How to choose?

Before choosing a new jack, you need to decide where and under what circumstances it will be used. If you just need to replace an old worn-out unit with a new one in order to put it in the luggage compartment and hope that it will no longer be useful, then you can choose a simple and inexpensive, but still high-quality lifting mechanism. If you plan to repair your car from time to time, then this will require better and more reliable models.

Give preference to branded units. Such products are of higher quality, are reliable and are accompanied by a manufacturer's warranty. As a rule, branded units come with detailed operating instructions - this can be an excellent help for a person who has no experience with such devices.

You should only choose any of these options in a specialized store with a good long-term reputation. In such an establishment, you can not only choose the product you need, but also consult with experienced sellers about the possibilities of its application. Ask the store staff for a quality certificate for the purchased products. This will save you from low-quality goods or fakes. If for some reason they cannot provide you with this document, then it is better to look for another store.

Be sure to inspect the item carefully before purchasing. Sellers should not refuse you this. The selected unit must be free of visible defects, and its moving parts must move easily, without jamming. If you find at least one damage, an incorrectly exposed part or a curvature of the product, ask for a replacement product.

If a marriage is found after payment, you should take the jack and go with it back to the store where you bought it. Be sure to take a check and a warranty card, this will allow you to exchange the product for a new one in case of breakdown.

Principle of operation

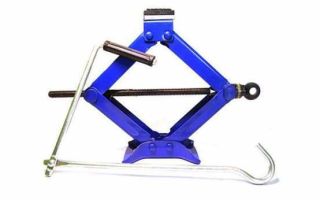

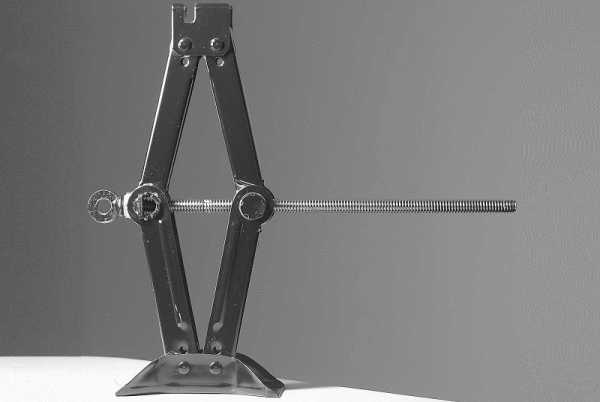

The work of the described jack is carried out by folding and unfolding a structure that looks like a rhombus. As the horizontal corners of the rhombus contract, its vertical corners begin to move away from each other. Thus, the work of the jack occurs independently of the propeller drive. A similar design of jacks can be equipped with different ways to drive the propeller:

- manual;

- electric;

- hydraulic.

A manual car jack is the simplest and most common of all. Everyone has seen him at least once. But a diamond-shaped copy with an electric drive can be found not so often. Its device is even simpler than the manual version. It needs to be placed under the car in the right place and plugged into the cigarette lighter. Further, the control of the ascent and descent is controlled by the control panel. An electric jack of this type cannot be called a necessity, rather, it is a pleasant addition that may not always be convenient to carry with you for years.

A hydraulically driven device is extremely rare. The reason for this is its high price and operating characteristics. In fact, this is a hybrid of 2 types of jacks (bottle and diamond-shaped). An oil pump is located on the housing, which pumps fluid into the working cylinder.

DIY rhombic jack repair

Despite the simplicity of the design, there are times when the question arises of how to fix a screw jack. Most often, the axle comes out of the drive mechanism.It can be repaired by replacing it with an ordinary construction hairpin of a suitable diameter, cutting it to size and welding a nut on one side.

In case of plastic deformation of the structure, it is better not to repair, but to replace the device itself.

Now the purchase of a good and reliable jack, and most importantly - suitable for a particular car, will take place without problems and unnecessary questions. It should not be forgotten that safety when working with it directly depends on the quality of the jack.

Mechanism description

The device operates on the principle of mechanics and works by turning the screw mechanism. The carrying capacity depends on the calculated pitch when forming a threaded connection, it increases with increasing pitch distance. In operation, the levers change location relative to the hinges that connect the driving elements into a single device.

The distance between the lateral movable elements becomes smaller as the screw is tightened, and the hinges of the upper and lower trapezium diverge. The change of angles between movably fixed rigid edges occurs smoothly. The movement is carried out using a screw pair.

There is a lowering or lifting of weight. The lifting height is measured with the mechanism in a fully unscrewed state. The lifting height is in the opposite twisted position.

Popular models rating

The Wiederkraft WDK / 81885 mechanism opens an overview of the best 3 ton trolley jacks. Key Features:

- two working cylinders;

- increased structural strength;

- reduced likelihood of stalling when lifting;

- maximum lifting height - 45 cm.

The disadvantage of the model is too heavy weight - 34 kg.

Rolling jack Matrix 51040. Its parameters:

- one working cylinder;

- reliable construction;

- pickup height - 15 cm;

- maximum lifting height - 53 cm;

- weight - 21 kg.

Double plunger jack Unitraum UN / 70208. The main characteristics of the model:

- metal reliable case;

- pickup height - 13 cm;

- lifting height - 46 cm;

- working stroke - 334 mm;

- ease of use.

