Manual sheet piling

Manual tongue and groove.

This tool has other names as well - groove, road builder. With its help, tongue piles are selected on the surface of a wooden workpiece - special narrow grooves, which are located at a strictly specified distance from the edge of the workpiece. The specified grooves in woodworking serve for reliable connection of various parts of wood structures.

The plane of this modification can produce sheet piles up to 12 mm deep and 2-10 mm wide. A fairly wide range of sheet piling depths is achieved with the help of an adjusting device, with which the worker can change the degree of immersion of the cutter into the tree thickness. The groove knife itself has a semicircular cross-section.

An additional metal block acts as a guide, with the help of which a strict parallelism of the groove is maintained relative to the edge of the workpiece. Thanks to this design, the dowels can be positioned up to 100 mm from the edge of the wood product.

Electric

Today, the stationary jointer can be produced in an electrical version. Professional devices are characterized by the following features:

- Quite a lot of mass and downforce.

- When working, you can achieve high accuracy.

- Increased labor productivity.

- Often, the design provides for the ability to quickly change knives.

Electrofuganok is used in industry and everyday life, the product is characterized by high performance characteristics. The only drawback in most cases is the high cost, as well as the significant cost of electricity.

Rating of the best models

Today, manufacturers produce a huge number of hand planers of a wide variety of designs and designs. So that your eyes do not run up when buying, it is worth bringing the top 5 popular models of planers, with the help of which it will be possible to qualitatively process a wooden surface.

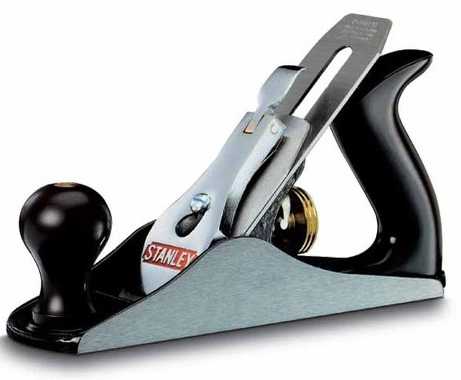

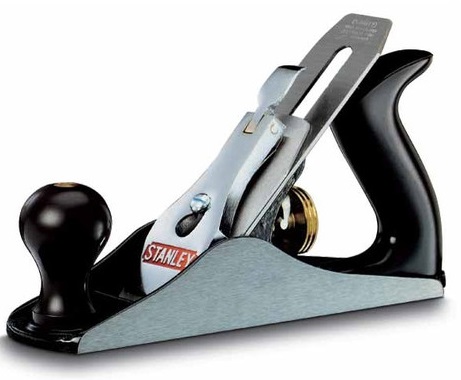

Stanley 1-12-034

A popular model that is actively used on construction sites. The company has been manufacturing working processing tools for over 170 years, so there is no doubt about the quality of the equipment.

The plane copes with the task perfectly. It can be used to treat the surface of all types of wood, including hard woods. The design of the tool provides for the installation of a special mechanism. With its help, it is possible to achieve precise adjustment of the angle of the blade, which allows you to quickly solve a specific task.

Pros of the model:

- robust construction;

- long service life;

- cast and comfortable tool handles.

The plane is literally made for comfortable work.

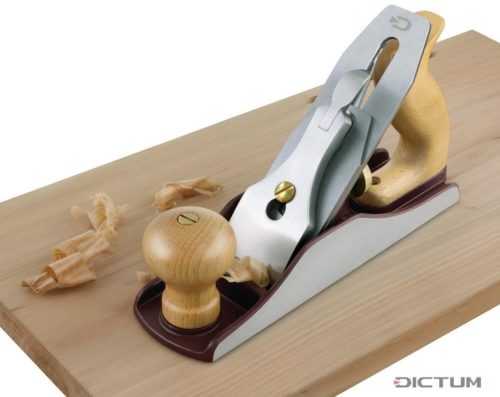

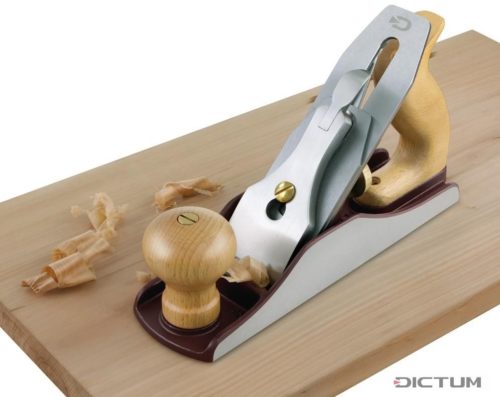

Pinie 51 mm

The peculiarity of the model is the use of first-class wood species in the manufacture of a plane. The tool is designed for finishing, as well as for jointing the edges of various parts.

