How to remove oil

The main methods used to fix the problem:

More often, oil enters the filter along with the gases that pass through it. To solve this problem, you will need to remove the hose from the filter, rinse it from impurities and debris that clogged the element, and then install the hose back. If this does not help, you will have to check the throttle valve. Carbon deposits and debris often interfere with the correct operation of the part, which causes high pressure in the engine. Most often, the problem is solved by repairing the damper or replacing it.

Slag can accumulate in the oil deflector of the vehicle; to fix the problem, you will need to clean this element and install an additional oil deflector.

If the air filter is damaged or clogged, it may itself be the cause of oil. In this case, the filter can be replaced or cleaned.

If the problem has not been resolved, then the cause will have to be looked for in the engine. This means that the car will need more serious repairs: replacement of oil scraper rings or other types of manipulations.

Oil in the air filter pipes often appears due to compression disturbed in the car's cylinders. You can check how the cylinders work by warming up the engine to operating temperature. If the values are not the same, then the engine needs repair. Especially often this problem occurs in old cars.

The owner will also need to check the valve clearances. If they are too large, oil will start to appear in the air filter. The same goes for the replacement of the oil seals. In a garage environment, it is difficult to determine the cause of a vehicle malfunction. Most of the owners turn to a car service, where the diagnostics are carried out by masters using special equipment.

If your machine's engine is worn out, you can postpone the overhaul as follows:

- The hose that conducts gases through the crankcase must be removed.

- A plug is installed on the union.

- The crankcase is vented through an extended hose that is passed through the bottom of the engine.

- Change the engine lubricant.

But these manipulations will delay the intervention of the repairmen by a maximum of 500 km. After that, the motor will need to be repaired or a new unit installed.

What the problem threatens

The very presence of oil on the air filter will not bring harm, however, this can serve as an alarming symptom that the need for an overhaul of the engine is approaching, and this procedure is time-consuming and expensive. The appearance of a symptom requires prompt contacting a car service for in-depth diagnostics of the machine.

Key features

When checking engine compression, remember that a difference of one or two units is acceptable. If the compression in the cylinders is very different from each other, then this indicates that the valves are burnt out or the rings are not pressed tightly, and it is time to change them.

It is worth paying attention to the color of the car's exhaust gases. If the piston group is badly worn out, then the smoke will acquire a bluish tint.

If, after checking the compression in the cylinders, no serious deviations from the norm were found, then there is no cause for concern, and the oil, most likely, comes through the crankcase due to the hose clogged with debris. The hoses are easy to clean or replace.

