Features of operation

The P-2 respirator is put on the face in such a way that the nose and chin are placed inside the half mask. In this case, one of its braids is placed on the occipital, and the other on the parietal part of the head. It should be noted that these two fastening straps do not have the ability to stretch. Therefore, for convenient operation, it is recommended to adjust the elastic straps using special buckles, but this must be done with the respirator removed.

When putting on a protective device, you must make sure that it does not squeeze too much in the nose and does not press strongly against the face.

It is very easy to make sure of the tightness of the worn protective equipment, you just need to tightly cover the opening of the safety valve with the palm of your hand, and then make one light exhale. If air does not come out along the line of contact of the device, but only slightly inflates it, then the device is put on tightly. The release of air from under the wings of the nose indicates that the respirator is not pressed tightly. If, after several attempts, it is not possible to put it on tightly, then it is best to replace it with a different size.

To remove excess moisture from under the mask, you need to bend your head down. In case of abundant moisture release, it is recommended to remove the device for a few minutes, but this is allowed only if a respirator is used as protection against radioactive dust.

After removing the respirator, remove moisture from the inside and wipe it with a napkin, then the device can be put on again and used as intended further.

In order to provide the R-2 respirator with a long service life, it must be protected from mechanical damage, otherwise it will be unusable due to the formation of through holes. You can not use this tool even if there is mechanical damage to the straps, nose clip, any tears of the plastic film and the absence of inhalation valves.

After each use, the respirator should be wiped dry with a dry, clean cloth (cannot be turned out). It is strictly forbidden to clean the half mask with rags soaked in organic substances. This can destroy the material of the protective device and reduce its strength.

Since the material of the respirator melts at a temperature of + 80C, it cannot be dried and stored near fires and heating devices. In addition, the half mask should be protected from the negative effects of precipitation, since when it gets wet, a significant loss of protective properties is observed and resistance to inhalation increases.

If it so happens that the respirator gets wet, there is no need to rush to throw it away - after drying, the device can be used as a respiratory protection against radioactive dust.

The main advantage of P-2 respirators is the fact that you can stay in them continuously for 12 hours. And this will not in any way affect the functional state and performance of a person.

If all conditions of storage and operation are observed correctly, then respirators R-2 can be used several times (up to 15 shifts).

For information on how to properly use a respirator, see the video below.

What is needed for welding zinc

When welding zinc, zinc oxide is released, which can cause short- and long-term damage to health. Inhalation of large quantities of vapors can poison the welder.Zinc vapor entering the bloodstream leads to an increase in body temperature, chills, weakness in the body, and nausea. Acute poisoning can lead to disruption of the liver and blood circulation, as well as the occurrence of cancer. Therefore, when welding zinc and galvanized steel, a special respirator with an aerosol filter should be used. An example of such a remedy is presented below.

3M 9925 welding respirator FFP2, class 2

- Manufacturer - 3M (USA).

- The "Premium" class respirator provides protection against dust, ozone, smoke, aerosols, mists, organic vapors.

- The basis of the product is a soft hypoallergenic material.

- Reliable protection against welding fumes is ensured by a specially designed multi-layer filter.

- The soft and comfortable pad is airtight and adheres well to the face.

- The expiratory valve helps remove moisture and heat when working in high temperature conditions and during high physical exertion.

- The half mask does not impede speech, retains adherence during mimic movements.

- The use of respirators of this model reduces the risk of occupational diseases by 90-95%.

- The half mask can be used at ambient temperatures from -30 to + 70 ° C.

- Has a long service life.

An important element of PPE for welding

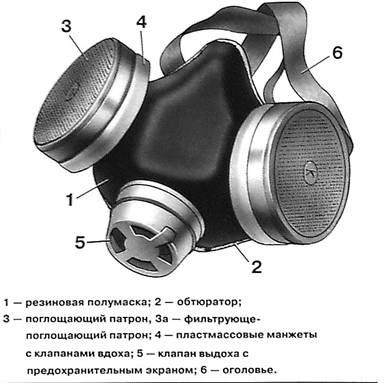

The respirator is a convex half mask, the design of which includes the following elements:

- adjustable nose clips;

- inspiratory valves;

- filter material that performs a protective function;

- two- or four-point fastening system.

Respirators provide protection against the following harmful and hazardous effects:

- oxides, oxides and aerosols;

- water vapor;

- welding fumes;

- gaseous compounds;

- industrial dust;

- glowing sparks and heat from welding;

- reducing the intensity of unpleasant odors.

In addition, respirators should not obstruct breathing and be compatible with the welder's mask.

It is recommended that you try on a half mask before purchasing. It should fit snugly against the face for reliable protection. The feeling of discomfort and pressure on the head is unacceptable. The inner material should be soft, pleasant to the body and not cause allergic reactions.

Video

The video below is, of course, advertising, but it allows you to get an idea of the importance of protection and the design of this PPE.

A respirator for a welder must have a minimum protection class of FFP2, which implies operation under conditions up to 12 MPC (maximum permissible concentration) of chemical elements and their compounds. Manufacturers also offer half masks with protection classes FFP1 and FFP3.

