Pros and cons of going to the workshop

The main plus of going to a workshop for repair or maintenance of a snow blower is that you only need to do the following:

- bring the unit;

- hand it over to the workshop workers;

- pick up the repaired device after their call.

Workshop workers independently:

- diagnose;

- determine the malfunction;

- purchase the necessary spare parts;

- will repair the unit.

There are much more disadvantages of going to the workshop:

- the need to deliver the unit to the workshop and take it back;

- high probability of poor-quality repairs;

- you do not know what parts the workers bought and what they put in your snow thrower;

- you do not control the process, so you do not know if the workshop workers actually did the work for which you have to pay.

The main disadvantage of contacting a workshop is the need to independently deliver a broken unit there.

If the snow blower is lightweight, it is easy to load and unload it yourself.

It is very difficult to load units weighing more than 50 kilograms into a car.

But there are snowblowers weighing over 100 kilograms, which are difficult to load even three of us.

Moreover, you will need to load and unload upon delivery to the workshop, then repeat the difficult procedure after repair. If the repair was performed poorly, you will have to perform all these steps again.

Many workshops offer paid shipping. But the prices for such services are usually high, especially since there will be two deliveries - to the workshop and back.

Because of this, the owner of the snow thrower is forced to travel to them several times. First, to carry out repairs, and then to re-repair or receive compensation.

In some cases, it is possible to obtain the payment of compensation or at least the money paid for the repair of the unit only through a court that lasts several months. After all, the judge can appoint various examinations to establish who is to blame for the breakdown of the snow blower.

Naturally, this is not always the case, but on many forums there are user complaints about the incompetence of employees:

- workshops;

- dealerships.

Therefore, you have to look for workshops with a good reputation, in which your relatives or friends have repaired the snow blowers.

And even in such workshops, there is a high probability that you will have to pay for works that were performed only on paper.

After all, the temptation is very great:

- assign extra work;

- get a few thousand rubles without much effort.

In addition, workshop workers purchase cheap non-original spare parts, and they demand payment as for original components.

After all, it is impossible to verify which parts were purchased by the workshop workers. Equally, it is impossible for an inexperienced snow blower owner to distinguish quality parts from defects or fakes.

How to properly change the lubricant - how to lubricate

Grease

Many people ask the question - how to remove the gearbox from the snow blower in order to make a scheduled lubricant change? This is not as easy as it seems at first glance, so we will describe this process in stages:

- We detach the plastic cover of the belt protection, as well as the cable of the drive auger.

- We unscrew the bolts that are located behind the snow ejection snail.

- Next, you need to remove the drive auger belt from the pulley.

- Next, you need to unscrew the bolts securing the auger shaft.

- Then you need to turn the snail to its natural position, after which we take up the gearbox and take out the screw mechanism with the impeller.

- We remove the shear bolts that attach the auger to the shaft, and then disassemble it.

- The gearbox itself must be disassembled into two components.

How to disassemble a snow blower gearbox with your own hands - a diagram

A reasonable question arises - how to disassemble the snow blower gearbox? The sequence of actions will be as follows:

- We clamp in a vice one of the parts of the shaft on which the gearbox is located.

- There are six bolts on the gearbox that connect the two halves of the housing. They need to be unscrewed.

- We take a hammer and tap the gearbox housing a little to make it easier to divide it into two halves.

Union

The disassembled parts of the gearbox are cleaned in gasoline to wash off the remnants of the old grease.

If you have a snow blower bought in a specialized store, then you should not have a question of how to lubricate the gearbox. All information is spelled out in the operating instructions for a specific model, it is also written there which type of lubricant is recommended for a specific gearbox.

However, it happens that it is quite difficult to find it. In such cases, gear lubricant is used for the gearbox of the snow blower from several manufacturers - Multifak, Litol, Tsiatim, etc.