Types of generator faults

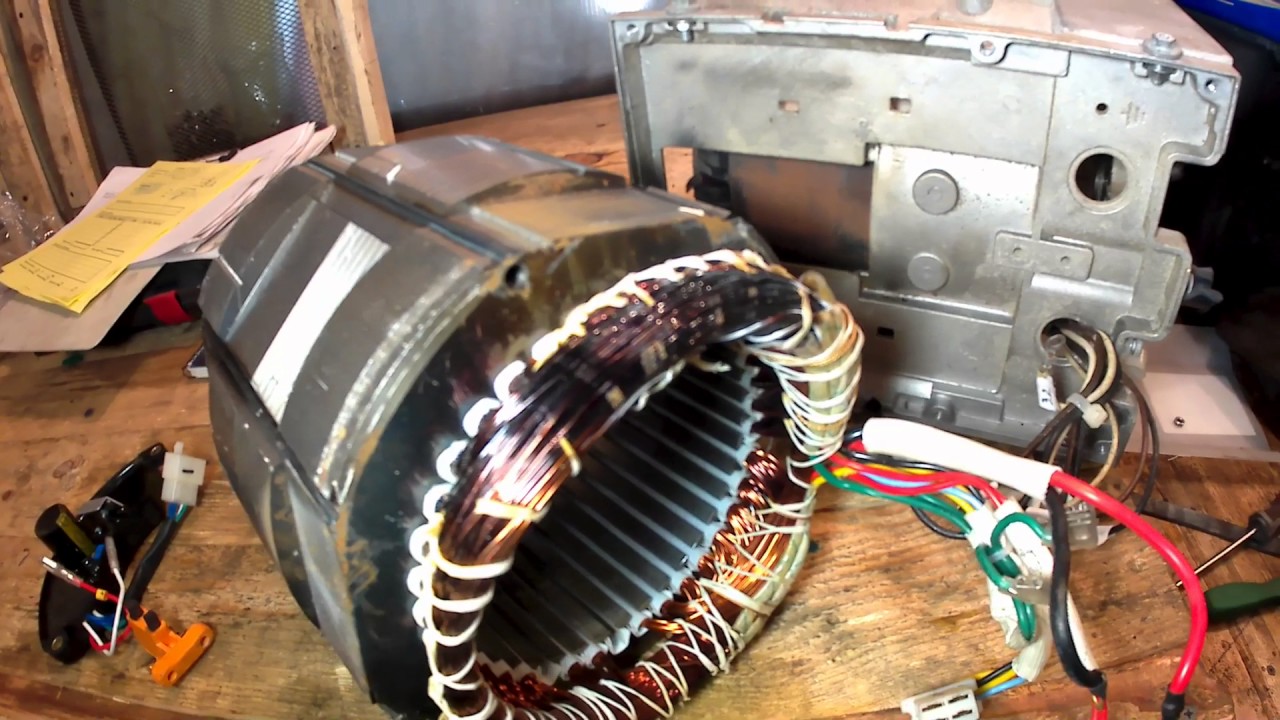

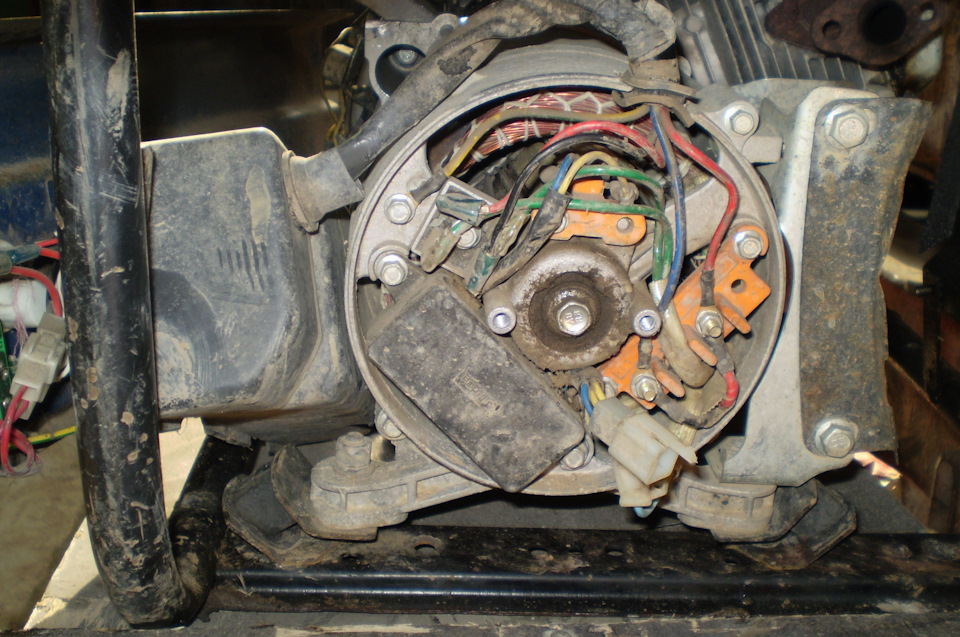

Due to the fact that any generator is an electromechanical device, respectively, there will be two types of malfunctions - mechanical and electrical.

The first include the destruction of fasteners, housing, malfunction of bearings, clamping springs, belt drive and other breakdowns not related to the electrical part.

