Advantages and disadvantages

The bison is used in the household for gardening and gardening work. The waste disposer has the following benefits:

- The garden shredder turns the branches cut from the trees into chips and small sticks used for food of herbivores.

- The resulting mass is used as compost or shelter for perennial plants for the winter.

- The chips are used to cover the floors in the chicken coop.

- Cheap shredders are used to grind large freshly cut grass and tops of plants used for feeding pets and birds.

An important advantage of the equipment is its mobility. The device on wheels moves around the site

The device provides the practicality of using plant waste. The shredder ensures that the site is kept clean.

The knives of the device are made of metal, therefore they are resistant to abrasion. The type of cutting element is a key consideration when choosing a crusher. The shredder knives have a milling design, therefore, the installation is purchased for processing coarse branches.

The disadvantages of using the Bison garden shredder are the need to connect it to the power supply. If the outlet is located remotely, then the use of the equipment is impossible. When moving on wheels, grass is wound, and it is inconvenient to carry a 16-kg apparatus in your hands. During the processing of organic substances, particles fly out of the device.

The official website contains information about the continuous improvement of the crusher's quality.

The Bison shredder is a machine for processing grass, tops, leaves and twigs, the mass of which is used in the household. There are two units in the manufacturer's line, which guarantees the buyer the opportunity to choose a device that is suitable in terms of power and performance.

About the Bosch garden shredder - how it works, the best models

Garden gasoline shredder for branches - what is it, how it works

All About Garden Shredders - Branches & Grass Shredders

Makita UD2500 - parameters and description of the chipper for the garden

Submersible sewage pump with grinder - description, characteristics

A nozzle for chopping branches on a walk-behind tractor - what is it, characteristics

How to use, step by step instructions

After purchasing the device, before turning it on for the first time, lower the lock 7a and turn the seventh regulator counterclockwise until the maximum clearance is set. Depending on the type of plant waste that will be processed by the shredder, the degree of processing is established.

The Zubr chopper has a thermal switch, which is used when the motor overheats or the electrical network is overloaded. If the device turns off, then turn it on again after 3-5 minutes to cool the motor.

When processing grass and other plant debris, the cutting elements become clogged. To clean them, turn off the crusher by pressing the 0 key with the second switch. Disconnect the shredder from the mains. Remove the cover and unscrew the screw. The cutting elements are cleaned from waste by hand.

Do not turn off the device until it has recycled all the waste loaded inside. If they get stuck in the cutting elements, the chopper is blocked. The inlet and outlet openings are cleaned until the plant waste dries on their surface.

When assembling and adjusting, the device is disconnected from the power supply. The crusher is installed upside down and the frame rotates upside down. The axle, bushings, wheels and washers are being installed on the frame. We hold the axle and screw the nuts tight with the wrench provided by the manufacturer in the kit. Installing the container.

Before turning on the grinder, it is recommended to determine whether the voltage of the electrical network corresponds to the nominal one. The presence of mechanical damage on the crusher is checked. Connect the device to the mains. If the chopper has not been used for 3-5 days, then it should idle for 10-20 seconds.

If there is a smell of burning or abnormal noise, the equipment is disconnected from the power supply and the cause of the malfunction is determined. When operating the equipment, the network cable is laid outside the working area.

The shredder is intended for processing plant waste. It is recommended to store the unit in a dry, ventilated room. The device must not be exposed to moisture.

Do not use the crusher to recycle plastic or metal. When operating the equipment, to avoid injury, do not put the operator's hands in the loading opening. It is forbidden to push the loaded waste with your hands. It is recommended to process tree branches raw. Leaves, grass and tops are best crushed dry.

Terms of use

When working with a shredder, a number of recommendations must be followed.

- It is undesirable to recycle branches with knots. This can overheat the motor and cause the blades to dull quickly.

- Every 15 minutes of operation of the unit, it is necessary to take five-minute breaks.

- The optimal raw material for processing is fresh or dry grass, as well as branches that have lain for no more than a month. If the branches were cut a long time ago, then only those of them whose diameter does not exceed 3 cm can be recycled.

- When chopping too thin branches, the knife-type device often chops them into long sections, the length of which can be up to 10 cm. This is normal for units with such a cutter device, so there should not be cause for concern.

See below for an overview of the Zubr garden shredder.

Review of ZUBR shredder models

The manufacturer's line of shredders includes two models - ZIE-40-2500 and ZIE-44-2800.

ZIE-40-2500

In the garden shredder ZIE-40-2500, plant waste is crushed by a mechanism powered by a 2.5-watt motor. This power of the motor allows you to process soft plant waste and fresh branches, the diameter of which is no more than 40 millimeters.

