Description

Motoblocks Zubr, Cayman, Patriot, Texas, Foreman, Crossser, Viking, Forza are quite popular among buyers who appreciate the optimal combination of price and quality. Their use is advisable for a variety of agricultural work, with which this technique perfectly copes.

Here is just an incomplete list of what these walk-behind tractors are used for:

plowing of soil of different density;

- soil cultivation;

- mowing grass for making hay;

- harvesting (beets, potatoes, etc.);

- tillage between beds, etc.

As we can see, the Bison does almost all the work that is typical for the countryside. This is a real helper for any farmer who spends his time with benefit, i.e. cultivates the land, plants potatoes and other root crops, takes care of livestock, etc.

Such popularity is fully justified, because in the production of Zubr motoblocks, only high-quality components that have passed special testing are used. In general, the Zubrov lineup is quite extensive, ranging from small capacities to heavy units with power plants.

Today we have presented to our attention the Zubr diesel motoblocks with a 6 hp engine, in which diesel is used as fuel. This circumstance allows them to show higher performance indicators than engines of similar power, but running on gasoline.

In addition, diesel fuel is more economical, which is an additional plus in the direction of these motoblocks. In the category of diesel motoblocks with a power of 6 hp, the Zubr company is represented by the NT 105 model, which can cope with even the most difficult plots of land, i.e. virgin lands.

This became possible thanks to the use of a worm gear and multi-plate clutch included in the design of the unit.

If you have a full-fledged land plot with a vegetable garden and livestock, then it makes sense for you to purchase additional attachments for this walk-behind tractor, which will significantly expand the scope of its application:

- transportation of various goods;

- thanks to the use of a potato planter, you can plant potatoes in your garden rather quickly and efficiently;

- cleaning of snow masses, etc.

As standard, the Zubr diesel walk-behind tractor has a rotary tiller and pneumatic wheels. Even this minimal set is quite enough to compete with European manufacturers, differing from them in a more acceptable price.

For our compatriots, this is the competitive advantage that creates an increased demand for Bison equipment.

Specifications and price

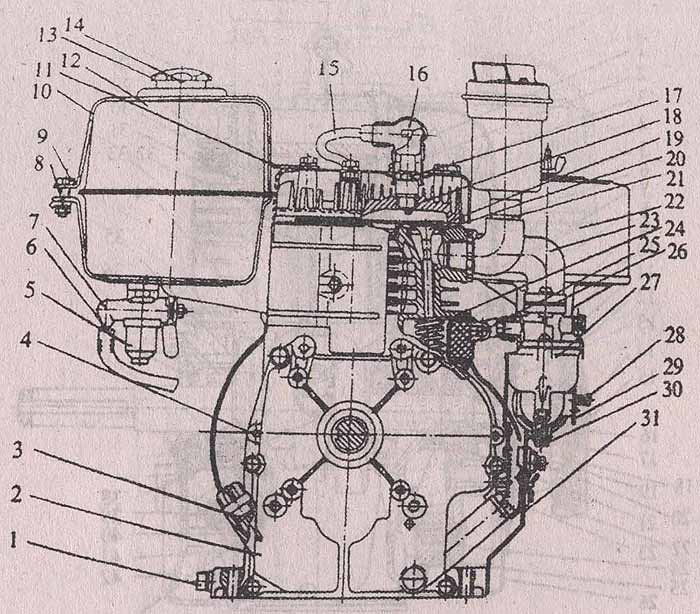

Motoblock Zubr NT 105 has a 4-stroke diesel engine of the KM178F brand.

HT 105

In addition, it has the following technical characteristics:

- type of fuel used - diesel;

- engine displacement - 296 cm3;

- maximum power - 6 hp;

- fuel tank volume - 3.5 l;

- width of the processed strip - adjustable, from 75 cm to 105 cm;

- digging depth - adjustable, from 80 to 300 mm;

- clutch type - multi-disc, in an oil bath;

- speeds - two forward and one backward;

- total weight - 120 kg;

- fuel consumption - 1.5 liters per one hour of operation;

- start type - manual;

- lifting capacity - 350 kg;

- type of cooling - air;

- overall dimensions - 174cm / 150cm / 98cm.