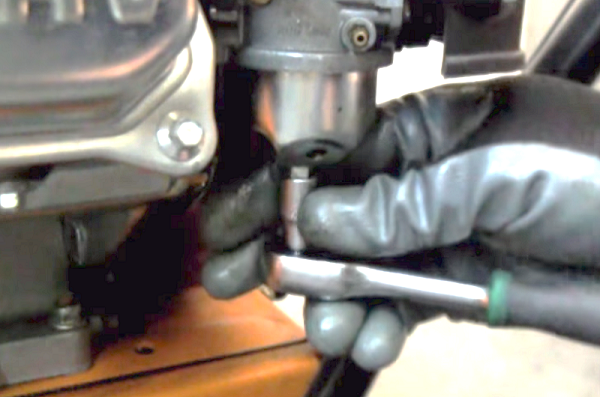

To add a certain amount of lubricant to the gearbox, you need to do the following:

Clean the reducer and the union from the existing dirt.

Unscrew the union and then pump in the required amount of grease with a syringe.

Screw the union back on.

It is important to understand that the presence of lubricant in the gearbox is a prerequisite for the high-quality operation of the entire snow blower. Therefore, it is necessary to replace it before each new season .. By the way, some companies warn the owner of the snowblower in advance that the gearbox is not completely filled with grease, so it must be filled after the first ten hours of operation of the unit.

DIY gearbox, see the video:

By the way, some companies warn the owner of the snowblower in advance that the gearbox is not completely filled with grease, so it must be filled after the first ten hours of operation of the unit.

DIY gearbox, see the video:

The most common breakdowns

In general, a lot of spare parts and components can break in a snow blower (see here). According to experts, the breakdown itself occurs as a result of improper operation of the unit by the person himself.

Snow blower breakdown

No wonder, in many application manuals it is directly written - before starting work, carefully read the instructions for the unit. But, the buyer very rarely adheres to this rule. First, the technique is used, it then breaks down, and then the person looks into the instructions.

By the way, there is quite useful information, in particular, how to fill in oil, how to start, what levers to press, etc.

There are several main breakdowns in a snow blower:

- Broken keys are one of the most common problems. shear bolts. They consist of soft metal, with the help of which the screw elements are attached. In the event that the unit runs over any obstacle, these bolts are sheared off, and the shaft itself stops.

- The dowels themselves are just a necessary consumable, which should be, as they say, "in reserve", each owner of a snow blower. Some people tend to replace them with ordinary bolts, thus wanting to save on the purchase of shear bolts.

- Instead, the result of such actions is a complete failure of the snowblower, as a result of which a replacement with a new unit. In general, shear bolts have a safety function, i.e. protect the more important components - the engine and the rotor mechanism.

- In second place is belt failure. Experts advise purchasing a spare drive belt directly with the purchase of the snow blower itself.The fact is that in the process of work, it wears out significantly, which inevitably leads to its breakage.

- In this case, we are talking not only about the belt going to the wheelbase, but also the drive belt of the auger mechanism, because they are both very vulnerable.

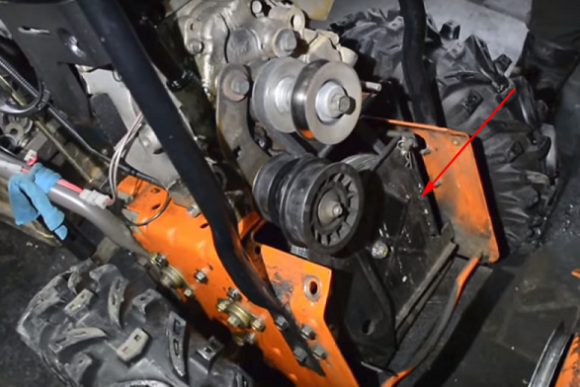

- The next most popular problem is the problem with the friction disc. It is the component that drives the wheelbase. The friction wheel, which is pressed against the disc, as it rotates, transfers movement to the wheels of the snow blower by means of gears.

- The increased load on the wheelbase can cause the friction ring to fail, causing the steel friction wheel to damage the soft structure of the friction disc made of aluminum.

