Maintenance and storage

The duration of the uninterrupted operation of the motoblock scythe mechanism directly depends on regular maintenance. As part of maintenance work, the device is cleaned of grass residues, mud deposits and dust. The degree of tightening of the threaded connections is checked - the loosened ones are tightened. The tension of the belt drives is measured. The cutter knives must be sharply sharpened. To do this, they must be periodically removed and sharpened. It is forbidden to do this in the hinged position. The balancing mechanism is adjusted after each operation. Its spring part is checked and adjusted.

Components subject to high friction should be lubricated regularly. Especially the bevel gearbox, cutterbar section and bearings need it. Lubrication is only carried out through the appropriate oil holes.

The order and list of works carried out to prepare for long-term storage is determined by typical characteristics. The main nuances of such preparation include cleaning from dust and dirt, removing moisture from metal surfaces, coating parts with special anti-corrosion solutions. Choosing the right storage location is an important factor. It must be dry, protected from mold, drafts and other aggressive influences.

You can see the rotary mower on the Neva walk-behind tractor in action in the next video.

Self-production

Surely the reader has a question "Isn't it possible to make a mower for the Neva walk-behind tractor with your own hands?" Well, nothing is impossible in this. Just to create a really high-quality and relatively safe device at home can take months of hard work, plus tools and materials.

The main thing to make first is a sturdy metal frame. For this, iron corners are suitable, which can be welded to each other. After that, you need to decide on the configuration of the future braid and start working on the tool itself.

Homemade rotary mower option

- Two working discs are removed from an old grain tractor seeder, and a chain and a gearbox from a chainsaw are used as a drive.

- It is necessary to make the blades separately with your own hands and use the holes pre-drilled in the discs to fix them on the discs.

- The knives should be movable so that there is less risk of damage if the scythe "finds" a stone or other solid obstacle in your meadow.

- It should be noted that the mower discs must rotate towards each other. Otherwise, even grass swaths will not work.

You should end up with something similar to this photo.

How to make a finger mower

- You will need to take two metal bars up to one and a half meters in length and drill a dozen holes in them for bolts.

- Bolts between the beams will need to fix a separately made rail with cutting edges with your own hand.

- This entire structure must be attached to a rigid frame and held by two rails.

- Just as for the rotary unit, you will have to make a belt drive with pulleys and bearings.

Of course, the work is interesting for DIY, but factory attachments are almost always more profitable in the end than their own.

If you want to choose a mower for the Neva MB 2 walk-behind tractor, study all the features of those areas where you want to work. As practice shows, there are no universal tools in this category.

The most reliable selection criterion can only be the experience of those who themselves used such devices. In any case, the mechanization of haymaking, especially if it is carried out in significant volumes by only one person, is a significant plus for the backyard economy.

Popular models

Domestic manufacturers produce these units in various configurations. A widespread braid is one that is produced under the Zarya and Zarya 1 brands - a product of the Kaluga JSC Kadi.

This model is multipurpose. It is distinguished by high performance indicators, ease of management, ease of installation and maintenance. The mechanism for attaching the mower frame to the rotary unit of the walk-behind tractor is simple and versatile, suitable for almost all domestic cultivators.

Another model widely used by Russian farmers is the KR-80. It is suitable for operation in combination with tselina, Neva, Kaskad, Oka walk-behind tractors. It can be used for mowing grass, large-stemmed shrubs, cereals.

The KRN-1 rotary suspended mower has similar characteristics. Produced in Russia and Belarus. Fits on most drive units. Has modifications designed for industrial processing of fields.

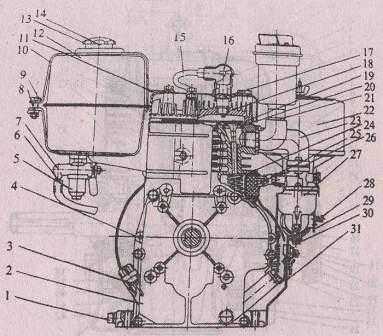

Before purchasing an installed add-on to the walk-behind tractor, you need to find out the characteristics of their compatibility. The Daewoo DAT80110 petrol cultivator is sometimes sold with additional attachments from the same company. They fit easily with its driving gear. Mowers from other manufacturers may be structurally different, which will interfere or negate attempts to connect the walk-behind tractor to the suspended unit