The knives on the mechanism are sharpened on both sides, which increases the duration of their operation. If one side is blunt or damaged, the knives turn to the other and the device shreds plant debris. When chopping wood, the 10 to 5 mode is used. The device works for 10 minutes, and rests for 5 minutes. If grass, leaves and other soft plant waste are being processed, then the working time is increased by 15-20 minutes.

ZIE-44-2800

The ZIE-44-2800 crusher differs from the ZIE-40-2500 model with its electric motor power, which is 2.8 kilowatts. A milling grinding mechanism is built into the device - a gear cutting wheel or gear. The device is designed for grinding dry and fresh branches, the diameter of which is 45 millimeters.

The shredder has a handle for adjusting the size of the chips. The device is equipped with a pusher, which guarantees the grinding of grass into green mass. Easy handling of equipment is ensured by a convenient handle and wheels.

The lineup

The assortment of Zubr shredders is not very large, and includes only 4 models, each of which has a certain specialization and special performance characteristics.

Grinder "Zubr" ZIE-40-1600

This model is indispensable for the disposal of grass and small shrubs. The device is equipped with a 1.6 kW electric motor, the shaft rotation speed is 3 thousand rpm, and the device weighs 13.4 kg.The device can grind mainly dry branches no thicker than 4 cm.In addition, the device is equipped with a function of adjusting the degree of grinding, which allows not only to dispose of plant waste, but also to obtain a substrate for various household needs

This is an important option when processing light raw materials, such as grass, and also allows you to insert the desired mode, not allowing the motor to run at full power.

The model is equipped with a sliding protective shutter that protects the operator from the departure of small branches and chips, and an electromagnetic switch that prevents the unit from spontaneously turning on after the power supply is restored in the event of a sudden shutdown. And also the unit is equipped with a recoverable thermal fuse that protects the engine from damage in case of overload. The performance of the model is 100 kg / hour, the cost is 8 thousand rubles.

Zubr model ZIE-40-2500

The device is equipped with a more powerful 2.5 kW motor and is designed for processing dead wood, leaves and fresh branches with a diameter of up to 4 cm. The cutter consists of two double-edged knives, equipped with a belt reduction gear that prevents the motor from breaking when the working shaft is jammed. The device is equipped with a switch-on lock and overheating protection, weighs 14 kg and costs 9 thousand rubles. The productivity of this device is 100 kg / h.

Unit "Zubr" ZIE-65-2500

This model is a more serious device and is capable of processing thick branches with a diameter of up to 6.5 cm. The chopping system is represented by a cutting shaft. The engine power is 2.5 kW, the unit weighs 22 kg, and costs 30 thousand rubles. The model is equipped with a protective shutter, a removable frame, a thermal fuse, a regulator of the degree of grinding and a reversal of the shaft, which helps to free the cutting shaft in case of jamming.

Zubr model ZIE-44-2800

The most powerful unit in the Zubrov family - it has a 2.8 kW engine and has a capacity of 150 kg / h. The shaft rotation speed is 4050 rpm, the weight is 21 kg, the maximum permissible thickness of the branches is 4.4 cm. There is a regulator of the degree of chopping, overload protection and a switch-on lock when the tank is removed. The cutter is represented by a gear-type milling cutter mechanism, which automatically draws in plant waste and crushes it thoroughly. The price of such a model is within 13 thousand rubles.

Grain grinders and root crop attachments

Bison 1a

The Zubr 1a grain crusher is considered the basic grinder in the manufacturer's model range. Its functionality is quite limited and is used for domestic needs: grinding cereals and corn. Nevertheless, this model is equipped with the necessary functions. An electric motor with a power of 1.8 kW is capable of processing up to 180 kg of grain per hour.

In addition to grain, the device is also suitable for chopping root crops and grasses, which will allow you to quickly prepare animal feed.

If necessary, you can change the grain fraction at the exit. For this, a sieve of the correct size must be installed.

Before use, you should carefully read the instructions. The crusher must be secured to a firm, level surface before starting. Before loading the crusher, the engine is started.

It is also important to monitor the quality of the loaded grain - you should avoid getting small stones and other solid particles into the cutting mechanism. The product has compact dimensions - 35 * 30 * 51 cm and weighs 13 kg

The product has compact dimensions - 35 * 30 * 51 cm and weighs 13 kg.

