Application area

The rack and pinion jack is a multifunctional device, because the vehicle can be lifted in four ways. In addition, the device can replace a winch, clamp and even a press. Let's consider all the options for using the tool in more detail.

Lifting the machine by the power units

Place the jack on a firm surface before lifting the machine.

Jacking up a car with reinforced protruding elements such as sills and bumpers is, by far, the most obvious way to use a rack and pinion "comrade". So, you can get the vehicle out of a deep and soggy track or raise the front of the car, thereby simplifying the task of the winch.

Lifting by the wheel

If your car is not equipped with reinforced structures, then a special accessory called the Lift Mate, which is often equipped with a lift, will help to pull it out of any substance. This device is put on the "beak" of the elevator and clings to the wheel rim by hooks hanging on rag slings. After this, the ascent is carried out.

Special slings are used to lift the machine by the wheel.

Bumper jacking

The device is suitable for almost all metal bumpers, under which the "beak" of the jack cannot be installed

There are situations when you need to lift the car by the bumper to replace a damaged wheel. But what to do if the latter is not able to withstand the weight of the car. In this case, you will be helped out by another additional device - Bumper Lift. This device is a chain sling with an attachment on the "beak" of the jack and one powerful hook with which you can grab the power elements under the bumper (frame, bridges, etc.).

Jack as a winch replacement

As noted earlier, the operation of the rack and pinion tool is not limited to lifting vehicles and other heavy loads. The Hi Jack can also be used as a hand winch. Sometimes, in order to free your "iron horse" from snow or mud captivity, you need to move it less than half a meter. And the capabilities of the rack and pinion jack are quite enough to solve such problems. Moreover, the lift can be located in the most convenient place, in front or behind the machine, and then push or pull the machine in the desired direction.

The main malfunctions in the operation of hydraulic rolling jacks and how to fix them

Jack part close up

The most common malfunction in the operation of these devices is the failure of seals and gaskets, which entails oily smudges. However, this problem does not require contacting the service and it is quite possible to fix it with your own hands. To do this, you first need to drain the oil from the apparatus, and then proceed with disassembly. The pistons are removed and the rod is inspected

When disassembling, you should always pay attention to the internal state of the device, as other elements may need to be replaced. For example, if the stem is bent, then this is a much more serious problem, a simple change of gaskets will not help.

Note!

If deformation or a crack occurs during operation due to errors in the production of equipment, then during the warranty period, you can replace the purchased product or require repair.

If dirt or rust is found, it should be disposed of with special fluids. Further, all seals and gaskets are changed. The very last thing about doing a rolling jack repair with your own hands is flushing and bleeding.

Important!

When refilling oil, do not use what was previously drained. It must be fresh .. Washing the jack also consists of several stages.

Where there was oil, a cleaning fluid is poured in to remove oily residues and dirt. After that, the lever moves to spread the liquid through the system. Then you need to add more fluid and continue to swing the lever until the stem reaches the upper position. Further, the check valve opens, and the stem returns back, which leads to the withdrawal of fluid from the system. If the liquid squeezed out is dirty, then another flushing is required.

Jack flushing also consists of several stages. Where there was oil, a cleaning fluid is poured in to remove oily residues and dirt. After that, the lever moves to spread the liquid through the system. Then you need to add more fluid and continue to swing the lever until the stem reaches the upper position. Further, the check valve opens, and the stem returns back, which leads to the withdrawal of fluid from the system. If the liquid being squeezed out is dirty, then another flushing is required.

After completely cleaning the system and draining the cleaning liquid, it remains only to pump the device with oil again.

There should be enough of it so that the jack can lift the load to the desired height. Oil is already poured into the hole and the lever continues to work until the rod rises slightly. Further, the liquid is poured until it is possible to raise the stem to the upper value. Then the shut-off valve opens, and the stem returns to its previous position, excess oil comes out of the hole. After bleeding, remember to close the drain holes and wipe the device.

Hydraulic and pneumohydraulic jacks are indispensable tools for the work of real pros. Thanks to their simple design, they are comfortable to use and do not spend much effort, and with proper maintenance, they will serve the owner for many years.