Advantages:

- increased blade strength;

- ergonomic handle, comfortable to use;

- chip remover.

"Stankosib Sherhebel 21065"

The tool is designed for initial or rough surface treatment. Its peculiarity lies in the extended blade. Together with a comfortable sole, the planer allows you to achieve high-quality removal of the primary layer of wood and eliminates any irregularities or defects.

Pros of the model:

- reliable construction;

- no deformation of the unit even under heavy loading;

- blade angle adjustment for quality processing.

The design uses durable blades made of steel billets.

Sparta 210785

The peculiarities of the planer include the possibility of extracting excess wood from the surface. Through this processing, it is possible to obtain smooth surfaces even on the smallest details. The body of the tool is made of cast iron, so it does not deform in any way even under heavy working loads.

Advantages:

- availability of a configurable knife centering function;

- use of high quality steel for the blade;

- the presence of a false knife of small sizes.

"Stankosib 21043"

The plane is small in size, therefore it is popular among both professionals and amateurs. The main purpose of the tool is the final erasure of the folds that go to the butt end of the obstacle.

The planer body is assembled from high quality steel. The manufacturer uses the St3 brand, which ensures resistance to any load and reduces the risk of deformation. The design provides a mechanism that allows you to adjust the cutting angle.

Advantages:

- compact size;

- the ability to handle hard-to-reach places;

- durable knife.

The blade is made of high speed steel. Therefore, it remains sharp for a long time and removes the required layer of wood.

Numbered dimensional marking of planers and jointers

At one time, back in the 19th century, a dimensional range of planers and jointers was developed, each of which for its own tasks. Each has a number badge from 1 to 8. From the smallest planer to the largest jointer.

Let us immediately note the difference between planers and jointers. If the first is to create a flat and smooth wood surface, then the jointer is used to fit boards, for example, when gluing them.

The # 4 planer is the most popular

The most common plane, which you can most often see at the master, is the middle one in the row - it has # 4 on it. It is recommended, firstly, for the start of carpentry practice. This size is the most popular in joinery use. It is designed for smooth planing. It should be noted that planers allow you to get a flat and smooth surface. These concepts are not identical. That which is linearly even is smooth, and that which is smooth to the touch is smooth.

Female (junior) plane number 3

The longer the sole, the smoother the surface should be. What is the difference between the plane number 3? No. 4 has a width of 50 mm, and No. 3 has 45 mm. It would seem that the difference is small. But in work they differ due to the fact that one already has a blade and it is a little narrower and lighter. Even a strong master does not always cope with large ones, for women this is all the more important. No. 3 is considered female or junior.

No. 2. By analogy, we can say that it is for children. It is for planing with children's hands.

The smallest plane - No. 1

No. 1 is the smallest plane, this is a gentleman's tool for various delicate work, and the fact is that if it is difficult to take a two in hand, then one can be taken by a not quite usual grip by the handle, but it will be taken with the palm of your hand and will be comfortable.

Planer setup

The rib, which is the working surface of the knife edge, has a small radius of curvature

To reduce it, it is important to sharpen the knife blade in several stages using a grinding wheel and a fine-grained grinding bar. A blade sharpening angle of 30 ° is considered optimal and versatile for working with hard and soft wood species.

Correct adjustment of the knife position will reduce the physical and time costs of processing the product. A slightly protruding point will simply slide over the surface of the product. And if the blade is extended far out of the block, it will grab onto too thick fibers and tear them. The cutting edge should protrude evenly and parallel above the sole, protruding 0.2-0.3 mm. You can observe these parameters with a ruler or by eye. Make adjustments with weak hammer blows, giving the blade the desired position.

Tool types

The classification is very extensive, associated with various properties.There are two main types:

- A manual jointer is found in almost any workshop. Its peculiarity lies in the prostate of the device, as well as its low cost.

- Recently, an electric jointer is often purchased. This is due to the simplicity of operation, as well as rather high efficiency in application. The only drawback is the relatively high cost.

