Preparing to make a wheelbarrow

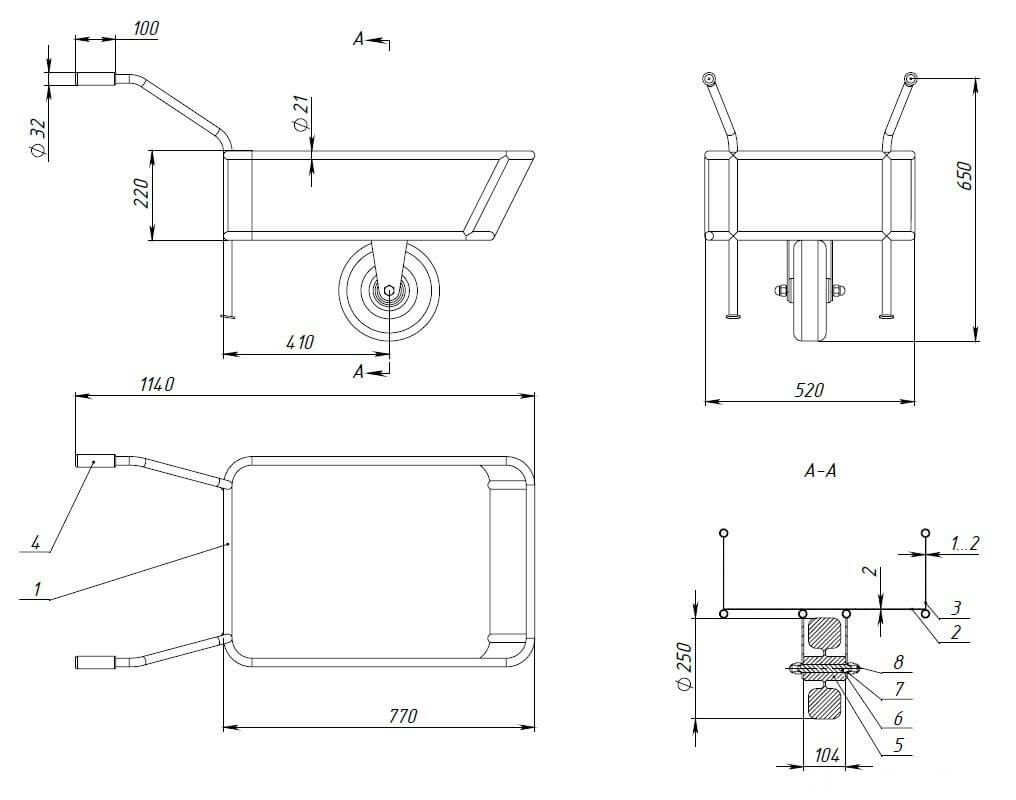

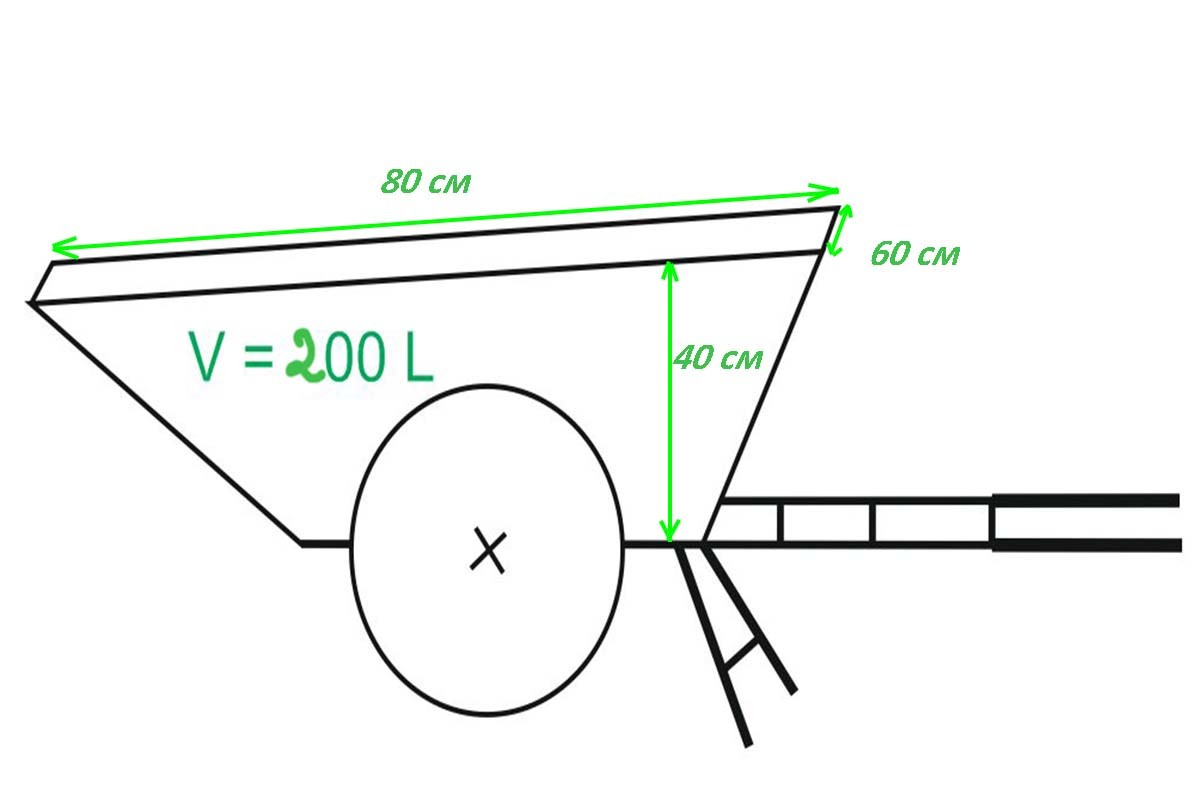

Before starting to make a garden cart with your own hands, create drawings based on a well-thought-out model. The main purpose of the device is preliminarily determined, what exactly and for what distances is planned to be transported. Depending on the purpose, the optimal dimensions of the body and wheels, as well as materials, are chosen.

DIY garden wheelbarrow

Having drawn an accurate diagram of the planned structure, you need to determine how much materials will be needed. Having carried out an inspection in your household, you can say with confidence what components are in stock and what you need to buy. In this case, you can immediately calculate the financial costs, determining the profitability of your actions.

Which wheels to choose

In the presence of unnecessary children's bicycles, scooters, strollers on the farm, the issue of finding wheels is solved very easily and quickly. Without cash costs, a self-made car for a summer residence will be provided with wheels. Depending on the completed design project, you can use a different number of wheels - from one to four.

If nothing suitable is found on the farm, then there is a need to purchase new wheels. They can be of different costs, but you don't need to save too much on them, buying the cheapest ones. It should be borne in mind that the wheels will have a fairly large load, so you should take care of high-quality and durable parts.