Bottle jacks BigRed

| BigRed hydraulic bottle jacks are designed for lifting loads or objects during repair, installation and construction work. The gap between the jack and the load can be compensated for by means of an adjusting (overhead) screw (for jacks from 2 to 20 tons). | ||

| Model | Carrying capacity | Jack Specifications |

| T90203 | 2t |

Bottle jack Big Red T90203: - minimum pick-up height - 181 mm; - jack rod stroke - 116 mm; - rod return - spring; - the stroke of the adjusting screw jack - 48 mm; - dimensions jack base - 88x92 mm - package size jack - 315x220x220 mm - jack weight - 2.7 kg; - set weight - 2.9 kg. |

| T90403 | 4t |

Bottle jack Big Red T90403: - minimum pick-up height - 194 mm; - jack rod stroke - 118 mm; - rod return - spring; - the stroke of the adjusting screw of the jack - 60 mm; - dimensions of the jack base - 92x100 mm - dimensions of jack packing - 325x235x235 mm - jack weight - 3.3 kg; - set weight - 3.5 kg. |

| T90603 | 6t |

Bottle jack Big Red T90603: - minimum pick-up height - 216 mm; - jack rod stroke - 127 mm; - rod return - spring; - the stroke of the jack adjusting screw - 70 mm; - dimensions of the jack base - 96x100 mm - dimensions of jack packing - 356x235x255 mm - jack weight - 4.5 kg; - set weight - 4.8 kg. |

| T90803 | 8t |

Bottle Jack Big Red T90803: - minimum pick-up height - 230 mm; - jack rod stroke - 147 mm; - rod return - spring; - the stroke of the jack adjusting screw - 80 mm; - dimensions of the base of the jack - 103x118 mm - dimensions of jack packing - 375x245x270 mm - jack weight - 6 kg; - set weight - 6.3 kg. |

| T91003 | 10t |

Bottle jack Big Red T91003: - minimum pick-up height - 230 mm; - jack rod stroke - 150 mm; - rod return - spring; - the stroke of the jack adjusting screw - 80 mm; - dimensions of the jack base - 110x123 mm - dimensions of jack packing - 365x290x280 mm - jack weight - 6.6 kg; - set weight - 6.9 kg. |

| T91203 | 12t |

Bottle jack Big Red T91203: - minimum pick-up height - 230 mm; - jack rod stroke - 155 mm; - rod return - spring; - the stroke of the jack adjusting screw - 80 mm; - dimensions of the base of the jack - 116x134 mm - dimensions of jack packing - 395x160x280 mm - jack weight - 7.8 kg; - set weight - 8.2 kg. |

| T92003 | 20t |

Bottle jack Big Red T92003: - minimum pick-up height - 242 mm; - jack rod stroke - 150 mm; - rod return - spring; - the stroke of the jack adjusting screw - 60 mm; - dimensions of the jack base - 144x150 mm - dimensions of jack packing - 330x175x285 mm - jack weight - 11 kg; - set weight - 11.4 kg. |

| T93003 | 30t |

Bottle jack Big Red T93007: - minimum pick-up height - 240 mm; - jack rod stroke - 130 mm; - rod return - spring; - the stroke of the jack adjusting screw - no; - dimensions of the jack base - 190x155 mm - dimensions of jack packing - 310x185x270 mm - jack weight - 21 kg; - set weight - 21.7 kg. |

| T95007 | 50t |

Bottle jack Big Red T95007: - minimum pick-up height - 236 mm; - jack rod stroke - 120 mm; - rod return - spring; - the stroke of the jack adjusting screw - no; - dimensions of the jack base - 218x176 mm - dimensions of jack packing - 360x185x270 mm - jack weight - 30 kg; - set weight - 30.7 kg. |

| Pneumohydraulic jacks Big Red: | ||

| T91203 | 12t |

Bottle jack pneumohydraulic Big Red TA91206: - working air pressure - 8..14 Atm; - minimum pick-up height - 260 mm; - jack rod stroke - 250 mm; - dimensions of jack packing - 270x160x274 mm - jack weight - 12.3 kg; - set weight - 12.7 kg. |

| T92003 | 20t |

Bottle jack pneumohydraulic Big Red TA92006: - working air pressure - 8..14 Atm; - minimum pick-up height - 265 mm; - jack rod stroke - 245 mm; - dimensions of jack packing - 292x279x190 mm - jack weight - 17.8 kg; - set weight - 18.2 kg. |