The price of this unit is about 35 thousand rubles.

This price does not include attachments, which must be purchased separately.

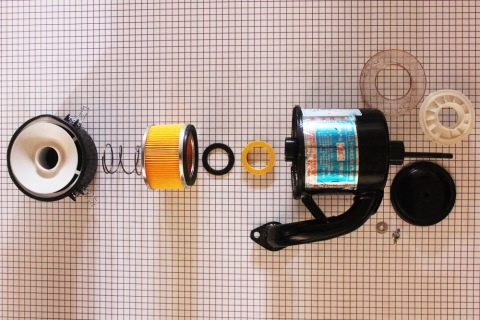

Self-cleaning of the unit carburetor

Do-it-yourself repair of a motor-cultivator is often associated with cleaning the carburetor. To do this, the assembly must be completely disassembled and cleaned according to the manufacturer's recommendations. The algorithm of work, as a rule, is described in detail in the operating instructions for the cultivator. All cleaning procedures performed are intended to restore the uniformity of the carburetor float immersion. To do this, it is also necessary to eliminate the deformation of the bracket, by means of which the float is attached to the piston system.

The dive setting is done with both open and closed needle valves. Use a screwdriver to align the bracket. All manipulations must be clear and accurate.

Along with the elimination of deformation, it will also be necessary to adjust the valves of the cultivator.

To do this, check the tightness of each of them. Performing this procedure allows you to restore the functions of the carburetor and return the amount of fuel consumed by it to normal.

Specifications

Motoblock Master with an American Quantum engine has the following technical characteristics:

- engine power - 5.5 hp;

- tank capacity - 3.6 liters;

- fuel consumption - 1.2 l / h;

- tillage depth - 25 cm;

- width of capture by cutters - 60 cm;

- weight without additional options - 45 kg;

- length with handle in working position - 130 cm;

- width - 70 cm;

- height - 98 cm;

- dimensions in transport condition - 78 × 57 × 75 cm.

You can buy a new walk-behind tractor in Moscow for 23,000-25,000 rubles, a full set of Russian-made options will cost another 9,000-11,000 rubles.

Analogs

The following models are similar in size and technical characteristics of the Master MK-265 walk-behind tractor:

- Champion BC 6712;

- Farmer;

- Centaur;

- AL-KO MH 4005;

- Gardena EH 600;

- Daewoo Dat4555;

- Lux 1400;

- GMC-1.8;

- Bison NT 105.

The price of the product depends on the type of power plant, the country of the manufacturer and the configuration.

