Functioning principle

There are many varieties of tools with a similar structure and principle of operation. The wrench consists of a barrel handle, inside which a functional mechanism is introduced that activates the operation of the engine, spring and chuck. Unlike a drill, the tool is equipped not with a drill, but with an elongated attachment for clamping the nut.

After starting the wrench, energy is supplied to the motor and gearbox, which includes the chuck. The additional spring provides reverse rotation for increased functionality. Modern types of tools have a speed adjustment function and replaceable nozzles.

Models

Before proceeding with the choice of heads, you need to select the wrench itself. Today in stores you can find a huge variety of different models. Below are the most popular options.

Bosch GDR 10 is a mobile impact wrench from a world renowned manufacturer. Among its advantages, buyers highlight high power (for a mobile model), long battery life and versatility. The only drawback is that it is not the most successful design. The device is not suitable for industrial work, because it is applicable for private use.

These models are the best on the domestic market, but not the only ones.

There are many more models to look out for.

Maintenance rules

Maintenance of nut wrenches consists in the timely replacement of rubbing, worn out parts, replacement of brushes of collector motors, cleaning, lubrication of units or elements of the tool. In this case, the user is only required to keep the device clean and tidy, and replace the brushes if necessary. All work that requires complete or partial disassembly of the nutrunner must be carried out in the appropriate service departments or workshops. Unqualified maintenance can cause poor-quality operation of the tool, and, ultimately, inappropriate tightening of critical threaded connections.

Application area

Most often, manual torque wrenches with a gearbox are used in industrial production for the installation and dismantling of fasteners for large metal structures. He found his other purpose in a car repair shop, where he became very much in demand. It is also often used on construction sites, in shipbuilding and other areas of production. Its widespread use by locksmiths is due to the need to work with massive structures or loaded threaded connections, which are problematic to disassemble with a conventional tool.

At home, these tools cannot be attributed to the necessary tools, which, for example, are screwdrivers, since they are easily replaced with wrenches or wheel wrenches, and a large tightening power is not required. As a rule, truckers buy such a device - it is very convenient for them to change broken wheels on trips without wasting much time. The "meat grinder" will also come in handy in the implementation of some home construction project, where large threaded connections are used.

Views

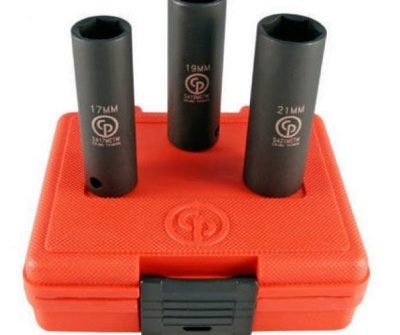

Impact sockets for impact wrenches can differ in a wide variety of parameters: from strength to shape. Each of their separate types is suitable for a different job, therefore, when buying heads for a nutrunner, you need to understand how and why to use them. There are several types of impact sockets.

Industrial and garage. The main difference between an industrial head and a garage head is the quality of the steel used. Industrial options have increased strength and elasticity, but are more expensive. If you need to use them to repair your personal car, then you should not spend much money. If you need to use a wrench for work, then it makes sense to think about buying them.

These are all types of attachments that can be found in the store. It is imperative to take into account all the nuances of the upcoming work before purchasing such products.

See below for a video overview of Impact Wrench Socket Sets.

How to use a wrench correctly

Before starting work, you must carefully study the user manual attached to the tool. It sets out all the basic operating rules or safety requirements that must be strictly observed.

It is especially important to determine the duration of continuous operation of the wrench, after which the tool must be turned off for a certain period of time to cool down. Frequent overheating will significantly shorten the life of the device

In order for the tool to serve as long as possible, you need to follow the rules of operation.

- The tool should be inspected for possible damage to the case, power cable, or other elements.

- Only standard devices or adapters are used, the use of inappropriate replacement heads is prohibited.

- The magnitude of the torque is set in accordance with the technical requirements for this connection.

- Work should be started at a low speed of rotation or with long strokes (if a percussion type of tool is used).

- The tightening is completed at high power (or short beats). Dropping power before the end of the tightening will loosen the connection.

- Reverse is used to unscrew bolts or nuts. The start of rotation (release of the nut) is performed at low speeds, then the mode corresponding to the condition of the thread is used.

Some models have their own, specific rules of work that differ from the generally accepted ones. All the necessary information is available in the manual, it also contains all the necessary information about the operating modes, other operational requirements.

Views

According to the principle of operation, a manual wrench can be of several types.

- Pneumatic. Such wrenches are the most compact in size, have a higher speed and accuracy. They found the widest application in car repair shops and service stations.

- Hydraulic. Hydraulically driven impact wrenches have the highest efficiency. When using them, there is practically no vibration during operation, their resource is higher than other types, they are very wear-resistant. Manual hydraulic impact wrenches are rare and only in production, since they are mainly stationary equipment and are too large for manual use. These are professional tools.