How to choose a quality tool: comparison of manufacturers and models

When buying a jack, you need to decide on the required carrying capacity. There are a large number of car tool manufacturers. The Hi-Lift jack is considered the most reliable and high quality. It is an American manufacturer that has over 100 years in the automotive market.

The highest demand is for Hi-Jacky cast iron jacks. On sale they can be found in two colors - red and black. They gained their popularity due to their reliability and quality characteristics. The disadvantage of such a device is its cost. It is larger than that of other manufacturers' models. But unlike the devices of Chinese companies, this unit has a length of 150 centimeters, but at the same time it does not bend, and retains its strength during operation. In addition, the model is characterized by a long service life. Such a tool will work properly for over 15 years.

The rack jack 5t "Matrix" is very popular. It makes it possible to hold a load at a height of 70 cm. The tool can be used as a winch.

Experienced drivers recommend purchasing a device that has a hook or loop to use as a winch. For original American jacks, this is provided immediately, for Chinese such devices there are no such devices.

The Czech-made DR 5 jack is considered to be a simple and reliable design. It is produced with a carrying capacity of 2.5 to 10 tons. The size of the working stroke of the device is small, in this regard, the lifting must be performed in several stages.

For repair shops, wall-mounted rack jacks from the MJW brand are often purchased. They are equipped with a cylindrical gear. Such a device allows you to lift, move the load horizontally.

When choosing which tool is better to buy, it is important to think about how it will be transported in the car. Not every trunk can fit a 1.5 meter device

Russian-made jacks are not inferior in quality. They are reliable and affordable.Among the assortment of Russian models there are many gear and lever models with different carrying capacities. They are effectively used in factories and in construction.

If necessary, you can purchase a combined rack-and-pinion jack. Such models can lift loads up to 15 tons. This is possible due to the fact that the load is evenly distributed both on the paw and on the butt.

Types of rack and pinion jacks

Types and principle of operation of jacks

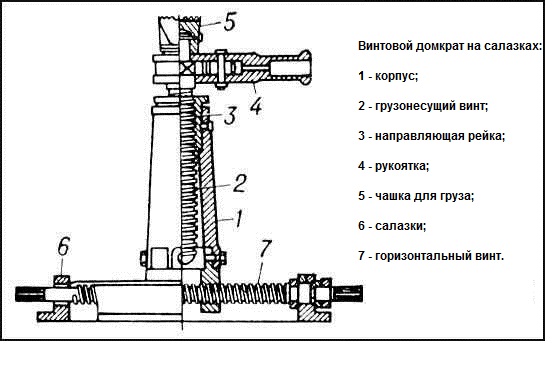

In the oldest jacks - screw and rack-and-pinion - lifting is carried out by the movement of mechanical parts. In rhombus, this is a screw rod, along which the working handle rotates (more precisely, it is rotated by a person), as a result of which the rhombus mechanism contracts, raising the working platform up.

Just? Simple, but not entirely - to use such a jack, you have to sweat, and it will take a lot of time. In addition, it is clear that such a unit will not cope with a heavy load - unlike a rack and pinion one. Here the handle and platform slide along a long bar with teeth and holes for better grip.

Such a miracle of technology does not require much effort, but there is plenty of time - at least to install it and find a suitable support. In addition, the inconvenient dimensions clearly will not allow you to carry the jack with you in the back.

