Preparing the walk-behind tractor for start-up

In the instructions, manufacturers always indicate how to properly start the walk-behind tractor. However, not everyone wants to waste time reading long pieces of paper and get down to work without familiarizing themselves with the operating rules. This is fraught with serious damage. It will not work to return under warranty the equipment that was used for other purposes or was broken through the fault of the owner. If the engine fails to start even once, even after several attempts, the reason may not be a bad part.

To make sure that the engine of the walk-behind tractor or the starting system is faulty, you must try to turn it on, exactly following the instructions. If the reason turns out to be in the wrong actions, you will not have to contact the repair. Sometimes it happens that the MB does not start and immediately stalls due to a factory defect. In this case, you can safely go to the warranty center to register a return.

When communicating with an employee, it is important to inform that everything was done according to the instructions and a breakdown due to the owner's fault could not arise

To start the walk-behind tractor:

- Check the oil level even if it was filled just a day ago. Sometimes sellers convince that the required amount of liquid has already been poured into the tank. You cannot believe in words, tk. an attempt to start the walk-behind tractor without oil will lead to breakdown and will not be accepted under warranty.

- Refill with fuel. The way to open the tank differs depending on the model, so read the instructions. For some types of engines, gasoline must be mixed with oil. The proportions are also indicated in the technical book.

- Open the petrol tap. Before doing this, it is necessary to move the pump lever to the “Start” position. The name differs depending on the manufacturer.

- Pump fuel from the tank with a starter and turn on the ignition. Then you need to pull on the starter and put the choke lever in the "Operation" mode. If everything is done correctly, the walk-behind tractor will start.

The described scheme of action is relevant for a gasoline engine without an electric starter, for example, the Lifan model. To start a diesel walk-behind tractor, you will have to spend more time. The main problem with this technique is its instability to frost. When the outside temperature drops, the fuel freezes, so the MB has to be warmed up before starting. The first attempt to turn on may fail if you do not pump the system with a starter, because everything inside is airy. Then, pump the decompressor several times. Some models indicate the exact time of this preparation. Usually it is enough to do this 5-6 times, and then pull it to its original position. If all points are completed correctly, to start the walk-behind tractor, just press the decompressor and turn on the starter.

Attention! If it was not possible to clean the airborne system by pumping the starter, you can unscrew the fuel cock and loosen all the supply connecting elements one by one. When the fuel runs out, everything must be returned to its original state.

Possible reasons

Does the walk-behind tractor start up and stall? Why it happens? There may be several reasons why motor vehicles do not start at start-up. These include:

- damage to the carburetor (in units with a gasoline engine);

- defect in ignition and heating devices;

- low base lubrication level.

When unusual changes occur in the unit, and its operation becomes unstable, first of all, the carburetor is checked. In this essential unit, the formation of a fuel-air mixture (FA) and its dosage for feeding into the cylinders of an internal combustion engine (ICE) takes place.And if the jets become clogged, an obstruction of the fuel system appears, due to which the carburetor loses its ability to guarantee the engine start. In order to eliminate the defect, the fuel line is repaired, which implies a partial analysis of the carburetor, flushing the pump, and purging the nozzles through the fuel nozzle.

When unusual changes occur in the unit, and its operation becomes unstable, first of all, the carburetor is checked. In this essential unit, the formation of a fuel-air mixture (FA) and its dosage for feeding into the cylinders of an internal combustion engine (ICE) takes place.And if the jets become clogged, an obstruction of the fuel system appears, due to which the carburetor loses its ability to guarantee the engine start. In order to eliminate the defect, the fuel line is repaired, which implies a partial analysis of the carburetor, flushing the pump, and purging the nozzles through the fuel nozzle.

If the Neva walk-behind tractor does not start, the reasons may also be different. Sometimes the problem is hidden in the malfunction of the spark plugs, which play an important role in starting the carburetor ICE, or the glow plugs, which ensure the start of the diesel engine. In the event that the fuse devices are made wet, which happens due to the throwing of their fuel assemblies, a spark begins to disappear in them. In the absence of sparking, the ignition of the fuel-air mixture does not occur, and, therefore, the engine cannot be started.

You can solve this problem in different ways:

- carry out minor repairs and replace non-working candles with new ones;

- "Burn through" the flooded candles and use a flame to clean them from traces of fuel.