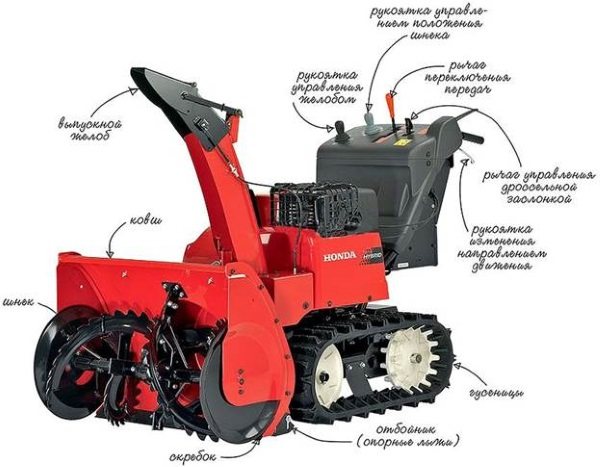

Construction of snowblowers

To learn how a snow blower works, you must first understand what it is made of. The main elements are a few details.

An engine that has a 4-stroke motor. These engines are pre-adapted for winter frosts with temperatures of -31 degrees. In most cases, motors from famous companies such as Briggs & Stratton, Tecumseh are in demand.

If the snow blower does not have an air filter, then this is a characteristic feature of a winter engine, since the filter can become clogged with snow, freeze up and turn into a plug. The snowblower must not be operated all year round, since the device can fail not only from winter dust, but also from ordinary dust. A sleeve motor is considered maintainable; it is installed on professional snow blowers.

The petrol model has a hand starter with a lanyard. Low-power cars have a manual start, while more powerful ones have an electric starter. The electric starter itself has two types - powered by a household electrical network and from an on-board battery. The first option can be started by connecting the motor to an outlet and pressing the button. To start a cold engine, you need an electric starter.

Snow blowers can be self-propelled or non-self-propelled. Often a manual transmission is installed on snowblowers. Some models have CVT and hydrostatic transmissions with different numbers of speeds. Snow blowers have 5 gears at the front and one gear at the rear.

The edge of the augers can be of two shapes: serrated and smooth.

The 2-stage snow plow has a strong, powerful auger. Its function is to crush adhering lumps of snow; it can also push snow towards the center of the bucket where the snow diverts to the impeller. The impeller itself will not be able to crush the snow. Its task is to set the speed for the incoming snow. Snow is thrown aside.

In single-stage types, the augers can touch the ground during rotation, so they are made of metal or rubber plastic. Thanks to the rubber-plastic material, the auger will easily withstand collisions with pebbles; will not break or deform. And the auger made of metal can break in this case.

The tires are branded with tread patterns X and V. These tires have good grip.

The outlet chute has two options: metal and plastic. Metal has practically no vibration. It is more durable and more accurate for throwing snow. But the plastic chute prevents snow from sticking to the device, it is much cheaper and will not be able to rust.

The gearbox can transfer torque from the shaft to the augers. Cross-country skis provide good glide. They support the front of the device. They can be adjusted in height by setting the degree of snow removal. There are reversible skis that can be simply turned over when worn. The scoring blade, which is located at the bottom of the bucket, must not touch the ground.

Snow throwers have chassis with wheels or tracks. Wheeled wheels move without turning on the engine.The tracks are more resistant to ice and slopes. The frame can include circular cross-section tubes. There are brands with rectangular tubes, they can provide the strength of the device.

The snow blowers also have the necessary headlights, which are charged using an on-board generator. All snow blowers have a control program with which you can adjust the engine speed, engage or disengage gear and wheel drive, you can adjust the height, direct the discharge of snow, and so on.

To set the direction, you need to rotate the outlet chute. Ordinary models have a handle for this. You can often find a worm gear. To make a turn, you need to turn a special handle.

It is very rare to find snow blowers that have an electrically driven directional design. Professional machines have levers on the panel. With the help of such a lever, you can change the height without interrupting the movement.

Causes of malfunctions and repairs

The main reason for shearing bolts is the owner's inattention to the coating he is processing. The fact is that there may be various stones, fittings, large pieces of ice, in contact with which there is a threat of damage to the engine.

Therefore, the bolts are cut off, thus stopping the rotation of the auger mechanism, so as not to aggravate the problem even more.