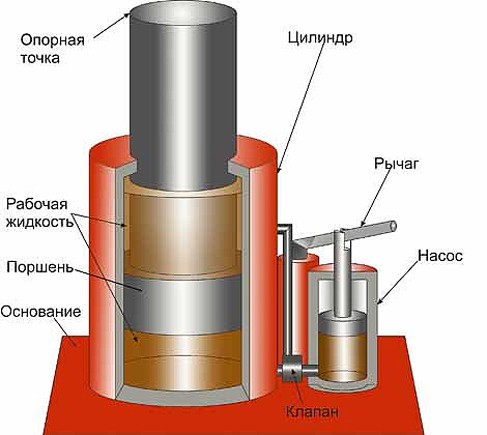

Here the lifting capacity is already provided by hydraulics - and this has its pros and cons

Of the pluses, one can certainly single out a large carrying capacity and smooth operation - and of the minuses, slowness and a certain degree of caution, which is absolutely necessary when using this mechanism.

Firstly, the jack must be located strictly vertically - to avoid leakage of the working fluid.

Secondly, it is necessary to constantly monitor it, the fluid (it is called hydraulic oil), the level in the working cylinders, change it in time, and also clean the moving parts. It is better to use the services of a master in such matters.

Also, this type of jack is widely used, such as a hydraulic bottle jack, which works on exactly the same principle. The difference in design is that outwardly such a jack resembles a bottle, not a cart. On the one hand, this additionally stabilizes the device, on the other hand, it is less convenient to carry it under the load.

A motorist on the road can get out of this trouble with a small digging - if it happens in a building, he will have to get out somehow differently.

Some enthusiasts use pneumatic, or inflatable, jacks. They are a very durable inflatable cushion that grows in size when compressed air enters it from a cylinder or exhaust pipe.

Of course, such a jack has its advantages - compactness, convenience, the absence of the need to apply physical effort - however, the mechanism does not differ in its high carrying capacity, and the pillow, although difficult, is still possible to break. And then the jack can be safely sent to the trash heap.

Rarely, but still this type of jack is used, such as an electric one. This is due both to the fact that the device went on sale relatively recently, and to the prejudices of many buyers, who unfairly believe that without a fixed connection there will be no sense from it.

We recommend that you change this opinion, since this type of jack functions using the energy of the built-in or car battery, while providing a good lifting capacity and lifting height.

Also, the jack is very compact and easily fits into a small case along with all the wires. Although for lifting loads weighing more than 4 tons, such a jack is completely useless.

We recommend to buy

Peculiarities

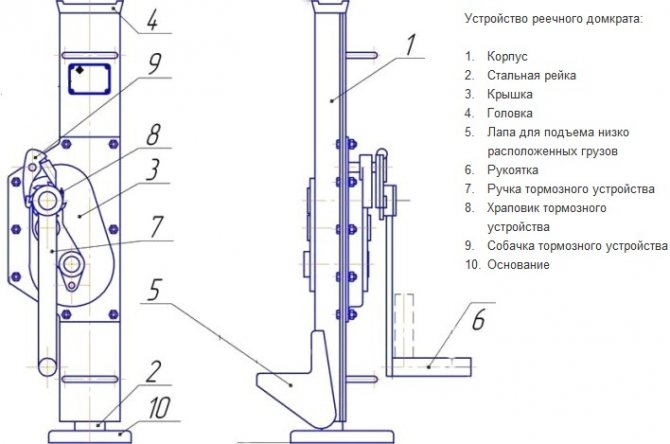

The rack and pinion jack has a simple design. It consists of:

- guide rail along its entire length (which depends on the model of the jack itself);

- round holes are located at an equal distance;

- handles, when pressed, the carriage and the support platform itself, on which the entire load rests, moves.

This site can be very low above ground level. Some models allow you to start lifting from 10 cm. The weight of the lifted load can be from 2 to 20 tons, depending on the model and device.

Each of the devices has its own transmission:

- Single stage models can lift weights up to 6 tons.

- If the model is two-stage, then the weight can be up to 15 tons.

- The three-stage models are capable of handling loads of up to 20 tons.

The principle of operation of such a mechanism is based on the interaction of the rack and the ratchet mechanism. To lift the load, the lever is forced downward. At this moment, the carriage is rearranged exactly 1 tooth along the toothed rack. To continue lifting, you need to raise the handle again to its original position at the highest point and lower the lever again. The carriage will jump 1 tooth again.