The equipment does not start due to the fact that a defect in the glow plugs appears. In a diesel engine, fuel is ignited by contact with hot air, which heats up in the cylinder when compressed by the piston. This happens without complications if the unit is already warmed up, and the heated cylinder walls keep the operating temperature in it. However, in cool weather, the heating of the motor is performed using incandescent devices, and if they break down, it will not work to start the walk-behind tractor.

The equipment does not start due to the fact that a defect in the glow plugs appears. In a diesel engine, fuel is ignited by contact with hot air, which heats up in the cylinder when compressed by the piston. This happens without complications if the unit is already warmed up, and the heated cylinder walls keep the operating temperature in it. However, in cool weather, the heating of the motor is performed using incandescent devices, and if they break down, it will not work to start the walk-behind tractor.

If, when inspecting a carburetor engine or diesel engine, no defective candles were found, but difficulties persisted, and even accompanied by pops into the muffler, it is necessary to check the functionality of absolutely all devices responsible for the flammability of the fuel. A defect in them may also be a prerequisite for the walk-behind tractor not starting. It is more correct to carry out diagnostics in a service center, where specialists will find the cause of the damage and professionally carry out the restoration.

Motorcycle equipment will not start even if there is a lack of lubricant in the engine. Certain modifications are equipped with special control sensors, which, if there is a lack of lubrication, do not allow the engine to start.

Particular attention should be paid to those variants of machines that do not have such meters. Sooner or later, the degree of the lubricant mixture will reach the limiting value, and if it is not compensated to the norm, this will soon lead to wear of the elements and, as a result, to the overhaul of the motor.

Basic recommendations for common models

Motoblocks on the market are presented from different manufacturers. But, as practice shows, there are several models that domestic consumers trust the most and buy them more often:

- "Neva";

- MTZ;

- Ural;

- "Patriot".

Accordingly, the launch rules are different. When you should perform the following steps: transfer the ignition switch to the ON status, close the flap (fully) and open the fuel cock; set the throttle lever to ¾ from the maximum position, pull the starter rope and move the choke.

To the motoblocks of the Minsk plant (MTZ), a slightly different approach is needed. Gasoline models with a manual starter are started according to the following scheme: open the fuel tap, set the choke lever to start, turn off the ignition and pump the starter 3-5 times. Then you need to turn the key in the lock and pull the starter again. After starting, the choke lever is moved to the operating position. Diesel models require pumping (to bleed off the remaining air), after which you need to sharply twist the starter until the engine starts.

To start the "Ural", you need to resort to the following work: set the gearshift lever to the neutral position and open the gas tank. Next, you will need to completely close the throttle channel regulator and partially cover the air damper.Then start the engine using the cord.

Launching the Patriot involves a different procedure: bringing the throttle lever to the highest position, pulling the purge cable - first pulling hard and for a long time, then with short jerks to start the engine, and then adjusting the throttle stick.

Why Does the Engine Smoke on a Motoblock

In this section, we will analyze the malfunctions of motoblocks and cultivators of all Salyut brands. Neva, Bison, etc., and their elimination and repair. Most problems are common to all types of motor units, their engines and other components.

Engine power has dropped

It often happens that a previously serviced walk-behind tractor, which has served for several years, suddenly loses its strength.

- If the power has dropped after long-term storage, it is possible that the walk-behind tractor was stored with a wet carburetor and fuel system, which led to sedimentation. In this case, you can start the engine and let it run; power is often restored after these actions. If there are skills, you can disassemble and clean, if there are no skills, it is better to contact the service.

- The carburetor is probably clogged. clean

- The petrol hose is clogged. You need to blow.

- Possible loss of serviceability of the crankcase cuff. Remove the casing and cover of the transmission, inspect the seal.

- Carbon deposits on the cylinder, muffler. Clean.

- The air filter is clogged. Clean.

- Without compression. Change piston rings, cylinder, piston.

Engine won't start

- If the engine is tilted, must be horizontal.

- Fuel may not be supplied to the carburetor. It is necessary to disassemble and pass the fuel system.

Motoblock smoke no.

Lifan LIFAN smoke engine, reasons, heated carburetor.

The engine after repair and adjustment, worked fine for an hour. He started smoking an hour later and after 20 minutes.

- The filter may be clogged. The filter needs to be replaced or cleaned.

- The outlet on the gas tank cap may be clogged. It needs to be cleaned.