Important! When buying new trolley wheels, you should pay special attention to their size. Small wheels can significantly impede the movement of the structure on uneven ground, it will take considerable physical effort to drive a wheelbarrow. Therefore, it is worth giving preference to medium-sized inflatable wheels with a metal rim, which will make it possible to move heavy loads in the trolley even on loose and uneven soil.

Therefore, it is worth giving preference to medium-sized inflatable wheels with a metal rim, which will make it possible to move heavy loads in the cart even on loose and uneven soil.

Optimal material for the body

Depending on the purpose of the home-made garden wheelbarrow, the size of the body, the shape and material for its manufacture are determined. Most often, metals are used for these purposes: aluminum or steel.

Aluminum is a more expensive material, but at the same time it has a number of advantages:

- significantly reduces the weight of the finished structure, which facilitates its operation;

- the body is absolutely not subject to corrosion, does not need constant painting.

Steel is stronger than aluminum. If you have a welding unit, you can perform any operations with it, giving the desired shape. The trolley with a steel body is heavy, which may require additional effort on the part of the operator. At the same time, the increased strength of the body allows you to move even very heavy loads without fear of damage.

Robust body

If there is wood on the farm, the trolley body can be made of wood. Old baby baths or troughs can easily fit. Even from unnecessary metal or plastic barrels, craftsmen make a body for a wheelbarrow. To do this, the container is cut in half vertically, and the load bowl is ready to be attached to the frame.

