Device, features of the use of a bottle-type jack

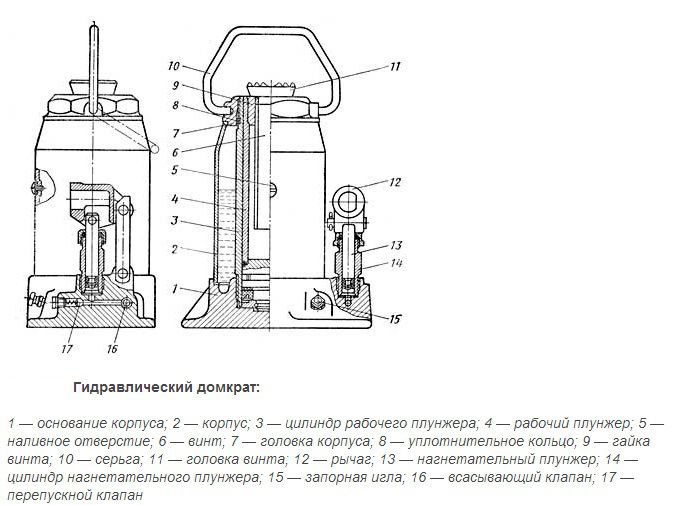

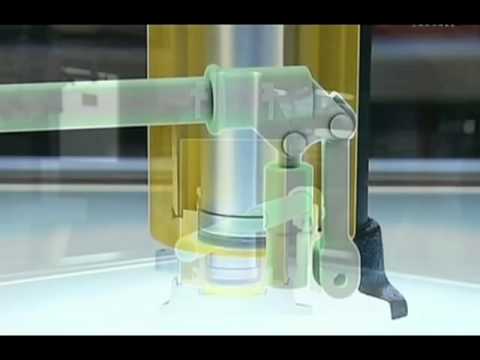

The illustration shows the components of the hydraulic lift.

The entire structure fits inside the reservoir with the working fluid. The lifting rod in the down position is completely recessed in the body. The lever handle is removable and does not take up much space in the transport position. Therefore, this type of jack easily fits in the trunk of a car.

A device capable of lifting a solid SUV (force of 5 tons) - measures (taking into account the unfastened handle) no more than a 0.7 liter bottle of wine. One person can handle such a jack.

- Easy to operate and maintain;

- High efficiency - up to 80%;

- Low effort on the working handle;

- Smooth operation due to the use of liquid;

- Possibility to control the lifting height with high precision;

- High reliability due to the absence of rotating and rubbing parts with effort;

- Lifetime - apart from O-rings, there is nothing to wear in the bottle jack;

- A good indicator of safety in work - in the event of a breakdown, a sharp fall of the lifted object or throwing a part of the tool towards the side is excluded;

- Wide range of applications, not limited to the operation only in cars.

- The jack body height is practically equal to the lifting height. This is typical for single-rod designs; telescopic (multi-rod) options are free from this drawback. This feature is partially compensated for by the screw - an extension cord that is unscrewed from the stem. Due to this drawback, the initial lifting height starts from 20-25 cm. This limits the dimensions of the device;

- Slowness. One cycle of operation of the injection pump provides a lift to an insignificant height. The higher the lifting capacity, the more movements of the handle must be made to lift;

- Inability to accurately control the height of lowering the load;

- Work only in an upright position. In a tilted or horizontal state, air will enter the hydraulic system, and it will have to be pumped;

- Large mass of the device, taking into account the working fluid;

- The high cost of the product.

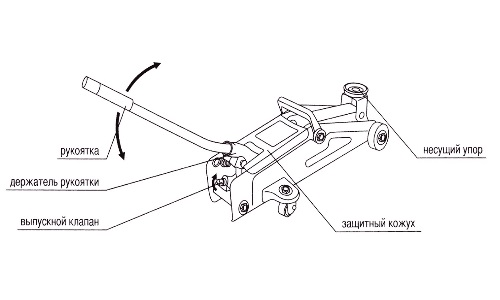

For work with low initial heights (for example, cars with a low landing), a rolling jack is used. It works according to a lever scheme, and a hydraulic cylinder is used as a driving force, as in a conventional bottle jack.