- Maybe it's a candle. It is necessary to check the connection of the wires, the engine stop button, remove the spark plug and clean it. Replace if necessary.

- Can refuse magneto. Replace.

Engine intermittent, stalls

- The engine is not yet warming up. It is necessary to warm up

- Potential contamination of the spark plug. It is necessary to clear the candle by removing the deposit.

- The end of the wire has little contact with the spark plug. Press the end of the wire firmly onto the plug.

- Malfunction of the magneto. Replace.

Motoblock foggy smoke

White smoke pours from the walk-behind tractor and starts working in the "chow".

- Possibly flooded with low-quality gasoline, or it is due to a strong tilt of the engine block. The oil from the crankcase tilts down and onto the valve, until it burns, smoke pours out of the stove. Also read the material "Repairing engine blocks"

The starter screams, the cord comes out

- May scream if balls have a lot of grease. It is necessary to clean the balls and the places in the ratchet where they are inserted.

The cultivator released some cotton, began to "float",

- Most likely, the power system is not coping, or the fuel level in the tank is low, the axis of the float may be skewed and, possibly, under the needle valve received by the debris, you need to remove everything and check the air filter, jets.

The material will be updated, we will wait for questions, stories about the detection of a particular malfunction and how to fix it. Also see the Answers to questions about a particular model of a walk-behind tractor on its description page.

Elimination of breakdowns

If you have any problems with your walk-behind tractor, then do not panic. Many of them are quite possible to eliminate with your own hands. It will be possible to make the setting or adjustment of certain systems without any problems, for example, to adjust the valves or idle speed.

Replacing many parts will also be pretty straightforward and straightforward. The main thing is to clearly follow all points of the instructions and act carefully so as not to damage the device.

The first step is to consider how to proceed if the walk-behind tractor stops starting normally and starts to stall during operation. So, first, let's figure out what to do if the indicated motorcycles do not develop revs to hot.

It is important to pay attention to several nuances.

- If you failed to start the technique with several attempts, then you need to inspect the candle. It is advisable to change it immediately.

- Check also the decompression and vacuum level in the tank.

- See if there is a spark coming from the wiring (this is best done in a fairly dark room).

- Make sure that the spark does not disappear under heating conditions.

If there are problems with the gearbox of the walk-behind tractor, then it is important to take into account the fact that it will be possible to repair it only if it is collapsible

If there are shortcomings with the supply of fuel, then here it is necessary to act as follows:

- look at the spark plugs - if they appear completely dry in front of you, then this indicates that the fuel does not penetrate the cylinders;

- pour fuel into the tank and restart the engine;

- look at the fuel cock - if it turns out to be closed, then you will need to replace its location to open;

- be sure to thoroughly clean the drain hole of the fuel tank;

- drain fuel, remove the tap and wash in clean fuel;

- and now remove the connecting hose located next to the carburetor, purge it together with the jets.

If we are talking not about a gasoline, but about a diesel walk-behind tractor, then here you can face the problem of turning the starter too lightly. This is usually due to poor cylinder decompression. To solve this problem, it is necessary to tighten all the nuts on the cylinder in turn, and also replace the gasket located on its head. You will also need to take a close look at the piston rings. If necessary, they will need to be washed or replaced with new ones.

But also diesel engines quite often suffer from clogged injectors. To get rid of such a nuisance, you will need to remove the damaged part, clean it thoroughly, and then install it in its original place. The main thing is to act carefully and consistently.

Often in motoblocks, a component such as a starter is damaged. Such a malfunction can seriously affect the operation of the motor vehicle engine. Basically, it happens that the screws of the starter fastening in the housing base are noticeably weakened. In this situation, the launch cord simply cannot move back to its original position.

If starter malfunctions are a sign of wear on a part such as a starter spring, then you need to be prepared for the fact that it will not be possible to repair it. A part that has undergone serious wear and tear will only need to be changed.

Consider what to do if there are problems with the engine speed.

- If the revolutions of motor vehicles grow on their own, this will indicate that the control levers and traction control have become weaker. These components will need to be adjusted again to resolve the above problem.

- If, when exposed to gas, the revolutions do not pick up, but fall, then you need to turn off the equipment - it may have overheated. Let the walk-behind tractor cool down.

- If the engine of motor vehicles functions with certain interruptions, then this may be due to a clogged filter or muffler. Turn off the walk-behind tractor, cool and remove all dirt and blockages of the necessary components of the structure.