When buying this or that agricultural equipment, you should pay attention to this issue.

do-it-yourself rotary lawn mower

There are many types of equipment for a walk-behind tractor, among which lawn mowers are considered one of the most popular both in large farms and in small areas. In addition to buying at specialized points of sale, you can do it yourself. However, the price of a lawn mower for a walk-behind tractor is low, so the purchase of a ready-made one will hardly burden anyone. Before choosing, you need to understand what you need to mow on the site. In addition, it is worth assessing the level of vegetation in the garden. Taking into account the density and height of the vegetation cover, two types of aggregates were created: rotary (also called disc) and finger or segmental.

Rotary mower for walk-behind tractor

This species is well suited for areas with small shrubs and low grass. It is also well suited for places with slight tilt angles in the range of 15-20 °. Possible lateral tilt should not be more than 8 °. The design has a significant disadvantage - an increased risk of injury. But there is also a plus - the cut off shoots of plants are laid out in even rows, making them easy to remove later.

Rotary mower for walk-behind tractor

The principle of operation of the rotary device is based on collecting and bending the grass with an installed shield and directing it to two or more discs, which will cut the stems at an adjustable level with the built-in knives. At the same time, the operating speed is quite high, and the structure itself is easy to assemble.

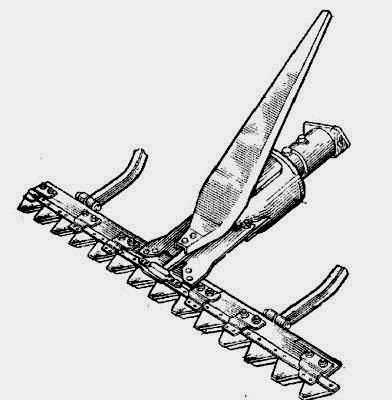

Segment mower for walk-behind tractor

The segment lawn mower for the walk-behind tractor is powered by knives that carry out reciprocating movements. This is due to the shaft of the walk-behind tractor. Such units are more difficult to operate and maintain than rotary ones, but much safer.

Segment mower for walk-behind tractor

Important! The clipping blades are positioned to the side of the machine, so the grass is not crushed on the next pass. They are height adjustable so you can cut very low grass

The flexibility of the cutting blade allows it to tilt up to 20 ° and cut weeds even on uneven ground.

Installing a lawn mower on a walk-behind tractor

The purchased lawn mower is installed on the walk-behind tractor using a special drive-connector included in the kit. To attach them, you need to combine the device shaft with rotating elements. Rotary devices are installed in front, and segment ones - on the side of the motor cultivator.

Review of the lawn mower for the Tarpan walk-behind tractor

The Tarpan home lawn mower works perfectly in tandem with the walk-behind tractor of the same name. Power transmission is carried out through a worm gear, which is much more reliable compared to belt and chain drives. The working width is 750 mm as standard. If additional equipment is installed, the size of the treated area increases to 175 cm.

How to make a do-it-yourself lawn mower for a walk-behind tractor

You will need 2 grain seeder discs, chainsaw reducer chains. You also need 8 knives made of hardened sheet steel, 4 per disc and a self-assembled frame with holes for fixing the shafts, on which the drive from the walk-behind tractor will be attached. The size of the device is selected in advance and adapts to the cultivator.

Do-it-yourself lawn mower for a walk-behind tractor

A do-it-yourself rotary mower on a walk-behind tractor is created as follows:

- Drill 6 mm holes on the disc.

- Secure the knives with a shank.

- Attach the discs to the shaft, thread a pair of shafts through the holes in the frame.

- Fasten the belts from the walk-behind tractor gearbox to the upper disc shafts using an adapter.

- Attach wheels or hang on a walk-behind tractor.

Note! Before starting work, you need to take into account that a home-made device can behave unpredictably, so you need to follow safety precautions. A do-it-yourself mower for a walk-behind tractor can last long enough if the assembly was carried out strictly according to the drawings

The need to mow the lawn arises for many gardeners. For this, in addition to the usual classic braids, you can use automated aggregates. In addition to autonomous systems that operate due to internal combustion engines, you can connect equipment attached to the working shaft of the walk-behind tractor. It is very convenient: it is inexpensive, easy to connect and works properly. In addition, such a lawn mower can be made by hand.