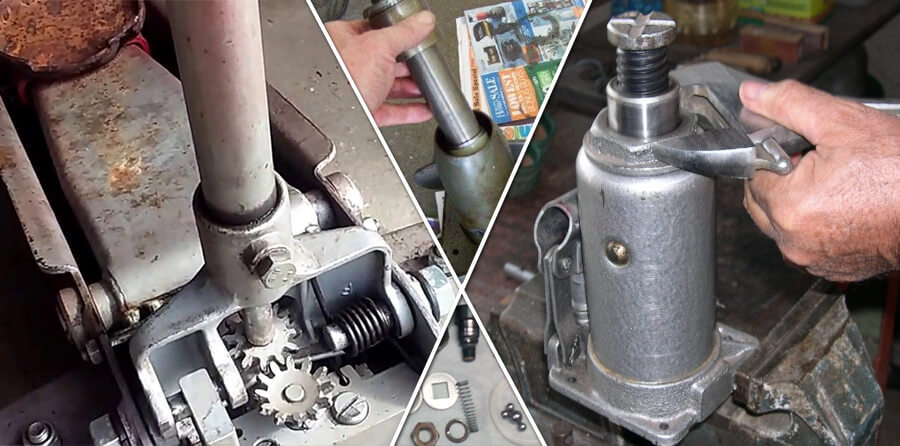

DIY hydraulic jack repair - features

The most common problem faced by the owners of these devices is oil leakage. Hydraulic jacks are designed with multiple oil seals and seals. Accordingly, under constant loads, they gradually lose their original properties. However, other malfunctions are also possible here, for example, air entering the cylinder.

The most common problem faced by the owners of these devices is oil leakage. Hydraulic jacks are designed with multiple oil seals and seals. Accordingly, under constant loads, they gradually lose their original properties. However, other malfunctions are also possible here, for example, air entering the cylinder.

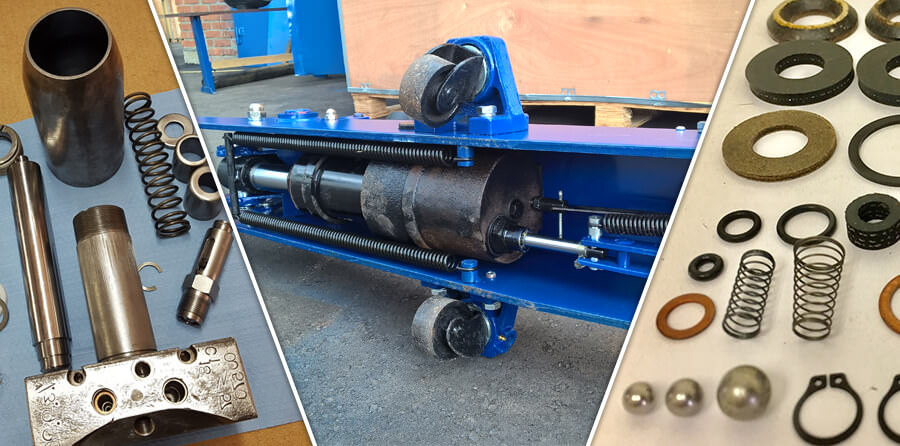

If the problem is oil leakage from the jack, then you will have to buy a special repair kit - it can be easily purchased in a specialized store or ordered via the Internet, choosing for a specific model. In this case, it will be necessary to replace certain parts of the jack that have lost their functionality due to natural wear and tear or mechanical damage.

It should be noted that in the process of such a repair, an oil change will be required. Accordingly, you need to buy a new one in advance in the required amount, as well as prepare a container into which you will drain the old one. It is not difficult to drain the oil from the jack - this is done by pumping the system. You will also need a set of keys - they will be needed to disassemble the jack.

The next part of the jack, which will need to be carefully inspected, is a valve that allows an incompressible fluid to pass through. We remove the part and examine it for deformations or dirt.In the second case, in order to restore the previous functionality of the jack, the valve can be simply cleaned, thereby eliminating the problem associated with oil leakage. If damage is found, the part will need to be replaced. If the external examination did not reveal any damage, then it is enough just to rinse all the parts in kerosene, removing dirt and remnants of old oil. In addition, it will be gentle to install new oil seals and seals from the purchased repair kit.