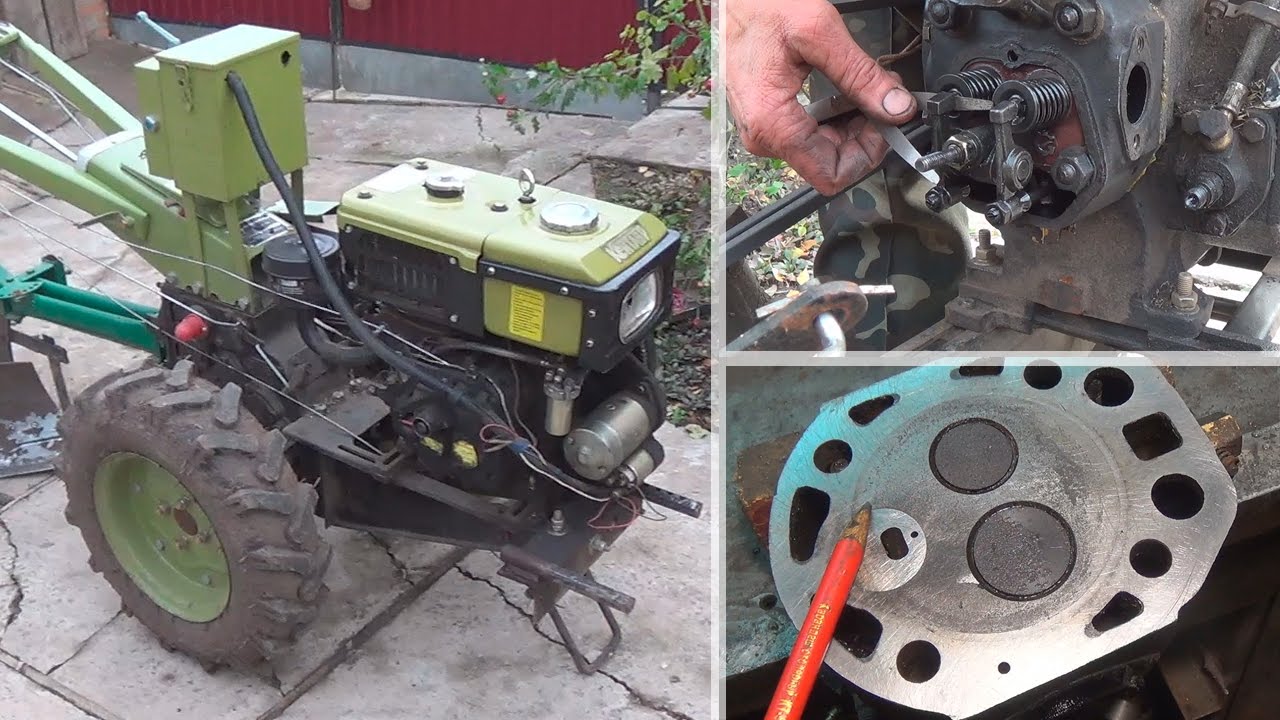

How to disassemble the engine

It is also necessary to disassemble the walk-behind tractor engine and inspect all components. Replace all defective, deformed or damaged parts with similar new ones. You can also inspect the carburetor, air filter and muffler, because there may be problems such as clogging or simple contamination.

In this case, you urgently need to inspect, disassemble and clean every part and assemble it again, if this is not done and the engine is used further, despite the poor condition, then new, already faulty breakdowns may appear. There may also be problems with the clutch housing or ratchet, then you need to disassemble the starting block and replace the defective part with a new one. It is also advisable to inspect the cylinder-piston part of the engine, because they also tend to wear out and break, if so, then they should also be replaced with new ones.

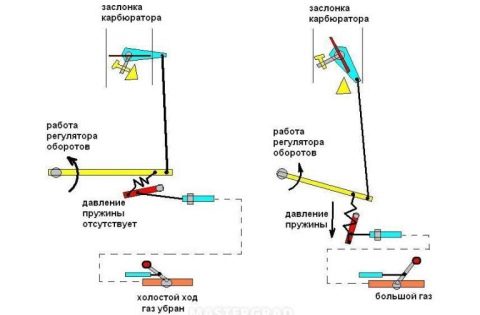

Adjusting the carburetor of the walk-behind tractor

The instability of the engine speed of the walk-behind tractor indicates that the carburetor needs adjustment. The need to perform this procedure, as a rule, arises before the start of the agricultural season, when the equipment has not been used for a long time, or after it, when the walk-behind tractor has been subjected to significant loads for a long period of time. Before proceeding with the adjustment, it is necessary to warm up the engine. The work process itself looks like this:

- The screws regulating low and maximum throttle are screwed in completely, after which they are loosened by about one and a half turns.

- The motor starts and warms up for about 10 minutes.

- The lever that controls the operation of the power plant should be set to the minimum position, but the motor should not stop.