Note! The body made of a plastic barrel makes the structure quite light and mobile, however, the movement of very heavy bulky goods can lead to its breakage and cracks

What and how to make pens

A do-it-yourself garden cart is usually made with one transverse or two longitudinal handles. The advantage of making household appliances on your own is that you can design a structure, taking into account the individual characteristics of operation and physique (height). Some gardeners note the special convenience of a trolley with one transverse handle, because it is comfortable to carry both in front of you and behind your back. Such a structure can be moved behind you, holding it with one hand, walking on an uneven road, while it will be extremely inconvenient to carry a wheelbarrow with two handles in this way.

Handles are attached to the frame with the body, for the manufacture of which different materials can be used:

- metal,

- wood.

Most often, preference is still given to metal because of its greater strength. If there are small diameter metal pipes in the household, they can be used in the structure of both the frame and the handles.

Additional Information! Metal parts are best joined together by welding rather than mechanical fastening. The part of the metal handles that you hold with your hands can be wrapped with a rubberized film for convenience.

DIY options

If at this stage you have not yet changed your mind about making a wheelbarrow yourself, then let's start studying this topic.

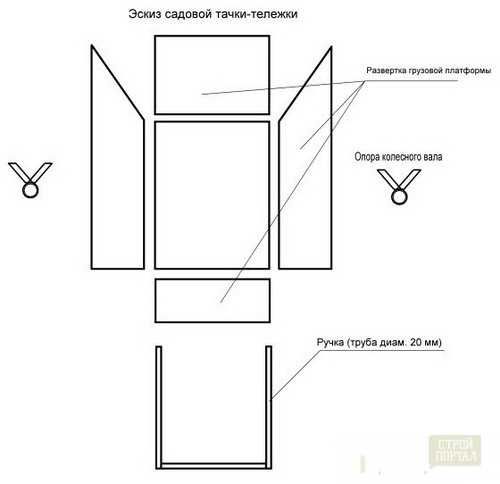

First, let's look at what the structures of frames and bodies can be.

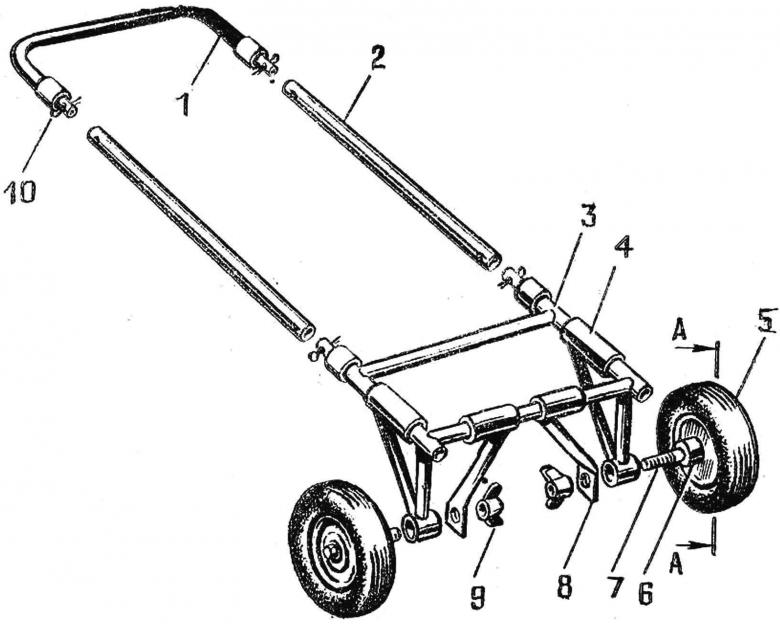

One of the options for the frame is to weld it from a square rod with a cross-section of 25 mm. You need to put two wheels on the axle. In turn, the axle is a stud fastened with nuts.

We also recommend reading

The body itself will consist of galvanized sheets. They need to be cut to the required size and screwed to the frame. As a result, we get an economic thing.

In this picture, we can see that the master did not unnecessarily try to make the wheelbarrow aesthetically pleasing. He needed to make a tool for transporting land, so that it took a minimum of time and money.

In the picture we see the fruit of the craftsman's labor

- An unnecessary container was taken for mixing the solution, which later became the body

- A frame was made of metal pipes for plumbing. They were arched and welded together.

- The axle for the wheel was also attached by welding. And the body was pulled with a wire so that it would not fall out when overturning.

This is not the most ideal version of a wheelbarrow, but it will cope with its functions.