Zarya mowers and domestic walk-behind tractors

The Zarya mower is available in two modifications: for related and third-party motoblocks. The KR.05.000 model with the prefix "1", "2", "3", "4" is adapted for the Oka walk-behind tractor or another motor-cultivator of the Kaluga plant Kadvi. The KR.05.000 type is intended for equipment from other manufacturers. Such a Zarya mower is attached to the Neva, Salyut-5, Kaskad walk-behind tractor.

The Zarya 1 rotary mower model is aggregated to the Ugra motor unit manufactured by Kadvi. to the menu

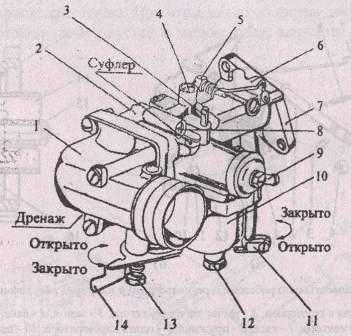

Principle of operation

The rotary mower for the walk-behind tractor works due to two discs with four freely rotating knives on each. The knives protrude slightly beyond the edges of the disc. Making turns towards the inside, the working elements do not scatter the cut grass, but neatly lay it in the swaths. to the menu

Field capabilities

Both rotary devices for the Zarya walk-behind tractor "bring to life" the most different areas. You can carefully mow your lawn, mow green vegetation on the side of the road or along the curb of your garden path.

Rotary mower Zarya with walk-behind tractor

Kaluga equipment is purchased by public utilities for work in vast areas - squares, parks. The cutting height can be adjusted, leaving stubble up to 7 cm (Zarya) or from 3 to 10 cm (Zarya-1).

Zarya is distinguished from a trimmer or brushcutter by a decent working speed. It allows you to mow up to 20 acres in an hour.

To summarize, one unit can, if necessary, replace the following devices:

- mowing machine;

- lawn mower;

- lawn mower.

to the menu

to the menu

Advantages over other models

At least four advantages can be distinguished:

- Less effort.Having worked with Zorya, it is very difficult to return to the segment mower. Due to the fact that the cut grass is collected in swaths, additional work with a rake and a thorough raking of the cut green mass is not required.

- Security. The second advantage is especially noticeable when compared to front clippers. When working with rotary technology, the operator is not afraid of stones, sometimes found in the grass. If the working part hits an obstacle, the fuse is triggered.

- Weatherproof. You can work with Zorya even with a tangible wind.

- Easy to customize. The mower is delivered ready to use. Light weight allows you to connect the equipment to the walk-behind tractor on your own. The dimensions of the unit will not be a problem for transportation.

to the menu

Interesting: Top-2 mounted rotary mowers by popularity: we understand in detail

Operating tips

The modern power trimmer scythe does not always cope with large areas of grass. Here, a mower driven by a walk-behind tractor turns out to be a more effective solution. For the successful operation of such equipment, you must follow a number of simple rules:

- always check the sharpness of the cutting elements before work;

- control the tightening of bolted connections;

- check the lubrication of parts, if necessary, additionally process the rubbing elements;

- protect legs while working, wear special glasses - flying stones can harm health;

- in the process of work, it is imperative to ensure that all turns and maneuvers occur smoothly and accurately, without sudden jerks;

- if there are protective covers in the configuration, they must be used for their intended purpose;

- if changes are detected in the sound of the mower, you should stop work until the causes of the problem are clarified;

- in case of a visual deterioration in the quality of mowing, you should take care of sharpening or replacing the knives.

Modern mowers for hay making, lawn trimming are the best solution for improving the available functions of the walk-behind tractor. With their help, you can refuse to purchase autonomous self-propelled equipment and carry out work on the basis of existing motorized tools for processing the site.

In the next video you will see the operation of the Zarya rotary mower on the Salyut walk-behind tractor.

Rotary mower KR-0.5

It has in its design one disc with knives. In addition, a special protective block is installed behind the disc. It allows you to protect a person while working with the mower from flying stones, grass stalks and other foreign objects.