You can see the High Jack in action in the next video.

All moving elements are protected by a casing to protect the mechanism from dirt getting into it, although the entire system may well be washed out in the nearest reservoir. Some owners of such devices lubricate all moving parts with oils. This is not the best solution for such a device. Since the oil, or to be more precise, its film collects all the dust it can, and as a result, the accumulated dirt complicates the operation of the entire mechanism. Moreover, such a substance cannot be easily washed off with water.

The described jacks are favorite accessories and indispensable helpers for off-road enthusiasts. Every self-respecting lover of such a vacation must attach a rack jack to his car. With its help, it is possible to pull out a multi-ton jeep with full marching equipment inside, which is firmly entrenched in a ditch or rut. The robust design and large dimensions make it possible to use the jack as an anchor, if necessary, in order to extract the machine with an electric winch. To do this, on an area where there are no trees, but there are various boulders, the jack is fixed between them, the car clings to it.

In fairness, it should be noted that the rack is not designed for such loads, therefore, after some such events, you can see a bent rack jack. There were times when they managed to bend it 90 degrees.

Like any tool that sooner or later has to be used, such jacks have their undeniable advantages:

- Simplicity of design and use. This type of lifting mechanism is very reliable and unpretentious in use. The seemingly weak structure is capable of withstanding serious loads.

- The large lift height allows a deeply stuck machine to be pulled out.

- Fast operation of the mechanism. You can lift the load to the desired height in a matter of minutes.

Of course, such a tool will not do without its drawbacks, which are worth noting:

- Very large size. Some models exceed the length of 1.5 m, so a place for such a necessary device is not found in every car, but only in large SUVs.

- The small support area of the jack itself forces you to carry with you the so-called "shoe". This is a support platform that increases the area of contact with the ground so that the weight of the machine does not sink the device into the ground.

- Not suitable for all types of cars. The specificity of the hitching to the car implies the presence of power elements of the body, which are abundant in prepared jeeps (power bumpers, thresholds, various lugs), all this is not available in a conventional car and it will not work to hook a jack on a plastic bumper to replace a wheel.

The most important rule when working with a jack like this is safety. This moment got into shortcomings for a reason

A car raised on such a jack is extremely unstable, therefore, it is categorically, under no circumstances to climb under it. In addition, very often the car breaks off the jack, in this regard, there is such a thing as a "hijack fall zone", falling into which is life-threatening.

If the car falls, and the jack is in a clamped state, then its handle begins to jump with great speed and, most importantly, force. It is impossible to stop it with your hands, and most injuries (knocked out teeth, broken jaws, broken ribs and limbs) occur at this very moment.

How to use?

But even the best jack can fail if used illiterately. It is imperative to observe weight restrictions and standards for lifting height. Attempts at the expense of "people's technical ingenuity" to bypass both of them do not lead to anything good. It is imperative to block the wheels or prevent the movement of parts of other cargo (if we are not talking about the machine).

The lifted load must not be held on one jack. Ascent time should be kept to a minimum as much as possible. It is necessary to consider where to place the jack correctly in each case. It usually has intuitive labels on it.

For information on how to choose a jack, see the next video.

Design features

The trolley car jack is a hydraulic lifting device mounted on four steel castors. This makes it possible to roll it under the car, which is why it got its name.

The trolley car jack is a hydraulic lifting device mounted on four steel castors. This makes it possible to roll it under the car, which is why it got its name.

Not a single car service or service station can do without the use of a lift. Large carrying capacity, convenience and ease of use, play a tangible help in the work of not only professional car mechanics, but also ordinary car enthusiasts.

The lifting mechanism consists of several elements:

- a metal frame that can withstand heavy loads for a long time;

- four metal wheels:

- two front ones - load-bearing ones, playing a supporting role;

- two rear ones are movable, ensuring the maneuverability of the unit;

- hydraulic piston raised or lowered into the housing;

- the platform is the part on which the machine rests;

- a handle designed to pump oil into the piston, which drives the mechanism.

