical wiring and headlights. In most cases, these elements are not required.