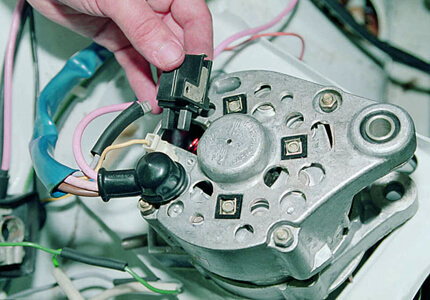

Electrical faults include winding breaks, diode bridge faults, brush burnout / wear, turn-to-turn short circuits, breakdowns, rotor beatings, and relay-regulator faults.

Often, symptoms that are characteristic of a faulty generator may appear due to completely different problems. As an example, a poor contact in the fuse socket of the generator field winding circuit will indicate a malfunction of the generator. The same suspicion may arise due to burnt contacts in the ignition switch housing. Also, the constant burning of the generator malfunction indicator lamp can be caused by a breakdown of the relay, the blinking of this switching lamp may indicate a generator malfunction.

The main signs of a malfunction of the auto-generator:

- When the engine is running, the indicator lamp for battery discharge flashes (or is continuously on).

- Discharge or recharge (boil-off) of the battery.

- Dim car headlights, rattling or low beeps when the engine is running.

- Significant change in the brightness of the headlights with an increase in the number of revolutions. This can be permissible with an increase in revolutions (overglowing) from idle mode, but the headlights, having lit up brightly, should not increase their brightness further, remaining at the same intensity.

- Extraneous sounds (howl, squeak) emanating from the generator.

The tension and general condition of the drive belt should be checked regularly. If cracks or delamination occurs, immediate replacement is required.