The main malfunctions of motoblocks

Diesel and gasoline engines have different motor resources. For the former, the normal figure is 4000 m / h, but the latter are capable of providing only 1500 m / h. Despite this, diesel models of walk-behind tractors are not in high demand. After all, both during the purchase and during the operation they are much more expensive. Therefore, most likely you are working with a walk-behind tractor equipped with a gasoline (carburetor) engine.

All breakdowns that may arise during the operation of agricultural mini-equipment can be conditionally divided into two categories:

- Engine malfunctions:

- startup problems;

- malfunctions.

- Malfunctions of other units and mechanisms:

- improper clutch operation;

- breakdowns in the gearbox;

- chassis problems;

- malfunctions of control and automation;

- malfunctions of walk-behind tractor systems (cooling, lubrication, etc.).

In many ways, the success of the repair of a suddenly out of order machine depends on the correctness of the diagnostics. With regard to maintenance, it is carried out precisely in order to identify small malfunctions, which subsequently lead to serious ones.

Why does the walk-behind tractor smoke with black smoke

Only the lazy did not see how our pride goes. The only and unsinkable aircraft carrier "Kuzya". He even passed through the English Channel, and did not drown! Damn it! Well done, however, but there is one very noticeable jamb. It smokes, contagion! It smokes so much that the environmentalists from Greenpeace were all numb at once! Specifically, our boat polluted the ecology with its black smoke! Not them, not me! There are many versions, but mine is cooler! Someone wrote, they say, the smoke from the old fuel, it burns out like. What is not clear? And I think this smoke is for intimidation! A company of demobilized sailors is sitting in the engine compartment, stocking up on a bag of selected hemp, and smoking, releasing smoke into the chimney, frightening enemies! They are scared, but we are thrilled! Well done, our strategists! All of Europe, together with America, was scared! And now they get high on deck, sunbathe! Have you seen the pictures of our sailors sunbathing on deck? This is the company that handed over the shift to another company. Then they will change again. These are in the engine compartment, and those are on the deck! My version is good and may well turn out to be plausible. One thing is not clear: Why is the smoke black? Who paints it in the pipe. Glory to the Russian fleet! Forever and ever.

In this thread, we will disassemble the malfunctions of motoblocks and cultivators of all brands, Salute. Neva, Bison, etc., and their removal and repair. Most of the problems are typical for all types of motoblocks, their engines and other components.