Rotary mower KR-0.5 "NEVA"

The mower is connected to the walk-behind tractor, like all attachments, using a hitch. Therefore, there will be no installation problems.

The video shows an example of the operation of a Neva walk-behind tractor with a rotary mower KR-0.5:

Specifications

The weight of the structure is about 30 kg. However, the Neva walk-behind tractor is designed to work with a lot of weight.

- The maximum cutting speed is between 2 and 4 km / h, depending on the density of the grass. At this speed, from 0.09 to 0.15 hectares can be processed in one hour.

- The knives on the KR-0.5 are installed at a height of 4 cm from the ground, that is, the remaining grass will be the same size.

- The blade rotation width is 56 cm.

- This mower is practical square: 70 cm high, 70 cm wide and 68 cm long.

- Rotary mower knives KR-0.5

Particular attention should be paid to knives. They are the main cutting element in all equipment.

They are made from high quality steel. Then there is further hardening and turning of the cutting parts. As a result, they are durable, sharp and inexpensive. They allow you to cut not only grass, but also small tree seedlings or other shrubs.

Over time, the knives become dull. However, don't throw them away right away. They can be removed and sharpened in any convenient way.At the same time, the operational properties will not change in any way, and the service life will significantly extend. The only thing that you should not get too carried away with this activity, because with a large depletion of metal, it is still better to buy new ones.

Replacing them is also quite easy, for this the lower part of the mower is removed, the old knives are unscrewed and new ones are attached in their place. Those. according to the instructions, it is quite possible to assemble and disassemble yourself

Design features

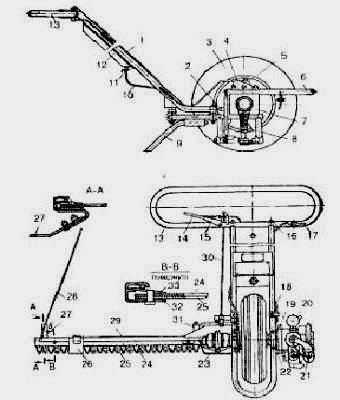

Devices manufactured by different companies may differ in external and some technical data. The principle of operation of such units is identical and dictates an integral list of nodal blocks included in the design.

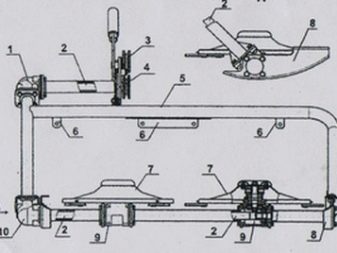

The standard rotor scythe is made of:

- frames;

- stretcher;

- balancing mechanism;

- cutting apparatus;

- field divider;

- traction fuse;

- racks;

- protection of the cutter bar.

Frame - an element designed to attach the attachment to the walk-behind tractor. Has two axes facing to the sides. One of them serves to secure the frame to the lower links of the leading apparatus. The second one is fitted with a traction overload fuse, held by bolts and two nuts. An element with a bracket is attached to the frame, which allows the subframe to be installed.

The subframe is the welded part that connects the frame and the cutting element. It consists of a rectangular body. On one side, a tube is welded with bushings embedded in it. In the middle there are "ears" for attaching the transport link and the device for adjusting the height. A bracket protrudes from the side, on which the traction fuse is attached. The drive itself and the belt drive protection are fixed on the subframe.

The balancing mechanism is designed to ensure that the cutterbar follows the terrain. Thus, the best possible mowing of vegetation is achieved. This mechanism also puts the mower in transport mode. Its adjustment is carried out with special tension bolts.

The cutting device is mowing. Its body is an all-welded crankcase. The cutting elements are supported on the ground by means of a special pallet installed underneath. The cutting device can have as many rotors on its body. In a motoblock modification, there are usually two of them. The rotors are equipped with two knives. The transfer of mechanical force from the motor to the knives occurs by means of a belt traction, gear units, a number of shafts and gears.

The field divider helps separate cut and uncut grass. It consists of a shield, springs and bolts. The spring mechanism allows the divider to move backwards when overflowing with cut vegetation.

During the mowing process, the cutter bar may bump into an obstacle. In order to avoid damage in this situation, the rotary mower is equipped with a traction safety device. With the help of this knot, the streamer can deviate from the working position up to the moment set by the user.