Details about the appointment

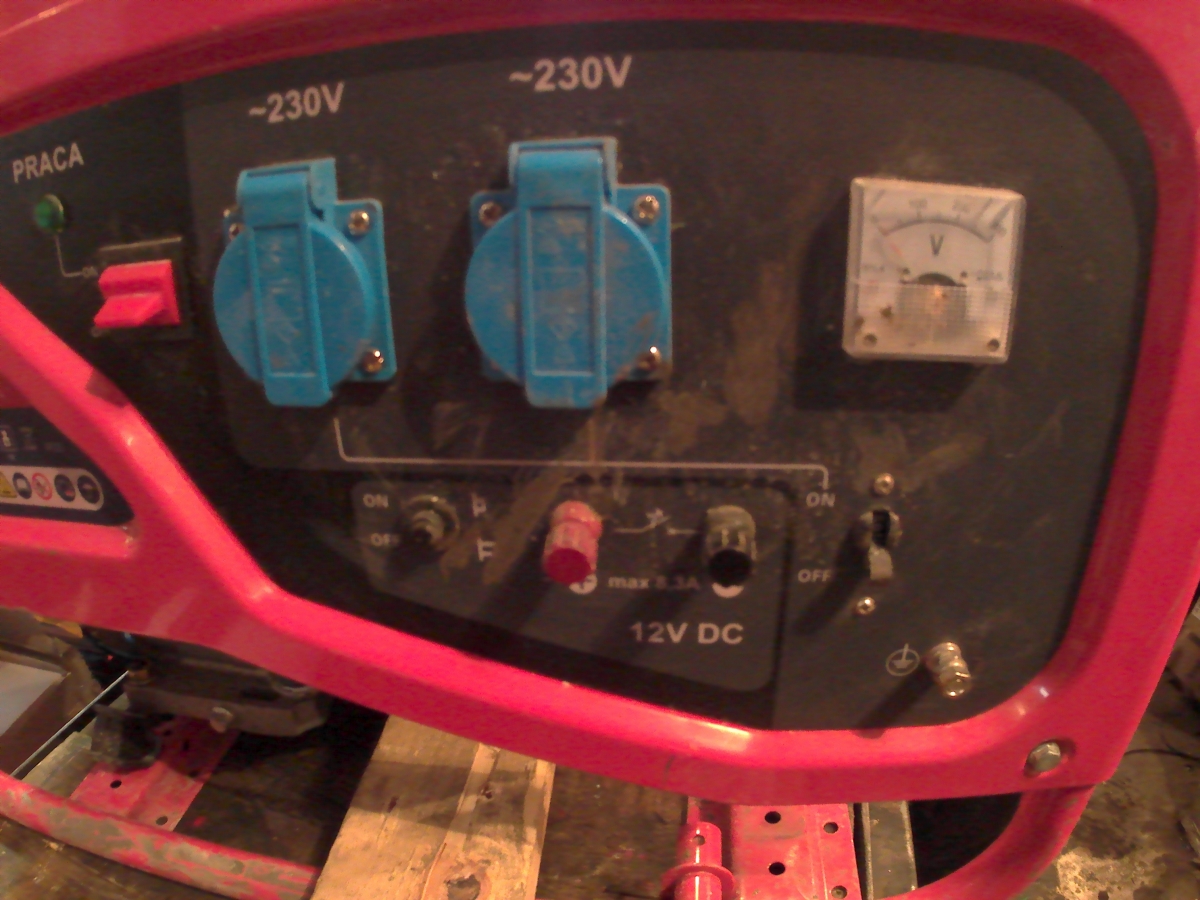

Equipment of this kind can perform different functions, each of which is extremely important:

- Providing an autonomous backup power supply to the facility;

- Functioning on an ongoing basis in the event that there is no power line in the area.

Given the magnitude of the load on such a compact device, it is quite logical that gas generators need to be repaired from time to time. In order to have to do this as rarely as possible, the main components should be serviced on time. The increased load on such a device lies in the fact that several consumers can be powered from it at the same time, and the duration of operation is often quite long.

Thus, even despite the need to repair gas generators from time to time, it is sometimes necessary to have a device of this type in everyday life. Among other things, there is another factor that testifies in its favor - this is the organization of a stable output voltage for connecting equipment with sensitive automation.