Respirators of the first class are designed for work on grinding stone or wood, the maximum permissible concentration does not exceed 4 units. Half masks of the third class will protect the worker from contact with powders and biological agents, 50 MPC.

Important! Respirators with protection class FFP1 are not suitable for welding, as they do not provide protection against all harmful and dangerous influences. The third class half masks make breathing difficult during metalworking, so they should also not be used when welding. 3M 9914

3M 9914

- Manufacturer - 3M (USA).

- Protection class - FFP1.

- A combined action respirator protects against aerosols, dust, mists, contaminants and has additional protection against organic vapors.

- The half mask is designed to work with organic solvents, used for painting and polishing.

- The presence of an exhalation valve.

- The filter layer is made on the basis of activated carbon.

- Ergonomic shape for comfortable wearing.

Carefully! The welder's respirator does not protect the performer from high temperatures and heat radiation, therefore, a welding mask must be used. Also, the half mask does not provide safety against highly toxic substances and agents that enter the human body through the skin.

Peculiarities

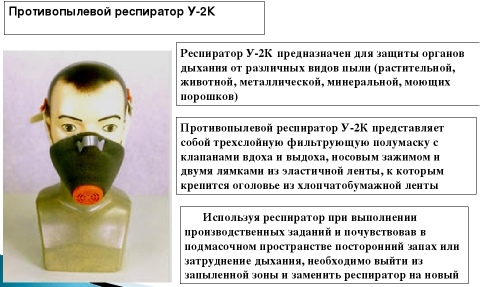

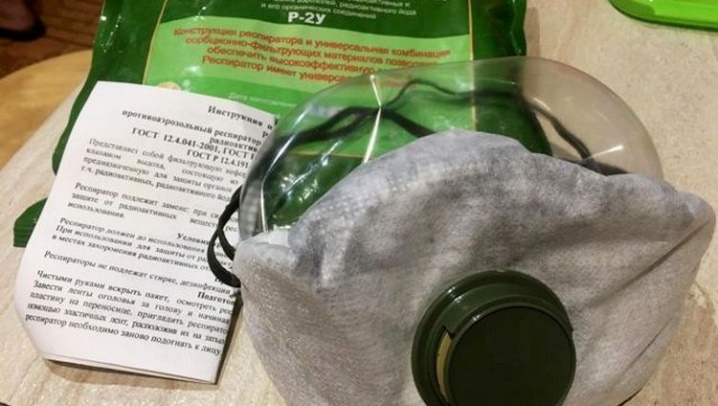

Protective respirator model U-2K is used in the national economy and in the event of an emergency regime in order to protect the human body from the ingress of fine mineral, chemical or radioactive dust, some types of bacteria and fungal spores into the respiratory system, as well as fertilizers in the form of a powder that does not the release of harmful gaseous vapors is characteristic. The U-2K respirator can also be effective for protection against aerosol liquids if their density does not exceed 200 mg / m³. The device works equally effectively both in winter and in summer, in various climatic conditions, with the exception of getting into an environment where moisture is in a drip state.

The respirator specifications do not affect the oxygen saturation of the air inhaled through the device. In addition, in the operating instructions, the manufacturer warns that the U-2K will not protect the human respiratory system from exposure to hazardous gaseous vapors. The weight of the U-2K respirator is no more than 60 grams, its operating temperature range is from -40 to + 50 ° C.

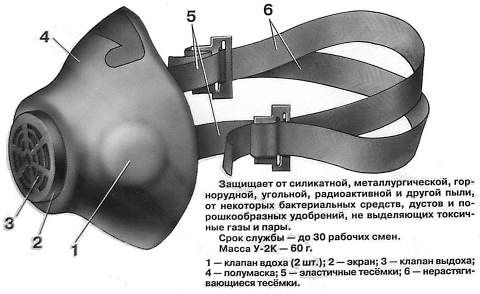

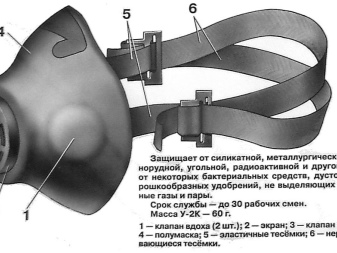

Three layers of filtering material are included in the set of the U-2K respirator. Foamed polyurethane (foam rubber), painted green, is used as the outer layer. An additional layer is a film made of dense polyethylene with valves for air inhalation. The layer reinforces the structure, which is located in the center, between the foam rubber and the film - this is a filter material made of polymer fibers. The valves, with the help of which the inhalation is carried out, are located at the front of the respirator; they have additional protection with a special screen. For ease of use, the protective device has an aluminum clip that allows you to fix the respirator in the nose area, and a thin rubber cord is mounted in the half mask around the perimeter, which makes it possible to tighten the edges of the device so that they are as close to the face as possible. In addition, for fixation on the head, the U-2K protective device is equipped with cotton and elastic slings, which are adjustable in length with the help of buckles.

Exhalation occurs through an opening called the expiratory valve. The inside of the respirator with moisture-resistant paint indicates the height of the person for whom this product is suitable. The manufacturer's marking and the date of manufacture of the product are indicated on the elastic band - this information is important, since the shelf life of this product is no more than 5 years.