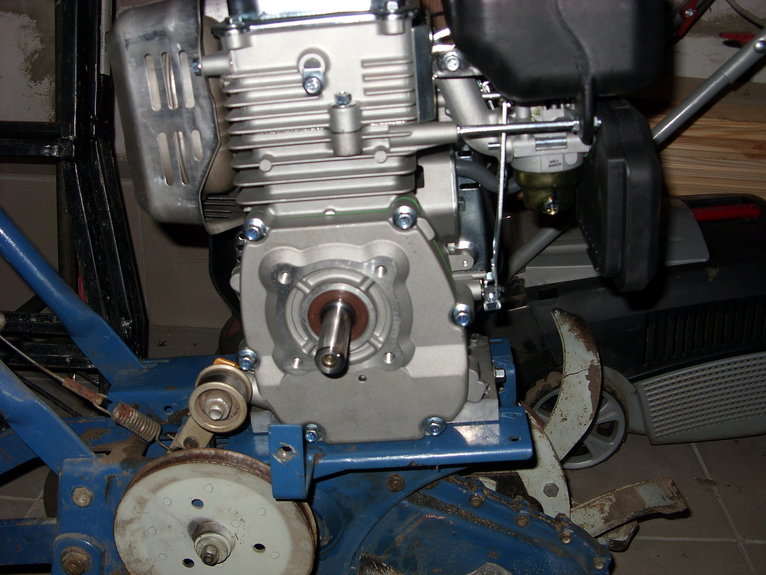

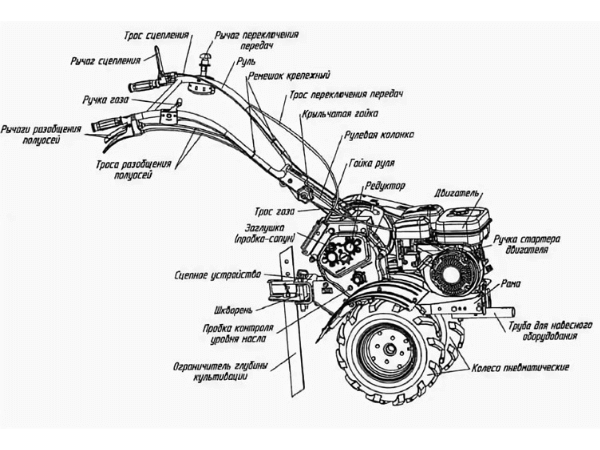

Walk-behind tractor design

First of all, the design of the cultivator depends on the type of engine used in it. It can be either two-stroke or four-stroke, run on gasoline or diesel. The engine used forms the basis of the device, so when the question arises why the walk-behind tractor stalls during operation or does not start at all, its nodes are considered to be the culprits. In addition to him, the motor-cultivator includes:

- transmission;

- chassis;

- Control block;

- hinged elements.