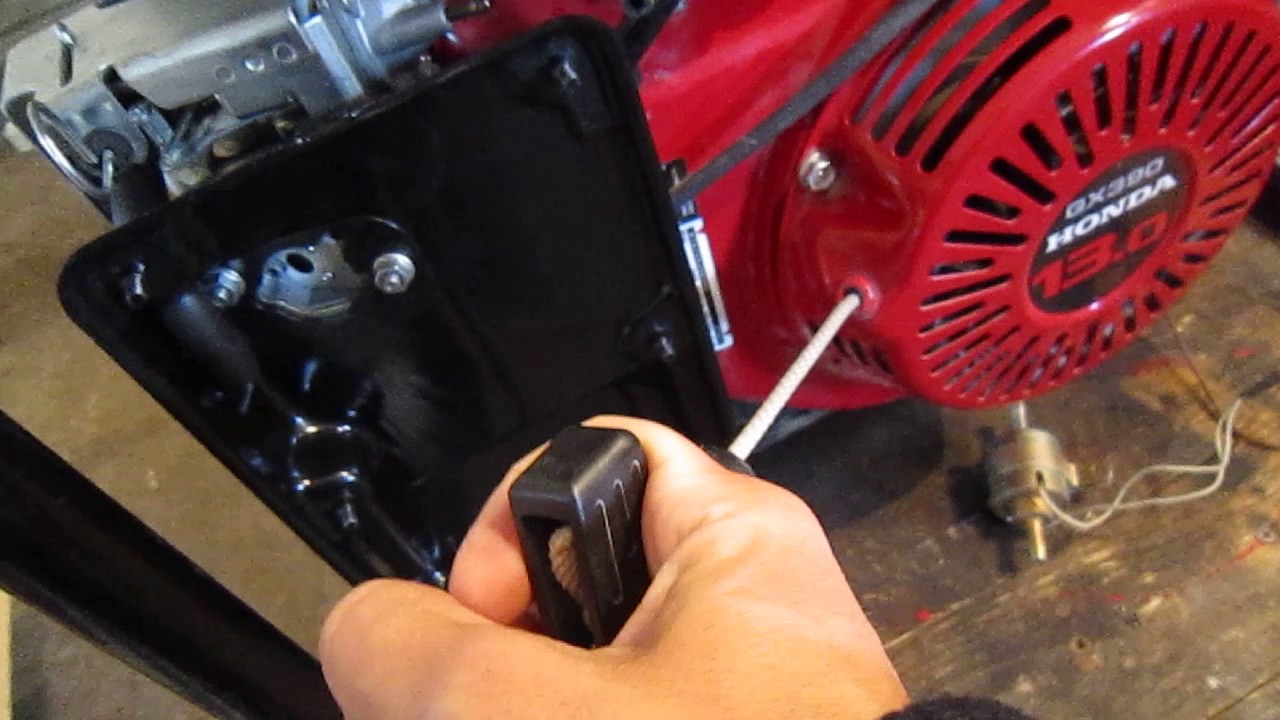

How to start in winter?

Surely everyone will agree that it is very unpleasant to be in a house where there is no electricity in winter in cold weather. And if you have a properly connected gasoline generator, such problems do not arise. However, the owners of such devices need to remember that there are several ways to start gasoline power plants in the winter.

- With any method of connecting the device, you must take care of the injectors. They should be held at a certain angle to prevent fuel fluid from spilling onto the spark plugs.

- You can inject a special agent to quickly start a gasoline generator into the carburetor. You can buy this substance at any electrical store.

- The easiest way to start a gasoline generator is to bring the device into a warm room, warm it up, and then put it back in place. Most likely, the unit has been frozen and, like a car battery, requires heating the electrolyte. This method cannot be called fast, but it is "miraculous".

To save the generator system from various damages during the cold season, the owner must drain the fuel fluid from the tank and lubricate the movable system components, especially when the next start-up will be made after a long time. But the most important thing is that a poorly working generator must be kept in rooms where the air temperature does not drop below 0 degrees.

Internal combustion engine problems.

The reasons for this may be the following:

- Lack of elements necessary for engine operation - fuel, oil, uncontaminated air filter. The presence of these components is the key to good operation of the gas generator; in their absence, a protective mechanism is triggered and the device stalls.

- There is no ignition spark. You can fix the problem as follows: using a special key, unscrew the candle, then, using sandpaper and an iron brush, clean off the carbon deposits that appear when using low-quality fuel due to its incomplete combustion. Then you need to wipe the candle with gasoline or alcohol, let it dry. After that, you should re-check for the presence of an ignition spark and try to start the generator.

- Insufficiently adjusted carburetor, the occurrence of soot when the generator is not working at full strength. Additional carburetor adjustment will help solve the problem.

- Other serious damage to the generator.

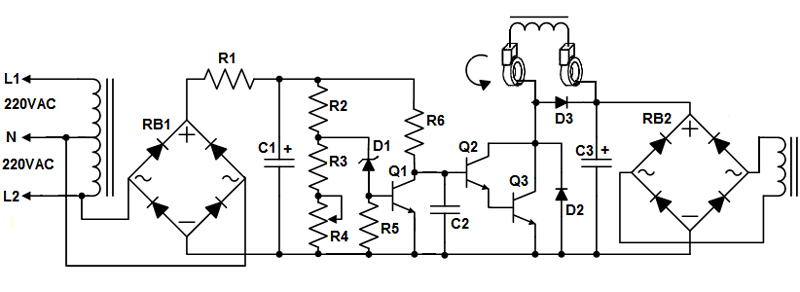

Problems in the operation of an electric generator usually arise from a lack of voltage, which arises for a number of reasons. This may be a lack of contact, a malfunction of the brushes, burnout of capacitors, PWM units, etc. If voltage surges are observed at constant motor speed indicators, then, most likely, the matter is in a malfunction of the excitation regulators. It is necessary to disassemble the device in order to find out the exact reason for its failure to work.