The materials used in the manufacture of the main part can vary significantly. A wooden tool is more common, since it is simple and much cheaper. It is suitable for a home workshop. There are also metal structures designed to work in extremely difficult conditions.

The classification is carried out according to what the task is. Examples include the following devices:

- For working with a piece of wood that has not been processed in any way. This variety is called sherhebel. In most cases, a metal is used that can withstand significant impact.

- If the finished parts need to be glued after processing, then a tsinubel is used. This embodiment is characterized by the fact that there are notches on the knife. After planing, small grooves appear on the surface. As practice shows, such a surface is best suited for gluing.

If in the future the resulting products do not need to be glued, then you can use a double or single jointer. The main types of carpentry tools are the following:

- The grinder is a type of design that is characterized by a shorter body and an increased rake angle, as well as a reduced chip clearance. The area of application consists in leveling the ends and removing various seizures.

- In some cases, a semi-jointer is used. It is characterized by a reduced length, but the required width remains. It is used when working with large parts.

- Falsebel is used for sampling and quarters. It has a construction that features a removable sole. The tool differs from others in width, it is a specific version of the execution.

- The zenzubel has a double-sided knife, made using high-quality steel. The width of this element is 33 mm.

There is also a mini jointer on sale. It is often used in a domestic environment because of its small size and sufficient performance. In addition, all devices can be divided into two main groups:

- Household is characterized by low cost, as well as reduced performance. It is widely distributed, since it costs less.

- The professional jointer is used for work in industry. Its main qualities are increased productivity, as well as the ability to work over a long period.

A variety of companies are engaged in the production of the tool in question. There is also an industrial jointer that can be used for a long period.

How to Choose an Electric Planer?

There are a huge variety of models of electric planers (bosch plane, rib plane, etc.), which are gradually replacing hand planers on the market of woodworking tools, because they are more productive, high-quality and efficient when working with products.

- technical parameters and configurations;

- functionality and details.

The technical side when choosing a model includes:

- power indicator - it directly depends on how thick the layer of wood will be removed by the electric planer during operation, while the thickness is adjusted by means of a special handle;

- the quality and width of the cutter - there is a direct pattern: the wider the cutter, the less you spend on wood passes;

- a complete set of a model for sampling a quarter is an additional useful device in individual models of electric planers with adjustable parameters of the width and depth of sampling, which allows you to tightly dock wooden boards together;

- stationary fastening function - allows you to use the tool as a machine: guide the board over it, and not vice versa;

- the number of revolutions - the higher the engine speed, the neater, smoother and cleaner the cut will be;

- limitation in operating time - depending on the purpose of the model for professional or domestic use, the time of continuous operation of the engine varies: for professional e-mail. planers - no restrictions, for household - about 20 minutes of continuous work and a break of 10 minutes.

With the functional choice of email. the planer should be given preference to the model:

- with a smoother sole with height adjustment;

- with two handles for easy movement;

- with the ability to adjust the thickness of the removed shavings;

- with reliable cutter protection;

- with directional flare for chip ejection;

- with a complete set for fixed installation;

- with ergonomic parameters.