- The throttle throttle adjusting screw will help to adjust the minimum idle speed so that the engine is stable, without extraneous noise and stops.

- The rotation of the screws makes it possible to accurately set the amount of combustible mixture that enters the motor.

- Tightening the screw contributes to the enrichment of the mixture, while unscrewing it, on the contrary, increases the volume of air entering the engine;

Using the idle screw, adjust the maximum idle speed. The same should be done with minimum speed, using the throttle stop screw. The essence of such an adjustment is that the shutter screw allows you to adjust the angle to which it is closed;

The lever responsible for controlling the engine should be moved to the “throttle” position. If the operation of the walk-behind tractor still cannot be called stable, the full throttle screw is adjusted until an ideal stroke is observed. However, the maximum permissible propeller speed is 2.5.

The accuracy of carburetor adjustment can also be determined by how the spark plug looks after a short period of time under load. If the working mixture is ideal, then there will be neither carbon deposits nor traces of fuel on the candle, which indicate too poor or, conversely, too rich combustible mixture. However, it should be noted that carbon deposits or traces of fuel on the spark plug can indicate not only incorrect adjustment, but also more serious problems of the walk-behind tractor, including faulty ignition or the cooling system.

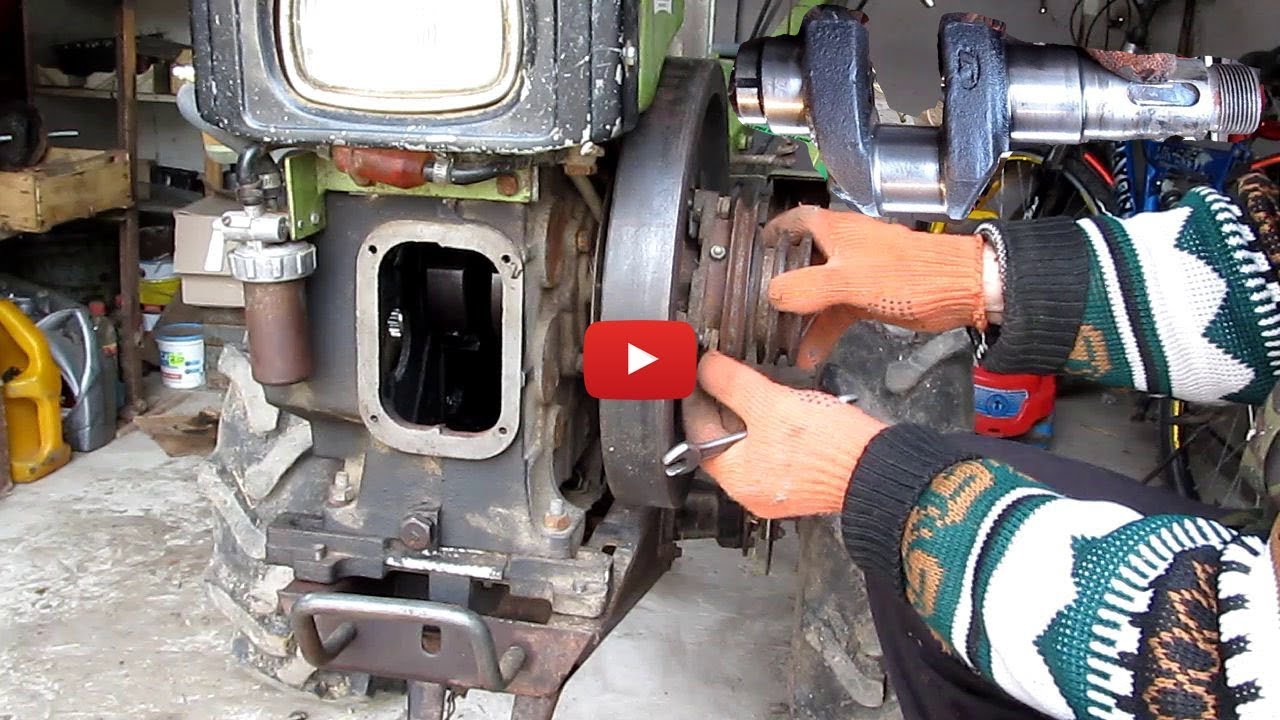

Adjusting the valve clearance of the walk-behind tractor