In this picture, we most likely see the result of the work of a perfectionist. Since the creator of this cart did not have a pipe bending tool, a grinder combination was used to cut the handles of the cart. The feet for the stop were installed ready-made. The body is completely welded from scratch from a sheet of iron with a thickness of 3 mm.

If you take a closer look, you will notice something:

The edges on the body are very smoothly cut, it feels like it's not even a grinder.

Along the entire length of the body, we see a very high-quality performance of welds.

Pay attention to what color the paint was chosen. This is an indicator that the wheelbarrow was not made in order to carry earth or brick in it, but for very clean work .. Here the owner did not try to make a wheelbarrow like in a factory: the bends are not so high quality, the quality of the seams is also not very neat

Although all this will not affect the performance of her functions

Here the owner did not try to make a wheelbarrow like at the factory: the bends are not as high-quality, the quality of the seams is also not very neat. Although all this will not affect the performance of its functions.

Workshop on making wheelbarrows (video)

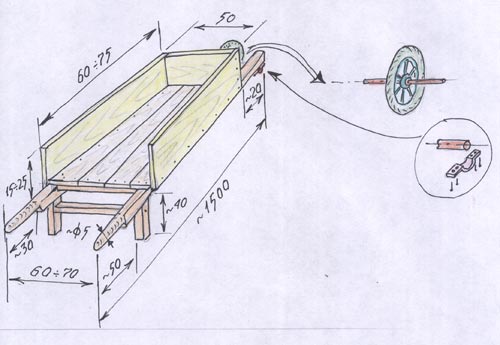

But what if you don't have a welding machine at hand, or have never used one? In this case, there is a lot of information on the Internet on how to make a garden wheelbarrow with your own hands at hand with only boards, screws, an axis and fixtures to attach it to the cart itself.

During assembly, it is preferable to use self-tapping screws made of galvanized material. Before you start tightening the screws, make holes in the boards, but so that the size is smaller than that of the screws. This is done to prevent the board from splitting during assembly with self-tapping screws.

In this picture, we see another version of the wheelbarrow. The bottom of the board is not as practical as if it was made of galvanized sheet. In this version, it remains to make the sides and put two wheels on the axle.

Another option for a garden wheelbarrow is to make it from a barrel. Moreover, the material of the barrel is unimportant. It can be plastic, metal, and even wooden, although you will probably need to suffer with it. The barrel is cut into two parts vertically, which means that two wheelbarrows can be made from it. The order of execution of the "barrel" trolley:

- The purchased barrel mode is in two parts.

- Putting together the framework, the versions of which you read above.

- We make the sides or ribs on which the barrel will be held.

- Installing the wheels.

As you can see, old things can sometimes come in handy, so think a few times when you want to clean up your garage. Then you can wrap the holders with electrical tape to make it easier for your hands. We can say that the car is ready. You can start making "sister wheelbarrows".

If you have an old bed, then we have another option for you. This will require: the bed itself and the wheels. The wheels must be powerful. Wheels from the ancient Zaporozhets are one of the options. The design of the trolley can be either on two wheels or on four. Assembly order:

- Removing the net from the bed

- We attach wheels with the help of welding or fasteners.

- We fix the bottom and sides from a thick steel layer.

- We mount the handle - to your taste, but it is better to make it with the letter "p", because it will be more ergonomic.

Everything, the creation is ready. It turns out a good homemade garden wheelbarrow for transportation of goods. It is an indispensable tool for transporting hay, building materials, firewood and so on.

Making a trailer with your own hands

After studying all the design options, in the manufacture of a homemade trailer for a walk-behind tractor, the simplest options are most often used. The tipper device is certainly more difficult to make, but its functionality is much higher.

Do-it-yourself work on creating a trailing device for a walk-behind tractor begins with a drawing. Thanks to this, it is possible to determine the amount of materials required and select complex assemblies that require the development of more accurate schemes.

Assembling the frame

The reliability of the frame is predetermined by the durability and strength of the hitch. This should be taken into account when creating a project for a future hitch. Thus, the following materials can be used in the manufacture of the trailer frame:

- Corner and rectangular pipe.

- The front and rear cross members can be made from a 25x25 mm corner.

- For side members, a 60x30 mm pipe is an excellent choice.

- To connect all the elements, it is necessary to make five additional crossbars, forming a lattice-frame.

- Four vertical posts are attached to the longitudinal pipes of this lattice at the corners.

