Safety engineering

When working with a jigsaw, you should follow the safety rules.

- To protect yourself from fine dust and shavings, use glasses, gloves, and a dressing gown.

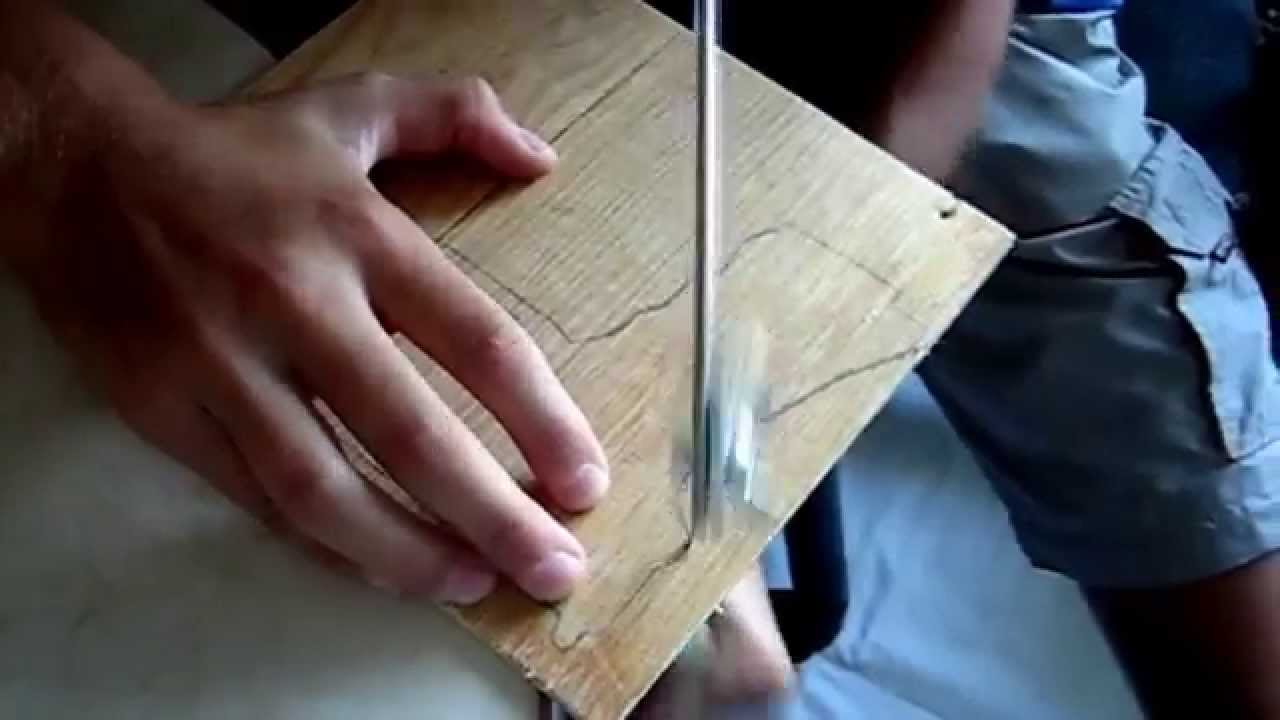

- Keep a distance between your hand and the blade when working. Thread carefully and calmly.

- Carefully read the instructions for the tools, study the parameters of the jigsaw. Use the tool as instructed to avoid injury and tool malfunction due to misuse.

- If you are a beginner, read the instructions carefully, understand how to use.

- Use only fully working and intact tools. Check the jigsaw and other equipment for damage and insulation integrity before each use.

- Do not use damaged blades.

- When working with an electric tool, attach the workpiece with a clamp, hold the jigsaw with both hands. If it is impossible to secure the workpiece tightly, work with an assistant, who must also observe safety precautions, wearing protective equipment.

- Observe fire safety when working with flammable substances: open flames and electric heating elements and devices cannot be located closer than 5 meters from the used workplace.

- Provide adequate ventilation to remove thread dust and paint vapors from the work area.

For information on how to saw out with a jigsaw, see the next video.