The next part of the jack, which will need to be carefully inspected, is a valve that allows an incompressible fluid to pass through. We remove the part and examine it for deformations or dirt.In the second case, in order to restore the previous functionality of the jack, the valve can be simply cleaned, thereby eliminating the problem associated with oil leakage. If damage is found, the part will need to be replaced. If the external examination did not reveal any damage, then it is enough just to rinse all the parts in kerosene, removing dirt and remnants of old oil. In addition, it will be gentle to install new oil seals and seals from the purchased repair kit.

Another, quite often encountered in hydraulic jacks, malfunction is air or dirt trapped in the working cavity. All this negatively affects the functionality of the device. Typically, this problem is caused by an insufficient volume of fluid in the hydraulic system. In most cases, it is because of this that air penetrates into it. Its presence, in turn, leads to the fact that the jack cannot cope with its functions, that is, raise the car to a certain height, or it will work very slowly.

In order to fix this problem, we need to open the bypass valve and the oil tank. Next, we pump the jack pump several times - this must be done quickly enough. This removes air that has entered the system that would interfere with the normal operation of the jack. After completion of pumping, close the bypass valve and replace the oil tank plug. Rarely, but still there are situations when one pumping does not help to fix the problem. In this case, you will need to repeat the procedure - sometimes several times.

In order to fix this problem, we need to open the bypass valve and the oil tank. Next, we pump the jack pump several times - this must be done quickly enough. This removes air that has entered the system that would interfere with the normal operation of the jack. After completion of pumping, close the bypass valve and replace the oil tank plug. Rarely, but still there are situations when one pumping does not help to fix the problem. In this case, you will need to repeat the procedure - sometimes several times.

It should be noted that air can be removed from the system in another way. To do this, first unscrew the shut-off needle. Next, we raise the plunger to the upper position - this is done using a special screw - and again lower it to its original position. It is best to repeat this procedure several times to ensure that air is removed from the system. In order not to worry about this problem in the future, it is recommended to periodically check the oil level in the working cavity. The more often you do this, the better. Topping up oil on time will help prevent air from entering the system.

If the malfunction is associated with the ingress of dirt into the working cavity, then here you need to proceed as follows. First, remove the head of the case, and then drain the old oil and pour kerosene inside. Next, we pump the mechanism with the shut-off needle removed. That's all - all that remains is to drain the kerosene and pour new oil into the jack. As you can see, it is quite possible to carry out all the work listed above with your own hands. There really is nothing complicated here, and the main task is to properly disassemble and then assemble the jack.

How to pump a hydraulic jack is a very common question among car owners. But it is also worth knowing about the device and types of the unit.

Air bubbles and how to fix this problem

As for the operating efficiency of the hydraulic rolling jack, it in most cases decreases due to the accumulation of air bubbles in the master cylinder. Bubble formation can be triggered by an insufficient amount of fluid in the working cavity.

Before carrying out repair work in such cases, you must first unscrew the plug in the oil tank and remove the bypass switch, after which you can start pumping the pump of the mechanism. This is necessary in order for the air bubbles to move from the cavity to the fluid container. After the pumping procedure, the tank lid and the bypass valve are closed, if all operations have been performed correctly, the jack will function normally.

Pumping oil into the hydraulic lift

Pumping oil into the hydraulic lift

Note!

If, after pumping, air residues were detected in the working fluid, it is recommended to resort to the procedure again.

Experienced experts recommend using another common method to remove air bubbles from the jack. To do this, the shut-off needle must be unscrewed no more than 2 turns, and with the help of a hand, the plunger must be lifted to the extreme point. After raising the toggle switch, after a certain period of time, it will return to its lowest position. It is worth noting that the procedure often needs to be resorted to 2-3 times, and in order to prevent air from accumulating in the working system of the lift, during its use it is necessary to control the volumes of the working fluid. If there is not enough oil, it should be topped up, while monitoring the quality, and also the cuffs for the rolling jack should be changed in time.

In order to prevent unwanted breakdowns of Chinese hydraulic lifting mechanisms, with their intensive use, it is imperative to change the working fluid and wonder why the rolling jack does not lift under load. It is worth remembering that if the oil level drops, it should be topped up, and then the entire structure should be pumped. Before proceeding with the repair work, it is imperative to study the manufacturer's recommendations, which are indicated in the technical passport attached to the jack. Otherwise, if you ignore all the recommendations, you can provoke a premature breakdown of the tool without the possibility of its further restoration.

Types of hydraulic jacks

Take a factory one or assemble a homemade one - it's up to you. There are various types of hydraulic jacks on the market. Each of them has its own characteristics, which you should know about in advance before purchasing a device.