- Electric. This wrench is a high-speed, high-precision tool with almost no vibration. In turn, they are subdivided into wrenches operating from the mains and from batteries. This type of equipment is effective, but manual models do not have enough power, for example, to quickly change a truck wheel on the road.

- Mechanical. Considering all the advantages of other types, the impact wrench, based on the mechanical principle of action, has become the most popular. The advantages of the mechanical principle of operation are great smoothness of loosening, uniformity of force, and a low percentage of broken bolts.

In addition, pneumatic and electric impact wrenches are available.This means that they implement the principle of operation, in which special hammers are included in the tool mechanism, which amplify the torque, which does not lead to increased vibration of the tool body itself. As a rule, with such impact wrenches (including those with elongated, that is, using an elongated shaft), special type heads are used - impact heads. They differ because they relate to the material from which the impact heads are made (in both cases, the same CR-V chromium vanadium alloy is used). The use of a thin-walled impact head is often found (they work with it when installing disks on tire changers), and thick-walled heads are called power heads.

Advantages and disadvantages

The advantages of a manual mechanical wrench are as follows:

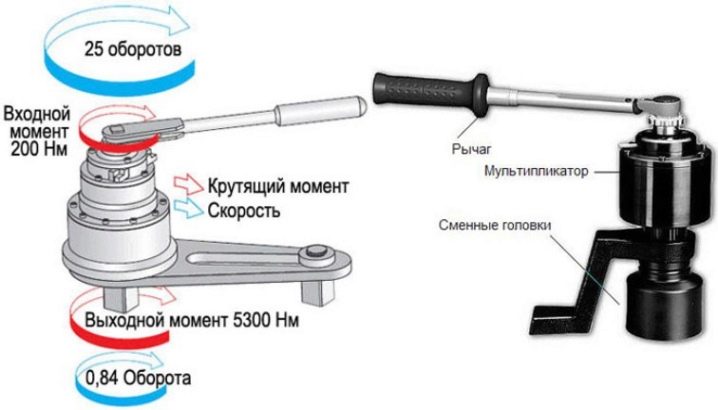

- the use of a multiplier that converts torque and enhances it;

- simple design and, as a result, reliability;

- smooth unscrewing of a threaded connection;

- lack of dependence on the availability of the power grid;

- small size.

The disadvantage is the relatively large mass of the tool, but it should be borne in mind that it is due to the use of reliable and durable metals and alloys in the design. Today, the combination "strong but light" implies too high a cost for such a wrench. They also sometimes blame him for relatively high power, since you can easily break a hairpin or break a thread

But this is not true, since any, even the simplest tool, requires careful and careful handling.

What it is?

Hand-operated nutrunners can be characterized as highly specialized devices designed for mounting and dismounting threaded connections. Simply put, these are improved wrenches that use the principle of increasing torque power. The wrench is quite compact, but it has a lot of power and can handle the largest hardware sizes. Due to its original appearance, this tool is somewhat similar to a meat grinder. For this reason, the drivers called him that.

The design of mechanical wrenches includes a lever, a planetary gearbox (also called a multiplier), an emphasis and a cartridge into which nozzles are inserted. The planetary gearbox increases the force applied to the rotation of the handle by more than 70–80 times. Such power loads required the use of durable materials, therefore, alloy steel is used for the manufacture of all parts of the wrench mechanism.

It is worth considering the following features of the impact wrench:

the tool has the opposite direction of rotation, that is, when the handle is turned in a clockwise direction, the nut will turn clockwise and vice versa;

it is necessary to set the stop correctly, because, for example, when unscrewing / tightening the wheel nuts of the left and right side of the car, its location will change;

when tightening a nut or bolt with such a tool, special care is needed; since there is a manifold increase in power, threads are often folded and bolts are broken.

Characteristic

It is worth considering in more detail the main characteristics of a hand wrench.

- Gear ratios. The most common gear ratio of such a "meat grinder" is a ratio of 1: 56, that is, when the handle makes 56 full turns, the tool head can make only one revolution. This slow rotation is not used to completely loosen the nut. The "meat grinder" is used at the first stage to remove the stuck fasteners, and later on it is much faster to use a regular key or unscrew it by hand. A nutrunner has also been implemented that operates according to a two-speed scheme, which allows changing the gear ratio according to the formula 1: 3. In this version, the nut can be completely unscrewed with a nutrunner.It is not necessary to resort to using a wrench, as the unscrewing time when switching to second speed is reduced.

- Torque / Torque. It determines the force that will be applied by the wrench to the nut. It is measured in newton meters (Nm). Different types of work require the application of the appropriate amount of torque. If it is necessary to unscrew the car wheel bolts, an effort of only a couple of hundred Nm is required. It would never occur to anyone to use a heavy, powerful wrench that develops a force five times more.

- A square for a nozzle. The technical specification defines the use of a square wrench-socket connection. Its size determines the size of the connections that this tool works with. For example, a 10-16mm fastener will require a half-inch square, and a 20-50mm nut will require a square of at least one inch.

- Wrench size. Of course, the dimensions of the wrench affect the ease of use and transportation. As a rule, more powerful tools are larger in size.