How to cut metal

File selection. For cutting out metal surfaces, files with a fine tooth are used - tooth pitch is 1 - 2 mm. Visually, such a file resembles a hacksaw blade for metal and can be used to cut other materials in order to improve the cleanliness of the cut.

Stroke frequency. The cutting speed must be set as low as possible.

Pendulum mechanism. The pendulum stroke is completely disabled.

Sawing process. The tool must be moved slowly over the workpiece, without pressure. The sheet of tin must be firmly fixed by placing it in advance so that the cutting line is as close to the support as possible.

If it is necessary to make a curved cut in a thin sheet, and it is not possible to position the workpiece so that the cutting line is close to the support, then it must be placed between two sheets of fiberboard or hardboard. In this case, all markings are applied to the top sheet of fiberboard. This will prevent burrs from forming.

It is also recommended to take short breaks from work and use additional sources of cooling to avoid overheating of the file.

Saw blade marking

When buying jigsaw files, we advise you to pay attention to their marking. At first glance, the number of alphabetic and numeric characters is a bit puzzling, but, in fact, there is nothing complicated here.

At the edge of the canvas, we see the letter symbol "T" or "U". It is easy to guess that this letter denotes the type of shank: T or U-shaped. Next, we find a whole series of numbers, but the first is important for us - it speaks about the length of the canvas:

- 1 - Standard short file (up to 75 mm);

- 2 - Standard file of medium length (up to 90 mm);

- 3 - Extended saw blade (up to 150 mm);

- 4 - Very long (over 150 mm).

Next, we again find the alphabetic Latin alphabetic character A, B, C or D. Here we are talking about the length of the teeth. The letter A marks the files with the shortest teeth, on the files with very long teeth we find the designation D, the rest of the letters show intermediate values.

The following letter indicates the material from which the saw is made and its purpose:

- F - the blade is made of a special bimetallic composition - the highest quality tool, used when performing a figured cut, withstands operation in intensive mode;

- R - this is how reverse tooth blades are marked. The files are designed to work with thin, exfoliating or laminated materials;

- X is the most common universal blade used for working on wood and metal.

- O - a saw with this marking has a narrow back, it is designed for curved cuts, allows you to make sharp turns, without losing the quality and accuracy of the cut;

- P - the blade is designed for oblique cuts, the body of the file is thickened, which prevents it from bending.

Quite often on canvases there are designations consisting of fragments or whole words. Such designations indicate the purpose of a particular saw, their decoding does not require much effort:

- Wood - marks for sawing in soft and fibrous wood;

- Hardwood - for processing hard wood;

- Inox - these saws are designed specifically for cutting stainless steel;

- Alu - everything is clear here, aluminum parts are processed with the canvas;

- Metal - yes, these are sheets for sheet metal and tubular metal structures;

- Fiber & Plaster - fiberglass;

- Soft-material - with such canvases you can cut rubber, cardboard, polystyrene, and other similar soft materials;

- Acrylic - saw blades for sawing polycarbonate and plexiglass.

Features of cutting round and oval elements

In this section, we will talk about how to properly saw round or oval elements with a jigsaw. First you need to apply markings to the material. In most cases, a hole is drilled in the workpiece, from which the product will be cut. In this case, the diameter of the drill should slightly exceed the width of the saw blade. To cut out curved elements, you must take a narrow file designed for such work.

The jigsaw is brought to the desired path slowly. If you want to cut a circle of the correct shape, you can use an additional device - a circular cutter. To do this, it is necessary to determine the center of the circle and, having fixed the stop-compass there, cut it out.

For such work, it is better to choose a narrow canvas. In the process of cutting, you need to focus on the position of the blade, since the elements that help when performing a straight cut (guiding "flies", lasers), in this case, will only knock down the direction.

In some cases, you can do without drilling a hole in the workpiece. For this, the tool is positioned with the edge of the sole behind the marking line. The jigsaw turns on and tilts with careful movements until it touches the work surface. The angle increases until the workpiece has been cut through. After that, the tool stops, the file is removed and set to the standard working position. Exit to the marking is carried out by the method of gradual rounding of the cut line. Any effort on the tool should be avoided.