Over time, with significant loads, the valve clearance of the walk-behind tractor engine changes. This may be due to wear on parts. Insufficient distance leads to the fact that the stages of gas distribution change significantly, as a result of which it is not possible to achieve a sufficient compression ratio, the power plant works intermittently and does not reach the declared power. In especially serious situations, you can even observe the deformation of the valves. If the gap is too large, significant mechanical noises are recorded, the gas distribution phases also change significantly, the valves open for too short a time, due to which the cylinder does not fill up properly, the power drops, and malfunctions occur. Clearance adjustment is necessary immediately, as soon as the engine operation becomes incorrect or occurs with significant noise. Ideally, the engine being adjusted should be cool.

So, first you need to get to the flywheel. It is on this part that the value of the top dead center is marked. The flywheel is hidden under the cover, and therefore will have to be removed. Before removing the casing, the oil bath of the air filter is removed. It is possible to facilitate the task in the process of removing the casing if you fix all the latches with rubber bands. All bolted connections are unscrewed with a wrench, after which the cover can be removed without problems.

Walk-behind tractor design

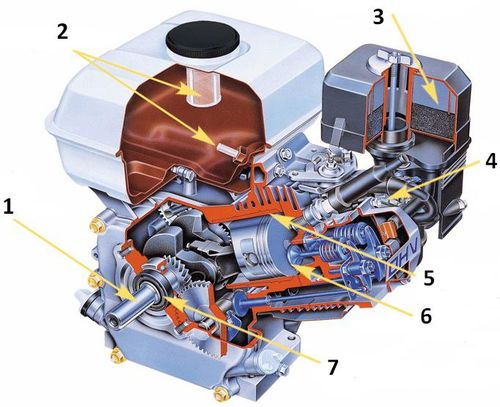

An important driving part of the described device is the engine, which is capable of operating on both gasoline and diesel fuel. Such a component of the equipment can be either two-stroke or four-stroke

A characteristic feature of these motors is that they are equipped with specially designed speed controllers, which can simplify the operation process. Engine power can vary from five to ten liters. It is also worth noting that the specialists face the greatest difficulty during repairs in this part of the walk-behind tractor.

The next element of the device is the transmission, which has a number of variations:

- Toothed.

- Toothed-worm gear.

- Belt-toothed-chain.

- Hydrostatic.