Repair

To prevent this from happening, it is necessary to pre-check the surface for the presence of various objects. By the way, this recommendation is directly spelled out in absolutely all operating instructions, which it would not hurt to read before starting to work with the snow blower.

There is quite useful information on the operation of the device, ways to quickly stop the engine, as well as precautions to avoid shearing the bolts.

This is very important, because these bolts cannot be repaired, and broken keys can only be replaced with new ones.

Considering that the average cost of one shear bolt is at least 100 rubles, a very frequent replacement can be a significant item in your budget.

Patriot

For example, a shear bolt for a Patriot snow blower will cost about 250 rubles. Considering that they are mainly sold in sets, then, in the end, shear bolts for Patriot snow blowers in the amount of three pieces will cost about one thousand rubles.

Ariens

Shear bolts for the Ariens snow blower are sold for about the same price - 300 rubles apiece. As a rule, several bolts fail at once, so it is advisable to purchase several sets of this consumable at once.

Ariens Shear Bolts

Champion

Shear bolts for Champion snow throwers come in several varieties - shear bolts and shear bolts with nut. Depending on this, their cost will add up - shear bolts with a nut will cost a little more.

As we can see, the price for shear bolts is about the same. There are certainly cheaper options for 100 rubles, but it is impractical to use them, because they may not fit a specific model of a snow blower.

Therefore, it is recommended to purchase strictly those components that are recommended for each machine, which is indicated in the technical passport of the device.

However, due to the fact that such bolts often fail, and the purchase of a kit costs at least one thousand rubles, the method of self-production of a shear bolt with the help of improvised means began to enjoy some interest.

Device and application

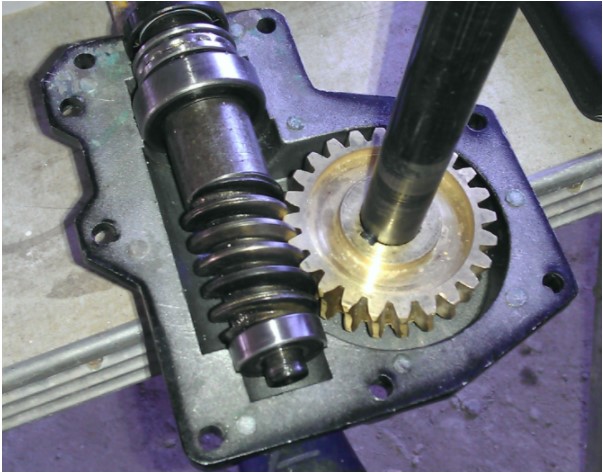

The torque from the engine of the snow blower is transmitted to the working system by means of a V-belt transmission and a power take-off shaft, to which the auger mechanism is connected through a gearbox, as well as a rotor. The gearbox itself is divided into two types:

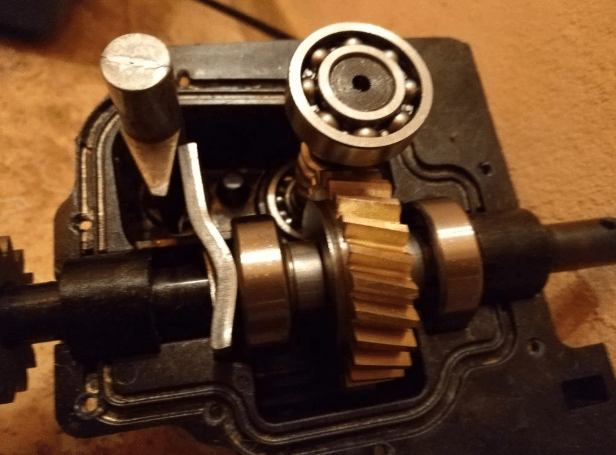

- Serviced. This type of gearbox must be periodically disassembled to change the lubricant. Such gearboxes have a longer service life, because the composition of the lubricant contains bronze components, which partially restore the gear wheel of the gearbox.

- Unattended.These gearboxes do not require any maintenance, but they are not repairable either. In the event of a breakdown, the gearbox is removed, and a new part is purchased in its place.

Reducer

As for the gear located inside the gearbox, it is made of soft metals. Basically, the material of manufacture is bronze.