The stand helps to hold the mounted unit in a comfortable position at the time of its attachment to the walk-behind tractor.

The machine blades rotate at high speed. For the safety of the person using the equipment, they are placed in a protective casing. It can be made of light metal or canvas fabric.

Various modifications of rotary mowers may differ in the presence of certain parts. Some of them can be purchased, while others can be made by yourself.

Neva mower for walk-behind tractor: rotary, segment

Among summer residents, gardeners, in small private farms, the use of motoblocks has become very popular. With all the variety of their models, the leading place is occupied by the Neva model, produced by the Krasny Oktyabr plant in St. Petersburg.This multifunctional motor-cultivator has a wide range of attachments, which makes it possible to use it for snow removal, plowing, loosening, hilling, mowing grass and coarse vegetation.

For the "Neva" walk-behind tractor, there have been developed very successful mowers of several modifications that have proven themselves well in the working process. Differ in design solutions.

Types of mowers for the Neva walk-behind tractor

For this unit, two types of mounted mowers are used:

- rotary type;

- segment type.

Rotary mower for walk-behind tractor

Having figured out on what principle the units work, what distinctive characteristics they have, you can make the right choice of its type. Here we need to imagine what we will mow.

Rotary mower "Neva"

The working mechanism of this type of apparatus is discs. There are two-disk and single-disk devices. The mower is fastened to the Neva walk-behind tractor in its front part from the drive shaft drive by means of a V-belt.

The most popular devices today are Zarya (two-disk) and Neva KR 05 (single-disk). The mowing height is adjusted with special skis. The skis also support the weight of the mower when working.

The grass cut by this type of technique is laid in rows, which simplifies its subsequent drying and harvesting.

Mower KR 05 has the following technical characteristics:

- maximum travel speed up to 4 km / h;

- productivity 0.15 hectares / hour;

- disk rotation speed up to 2500 rpm;

- coverage 56 cm;

- mowing height up to 1 m;

weight 30 kg.

It is a very compact, mobile and powerful device. He confidently overcomes obstacles in the form of anthills, thick branches, small stones, single shrubs, and also copes with heavily overgrown areas. KR 05 can be used for mowing grain crops.

Rotary mower with walk-behind tractor

Rotary mower KR two-disc "Zarya" has identical technical characteristics in terms of maximum travel speed and mowing height. The differences are as follows:

- productivity 0.2 hectares / hour;

- rotation speed of disks up to 2400 rpm;

- capture width 80 cm;

- weight 32 kg.

Segment mower for motoblock "Neva"

The working tool of this type of apparatus is the shearing knives, which are set in translational motion by the motor shaft. Knives are made of high-alloy hardened steel. Therefore, they do well with thick branches and small stones.

Adjustment of the mowing height and maintaining the weight of the device is carried out by the presence of special skis, as in the case of a mower for a rotary-type Neva walk-behind tractor. Distinctive technical characteristics of the most common segment-type aggregates of the "Neva" model KN 1.1:

Segment mower with walk-behind tractor

- maximum travel speed up to 5 km / h;

- productivity up to 0.35 hectares / hour;

- coverage 110 cm;

- mowing height from 4 cm;

- weight 45 kg.

How does the mower for the Neva walk-behind tractor work?

Safety when working with mounted mowers

When working with a unit of any type, rotary or segment, it is very important to follow the safety rules:

- Before starting work, it is necessary to check the reliability of all fasteners and connections.

- It is forbidden to stand in front of the cutter bar during operation.

- Stop using the device if a malfunction occurs.

- All repair and maintenance operations should be carried out only with the engine off of the unit.

- Check belt tension and nut tightness every two hours during the working process.

- Do not exceed the maximum permissible travel speed. The mowing will not be of good quality.

- Disconnect the mower drive when transporting it.

- Be careful not to allow contact with the cutting elements of the machine when moving or lifting it.

Mower with walk-behind tractor in operation

Both types of mounted mowers for Neva walk-behind tractors are produced by major licensed manufacturers. There are also many fakes, often from a Chinese manufacturer, where the quality of the equipment is in question.

The names of the mowers can be very different, but in fact the model is the same.