Difficulty starting the engine usually indicates a malfunction. Finding the cause in a timely manner means preventing its further development and suppressing the negative impact on the operation of the unit.

Often, several interrelated factors act as the cause of a malfunction. In this case, they have to be eliminated in a complex manner.

Most often, the circumstances that prevent the normal start of the engine are:

Poor ignition system. The following options are possible here:

Problems with the spark plug: the distance between the electrodes is too large or too small (it is necessary to place the electrodes at the optimal distance), insulation failure (replacing the spark plug with a new one will help), the formation of strong carbon deposits (the spark plug must be thoroughly cleaned);

Problems with the ignition coil: insulation failure or winding rupture (replacement is required), incorrect connection of circuit elements or interruptions in its operation (if it is impossible to eliminate the malfunction of the microcircuit, it must be replaced).

Poor fuel system

Reasons and remedies:

- Lack of fuel in the tank (it is necessary to fill the tank);

- Clogged or pinched fuel hose (requires thorough cleaning or complete replacement of the hose);

- Air trapped in the fuel hose (check the tightness of the connections, tighten if necessary);

- Low quality gasoline or diluted with water (fill with higher quality fuel);

- Problems with the carburetor: breakdown, fuel or debris getting into it. Disassembling and cleaning the carburetor will solve the problem. Also, the reason may be in an incorrectly installed throttle valve, which is solved by carefully adjusting this part.

Problems in the main components of the engine

Reasons and remedies:

- Loosely tightened cylinder head bolts (tighten tighter)

- Piston, piston rings or cylinder worn out (needs repair or complete replacement)

- Poor contact between working chamfers and saddles (repair needed)

- Stuck valve (repair needed)

- The gap between the valves, the value of which differs from the gap value provided for this model (careful adjustment of the gap size is required);

- The intake manifold gasket does not impede the passage of air (tighten the bolts; if air continues to flow, the gasket must be replaced)

- Poorly tightened spark plug (tighten the spark plug more tightly)

Does it make sense to use it?

As mentioned above, the purpose of the hydrogen plant is to save the volume of fuel used, and it does not matter in which mode the car is used - in the city or along the highway. The indicator of the saved fuel directly depends on the power of the installation, as well as the model of the vehicle and the features of the operation of its power unit.

Today, such a device is not so often used by motorists. But those drivers who have installed a hydrogen unit on their car note that with normal engine operation, fuel savings can be in the region of 15-30%. However, every motorist should understand that the use of such devices contributes not only to fuel economy, but also affects the functionality of the car as a whole, and not always on the positive side (the author of the video is the Meso channel).

Elimination of basic malfunctions of the gas generator on your own.

The basic principle of the repair of any equipment is the elimination of faults by exclusion. How we do it. A generator comes to us and we start checking:

- First of all, we inspect the appearance for mechanical damage and oil leaks, as well as the presence of rust in the tank. Next, we check the presence of oil and turn the engine with the starter (see the compression resistance and extraneous noise). Trying to start.

- If not, watch the spark. We immediately take a new candle (leaning the candle against the ground, turn the engine), if there is no spark or it is weak, we try to disconnect the wires from the oil sensor relay and replace the candle cap. If it does not help, look at the ignition switch or the power button. If everything is in order there, then the ignition coil is faulty.

- If there is a spark, we try to start it. If it starts and stalls or runs on a closed damper, the carburetor is definitely clogged. Many say that they cleaned themselves, but the symptoms are the same. This is obvious, you need to clean the carburetor by disassembling it to the bolt with special means. And this is half the battle, then you need to install it and correctly adjust the rods and springs of the damper and the speed regulator. If it does not start at all, add some gasoline to the combustion chamber, through the spark plug hole, or through the open choke of the carburetor.

- Rust in the tank is a very unpleasant problem, you can clean the fuel system and everything will work. But, soon, after a while, this rust will get into the carburetor (in the jets, under the needle) and the symptoms will repeat. If there is rust in the tank, it is almost impossible to remove it. You can pour special agents (such as a solvent) into the tank for the night or install a fuel filter, but the only salvation will be to replace the tank.