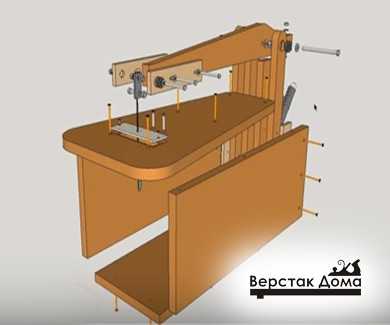

For cutting non-standard shapes or patterns, the jigsaw is installed using special fasteners or a saw table in a stationary state, with a file upwards. In this case, you will not have to wield a jigsaw, but the workpiece itself, moving it in accordance with the markup. This cutting method provides maximum visibility of the work process, adherence to the cutting line, and control over the workpiece. Tool settings are set according to the material being processed.

How to assemble?

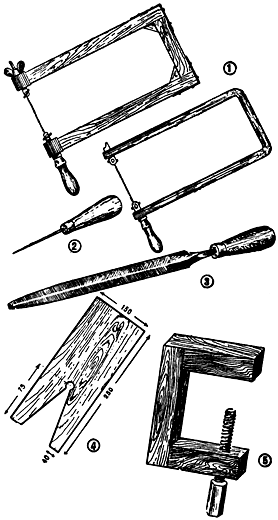

After you have selected the material and applied the outline of the pattern, you need to assemble the working tool. This is not difficult to do. To begin with, you need to tighten the file near the handle at the bottom, then carefully thread the free end into a special groove on the opposite side and, pressing the handle a little, fix it in it. Keep in mind that the teeth of the saw surface must also point downwards, towards the handle of your tool.

Many inexperienced users try to squeeze the frame as much as possible - this should not be done: the only thing you will achieve this way is to break the metal arc. It is quite enough just to bring the ends closer to each other by 1-1.5 cm.Usually, the handle is squeezed by hands or rests against the chest with the tool. If you do not have the strength to tighten the drums by hand, you can resort to using pliers.

Keep in mind that thin files often break - if you plan to use the tool regularly, you will have to collect it quite often. That is why it is better to learn how to assemble before starting work, because the faster and easier it is to change the saw blade, the easier the whole work will be as a whole.

Professional secrets

It is imperative to check how firmly the canvas is fixed.

This mechanism can have its own characteristics, depending on the manufacturer.

For working with any cutting tools, the fastening of the blade, its general position, is really important. A useful device will be responsible for the removal of sawdust

Its working principle is very simple. There is a flow of air from the fan cooling the motor

A useful device will be responsible for the removal of sawdust. Its working principle is very simple. There is a flow of air from the fan cooling the motor.

It is used to remove debris. The retract system makes the cutting line more visible to the eye of the master.

The drill can be easily changed when making holes using a technique called "pocket". To do this, it is enough to tilt the jigsaw forward, then the tips with a rounded shape will rest on the surface being cut.

Above the line of the future cut, the blade must be positioned with maximum accuracy. Lower the control saw horizontally and then continue practicing.

For such work, first marks are made inside the material, and then, already along them, the instrument itself is found. With a square or rectangular shape, the canvas is pulled back a little before the wizard guides the tool to the next side. And so all four are processed.

The use of plunge sawing is permissible if it is impossible to create holes of the required dimensions. For this, the jigsaw tilts forward until the file reaches the workpiece. Gradually, a through hole appears during this process.

Description and device

A manual jigsaw, from a technical point of view, is a very simple device. It consists of a metal arc, between the tips of which a sawing tool is attached. A handle is attached to one of the ends of this arc - the master holds the device for it during his work. The most important element of a jigsaw is the saw blade, since its quality and sharpness determines how easy, convenient and effective the tool will be.

Unfortunately, modern files are not at all worthy of quality, therefore experts recommend giving preference to imported ones, for example, products from Swedish manufacturers have proven themselves very well.