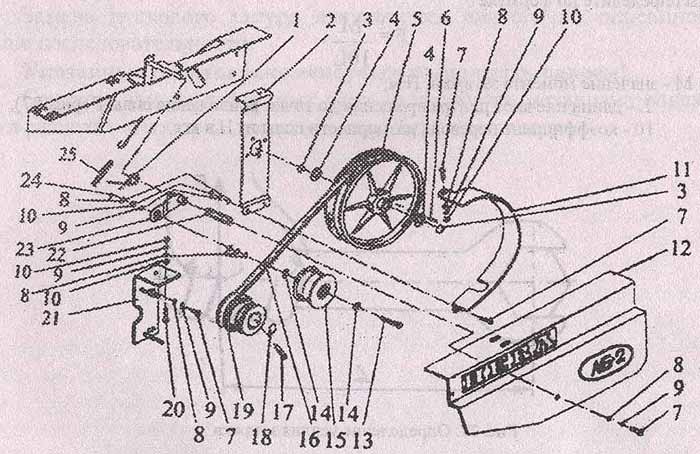

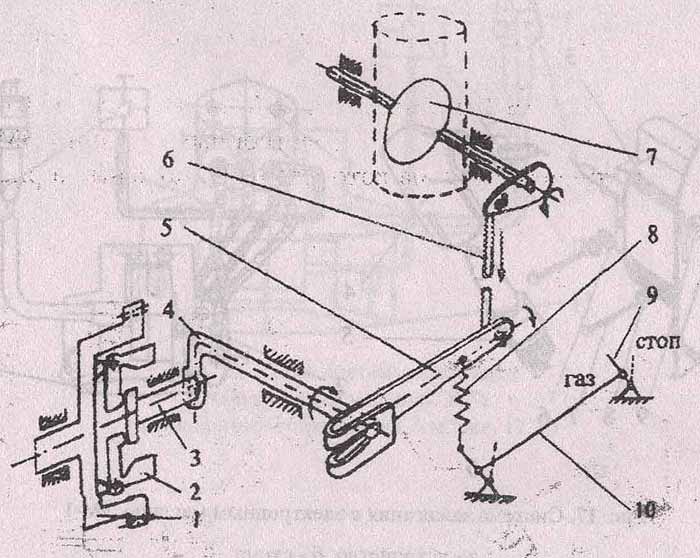

An important component of the described device is considered to be an aggregated system, thanks to which it becomes possible to attach additional agricultural devices to the walk-behind tractor. This mechanism can be controlled either on its handles or on the steering rods.

And also in this place is the clutch and gas. In some complex structures, sometimes you can find a brake

This mechanism can be controlled either on its handles or on the steering rods. And also in this place is the clutch and gas. In some complex structures, sometimes you can find a brake.

Principle of operation

The cultivation of the land with the "Master" motor-cultivator is carried out as follows:

- when the engine is started, the translational energy of the piston is converted into torque and is transmitted through the gearbox to two short rotors;

- each of the rotors is equipped with a long rod with a cutter at the end;

- when the cutters rotate, their sharp knives cut off the upper layers of the soil, paint them finely and mix with the lower layers;

- such rotation of the cutters causes the forward movement of the cultivator with simultaneous processing of the soil;

- the depth of entry of the knives into the soil is regulated, and if necessary, the maximum depth of the cultivator is made heavier with lugs.

Replacement and adjustment

Quite often, unfortunately, it becomes necessary to completely change the motor on the walk-behind tractor. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about the products of Chinese factories have long since become irrelevant. To avoid overpaying funds, you need to carefully analyze how productive the power plant should be. Buying a unit that is too powerful is simply irrational.

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to start disassembly only after flushing the engine and removing oil from it.

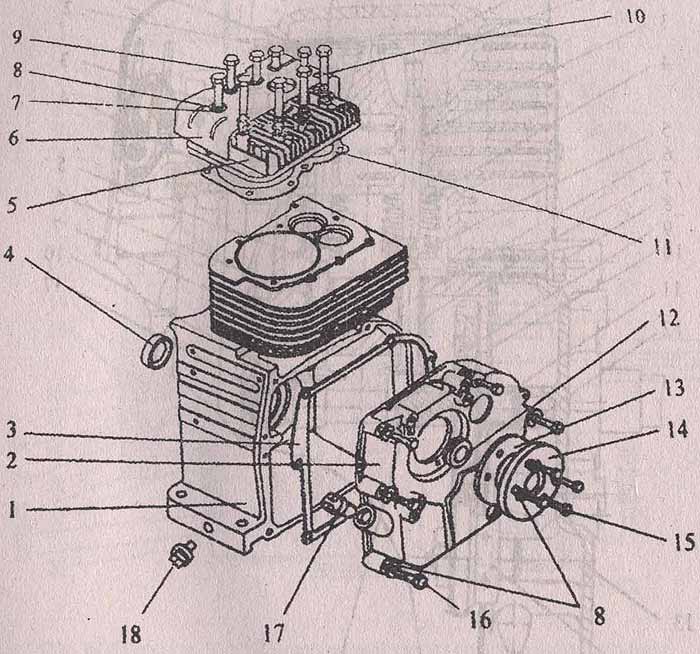

The lubricant is poured out only when the engine is warmed up after a short operation. Then it's time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- screen covering the cylinder.