Making a one-piece trailer is pretty straightforward. Some homeowners decide to make more sophisticated devices. In such a situation, all subsequent actions depend on the choice of a specific type of trailer:

- On a tipper hitch, the tailgate must be hinged.

- If it is planned to manufacture a trailer with folding sides, then all three sides, except for the front one, should have such a design.

- The frames of the folding elements should be made separately from the general frame. For simple models, they can be its common elements.

Frame sheathing

This is one of the simplest steps in creating a tow hitch. However, there are some nuances and they must be taken into account.To carry out work on the sheathing of the frame, it is worth choosing those materials that cannot increase the cost of the hitch:

- Wood is the most readily available material, but not the most practical due to its low resistance to moisture. In order for the boards to serve as long as possible, it is imperative to process them with special compounds and constantly monitor the integrity of the coating.

- Plastic - is devoid of the main drawback of wood, but at the same time it has a weak resistance to mechanical damage.

- Metal sheets - must first be treated with anti-corrosion compounds and are the most durable, but also quite expensive material.

Chassis

This structural element can be taken from an old vehicle, such as a garden wheelbarrow. An additional pipe is required to secure it. The hub can be pressed in, and its rear part can be bored and fixed on the axle

In this case, it is extremely important to ensure that there are no distortions.

For wheel mounting, pins are the best option. They will provide a fairly reliable and durable connection. Bolted connections can be used to reinforce structures. The final stage of work on the manufacture of the undercarriage will be the fastening of the hubcaps.

For wheel mounting, pins are the best option. They will provide a fairly reliable and durable connection. Bolted connections can be used to reinforce structures. The final stage of work on the manufacture of the undercarriage will be the fastening of the hubcaps.

After creating the hitch, it remains to make the hitch. This is a separate element, and at the same time it is very responsible. The simplest way to connect a walk-behind tractor to a trailer is a pipe-in-pipe assembly. A short piece of pipe is attached to one end of the pre-bent pipe in a vertical position.

At the opposite end of the main element (curved pipe), a second segment is welded, and it is necessary to fix a pivot on it, which will act as a connecting element. This robust design is easy to manufacture and highly reliable.

Material selection

With self-production, available materials are often used, and the question of choice is not worth it. However, in the case of purchasing the necessary components, the following options are available:

- Wood - allows you to get by with a minimum number of tools. Cutting is done with a hacksaw, fastening with bolts and corners. However, the tree is unstable to adverse weather conditions, and after several seasons the joints will loosen, begin to rot and break.

Ferrous metal - a do-it-yourself garden cart from this material will be durable and cheap. Although the work will require more tools, in particular, a welding machine and a grinder.

Stainless steel or galvanized steel is the most durable material that is not exposed to moisture. Such a cart will cost more than the others and will require tools similar to the previous version, but it will last for many years and may even be inherited by children or grandchildren.

The choice of manufacturing material depends on financial capabilities, however, it is highly discouraged to give preference to wood, due to its fragility.

Which model to choose

Before you start making your own garden wheelbarrow, you need to accurately determine its preferred design and dimensions. Garden implements for moving loads usually have 1 to 4 wheels. Single-wheeled cars are characterized by mobility, they are easily moved along narrow paths between the beds without damaging the plants. However, it is still not very convenient to transport very heavy loads on them. Although if it is not planned to often move heavy building materials, sand, crushed stone or brick around the personal plot, then a one-wheel wheelbarrow is an ideal option.

Two-wheeled carts are more stable than single-wheeled designs, but a wider track is required to move them.A three-wheeled or four-wheeled self-made wheelbarrow for a summer residence is a very stable device, it does not turn over, does not require special efforts and skills when moving large loads. However, she is not very mobile, especially in cramped circumstances.

Four-wheeled

Knowing the main features of each type of garden wheelbarrow, you can choose the optimal model for working on your personal plot.

Making a one-wheel wheelbarrow from different materials

If you do not plan to move very heavy loads, then wood may well be suitable for the manufacture of a one-wheel wheelbarrow. Strictly according to the dimensions specified in the drawing, you need to make a frame of two wooden bars 3-5 cm thick, 120-140 cm long. The bars must be connected in such a way that a structure similar to the letter "A" is formed. The distance between the spaced ends of the bars should be equal to the width of the person's shoulders, since these will be the handles for which the cart will be rolled.