Many people wonder if a hand jigsaw can completely replace an electric one. The answer to this is categorical - no. Both tools have nuances of use, so in a home workshop they should complement, not mutually exclude each other. A handheld device will not be able to cut through thick wood and dense metal, but its cut comes out thinner and much more accurate than the one that is obtained when working with an electrical modification.

Views

Manual

The hand jigsaw is the simplest version of this device. It looks like a metal structure in the shape of the letter U, at the ends of which a cutting blade is fixed with clamps. On the other side of the frame is the jigsaw handle. Clamps are used to not only hold the plate, but also to adjust its tension and vary the working planes. A manual jigsaw is a rather fragile device that does not differ in a long service life, therefore experts always recommend that you immediately purchase spare cutting blades for it.

Electric

The jigsaw is the most popular variety with maximum ease of use. The thin saw moves straight up and down along the markings, and the working stroke is carried out only when moving up. This mechanism makes the jigsaw dock with the surface instead of pushing it away.As a result, the lines are very neat and smooth, requiring no additional sanding.

It does not require additional adjustment - it is enough to carry out the initial adjustment correctly. The cutting blade is tightened immediately before use, and this is sufficient. The jigsaw can be equipped with different files to create different cuts on different metals. For example, it can be straight or curved lines, circles and rectangles made on wood, plastic, ceramic tiles, brick and even steel. Saws change very quickly.

Laser

A laser jigsaw is an electrical device with a laser that allows you to perform a wider range of jobs. In addition to the usual straight cut line, the laser jigsaw is capable of other types, such as corner cuts. The main part of the device is a motor in a plastic case, where a garbage collection system is also equipped. The cutting blade is fixed to the drive shaft, which is also hidden under a plastic surface that prevents sawdust from flying directly into the worker's face.

Work rules

For novice craftsmen who decided to get acquainted firsthand with the work of a jigsaw on wood, it is recommended to start by cutting out a simple product (squares, rectangular parts), since sawing carving requires a certain skill.

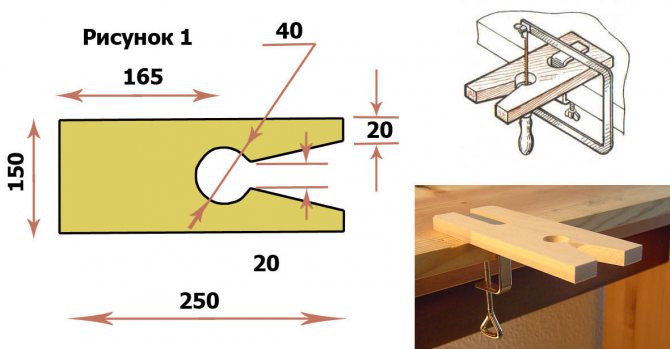

If the work is one-time and uncomplicated, then it is more advisable to purchase a manual model. When planning to start working with a manual model, you should take care of purchasing a stand (in fact, it is not difficult to make it yourself). The stand is a small rectangular bar that allows you to fix the cut blade so that it does not slip during work.

Well, when it is still supposed to periodically use the device in question, it will be easier to work with a jigsaw, which has a certain set of functions that can significantly simplify the thread.

More experienced users can try to carve some curly parts. To do this correctly, you need drawings that are applied to the canvas, only after that cutting is permissible. For these purposes, it is better for beginners to purchase a high-quality electric jigsaw. Moreover, the latest models are endowed with functions that greatly simplify the work (especially important for beginners):

- function that regulates the speed of the notch;

- the function of smooth rotation of the tool, which allows you to change direction or round off during cutting;

- function that fixes the angle of cut, eliminates the appearance of curved parts.

As for the more delicate profile work, then you cannot do without a manual jewelry model of a jigsaw, having mastered the work with which, it will be quite possible to practice cutting according to your own sketches.

It turns out that a wide range of jigsaws for wood has a number of advantages in comparison with the well-known ordinary saw. This is ease of use, wide range of applications and high performance.

How to choose a jigsaw, see below.