This is understandable, because in the event of jamming of the auger mechanism, it is necessary to prevent damage to the engine, which is the main working unit of the snowblower. The augers themselves are attached to the shaft with shear bolts, which provide initial protection.

In the event of an emergency, these bolts are sheared off to avoid damage to the engine. If this does not help, then the gearbox will take the brunt of the blow, protecting the snow blower motor.

Depending on the classification of snow blowers, more precisely, the scope of their application, the type of gearbox housing also depends. For professional models of snow blowers, which are used to remove snow masses from large areas, the gearbox housing will consist of cast iron.

In turn, household-level models have a gearbox made of an alloy of silicon and aluminum. The body itself consists of two halves, which are bolted together.

Serviceable reducer

In addition, gearboxes may differ in their overall dimensions, as well as in the dimensions of the gear included in their device. This directly depends on the size of the snow blower bucket - the larger it is, the larger and the size of the gearbox itself.

When buying, you need to pay attention to this, because snowblowers of different capacities must also have different gearboxes. If representatives of one model range of units have different power, but one type of gearbox, then they are unlikely to be completely reliable

What to do if the snow blower won't start

First of all, check the fuel, and it is better to replace it. This is usually enough. But there are other reasons not related to gasoline:

- The snow blower oil sensor prevents the combustion engine from starting. First, the level and quality of the oil is checked, then the serviceability of the sensor.

- Starter does not start. Check the battery charge. If the starter is not broken, the snow blower should start after charging.

- The starter hardly turns the engine crankshaft. The reason may be strong thickening of the oil in the cold. Tow the vehicle to a warm area and leave it there until the snow blower oil has the desired fluidity.

If the problem is a malfunction in the candles, then they should be cleaned of carbon deposits, dried and installed well. Then check the condition of the candles. If they are working properly, and the device does not work, then the problem is in the ignition system. We need repair of snow removal equipment in terms of this system.

The snow blower won't start, what should I do?

The machine does not start well if the air filters are clogged. They should be rinsed and dried. Also, unregulated internal combustion engine valves can be the cause of unstable speed.

When the equipment does not start, the reason may lie in a carburetor malfunction. This can be caused by debris entering the fuel passages, which prevents fuel from entering the mixing chamber for the snow blower. The carburetor will need to be cleaned.

Common snow blower malfunctions and their causes

Snow blowers are quite easy to operate, and minor repairs to snow blowers can be done on your own. And spare parts for snow blowers are quite affordable.

The machine does not throw snow common malfunction

Frequent snow blower malfunctions:

- The car will not start - the spark plug is faulty.

- The snow plow engine is unstable - the spark plug electrodes are clogged or the gap between them is not adjusted.

- Dark exhaust fumes - poor fuel or choked carburetor choke.

- The device does not move forward - loosening of the cables and belts.

- Perceptible vibration - Mounting screws are loose.

- Starter rope stuck - flywheel jammed.

- The machine does not throw out snow - a foreign body has got into the auger, the protective bolt is cut off, the drive belt tension is poor, the auger is iced up.

Snow blower auger malfunction

If the auger does not spin or the rotation speed drops, then there may be such reasons:

- grind off protective bolts;

- weak tension or rupture of the auger drive cable;

- malfunction of the snow blower gearbox.

Replacing shear bolts

Shear bolts for the snow blower are needed in order to prevent malfunction of the gearbox, and therefore the auger. They are machined from non-solid metal and are used to secure the auger. When in contact with a hard obstacle, the bolts are cut off and the auger stops working. That is, the engine is running, and the snow is not thrown away.

Important! There is no point in repairing these bolts, they are simply replaced with new ones (the auger and shaft holes are aligned, the bolt is inserted and tightened)

Replacing the auger drive cable

Loose or broken auger drive cable may result in poor performance or stalling of the auger screw. To eliminate the loosening of the cable, the pressure on the pressure roller drive belt is adjusted. In the event of a break, the cable is replaced with a new one. To do this, it is removed from the handle and then separated from the pressure roller.