The need to provide their home with an uninterrupted power supply system arises for many - the quality of domestic power supply is low, which is especially typical for suburban and rural areas. The most common solution is to purchase a gas generator - these devices are presented in a wide range and have an affordable price. However, a gas generator, being a rather complex device, has many features, the knowledge of which is necessary for every owner to use this technique correctly.

Engine breakdown

- The equipment stalls immediately after starting up or does not start at all.There may be several reasons: lack of a spark, poor fuel supply, gas distribution mechanism, mechanical breakdowns (connecting rod breakdowns, crankcase breakdowns, etc.).

- Spark. The problem may be a burned-out coil, spark plug, or cap. The relay or the oil sensor itself can fail (it stops the spark if there is little oil), as well as the wiring.

- Poor fuel supply. One or more elements of the fuel system are clogged or faulty - gas tank, filter, tap, carburetor.

- Timing If the gaps and scale on the metal increase and accumulate accordingly, the engine may not start.

- Smoke from the engine. Problems with pistons and / or cylinder. Oil enters the combustion chamber due to the depletion of the piston - hence the smoke. Too much oil in the fuel mixture is also smoke.

- The motor started knocking. Abrasion of the crankshaft or other engine elements.

- Fuel in the crankcase. Gasoline and oil are draining from the crankcase. Breakage of the carburetor. The reasons are its obsolescence and / or the accumulation of dirt.

- The motor wedges. Aging of the engine, lack of oil, excessive carbon deposits in the combustion chamber.

Overload

Sometimes it happens that a power plant can be overloaded with consumers and devices, the sum of the capacities of which exceeds the rated power of the generator. Try to run the generator completely without load, or simply disconnect several appliances from it.

Carburettor clogged

Check the gasoline generator carburetor for blockages.

Gasoline injection needle clogged.

If the needle is clogged, clean it. Blow it out using a car compressor. Apply the attachment.

Video instructions for cleaning the carburetor needle

Blockage or sticking of the float mechanism for supplying fuel to the gasoline unit.

Purchase a carburetor cleaner and clean the entire structure. Wait a few minutes, and then move the float mechanism with your own hands and blow out the valve.

Valve repair

The valves of the gasoline engine are controlled by the timing belt. To test its operation, remove the block cover by unscrewing a few bolts. You will see several valves and a tappet. You need to push the shaft in the right direction. If you see that everything is moving, but the valves are not moving, then they are stuck. To repair them, take a carburetor cleaner and a hammer.

Turn the rocker arm and carefully hammer the valves with a hammer. Then, turning the shaft, push the valves back, pouring plenty of liquid over them.

Repeat this action until the valves come off.

The generator works but does not supply energy.

If the gas generator starts, but does not produce energy, then most likely the engine is damaged, or the internal settings of the generator are lost. Take a voltmeter and ammeter and compare the readings at the power plant with the readings indicated in the instructions. If the readings differ, then this is undoubtedly an internal breakdown and your unit needs professional expertise and repair. So call the experts.

Emergency start of the power plant with a drill and battery

If your portable generator starts but does not output voltage, you can:

-

Use the battery after correctly connecting the wires to it (plus to plus, minus to minus).

Remove the spark plug and start the petrol unit by pulling on the starter cord.

Launching with a drill.

Use a drill to restore the magnetic field of the alternator. This video will clearly show you how to do it yourself.

Advice: the best way to prevent damage to expensive equipment is to maintain it correctly and in a timely manner, even if your autonomous power source only works from time to time. Also, timely change filters and other elements that require periodic replacement. Remember that it is better to play it safe and replace the filter than to rely on chance.

Finally, remember to use good quality oil and fuel.

You will save a lot of money and time if you are familiar with the basic troubleshooting methods and can repair a gasoline generator yourself. Most of these techniques are described in the instructions for use for your model. Study it first before calling the experts.