Examples of finished works

Craftsmen have been using the art of wood carving since ancient times to create jewelry and decorative items. The jigsaw creates pictures and portraits, toys, dishes and much more.

For home

Craftsmen create real masterpieces from wood - these are boxes and lampshades,

and decorative shelves,

exclusive furniture and toys.

For garden

There is also a place for a flight of fantasy. These can be decorative figures,

garden furniture.

It can also be decorative ornaments for flower beds and front gardens, wooden flowerpots and fences.

Toys

Toys are a separate kind of creativity, the masters approach it with special trepidation and love. Cut out wooden puzzles with a jigsaw,

rocking toys and many others.

Views

Hand jigsaws are very diverse: large and small, children's, school and professional. There are models designed for sawing tiles, as well as jewelry options. All of them differ in size, as well as in the features of the files. There are quite a few manufacturers of jigsaws these days, because the tools differ greatly in prices, equipment and, of course, quality. Saw blades come in a variety of sizes and structures.

The most common files are with straight double teeth, as well as spiral files.

The first option is optimal for creating a fast and straight cut. In most models, the length of such blades is 13 cm, and the working surface is 8.5 cm. These devices can be used to cut wood, plywood, and plastic. Spiral blades, unlike straightened ones, are characterized by a twisted shape, therefore they are often used to create round elements - due to their peculiar shape, the file will not get stuck in a wooden blank.

When making a decorative cut, special tools are required that allow you to create smooth lines and bends, even of microscopic dimensions. For such manipulations, it is best to use a jewelry hand jigsaw - unlike the more common analogue used when working with wood and other sheet materials, this device is lighter and more compact.

Sawing technology

Preparation

When we cut out of plywood with a jigsaw, the quality of the finished product largely depends on how responsibly we approached the preparation process.

To avoid excesses in the course of work, you need to spend only a few minutes:

- We inspect plywood intended for work for damage and veneer delamination.

- We check the quality of drying by making a test cut.

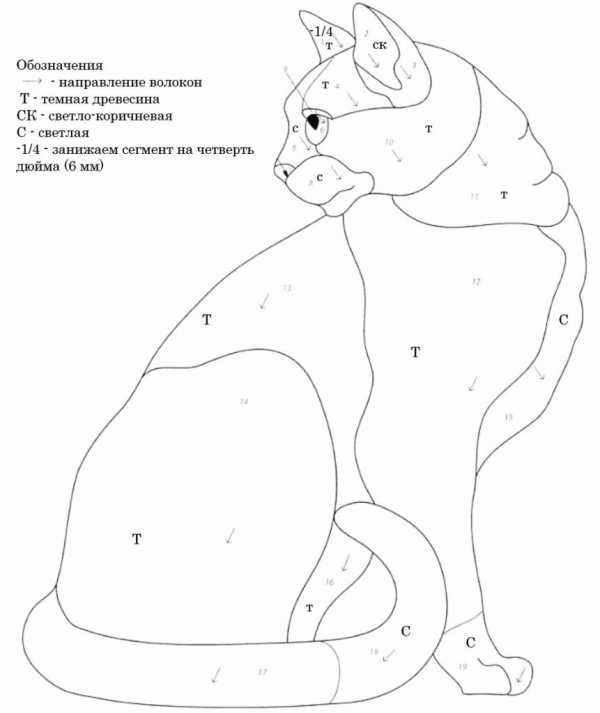

- We attach the template printed on the printer to the plywood and fix it with adhesive tape or pushpins.

- Simple shapes can be transferred to plywood by piercing, leaving marks from the awl on the material.

Copy the drawing

For clarity, paint over with a pencil on the workpiece those places that should be removed after cutting. It is better to do this immediately after translating the template, since then it will be more difficult to understand the interweaving of the lines.

Basic operations

So, the preparation is complete, and you can proceed to the first attempts to cut something out of plywood with your own hands. Of course, if you have never picked up a jigsaw before, then you should practice on simple products before embarking on a large-scale project. Furniture work with a jigsaw

The work begins with sawing out the contour of the workpiece, after which the internal cuts are made. To make a through hole, first we drill the plywood with a drill, and only then insert the jigsaw blade.