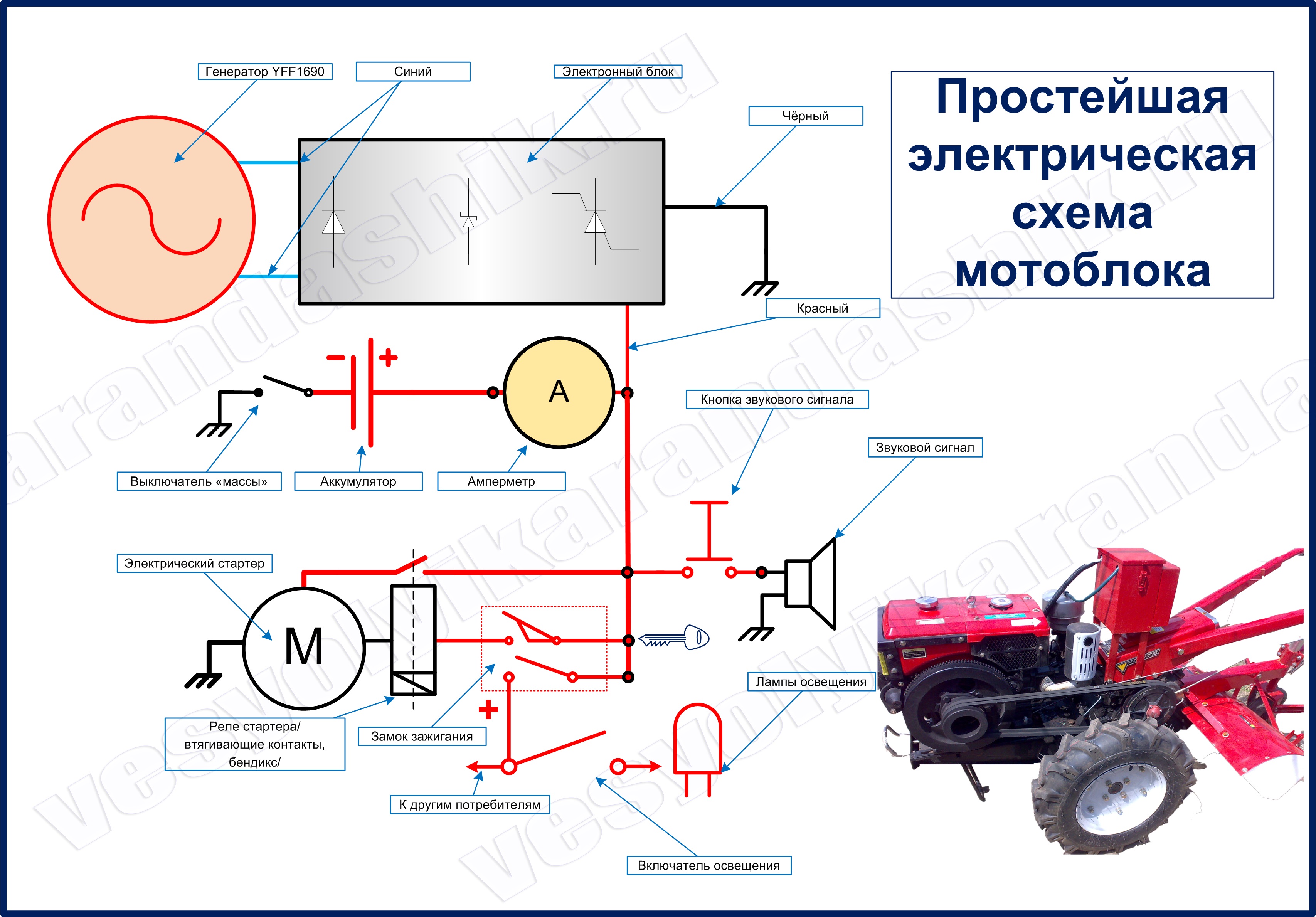

Each part of the device is characterized by its reliability and affects the flawless operation of the walk-behind tractor. To a greater extent, this applies to the transmission, which is subject to the greatest load during operation. Components and malfunctions that occur can be conditionally divided into electrical and mechanical. Mechanical assemblies include all elements involved in the transfer of kinetic energy, and electrical assemblies - electronic components that provide starting, control and maintenance of the engine.

Causes of malfunction

As soon as you find that the "Cascade" walk-behind tractor has stopped starting, you need to immediately start looking for the reason. Check the fuel level first. If it is not in the tank, the car will not start. But also with an overabundance of it, there can be problems. Check the spark plug, if it is completely wet, then there is too much fuel. You need to dry the spark plug and cylinder and try to start the unit again.

Another reason is battery discharge, but this only applies to walk-behind tractors with an electric starter. You just need to charge it, and no repairs are required.

There can also be several reasons why the engine does not start or does not develop power:

- Poor quality fuel. Always buy a proven brand of gasoline.Bad fuel must be replaced with good fuel;

- Dirty filter, which leads to insufficient air flow into the carburetor;

- The muffler is clogged with soot. You need to disassemble the muffler and, if necessary, thoroughly clean it from combustion products;

- Dirty carburetor. It is necessary to remove the part and carefully clean it of any contamination. However, it is better to do this after you have studied the operating instructions and any repair work;

- The ignition system is not working well. Clean the spark plug and also check the electrode gap. It needs to be configured.

Often, problems with starting a walk-behind tractor arise after winter. You can't just leave equipment in a cold, damp place. Because of this, various breakdowns will occur, such as corrosion, damage to the insulation of wires, oxidation of parts, watering of oil.

Before starting the unit after winter, you need to very carefully check each of its components. In this case, there should be no damage, bends. Check the oil level, as lack of oil will damage the piston system at start-up.

If the oil is old, the "Cascade" walk-behind tractor may also not start. It must be replaced immediately with a new one.

If you have a diesel unit, then immediately after purchase it requires careful and thorough running-in. There may be air in the fuel supply system. Do not rush to give heavy loads. Test the equipment, and after that you will be able to actively use it and not be afraid of various breakdowns. On the site you will find more detailed information about all breakdowns, their causes and remedies.

As you can see, there are a lot of reasons why the "Cascade" walk-behind tractor does not start. If you understand technology, then it will not be difficult for you to quickly solve all the problems and start working again on cultivating the land and caring for the site using a walk-behind tractor.

Subscribe to us

Other common problems when starting the engine

What to do if the motor of the walk-behind tractor works intermittently and does not develop the required power? There may be several reasons for this behavior:

- Clogged air filter.

Air does not enter the carburetor, which means that the fuel does not burn well - the filter will have to be cleaned or changed.

Fuel residues and combustion products form a thick deposit on the inner walls of the muffler, which must be removed.

In this case, the assembly will have to be removed, disassembled and properly cleaned all of its components. After that, the carburetor must be assembled and properly adjusted.

- Wear of the cylinder-piston group.

Temperature and high loads do their job, and even the most durable metal wears out and deforms over time. Such parts should be replaced immediately, otherwise you can pay for this with irreparable damage in the engine itself.

- Damaged ratchet housing or ratchet

The presence of this problem is indicated by the lack of movement of the crankshaft when the engine is started. To replace the clutch housing and ratchet, you will have to completely disassemble the starting block.

- Loosen the screws securing the starter housing to the engine housing.

If the starter cord does not return to its original position, the starter must be adjusted. For this, the screws are loosened, and the position of the knot is set by hand so as to ensure the normal return of the cord.

A fairly common reason for the lack of return travel of the starter cord is the failure of the starter spring - it will have to be replaced.

The service life of any equipment is significantly increased by competent maintenance of its main units and components. The promptness of replacing worn-out spare parts is also of great importance. Therefore, in the event of the slightest malfunctions and malfunctions, they should be addressed immediately - as a result, this will prevent much more serious and expensive problems.