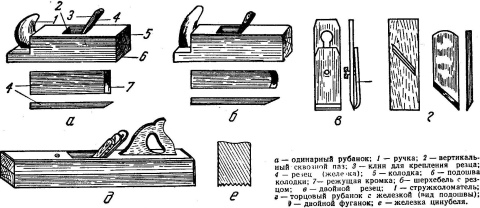

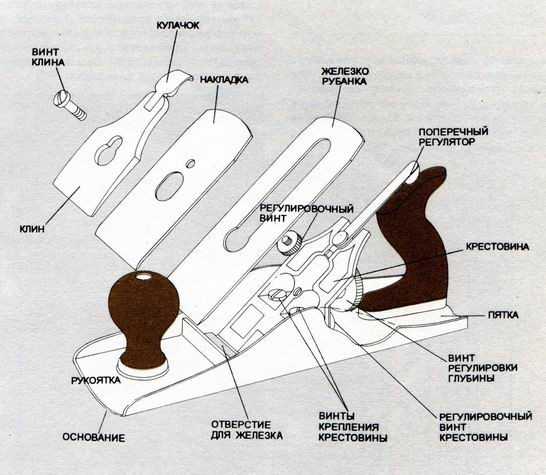

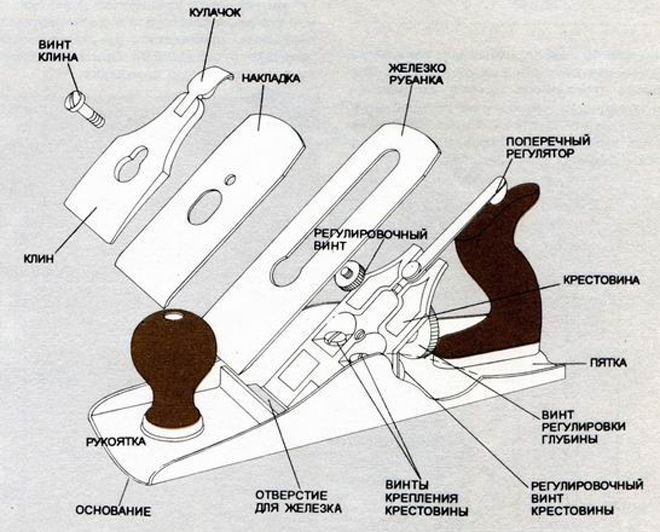

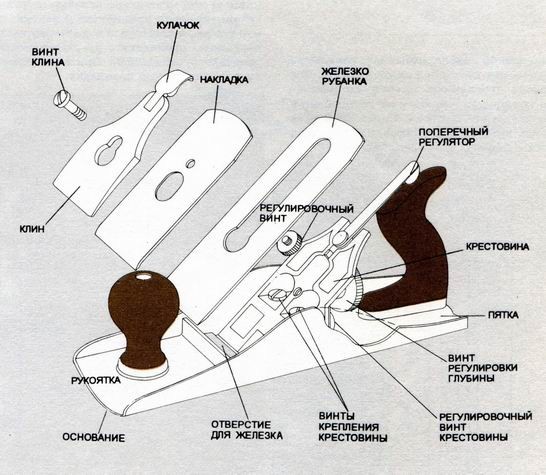

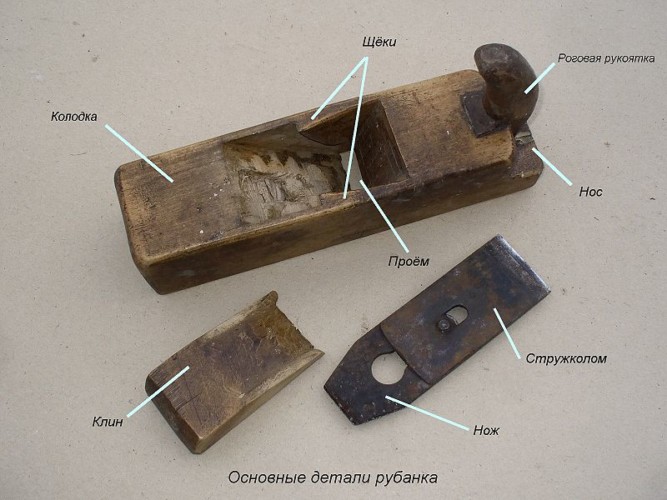

Planer device

The plane has a simple design, reliable and time-tested. What a plane looks like is known to all experienced wood carpenters. The main part of the instrument is a last with a perfectly flat and smooth sole, wood or metal. The simplest types of planers include a wedge, which is hammered in to hold the cutting element. On both sides of the sole there are handles, the first for a secure hold of the tool, the second for translational movements. Other important elements of the planer:

- clamp in which the knife is installed;

- cutting element made of durable metal, installed in a special slot on the block.

Figured planing

Planers classified in this category are designed for processing grooves, projections, edges.

Zenzubeli

With their help, quarters are selected and cleaned, rectangular cuts, grooves, folds are formed, perpendicular elements of the workpieces are rounded. The chisel cutter is made in the form of a blade with a straight or oblique cutting edge, it depends on how the knife is fixed in relation to the sole. The oblique blade has two cutting edges, both sharpening is applied to them. Tooth teeth are used where a dovetail groove needs to be formed. Even processing across the grain gives a perfectly smooth surface.

It is better to start choosing a quarter with a falzgebel, and use a zenzubel for finishing work.

Cantenhobeli

This is an edge picker used for chamfering, processing ends, edges, bringing to specified dimensions.

The main difference between the cantenhobel and other planers is the trapezoidal shape of the blade.