Below we describe the sequence of performing the basic operations using a hand jigsaw. The use of an electric or band saw has its own nuances, but having mastered the basics, you will not experience difficulties when working with more advanced technology. Straight cut

The simplest operation is cutting in a straight line.

The instructions for this operation are as follows:

- Insert the jigsaw file into the drilled hole so that the teeth are directed towards the handle.

- We stretch the canvas so that it does not vibrate during operation, and fix it with a screw.

- We put the workpiece on the workbench, press it with the left hand against the sawing table and gradually start sawing.

- When cutting a straight line, move the jigsaw up and down, gradually feeding the workpiece under the saw.

- Control of the straightness of the cut can be ensured by placing a guide bar on the workbench.

Tool position when cutting

Curly sawing is more difficult, and you should start it only when you have fully mastered a straight cut:

- We fix the jigsaw file in the same way as in the previous case.

- We lay the workpiece with a clearly drawn line on the workbench.

- We saw with movements from top to bottom, feeding the plywood with our left hand so that the blade does not go beyond the line.

- When the file is displaced in relation to the template line, stop moving with the left hand until the file starts to move freely. After that, we correct the position of the plywood and continue working.

All elements are cut according to this principle, including obtuse corners. But it is not worth cutting out an acute angle by turning the workpiece, since there is a high risk of breaking off the final fragment. In this case, you should make two cuts, connecting them at the top of the corner. We process the edge of the workpiece with a file

After cutting out all the elements, the workpiece must be filed, since even the most accurate work does not allow making a product with perfectly straight edges. We carefully grind the outer and inner cutting lines with wood files, after which we process the entire workpiece with sandpaper and sandpaper.

The final stage is the finishing of the product. Plywood can be stained, painted or varnished.

Safety engineering

Sawing out of plywood does not apply to traumatic activities, but nevertheless, safety rules must be observed:

- For work, use only serviceable tools.

- Do not cut with saw blade debris or band saw fragments.

- Insulation should be checked when operating a power tool to avoid electric shock.

Eyes and hands must be protected

- Sawing with a jigsaw or a band saw is carried out only on a special workbench, while the cutting part of the tool must be limited by special devices (frames, shields, etc.).

- During the work, you need to use personal protective equipment: glasses, gloves, an anti-dust mask or respirator.

Features of cutting straight elements

Despite the fact that this type of work is one of the most common, with a lack of experience, difficulties may arise with how to smoothly saw off any element with a jigsaw. It is recommended to opt for a wide blade, designed for straight cuts, in order to better maintain the marking line. For an even cut, the presence of the "soft start" function plays an important role. In this case, the tool begins to gain momentum gradually, due to which the jigsaw is better controlled at the initial stage of cutting.

In the process of work, you should not make excessive efforts to move the jigsaw forward, otherwise this will lead to failure of the file or the mechanisms of the tool. A worn-out blade should be replaced immediately, since a dull file will cause an increased load on the electric drive. The workpiece to be sawn must be securely fastened.

For straight cuts, you can use a rip fence or a guide bar.

Sawing with a guide bar

First, the workpiece must be marked. After that? by installing the jigsaw in a special shoe, and then the shoe in the tire, the tool is positioned along the cutting line.

Having installed the file of the tool exactly along the cutting line, the guide bar is fastened.

The tool is started up and driven along the tire. Little depends on the operator. The quality of the saw and the jigsaw itself will affect the quality of the cut much more.

There are busbars with clamps that allow you to make both straight cuts and angled cuts.

Sawing with the rip fence

The parallel stop often comes with a jigsaw, but regardless of this, almost all models have a slot in the sole for attaching the parallel stop rod.

It is possible to make a high-quality cut using this device only in the following cases:

- The reference plane along which the shoe will move must be flat and parallel.

- The jigsaw must be of high quality and resistant to sideways movement.

- The rip fence itself, that is, its rod and shoe, must be strong and rigid.

- The operator must firmly press the shoe against the supporting surface when moving the tool.