The gas generator works intermittently

A regulator malfunction is signaled by a situation when the speed of the gas generator is floating under load, there are interruptions in starting a cold and hot engine. If you do not take measures, the situation will be aggravated by premature wear of internal components and failure of the device.

Adjusting the frequency of a gasoline generator can solve the problem, but it must be done correctly. The work will require a tester to measure the frequency and a long screwdriver with a Phillips tip. Compliance with the given algorithm of actions will allow you to perform maintenance of the power plant quickly and safely:

- The first step is to disassemble the carburetor to gain access to the fuel jets. Then, using a compressor, the jets, channels and emulsion tube are carefully blown through.

- The next task is to find the number screw and set the throttle valve so that the minimum clearance value is 1.5 mm. Upon completion of the manipulation, the parameters at the output are checked. The value should not go beyond the range of 210-235 V. It is optimal to achieve a balance between the number of revolutions issued and the voltage.

- Next, you need to work with the mixture quality screw to eliminate interruptions during idle. It is found in a special hole, screwed in until it stops, and then loosened by two or three turns. During the adjustment process, make sure that the operation of the device during a cold start of the engine or at idle runs without problems.

Violation of the given order of work will lead to a decrease in the effectiveness of the adjustment, and the master will not achieve the set goal. If the algorithm is followed, there will be no further interruptions. A simple test can be used to make sure the adjustment is correct. You need to put a clean candle, turn on the gas generator for a couple of minutes and assess its condition. The presence of carbon deposits is a sign that the adjustment should be continued by gradually loosening and tightening the bolts. If the spark plug is clean, the test is passed and the device is ready for further use.

Mechanical faults

The presence of any mechanical faults can be said if the starter works, but the engine does not start, since the crankshaft does not rotate.

Parts to be checked: one-way clutch lever, clutch ring, buffer spring, flywheel crown.

One of the reasons why the starter does not rotate the crankshaft

When the starter is spinning, the engine may not start if:

The clutch slips, the shut-off lever is out of order or it has jumped off the axle, the clutch drive ring is worn out, or the buffer spring does not cope with its task. When a grinding noise is emitted at startup, these symptoms may indicate wear on the flywheel ring teeth. In this case, it is worth checking the adjustment of the gear travel and the condition of the buffer spring.

If you heard a non-typical noise during the operation of the starter, then it is worth inspecting it from the pit and the engine compartment, since one of the following starter malfunctions may have occurred:

- bearing bushings are worn out, as well as journals on the armature shaft;

- the fastening bolts of the starter are loose;

- damaged teeth;

- inside the starter, the pole attachment has weakened, as a result of which the anchor began to touch it.

But besides the fact that problems with the starter can arise during the start-up phase, they also happen after its start. This is a typical situation when the starter does not turn off, but continues to turn. And the fault of such a starter problem may be:

- Stuck drive lever or armature shaft drive.

- Traction relay stuck.

- Contacts on the traction relay are stuck together.

- The return spring of the ignition switch or the freewheel spring is worn out.

In this case, you must quickly disconnect the starter terminal or starter relay terminal and begin to search for the cause of the starter malfunction.

And if you have not yet encountered the above-mentioned breakdowns, but when the engine is started, the starter still behaves unusually, then you should take a closer look at the symptoms that promise an imminent failure:

Starter malfunction lurked in the brush assembly

WITH

After start-up, it starts out of gear with a delay. There is wear on the teeth in the bendix gear or the flywheel crown;

The starter motor started to spin with great difficulty, although the battery is charged. Such a response most likely indicates that the brushes are worn out or a bearing depletion has appeared.

The service life of the starter is about 70-200 thousand km and in order for it to serve your car as long as possible, periodically you need to carry out some preventive work.

In order to properly check the starter and its subsequent repair, it is recommended to study the technical characteristics of a particular model. The main ones are: the nominal voltage and its power, the consumed current and the resulting torque, as well as the shaft speed.