To use such a device, a flat and solid floor is required. If a trolley jack of 3 tons or more is used, the surface must be concrete. The steel wheels are coated with polyurethane, which allows the mechanism to be used on any floor covering without the danger of causing damage.

To use such a device, a flat and solid floor is required. If a trolley jack of 3 tons or more is used, the surface must be concrete. The steel wheels are coated with polyurethane, which allows the mechanism to be used on any floor covering without the danger of causing damage.

The hydraulic lift is adapted for long-term stay under load without the use of additional means or mechanisms. No cranes, chains or winches are needed anymore. The service life of such devices is long, which does not require frequent intervention.

In order to protect the body paintwork, it is recommended to equip the lifting platform with a thick rubber pad. Additionally, they ensure safety during work by placing stoppers or stops under the wheels on the opposite side of the machine.

The lifting device has important advantages:

- High efficiency and complete autonomy.

- Safety of any work under the machine.

- Storing the mechanism does not require special conditions and additional free space.

How to use?

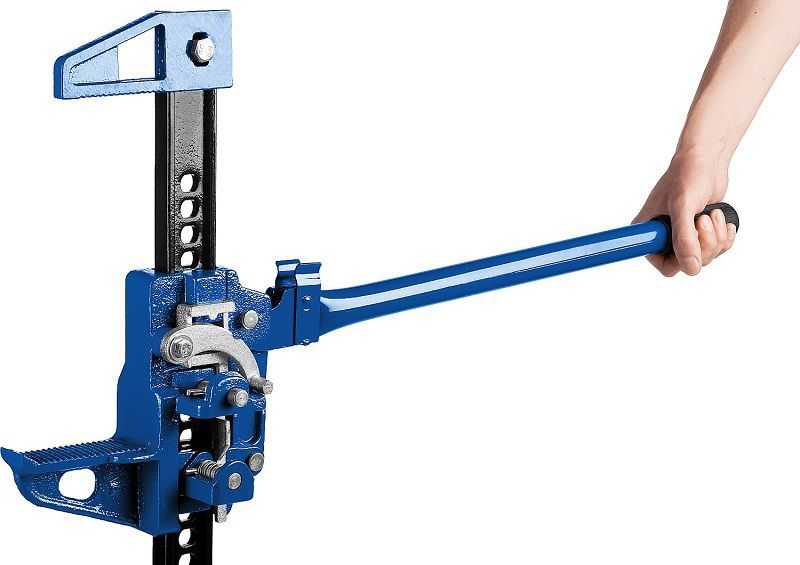

The rack jack for 3 tons is very easy to use. The carriage has a lift direction switch. If the product without load is switched to the lowering mode, then the carriage will move freely along the rail. In the case of installation in the lifting mode, the mechanism begins to work according to the principle of a reverse key, moving only in one direction (up). At the same time, a characteristic crackling sound will be heard. This is necessary to quickly set the device to the desired height.

Lifting is carried out using a lever - it is necessary to press on it with force, and in the lower position, fixation takes place on the next tooth.

It is very important to hold on to the lever firmly, as if it slips, it will begin to return to its original position with great force. Lowering a load requires more attention than lifting

Since everything here happens in the reverse order and you do not need to press on the lever, and not let it shoot into the rail. Many people forget about it and get severe injuries.

Most importantly, keep your fingers, head, and hands away from the flight path of the sliding lever.

The following video provides an overview of the Hi-Jack rack jack from the American company Hi-Lift.

Conclusion

Before purchasing this or that type of jack, you need to find out about the weight of your car. This will eliminate the possibility of purchasing a device with an incorrect carrying capacity. This parameter should be selected with a small margin.

It must be remembered that powerful mechanisms are more impressive in size and weight, therefore, a certain amount of free space will be required for their transportation and storage. Experts have recently been recommending the purchase of domestically produced goods more and more often, because, in comparison with foreign ones, they do not differ much in functionality, but they are much cheaper. And it will be quite difficult to find service centers for imported devices in your city if you do not live in a metropolis. As practice shows, domestic jacks are more maintainable, you can fix the problem when it occurs on your own, without resorting to outside help.