Then remove the crankshaft pulley. Following the pulley, it is required to remove the fan, reflectors, insulating flywheel casings. Unscrew the cover, removing the rings and coupling housings. With the washer removed, you can press out the flywheel with a piece of wood.

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is obtained, remove the oil spray and locknut. Having repaired and changed the damaged parts, the engine is assembled in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Damaged valves for a gasoline walk-behind tractor are replaced after removing:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

Installation on an elastic band is advisable if a Chinese motor is installed on domestic walk-behind tractors. Rubber cushions are often used as a platform. Parts of the front shock absorber from a classic car are suitable as them. Along with the need to rearrange individual parts of the walk-behind tractor, many people have a need to put the electric starter on their own. This starter will have to be correctly connected to the battery.

The crown is attached only to the removed flywheels. Pre-remove all interfering parts of the motor. To remove the flywheel, in many cases, you cannot do without a special key. A generator and its magnets are placed in the flywheel assembly. When the terminals and contacts of the battery are aligned, a test run of the walk-behind tractor should be carried out.

Which engine to choose for a walk-behind tractor

When choosing a motor for a walk-behind tractor, you must consider:

- expected operating conditions;

- mounting versatility;

- constructive compatibility with the existing model of agricultural machinery;

- engine life declared by the manufacturer.

This important unit must match the chassis and transmission of the equipment, it must be in good relation to the dimensions.

Attention should be paid to the presence of a lighting coil, which will allow you to connect the headlights to use the unit in the dark

Specifications and functional parameters to be taken into account:

- Departure of the shaft. The optimal and most common modification is for a 19- or 20-mm key. Slightly inferior in demand are units with spline-type output. Less common are models of a conical structure.

- The presence of an oil level control sensor, which is equipped with all motors, except for ultra-budget ones. Such an indicator is a guarantee of the durability of the motor.

- Universal mount designed to provide easy installation of the engine.

- Air filter with double cleaning or oil bath. The second option is easier to maintain. It is compatible with walk-behind tractors with low ground clearance. Well protects the mechanism from the penetration of soil dust and solid particles.

- Motor resource. It is advisable to choose an engine with an indicator of at least 3000 m / h.

Many models have a built-in speed controller. When the load changes, the mechanism independently determines the torque, which increases production efficiency and saves fuel. It is advisable to choose a gas engine or diesel unit equipped with such a device. TATA walk-behind tractors with a productive power plant and automatic clutch are in great demand. They are made of first-class wear-resistant materials that can withstand overheating and atmospheric precipitation for a long time.

Such equipment is recommended to be selected for work on large areas of land, heavy soils and in difficult operating conditions. An engine from China, for example, produced by the Lifan company, is suitable for processing private agricultural land, its own garden and the local area. These are compact and functional units that can be used in various business operations. Due to the relatively low cost, such power plants are available to a wide range of buyers.

A similar engine is equipped with a two-valve drive. Lifan motors use exclusively air cooling, which is due to the scope of application of the units. A good domestic analogue for use in a household or on a small farm is the Oka walk-behind tractors manufactured at the Kaluga Engine plant. The operator does not need much physical effort to operate this compact device. The equipment is equipped with a powerful but economical power plant.

Oka walk-behind tractors are equipped with an adjustable steering column, are distinguished by a narrow body, reasonable price and cable control. If you need a weighted model for arable work, you can choose inexpensive but high-quality Belarusian equipment, for example, MDZ-12. This walk-behind tractor comes with a powerful 12-horsepower gasoline engine. Structurally, it is arranged on one axis, which ensures optimal balancing and maneuverability of the unit.