Algorithm of actions for making a wooden one-wheel wheelbarrow:

- Form a box from the boards into which the transported cargo will fit.

- Securely fasten the box on top of the frame, and from below, at the junction of the bars, insert the axle on which the wheel is attached.

- In order for the wheelbarrow to be stable when installed for loading and unloading, props are attached from the bottom of the frame at the level of the edge of the box closest to the handles. The struts are sized so that the body of the installed structure is parallel to the ground.

Note! To impart durability to the structure, you should use hard types of wood, such as oak, elm, maple. It is better to refuse conifers

To move heavier loads, you can make a one-wheel wheelbarrow from metal in the same way as from wood. A frame in the shape of the letter "A" is welded from a metal pipe, the body is attached to it from above. It can be made from a metal sheet or by cutting an iron barrel. For a metal wheelbarrow, it is better to choose a powerful wheel with a larger diameter. On the frame of the frame, 2 supports are welded opposite the wheel, on which the structure rests during loading and unloading.

Note! When making a structure from metal, all connections must be made by the welding method

Cars with two wheels or more

A metal homemade product on two wheels will help to move massive loads without much effort; it is better to refuse wood in such structures. Weld a rectangular frame of the required size from metal pipes. On one side, in the lower part of the supporting structure, place an axle on which 2 wheels are located, and on the other side - a metal stand. Weld the handles to the edge of the rectangular frame, where the wheels are located, and place the body on top of the frame.

If desired, instead of a metal stand in the lower part of the frame, opposite the handles, you can make an axle on which the wheel will be installed, then you get a three-wheeled structure. If 2 wheels are installed on this axle, then a four-wheel model will be released.

Note! For convenience, it is worth putting on pieces of a thick rubber hose of a suitable diameter on metal handles. Hose pieces should be preheated for easy donning.

For garden work in the country or on a personal plot, a hand-made wheelbarrow can serve as an ideal option if you do not want to spend money on a ready-made device and have free time and a desire to show your design skills.

vote

Article Rating

Main structural elements

In general terms, the design of different models of bogies does not differ significantly and consists of the following main parts:

- Frame - a corner, square or round profile is used for it. The last two options can withstand more significant loads. You do not need to weld the frame, in which case the wheels and the handle are attached directly to the body.

Body - in the factory version it is a stamped element with no welded seams. When the decision is made to make a cart with your own hands, you will need to cut out pieces of sheet metal and weld them together. To improve the docking, a metal corner is applied to the ends.

Wheels - chamber varieties are the most convenient to use. They allow you to move the wheelbarrow around the site with maximum ease. Wheels from a bicycle, moped, or even a motorcycle will do. You can also purchase ready-made copies created specifically for wheelbarrows.

Handle - the most common options are in the shape of the letter "P", "T" or "H". A good grip is provided by the handle with the letters "P" and "H".

Step-by-step manufacturing of the trolley

To make a garden cart at home, you need to prepare the following parts and tools:

- The main material is plastic, wood, sheet metal.

- Fastening mechanisms.

- Wheelsets.

- Wheel axles.

- Auxiliary fittings: handle, guides, stop.

You should also stock up on ready-made drawings, but the device diagram will depend on the model chosen. The whole process of construction work can be roughly divided into several stages:

- Selecting dimensions and creating a drawing.

- Arrangement of frame installation.

- Installation of the chassis.

- Handle attachment.

- Arrangement of the main building.

Each stage is performed sequentially, and with an orientation to the instruction diagram. As a master class, it is worth considering the instructions for creating a wooden cart for garden work.

Dimensions and drawing for trolley

Its stability in further operation depends on the size and shape of the trolley. The standard dimensions have a wheelbarrow with the following parameters:

- The diameter should not exceed 60 cm.

- The maximum length of the frame installation is 100-110 cm.

- Body height in the range of 55-60 cm.

Arrangement of frame installation

Previously, wooden blanks are subjected to special processing: they are impregnated with an antipyretic, antiseptic and antifungal solutions. This step will significantly extend the life of the structure, increase moisture resistance, and protect against pests. Also, surfaces can be additionally sanded with sandpaper. To fasten the frame, the bars are connected at the joints using screws and metal corners to further strengthen the installation.

If it is envisaged to make a frame from metal pipes, you should use a grinder to cut parts and welding to connect the frame. It is best to coat the product with water-based paint before further assembly to prevent possible corrosion.