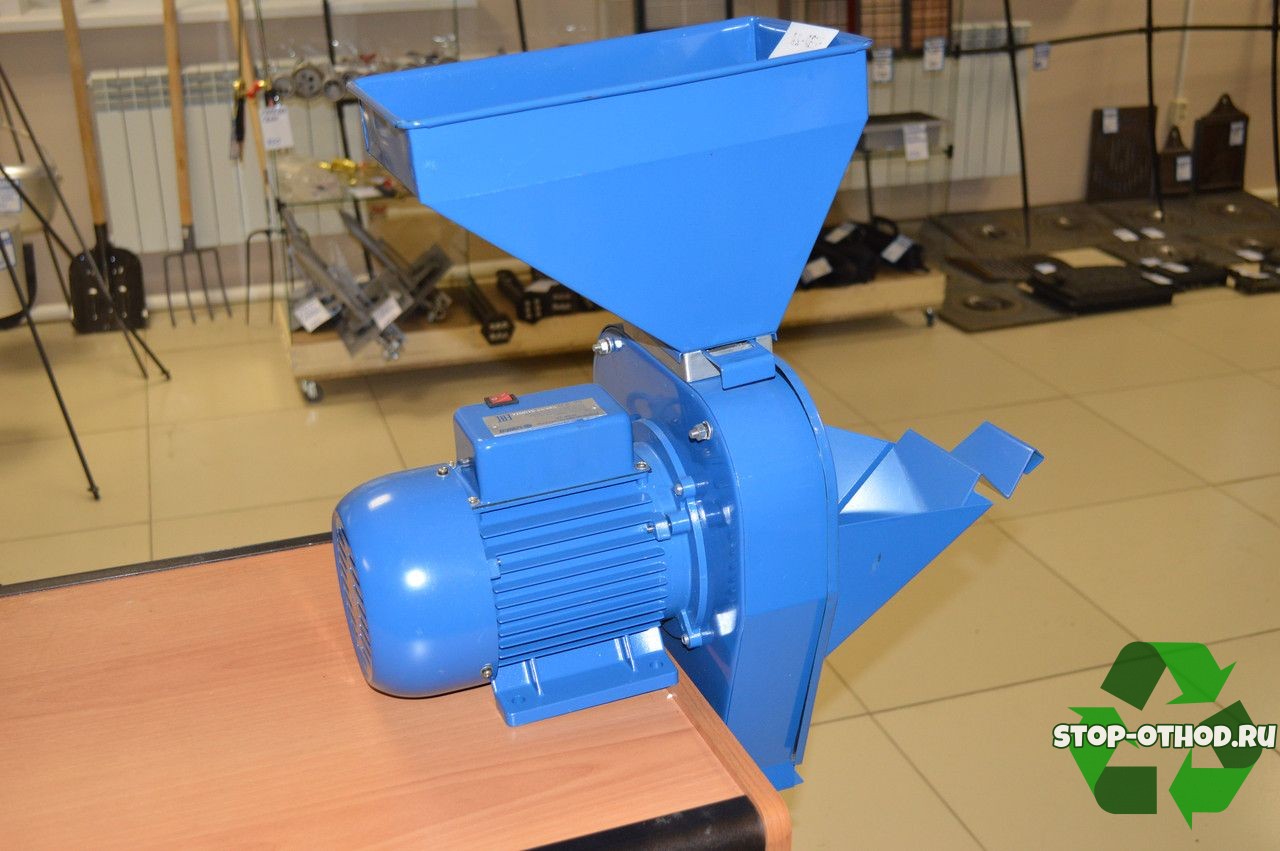

Bison 2a

The Zubr 2a grain crusher is equipped with hammer knives, which easily grind grain and root crops. For crushing root crops, a special nozzle is included in the kit. If you have a nozzle, you can easily chop beets, potatoes, zucchini, carrots. Thus, any vegetables that have grown in excess on the site are suitable for animal feed.

Thanks to the changeable sieve, you can select the size of the grain and corn fraction at the exit.

The device is suitable for grinding various grains: barley, oats, sunflower seeds and corn.

The grain crusher consists of the following parts:

- Electric motor.

- Hammer type cutting device.

- The container in which the grinding takes place

- Loading hopper.

- Sieve for sifting the finished feed.

- Grain feeding flap

- A feed cutter consisting of a grater and a loading container.

The device weighs 17 kg, dimensions - 44.5 * 30 * 51.5 cm.

Bison 3a

Product 3a is not the last among the Zubr crushers. The unit is capable of processing large volumes of grain and is designed for continuous operation.

The only drawback of the model is limited functionality. Bison 3a is not intended for crushing root crops. If you need to prepare food not only for birds, but also for livestock, you should give preference to a different model.

But for crushing grain, this model is ideal. Thanks to the powerful engine (1.8 kWh), the device will process large volumes of grain. The manufacturer's declared capacity for grain processing is 180 kg / h, and for the processing of corn cobs - 85 kg / h.

The replaceable sieve allows you to adjust the coarseness of the grinding.

Product dimensions - 40 * 30 * 51.5 cm, weight - 15 kg.

Bison 5

The Zubr 5 model is a multifunctional and productive device. It can be used to prepare any kind of feed. It includes a grass cutter and grain crusher capable of handling impressive amounts of forage.