Some models can be equipped with two cutting elements. Depending on the position of the knife, you can cut along the edge at an angle. In this case, a fold is formed for the future joining of two parts, gaps are excluded.

Tongue and groove

With their help, a longitudinal groove is selected. The groove consists of two blocks connected by screws. One of them serves as a guide, the second serves as a mount for the blade. With an adjustable stop, the edge of the groove can be set at the desired distance from the edge. Due to the stop protrusion, the penetration occurs to the required parameters, while the blade does not bend.

Federgubeli

Curly end the plane is intended for forming a longitudinal protrusion along the edge of the workpiece. This is provided by a blade with a central opening. After passing along the edge, a ridge remains. It fits into the groove. As a result, two parts are connected.

Kalevki

Equipped with a replaceable blade with a shaped cutting edge. They have a multi-stage sole.The tool is most often used for the manufacture of decorative parts: cornices, baguettes, and other wooden elements.

Falzgebeli

Needed to select a groove along the edge of the workpiece without preliminary marking. Includes multi-step outsole. The wide last helps to form grooves of the same size. If it is necessary to process the vertical wall of the quarter, an additional side cutter is installed on the rebate.

Staples

Designed for rounding the edges of parts. These planers have a blade, the edge of which is provided with a semicircular recess. There is a concave sole. When processing the edge of rectangular ends of parts, the knife removes the chips in such a way that the edge takes on a rounded shape.

Planer device

Over the course of the evolution of the planer, quite a few of its varieties have appeared, which can be used not only for processing wood planes, but also for curly cutting. To enjoy manual labor, you need to be able to choose the right plane, and then you will get real works of art from an ordinary piece of wood.

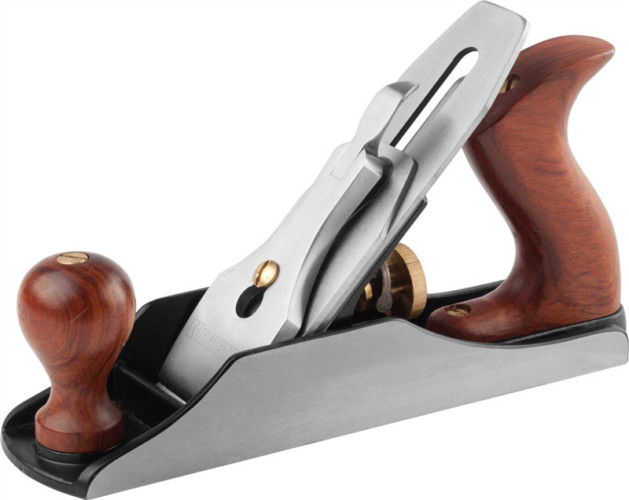

Modern planers can be roughly divided into wooden and metal models. Each of them has its own advantages and disadvantages, but structurally, the tools are similar, like twin brothers.

A standard plane consists of the following parts:

- sole, she is the body;

- cutter;

- wedge;

- slot for the exit of the shavings;

- cutter clamp;

- cutting depth regulator;

- horn - front handle;

- emphasis - rear handle.

The key element of the design is the cutter - this is a cutting tool made in the form of a sharpened plate.

The blade is located at a given angle to the surface to be treated. Thanks to the regulator, the knife extends to a certain distance, which allows you to fine-tune the depth of cut, the thickness of the removal of chips. In factory models, the angle of the blade is standard, but professional carpenters change it depending on the type of wood being processed.

The handles also play a role. The front, called the horn, has a guiding function and is usually curved to provide a better grip. The back is a stop, thanks to which the effort necessary for work is created.

With the sole, which can be made of wood and metal, everything is not so simple. The main criterion for this structural element is a perfectly flat surface.

If this requirement is not met, it will be difficult to use a hand plane, and you can simply forget about the accuracy of planing. Taking into account these nuances, the metal sole looks preferable: it is made according to a template, so it has the correct geometry a priori. However, mistakes made by the manufacturer during casting reduce these advantages to zero. Moreover, the metal is subject to corrosive changes.

The wooden sole is lighter, and in case of deformation, it can be straightened on its own, breathing a second life into the plane. However, wood is not a durable material, it is subject to mechanical wear, loses its original properties with prolonged exposure to moisture or high temperatures.

> Despite the typical design, there are more than 10 varieties of planers, and each tool performs a specific function in the processing of parts. Let's take a closer look at these products.