Installation of the undercarriage

On the lower surface of the future trolley, rails for bearings are mounted. A single-wheel rail is positioned along the vertical axis to center the weight.

For 2 or 4 wheels, parallel wooden strips are used, on which the fittings are attached. You can also use a ready-made axle from an old cart. At the same stage, the wheels are attached and a test rolling of the wheelbarrow is carried out to identify malfunctions.

Handle assembly

On the advice of experts, the handle should be made from a durable iron rod. Experts advise using a bicycle handlebar or an old scooter mount. In the technology of the fastening mechanism, the choice remains with the master: to make the handle fixed or folding on hinges.

Arrangement of the main building

The body is made of durable material with sufficient resistance to moisture and mechanical damage. This material is most often a metal sheet. For work, you will need to prepare sheet metal, welding and a grinder.

According to preliminary calculations, workpieces are cut out of metal, scalded or grinded off sharp edges. The body is fastened using screws and metal rivets.It is desirable that the body be as tight as possible, especially if it is supposed to transport bulk cargo.

What are the carts

A wheelbarrow is distinguished from a trolley by the number of wheels. The design with one wheel is called a wheelbarrow, if there are more than one wheel, we are dealing with a trolley.

One-wheeled "equipment" is indispensable for the garden, vegetable garden. Vehicle maneuverability is good for narrow stitches.

It is reasonable to have both types on the farm, the wheelbarrow is not stable, one wheel requires tension when driving. It is more convenient to carry loads on two or four-wheeled structures.

Advice: a wheelbarrow is made for certain purposes, those works that provide for the presence of such wheeled vehicles. For example, for fertilizing.

Another reason to get both a wheelbarrow and a trolley is to use it for different purposes. If you first removed the manure from the cowshed, then you cannot use it to transport the crop from the orchard. Therefore, making yourself an assistant is the right decision.

Metal and wood are the main materials used in the manufacture of trolleys, as they have the required strength characteristics.

Carts differ from each other in the number of wheels and dimensions. You can make yourself:

- one-wheeled cart;

- two-wheeled cart;

- a trolley in the form of a platform on four wheels;

- folding cart.

Assembling a durable helper

If you plan to use a wheelbarrow to transport various heavy loads, building materials, bulky items, it must be made with 4 wheels. This design is usually made of metal elements. To draw up it, the performer must have a welding machine and tools for a locksmith. The frame of the cart is made up of pipes and pieces. They are welded together on one platform.

The handle and wheels are welded onto the frame. Experts recommend equipping it with tires, increasing the carrying capacity and simplifying the driving process. Each wheel is individually welded to the frame. The container is mounted on a platform. Various cargoes are loaded into it for transportation. Use an old or new pallet for this purpose. The device for loading and transporting materials is preferably fixed on the platform.

The operation is performed by welding or fastening. The first option is suitable for carts that are not planned to be dismantled soon. The bolted connection allows the container to be changed as needed for transportation.

Originally posted 2018-03-28 15:13:01.

1 Garden trolley and wheelbarrow: what's the difference?

Many people think that both of these devices are no different from each other. And there is some truth in this. But still, there is a difference between them. A one-wheeled cart is commonly referred to as a wheelbarrow. The cart has two, three or four wheels.

Features of the wheelbarrow (unicycle):

- high maneuverability and reliability;

- small wheel track (can easily pass along narrow paths);

- easy and convenient unloading (you just need to raise the handle and tilt it to the side).

One-wheeled garden trolley

but at the same time

- heavy load on the arms (you need to make efforts to maintain balance);

- instability (when loading the wheelbarrow, you need to make sure that it does not overturn).

Features of the cart:

- stability (axle and 2 (3,4) wheels do not allow it to roll over);

- ease of movement;

- the ability to carry heavy loads.

But at the same time, it has low maneuverability.

It should be noted that the most clumsy is the 4-wheeled trolley, but its plus is that it can carry heavy loads with a minimum amount of effort. A two-wheel barrow is characterized by greater maneuverability, it does not sink into the ground as much as a one-wheel barrow.

The advantage of a one-wheel wheelbarrow is its high cross-country ability in narrow areas, it is easier to deploy and unload. Since garden carts and wheelbarrows are in great demand among gardeners and summer residents, let's look at how you can build these devices with your own hands.