The Zubr 5 grain crusher is equipped with a feed cutter for crushing root crops. In addition, there is the possibility of processing legumes, as well as vegetables and fruits. The device allows you to adjust the size of the fraction at the outlet. The cutting mechanism is made of high quality materials, therefore it does not break down and ensures high-quality processing of raw materials.

Performance:

- 180 kg / h in grain processing

- 650 kg / h when crushing root crops

Dimensions - 53 * 30 * 65 cm, weight 22 kg.

Bison extra

Bison extra is a multifunctional device for grinding grain and legumes. It has an average productivity, but thanks to the hammer mechanism it is characterized by uniform grinding of raw materials.

The Zubr grain crushers use the hammer mechanism of the grinder, which has advantages over rotary ones. No high rotation speed is required for uniform crushing, which results in lower energy costs.

According to farmers who use Zubr products, the devices are easy to operate, productive and rarely fail.

The motor power in the Zubr extra model is 2 kW.

Grain grinding capacity - 260 kg / h.

Dimensions - 44.5 * 29.5 * 51.5 cm, weight 28.4 kg.

The model range of Zubr crushers differs only in performance, size and functionality. Depending on the main technical characteristics, each customer will be able to choose a model that meets his requirements.

The range includes units for household use, as well as for medium and large farms.

Garden shredder Bison - what is it, for what purpose

The bison chipper processes grass and leaves into organic fertilizer, branches into sawdust. Electrical equipment is used to produce mulch. Garden shredders are equipped with a transformable frame, so the equipment is reduced in size during storage.

When the device is assembled, the mulch box becomes a cover that protects the device from mechanical damage. For the manufacture of the case, an impact-resistant plastic is used that is resistant to corrosion, precipitation and ultraviolet radiation.

You can turn on the equipment only by pressing the button. If the power supply disappears and reappears, the device will not turn on by itself.

The equipment is equipped with a bimetallic thermal fuse, which guarantees disconnection during mains loads. If the mulch drawer is removed, the system protects the shredder from starting up. The lid has a loading opening, which in its shape resembles the letter G. The branches are fed through a calibrated slot one piece at a time, so the motor does not overheat.

A pusher is included with the device, which is similar in shape to a spatula and simplifies chopping branches and green mass.

Principle of operation

The garden shredder has a housing in which a funnel is located. The equipment is equipped with a cutting or shredding system. Soft branches and grass are ground with knives. Branches, leaves and grass are loaded into the funnel and pushed through with a shovel. When the cutting tool moves, the branches are shredded. At the bottom of the body there is a hole from which sawdust comes out.

To prevent the recycled fertilizer from spilling out onto the floor, a plastic bag or boxes are placed under the hole.

The shredder consists of:

- loading hole,

- container,

- switch,

- thermal fuse cocking buttons,

- direction of rotation switch,

- screw,

- regulator of the degree of processing,

- frames,

- regulator retainer,

- wheels,

- back cover,

- container retainer.

The electric motor converts electrical energy into mechanical energy, which drives the sprocket sprocket. The part rotates close to the fixed plate - this ensures shredding of plant waste.

Purpose

The garden shredder acts as an irreplaceable assistant in preparing the site for winter, during which the area is cleared of accumulated debris, sawn off and dry branches and old grass. The units perfectly cope with any waste of plant origin. They are used for processing leaves, twigs, root residues, grass cuttings, small and medium shrubs and tree branches. The crushed substrate is introduced into the soil as an organic fertilizer, and also covers the trunk circles of fruit trees and rhizomes of perennial plants in the autumn period. Depending on the field of application of the substrate, the degree of grinding of plant waste is regulated.

BLACK + DECKER BEGAS 5800-QS 2.8 kW

BLACK + DECKER BEGAS 5800-QS is an electric garden shredder in a different price category (it costs about 20,000 rubles). This is not to say that such a cost is completely unjustified: working with this unit is much more convenient than with the previous participant in our rating. Here are its main technical characteristics:

- body made partly from impact-resistant polymer material and partly from steel;

- the maximum diameter of the recyclable waste is 45 millimeters;

- total weight 27 kilograms;

- screw grinding system;

- power 2 800 W.

BLACK + DECKER BEGAS 5800-QS is equipped with a special plastic container for collecting recycled 48 liters. It is attached to the bottom of the fixture. This is very convenient, since it does not allow crushed vegetation to scatter around the site. Also, the comfort of use is increased by an automatic pusher.

The BLACK + DECKER BEGAS 5800-QS has four small wheels for moving. True, due to the weight, which is almost thirty kilograms, as well as the dimensions, it is rather difficult to transport the unit from one place to another - it will not fit in the trunk of any "passenger car". And storage problems can arise.

Power is supplied from a 220/230 Volt household power supply.

BLACK + DECKER BEGAS 5800-QS 2.8 kW