Malfunction of the auger gearbox and its repair

When the auger shaft stops spinning (or rotates in jerks), then it must be disassembled to find out the causes of the breakdown. The gearbox is most likely out of order from abrasion of the gear teeth.

For repairs, it is required to separate the snow blower from the engine. Then you need to disassemble the auger to the gearbox on the shaft.

Malfunction of the auger gearbox repair it

The gearbox is bolted from two halves, when unscrewing the gears are revealed. The damaged gear is replaced with a new one and the unit is assembled. In this case, it is better to service the snow blowers in a specialized center.

Important! During assembly, the halves of the gearbox must be thickly treated with graphite grease.

What kind of belt problems do snow blower owners face?

During its operation, the drive elements of the snowplow equipment are in constant motion and interact with other units of the unit. Because of this, they fail quite quickly. The list of typical snow blower belt faults includes:

- overheating and deformation - this occurs during the operation of the snow blower without interruptions for cooling. Due to intensive use, all important parts of the machine, including the drive part, heat up. It is made of soft elastic material that cannot withstand prolonged exposure to high temperatures. As a result, the drive element is deformed. To eliminate this, you need to give the unit some time to cool down. It is best to leave the car with the engine off for 10 minutes after every hour of operation;

- stretching - this problem is faced by those owners of snowblowers who, when using the unit, too often manipulate the throttle and auger drive levers. Each time you press the lever, the corresponding part is tightened, which, over time, leads to a change in its original factory length. To solve this problem in the future, you need to press the throttle and auger drive levers only when necessary;

- drying out - this malfunction causes insufficient lubrication of the drive parts. Because of this, the constantly heating elements of the snow blower lose their elasticity and shrink quickly;

- break - the cause of this malfunction lies in the banal wear of the part, or its constant contact with the hot assemblies of the snow blower. If during operation the snow blower constantly touches the heated mechanisms of the machine, then, over time, it breaks off.To prevent this, the operator must constantly monitor the location of the part in relation to other components of the machine.

Another common malfunction of the drive parts of a snow blower is associated with their blocking when passing the next turn on the shaft head. The cause of this problem is the accumulation of moisture, dust and oil, which interferes with the normal movement of the part. Regular cleaning of the belt compartment from snow and dust will help to solve this problem.

Another common malfunction of the drive parts of a snow blower is associated with their blocking when passing the next turn on the shaft head. The cause of this problem is the accumulation of moisture, dust and oil, which interferes with the normal movement of the part. Regular cleaning of the belt compartment from snow and dust will help to solve this problem.

Snow removal equipment repair - unit repair methods

In various models of snow blowers, there may be other breakdowns associated with the design features of these snow blowers. For example, repairs to Craftsman snow blowers often focus on troubleshooting the outlet chute. In this case, the first thing to do is to make sure that the safety bolts and the worm gear are intact. To do this, you will need to dismantle and disassemble the gearbox of the unit. This is done in the following order:

- First, detach the bucket from the machine frame;

- Next, carefully pull out the gearbox;

- Then remove and check the "worm" which is located on the shaft. Most often it is cut off the mechanism;

- To fix the problem, buy a new "worm" and install it instead of the old part.

For Patriot snowblowers, one of the most common problems is the lack of starting the engine. In such cases, experts advise to immediately check the engine compression. If this indicator is within 6-8 atmospheres, then the problem can be eliminated by replacing the old starter cord. To do this, you need to act in this order:

- Remove the protective panels and unscrew the return mechanism;

- Cut off the old cord and untie the knot inside the starter box;

- Turn the mechanism 7 full turns counterclockwise and fix it with a screwdriver;

- Insert the new cord and tie it into a tight knot where the old cord was attached;

- Release the return mechanism and it will rewind the cord itself.

If this does not help, then you will have to buy a new engine for the snow blower.

Owners of Profi brand snowblowers often have to figure out why their unit is not moving forward. The reason for this may be hidden in the gearbox of the machine. To quickly fix the problem, it is necessary to disassemble the assembly and replace the damaged gear inside it.