Rack model of professional type Stels High Jack / 50527. Peculiarities:

- metal reliable construction;

- pickup height - 11 cm;

- lifting height - 1 meter;

- working stroke - 915 mm;

- the perforated body allows the jack to work as a winch.

Rack and pinion mechanism Matrix High Jack 505195. Its main indicators:

- pickup height - 15 cm;

- maximum lifting height - 135 cm;

- robust construction.

With such a powerful design, the jack is difficult to use from habit. Disadvantage: Effort is required.

Bottle jack Kraft KT / 800012. Peculiarities:

- the presence of a coating of the structure with a protective layer against corrosion;

- reliable and durable construction;

- pickup - 16 cm;

- maximum rise - 31 cm;

- stable outsole.

An inexpensive device has a large pickup, so it is not suitable for all low-slung vehicles.

Hydraulic bottle mechanism Stels / 51125. Key Features:

- pickup - 17 cm;

- maximum rise - 34 cm;

- the presence of a safety valve;

- the structure is equipped with a magnetic collector, which excludes the appearance of chips in the working fluid;

- increased service life;

- the likelihood of minor breakdowns is minimal;

- product weight - 3 kg.

Mechanical model Matrix / 505175. Indicators of this model:

- pick-up height - 13.4 mm;

- maximum rise to a height of 101.5 cm;

- reliable case;

- smooth running when lifting and lowering;

- compactness;

- the presence of a manual drive.

Pneumatic tool for 3 tons Sorokin / 3.693 has the following features:

- the ability to use on an uneven surface;

- the presence of a hose for connecting to the exhaust pipe (length - 3 meters);

- Comes with a handy bag for transportation and several rugs for safe work;

- the package contains glue and patches in case of damage.

Views

Jacks of this design are divided into several types, an overview of which is given below.

Screw

The most common types of jacks that are used to repair a car or truck. They are inexpensive and reliable in design. They work thanks to a threaded screw that rotates in two directions, due to which the load is lowered or lifted. This type of tool is considered one of the most budgetary and common among motorists.

Such devices are most often used for car repairs as a stand. Models of this tapa can lift loads weighing up to 15 tons. The structure of the mechanism consists of a cylindrical all-metal base with one or two lifting screws, which are located inside the base.

The main advantage of this type of jack is its stability and strength. They can be used without additional stands and supports. Most of the models of these lifts can lift various loads to a height of 365 mm, but there are models in which the lifting and picking heights are greater.

Hydraulic

They have a large carrying capacity with the same dimensions of their screw competitors. Hydraulic rhomboid models have a large footprint, good stability, and a small lift height.

These models are suitable for repairing heavy vehicles with low ground clearance.

Mechanical

This type of jack is equipped with a reversible ratchet instead of the usual handle. Otherwise, it is the same diamond-shaped jack with a screw, but it has become much more convenient to twist. Thus, they can work in places where free space is limited. Lifting capacity and working height may vary depending on the model.

The head on which the knob is inserted has a hexagonal shape, and in case of breakage or loss of the ratchet, it can be replaced with a regular ratchet wrench with the required head.

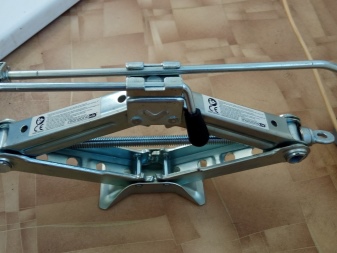

Trolley

Jacks of this type are a long stretched trolley on metal wheels. Such devices are very bulky and heavy. Carrying them with you will be quite problematic, given the large dimensions, which is why the unit will take up a lot of space in the trunk. In addition, its heavy weight will make it difficult to work with it, which requires a flat and solid surface (not easy to find on the side of the road).

This type of jack is more suitable for garage repairs. Depending on the model, such a jack can have a lifting capacity of up to 10 tons. It is equipped with a hydraulic drive and a powerful frame. Thanks to this, it can be used in an unheated garage. These models have a fairly low pickup height, and lift heights up to 65 cm.

Rolling jacks are often found in tire shops, service stations and other organizations where partial lifting of the machine is needed.

Specifications

Jacks are uncomplicated mechanisms used to raise loads to low heights. These are mainly mobile and compact devices that are easy to transport.

Jacks for 3 tons have their own characteristics, which depends on their type. Hydraulic models are a cylinder with a piston, a reservoir for working fluid and a lever system. The principle of operation of such a jack is based on the pressure of the working fluid on the piston. When pumping (manually or with the help of a motor) fluid from the reservoir into the cylinder, the piston moves upward. This is how the load is lifted. The upper end of the piston rests against the load being lifted from below.

The hydraulic jack is equipped with two valves: an inflating valve and a safety valve. The first one moves the liquid into the cylinder and blocks its reverse movement, and the second one prevents the device from overloading.

There are lifts in the form of rails and trapezoidal mechanisms.Their principle of operation is based on the mechanical movement of levers or screws, which ultimately influence the lifting mechanism.

A variety of materials are used for the manufacture of jacks: aluminum, ultra-strong steel, steel, cast iron. The density of the material affects the strength and load capacity of the mechanism.

Lifting devices designed for a load weighing 3 tons have a small weight - up to 5 kg. Some of them are worth getting to know better.