- Bottle-type unit. The most common and at the same time the most constructively simple variation of a hydraulic jack. Bottle lifters lift loads up to 100 tonnes, have an impressive footprint and a compact body. They are widely used for work in car services. The bottle hydraulic jack has two modifications - single-rod and double-rod. The first ones have a simple design, they are used in construction, repair of railway cars, in the manufacture of pipe bending and pipe cutting units. The two-rod mechanism can work in vertical and horizontal positions.

- Roll-up. The rolling device outwardly resembles a trolley moving under the load being lifted. It is operated by a hand lever, the adjustment is carried out by oil valves. It shows itself perfectly when lifting a load on one side, it is important to use it when replacing wheels with a car. But it requires a flat, hard surface to work. It happens homemade.

- Hybrid. It combines a bottle and roll-type hydraulic jack, is widely used in car services. Control is carried out by levers and foot pedals.

- Rhombus. Relevant for car service. Its supporting structure is connected by hinges and forms a rhombus, which influenced the name of the device. Compact, relatively lightweight, easy to transport.

- Hook-on. They are used where it is necessary to lift a load from a low height. For its work, a bottle scheme is used. Maybe homemade.

Assembling a home-made unit with your own hands, or buying a bottle-type hydraulic factory jack is your personal decision.

What does a hydraulic jack consist of?

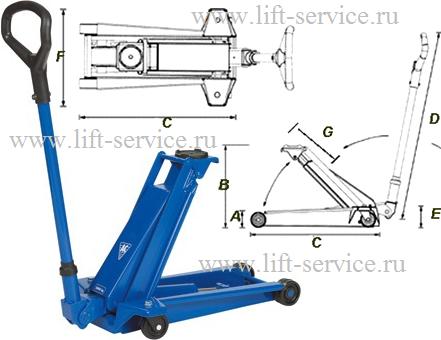

Rolling hydraulic jack

Rolling hydraulic jack

The main parts of hydraulic jacks are:

- liquid, which is most often used as oil;

- device body;

- a piston that extends from the cylinder.

For the production of the body of this hydraulic type device, strong hardened steel is used.The main functions of the body - it also acts as a guide cylinder for the extended piston, as well as a reservoir for oil or any other working fluid.

This jack can be equipped with a hydraulic pump that is air, hand or foot operated. The retractable hydraulic cylinder and the lifting mechanism itself are located in the openings of the device body.

The most commonly used hydraulic jacks of the bottle and rolling type are nowadays. The first type is widely used in the automotive industry, as well as in the quality of power units for presses and other similar equipment. Rolling jacks differ from the previous ones in the arrangement of the working cylinder, which is not installed strictly vertically. It is most often used by motorists to repair cars, as well as at service stations for the same purpose.

The design and principle of operation of the rolling jack

The design of a rolling lift is somewhat similar to a trolley on wheels, which allows you to adjust and use the mechanism for repairing any car. This model of the lift is distinguished by the presence of additional attachments, which several times increase the possibilities of its use.

Note!

If we consider the principle of operation of the rolling mechanism, then it is similar to the operation of a hydraulic bottle jack. The only difference is the ease of use and design. Metal is used to make the body of the lift, after which it is mounted on two pairs of wheels

Mechanisms are pre-built into the jack body, with the help of which the vehicle is lifted, as well as a hydraulic cylinder, which in the retractable position provides support and lifting of the working platform. Due to the fact that the platform rises, the load will be lifted to a certain height level

For the manufacture of the body of the lift, metal is used, after which it is mounted on two pairs of wheels. Mechanisms are pre-built into the jack body, with the help of which the vehicle is lifted, as well as a hydraulic cylinder, which in the retractable position provides support and lifting of the working platform. Due to the fact that the platform rises, the load will be lifted to a certain height level.

With a lever, the hydraulic rolling jack structure can be easily moved. To lower the platform, use the handle to turn the screw, which will open a spare sample of the special valve. As a result of the release of oil pressure in the working cylinder, the vehicle will be lowered to the desired level.

Professional and industrial use involves the operation of various models of rolling mechanisms capable of lifting and fixing loads weighing more than 20 tons.

The disadvantages of such structures are represented by their high weight, which prevents their transportation, as well as the obligatory presence of a flat, solid and horizontal surface.

Rolling jack design

Rolling jack design