Owners of Energoprom snow blowers often do not know what to do with excessive vibration of equipment motors. First of all, you will need to check the reliability of the support frames and mountings for the engine of the unit. It is often sufficient to simply tighten the fastening bolts tighter and the problem will disappear immediately.

Instructions

Over time, everything breaks down. Any technique has a tensile strength and does not work forever. As for the Patriot, Champion, Honda, Foreman snow blowers, some of its units are specially prepared so that special simple parts break down in them.

Shear bolts

Thanks to this, all important parts can be kept intact. This part shear bolts is the second consumable of the snow blower, after gasoline.

Shear bolts are made in such a way that they would come off on their own in case of excessive load on the auger. In this case, the gearbox will remain intact, and the bolts just need to be replaced. But you will not learn to buy them all the time for reasons of economy.

Shear bolts

The cost of the kit, although not very large, becomes very tangible at high consumption. Therefore, it is worth seriously thinking about how to make shear bolts for a snow blower with your own hands.

To do this, you need to take bolts of the required diameter, be sure to pay attention that the diameter of the bolt is the same along the entire length, this is important, and just transfer the dimensions of the native shear bolt to the workpiece.Then you just need to make grooves in those places where they are on the native bolts

In principle, not a difficult operation, but useful for the wallet.

Caterpillars

As for the tracks for snow blowers MTD, Hooter, Kraftsman, Stiega, you will need a lot more tools and consumables. But the result will still be beyond praise. One of the simpler options is to make tracks from an old tire.

Its main advantage is that the result is a closed circuit, which means it is durable and reliable.

In production, it is also quite simple - an edge must be cut off from an old tire of the required size. A knife soaked in soapy water or a jigsaw with a fine-toothed attachment is suitable for this. After the jigsaw, it is best to process the edges, achieve more smoothness, to avoid tears.

If necessary, you can generally solder. The only drawback of this design is the fixed size of the future track. But if necessary, you can make a larger cut if you need a narrow track, or tie the two together if you need a wider one.

Reducer

As for the gearbox, everything is simple here - its service life is the longest of all moving parts. The gearbox transmits the driving moment from the motor to the auger, and is located on the auger axis.

In fact, several gears, with regular lubrication, will not cause any special problems, especially since the total time of using the snow blower does not exceed several tens of hours.

In this video, the assembly of the snow blower gearbox.

Friction disc

Another part that often breaks is the friction ring. Too much force on the wheels leads to the fact that a pair of wheel - friction disc slips, which is why the friction ring is worn out and then ruptured.

As a result, the friction wheel made of steel leaves deep grooves in the aluminum friction disc. But these are not the only problems. In the process, the belts are erased and the clutches are completely out of order.

And due to the fact that it is practically impossible to make such a ring at home, it is better to closely monitor the progress of the snow blower and not try to enter a skid on it.

The video shows the replacement of the friction disc.

Chains

Snowblower chains are just a parade of variety. Here you can see absolutely all of their types, especially if it is made by hand. Absolutely everything is suitable for connecting the motor and the auger. Bicycle chains are often used in DIY installations, along with bicycle sprockets.

But this option is only suitable for low-power units. As for the protection on the wheels, it can also be replaced with improvised means. It is enough to have at your disposal a piece of chain, and in the best case, a welding machine.

But if it is not there, you can do with a simple riveting with a hammer. The only condition for making the right chain for the wheel is that it should not be too small and too loose. And the best option is the shape of the ladder.

True, it is possible to make something like this at home, but such a product will be far from the functionality of the factory part. Here, cheapness is very inferior to quality.

Output

Self-service and repair of a snow blower has both pros and cons.

If you carry out the maximum number of routine and repair work with your snow blower yourself, then:

- you will save a lot;

- you will not be deceived by dishonest workshop workers.

However, with self-repair and maintenance, you will have no one to make claims in connection with poorly performed work.

By reading this article carefully, you:

- learned where to look for snow blower repair manuals;

- learned to select spare parts and consumables for them.

Thanks to this, you will be able to independently service or repair your snowblower, if for some reason it is impossible to carry out these works in:

- a good workshop;

- dealership.

In this video, you can look at an example of repairing a friction ring and find out a lot of useful information about the snow blower in general: