Replacing the gearbox with your own hands

If there are full-fledged problems in the gearbox, then it will need to be completely dismantled and replaced with a new one. It is possible to disassemble the gearbox of the Neva walk-behind tractor only after it has been cleaned and all the oil has been drained.

The process looks like this:

- the contents are drained, after which the mechanism is cleaned;

- after detaching from the structure of the equipment, the mechanism is dismantled and completely removed;

- a new mechanism is installed;

- refueling is in progress;

- running-in is carried out for at least 20 hours, during which all mechanisms are set up.

It is required to remember that after a complete replacement, the running-in is done during the working process, but without the need for enhanced operation.

Replacing the lubricant in the Neva is a mandatory procedure. When carrying out it, it is worth considering all the features of the gearbox, including the required brands of oils. If the replacement is not carried out in a timely manner or correctly, then in the future repairs, including major ones, are possible, since the technique is very demanding on high-quality lubrication.

User manual

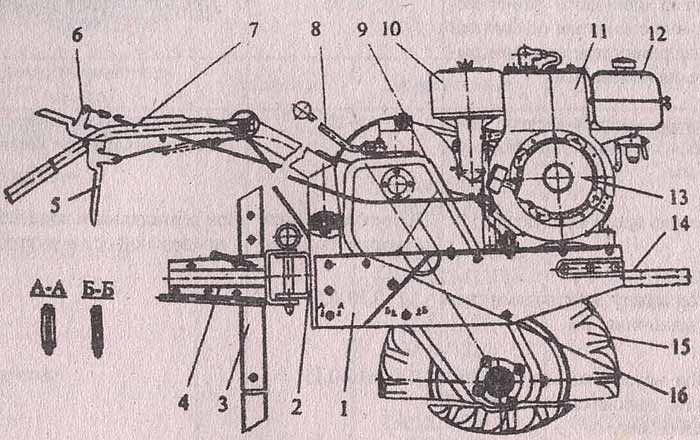

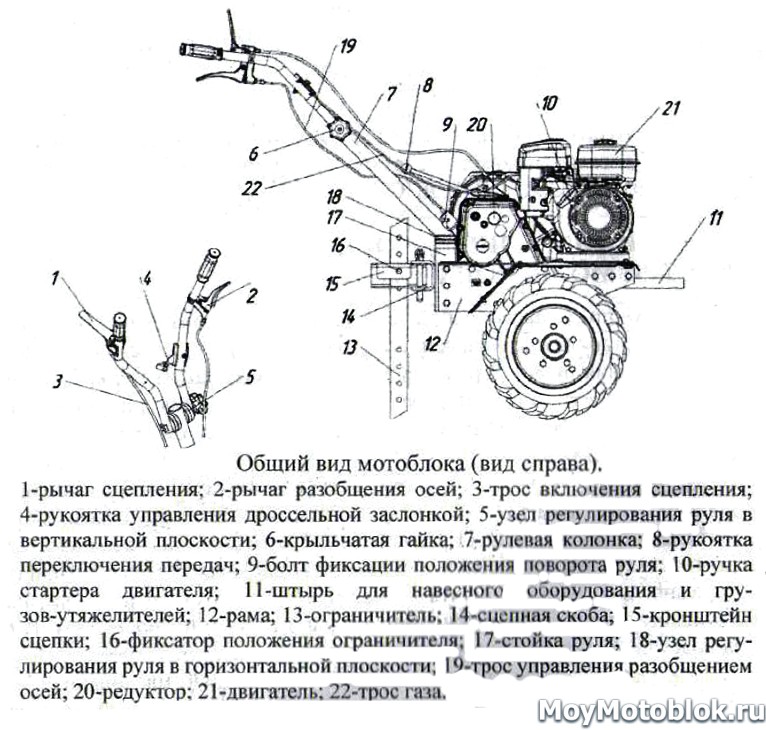

Before using the MB, it must be assembled and prepared for work.

When you receive the cultivator, pay attention to its power unit. It should have a sticker with a safety icon

Latest modifications of the Lifan 8 hp engine. with. Lifan have distinctive features that must be taken into account when assembling MB. Modification of the Lifan walk-behind tractor 900 mm - 1100 mm involves the installation of additional equipment for expanding the plowed harrow.

When working with a motor-cultivator, it is important to observe the following safety precautions:

- Inspect the engine before each launch.

- Beware of flammable objects when running the Lifan engine.

- Keep children and animals away from the working MB.

- You can fill the tank only when the MB is switched off.

- Do not run the engine indoors.

Starting work without running in the Lifan engine entails premature breakdowns and equipment failure.

Running in the Lifan walk-behind tractor

Running in the engine of the Lifan walk-behind tractor allows you to prepare the cultivator for full-fledged operation with a full load of equipment. The purpose of running-in is the running-in and grinding in of all elements of the power unit. The process of running in the Lifan engine is as follows:

- Check the oil level before starting the engine.

- Fill the fuel tank.

- Start the walk-behind tractor at medium speed.

- Within an hour, you need to test the car in all gears one by one.

- Use the cultivator to carry out all operations (plowing, cultivating, transporting cargo) at medium speed and only on the previously plowed land.

- After running-in, change the oil and fill the fuel tank.

- MB is ready to work at full capacity.

It should be remembered that the running-in process is described in detail in the user manual. Before taking any action, read the manual and proceed as described.

Land cultivation with motoblocks Lifan

The purpose of Lifan motor-cultivators is high-quality cultivation of the land for planting, caring for seedlings and harvesting. This type of equipment is perfect for processing medium and small areas with any relief and different types of soil. Plowing the land on this unit is available to a depth of 200 mm, which allows you to dig up only the fertile soil layer, leaving the deeper clay layers untouched.

Thanks to a large selection of attachments using the Lifan walk-behind tractor, you can perform any kind of gardening work, depending on the season and the needs of the consumer. By changing the components, the motor-cultivator can be used all year round, starting with plowing and planting, and ending with snow removal in winter.

The standard complete set of the walk-behind tractor includes:

- Cutters.

- Wheels d350 mm for a walk-behind tractor.

Additional equipment:

- Plow.

- Hay mower.

- Potato digger.

- Pump equipment.

- Snow removal equipment, etc.

The Lifan engine power in the latest models makes it easy to cultivate virgin lands with complex mixed soil. However, when working with a motor-cultivator, do not forget about the need for technical maintenance.

Instructions and recommendations for use

The reliability and long service life of the walk-behind tractor depend on the operating conditions, maintenance, care of the unit, and competent running-in after its purchase. To do this, you must follow all the recommendations for the operation of equipment.

They boil down to the following:

- Assemble the walk-behind tractor. The assembly diagram can be found in the instructions that came with the purchase to the unit.

- Fill up the tank with clean gasoline.

- Check the oil level in the engine crankcase.

- Inspect the wheel mounts.

- Check engine valve clearances. The valves are adjusted using the 0.10-0.25 mm feeler gauges.

- Run in as follows:

- do not start work with a cold engine;

- first, the engine must idle;

- do not load the engine during operation;

- running-in must last at least 30 hours;

- only work in first gear;

- after running in, change the engine oil, check the bolted connections.

- Adjust the tension of the forward and reverse belts of the V-belt transmission by changing the length of the chains.

- Check the operation of the controls.

- Lubricate the starter in a timely manner.

- Fill the gearbox with oil in time.

- Do not allow it to enter the filters.

Many farmers are wondering what kind of oil should be poured into the walk-behind tractor. In particular, they are interested in the MB 6841 walk-behind tractor with M-12GI or M-10GI filling. These are old brands of oils and it is not easy to find them.

The following fuels and lubricants are suitable for Cascade walk-behind tractors:

- in the fuel tank - motor gasoline Normal-80, GOST R 51105-97;

- into the crankcase - motor oil M-5z / 10G1, M-6z / 10V, M-6z / 12G1, GOST 10541-78;

- for the gearbox - transmission oil in accordance with GOST 23652-79 or aviation MS-20, GOST 21743-76.

Do not mix synthetic and mineral materials.

The operating instructions also contain safety information that is aimed at protecting the operator as well as protecting the equipment from damage during operation. It is strictly forbidden to warm up the engine with an open flame, for example with a burner. Work on terrain with difficult terrain should be carried out only at low speeds, the same applies to work at great depths. High speed under these conditions will overload the engine and put the operator at risk.

To set the walk-behind tractor in motion, you must select the gear with the handle and using the designations on the body, then press the forward or reverse lever. It is forbidden to change gears with the forward or reverse lever cocked into the working position.

Carburetor setting

The initial carburetor adjustment is made at the factory. The user must not perform any repair work during the warranty period. If starting poorly, inspect the spark plug. If the candle is damp, then problem in the ignition system... If the spark plug is dry, check for fuel to the carburetor.

Carburetor repair on the Cascade walk-behind tractor is carried out only in specialized workshops.

What kind of oil to fill

It is necessary to fill in oil together with the lubrication of all parts, as well as with an oil change in engines.

What kind of oil to pour into the gearbox of the walk-behind tractor and how much depends on various nuances, including the season of work.

The engines are filled with engine oil, which must not be poured into the gearbox.

The choice of oil depends both on the season in which the work is performed and on the data specified in the operating instructions.

According to the models of the walk-behind tractor, the transmission oil is distributed in accordance with GOST:

- TEP-15, TM-5;

- TAP-15V, TAD-17I.

This is a standard that is prescribed in accordance with the corresponding GOST 23652-79.

Oil for the Neva walk-behind tractor must be of high quality and from a good manufacturer - this is a prerequisite.

It is worth considering that each oil is used only in the allotted period. For example, TEP-15 is used in the summer. The minimum temperature limit is -5 degrees. If the temperature is lower, then you will have to use TM-5, which has a minimum of 25 degrees of frost. These oils are also used in various modifications.

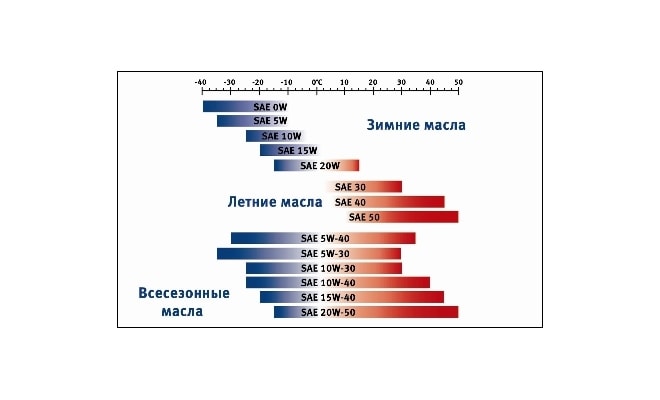

Classification of grades of oils

To increase the service life of a gasoline or diesel engine, you need to make the right choice of engine oil. Failure to replace it in a timely manner reduces the service life of the engine. How to choose it, in what quantity, how to pour it into a walk-behind tractor - let's talk about this in more detail.

The kit of each mini-tractor or walk-behind tractor includes instructions and a product passport. In the instructions, the manufacturer lists the suitable grades of fuel and lubricating fluids that can extend the life of the equipment. The engine oil performs the following functions:

- cooling;

- lubricants;

- seals;

- cleaning.

With air cooling, the grease settles on the walls of the hot cylinder. These deposits contaminate engine parts and make lubrication difficult. Therefore, antioxidant additives are present in the lubricant. They clean the cylinder walls from carbon deposits and extend the service life of the walk-behind tractor. Different climatic zones require the use of different oily fluids. They differ in viscosity, composition and purpose.

By viscosity

The viscosity is determined according to the SAE J300 standard. For mechanisms, it depends on the following characteristics:

- unit design;

- features of work;

- the age of the mechanism;

- ambient temperature.

Motor oils are divided into winter and summer oils. Winter grades are marked with the letter W. Low-viscosity winter grades are often used with the designations SAE 0W, 25W, as well as with intermediate values of 20W, 5W, 15W and 10W. Compositions for use in summer do not have letters in the name. They are distinguished by high viscosity and are designated SAE 20, 60, CAE 30 or 40. When using summer grades in winter, problems arise associated with starting the unit. Winter varieties in the summer are not able to provide high-quality lubrication.

Scientists have developed all-season compounds that are used for pouring into a walk-behind tractor in summer and winter. Their designations are 5W-40, 10W30.

By composition

In addition to seasonal characteristics, lubricants are divided into types according to their composition:

- mineral;

- synthetic;

- semi-synthetic.

The air-cooled engine heats up quickly during operation. Engine oil lowers its temperature. The wrong category causes damage to the motor. It is not recommended to use synthetic oil mixed with mineral oil.

See »Characteristics of the Parma MB-01-6.5 walk-behind tractor and consumer reviews

By appointment

When it becomes necessary to replace lubricating fluids, each manufacturing company recommends filling its own brand. For agricultural machines, Honda uses all-season 10W-30 grade SF. Subaru in its recommendations indicates for work in temperate climates 10W-30, in cold regions - 5W-30. Oil quality category - SE.

Lifan's products require an SAE-30 summer grade, and an SAE 10W-30 grade for winter conditions. There are no quality conditions.The Kaluga Engine motoblocks are filled with an all-season composition 10W-30 or 15W-30 of SF or SH quality.

How to do it yourself?

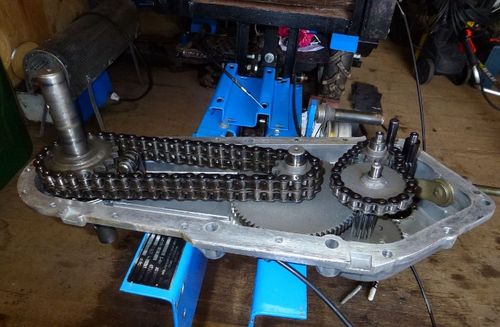

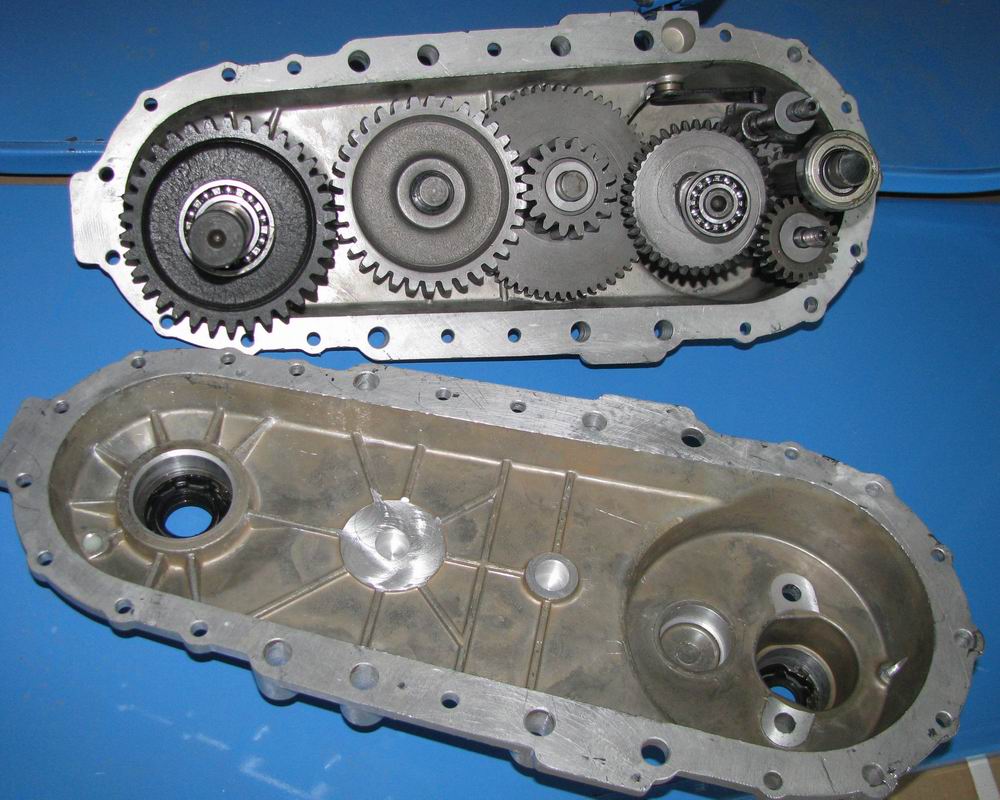

If you have access to a huge selection of necessary spare parts, then, of course, it is easier to make gearboxes yourself.

But please note that such a spare part needs serious equipment for metal processing. If you have this, then you can choose a housing of optimal parameters, make holes for shafts on bearings and make a device no worse than at a factory.

Initially, you need to calculate the rated power without errors. Thanks to the correct results, you will be able to find out the optimal angle to find on the bevel gear. You need to calculate the number of spins in 60 seconds.

The gearbox made requires the determination of the conditions of its operation, including the load. Its performance will be top notch with the right temperature and lubrication. The next step is assembling the gearbox. The case can be taken from the factory. According to its diameter, you can identify the bearing housing for the shaft. A vernier caliper and a drill will help you with this.

The steel flange must be mounted on the front of the gearbox. Inside, we mount a flange bearing and a washer. The flange is secured with screws at the generator itself. The key and gear must be selected in advance. All units that are in contact with the transmission system are fixed to the rotary generator.

Algorithm for changing the oil in the walk-behind tractor

Before using a new lubricant, it is important to clean the gearbox of the compound used. Change the lubricant immediately after the end of the use of the equipment, before the oil has had time to cool

You can quickly change the oil with your own hands according to the following scheme:

Change the lubricant immediately after using the equipment, before the oil has cooled down. You can quickly change the oil with your own hands according to the following scheme:

- The walk-behind tractor is installed horizontally;

- Two plugs are installed. Through one, the already used composition is drained, the second is used to fill in new oil;

- The lubricant filling cap is unscrewed. A wide container is installed under the drain hole;

- The drain cover is unscrewed until all the used oil drains out;

- The drain cover is screwed up to the stop with a spanner wrench;

- The funnel is inserted into the filling hole and new oil of the appropriate grade and temperature is added;

- The lid is screwed on. With a special dipstick, you can check the amount of the poured product.

For details on the specifics of the replacement procedure, see the introductory video.

If the equipment is operated under normal conditions, the oil in the gearbox changes once every hundred hours of operation of the walk-behind tractor. When working around the clock, replacement is done every fifty hours. In this way, various breakdowns of agricultural machinery can be prevented.

| Walk-behind tractor brand | Recommended oil change intervals |

| Favorite (ZiD) | Change the oil in the gearbox for the first time after a day of operating the walk-behind tractor. Further, it is enough to replace it once every 250 hours of operation. |

| Virgin land | The first oil change is made after 50 hours, then every 200 hours of operation. |

| Ugra, Oka (Kadvi) | Replacement during continuous operation every 100 hours. If the equipment is stored, it is sufficient to change the oil once a year. |

| Agate | After 100 hours of operation. |

| Belarus 08N-09N (MTZ) | After 250 hours of operation. |

| Vario | Once every two years when the equipment is idle or every 100 hours with constant operation. |

| Neva | During continuous operation, the oil is changed every hundred hours. |

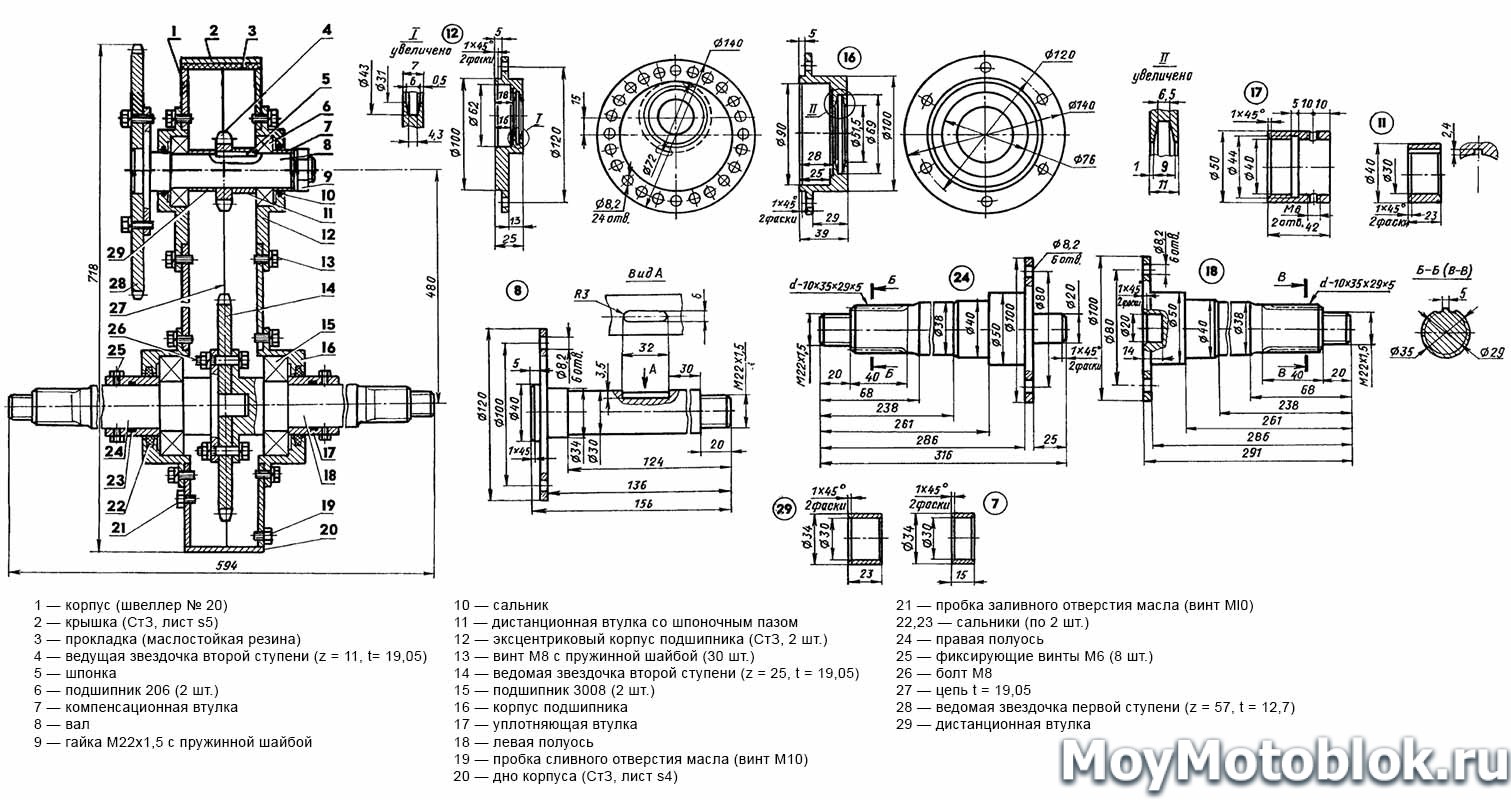

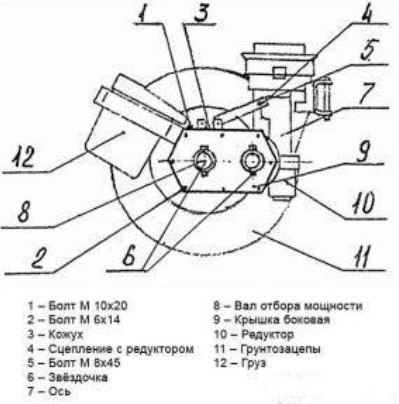

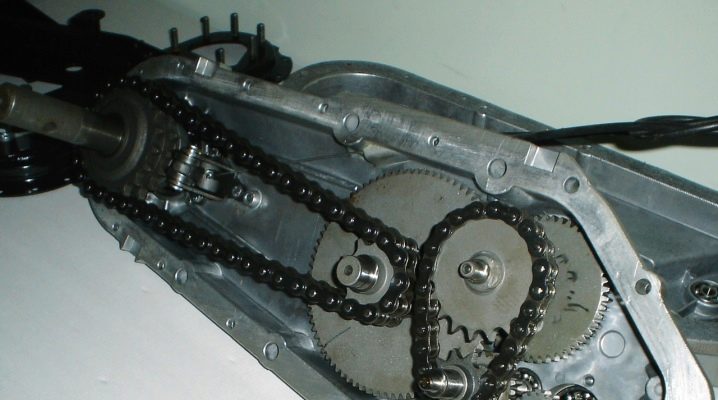

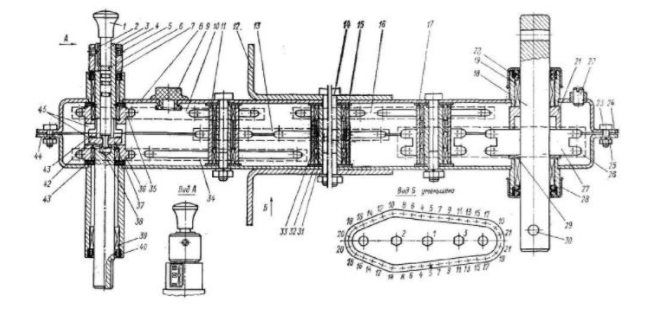

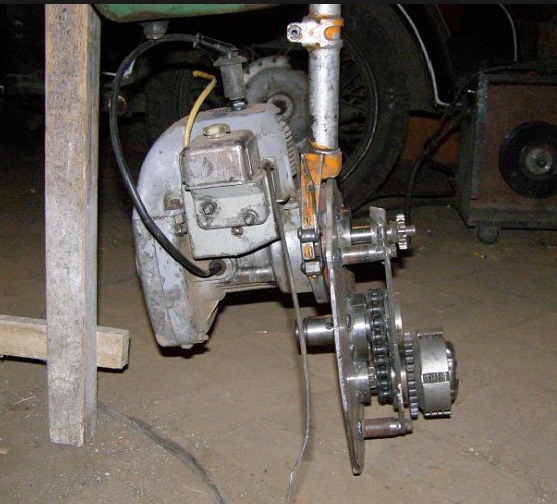

In the context of the Oka reducer looks like this

The body of the part is steel, it consists of two parts, which are fastened with three bolts and a sealing gasket. Squares are welded to each part of the body, which form the supporting frame of the device.

The transmission of the motor-block reducer torque device is supplied from the left or right shaft sprocket. This part is brought into engagement with the help of a cracker, which is moved along the shaft axis with a special shift knob. The recessed handle engages the sprocket and engages first gear. If the handle is pulled out to the end, then the second gear will be engaged. In the middle position, the shift will be neutral.

In this video, you will learn how to repair the gearbox of a walk-behind tractor:

With constant care of the device and regular checking of the oil condition, the gearbox will last long enough. If the device malfunctions, then the following reasons are possible:

- oil flows;

- the semiaxis decoupling mechanism has malfunctioned;

- the edge on the axle cover is worn out;

- transmissions are not recorded.

In the latter case, a violation of the adjustment of the transmission or a malfunction of the spring is possible. To remedy the situation, it is necessary to disassemble the gearbox of the walk-behind tractor and replace the defective parts as shown in the drawing of the multicultivator.

The device may also not work due to an open circuit or lack of kinematic connection inside. To disassemble the gearbox, you must perform the following steps:

First, the engine and steering knob are removed. Then the pulleys and traction.

Then the wings should be removed from the base frame and the steering rack.

All clamping bolts of the elbows are turned out.

Then the wheels are removed

It is important to clean the device of dust and dirt before disassembling the device, otherwise the dirt inside the structure may impair the operation of the gearbox. It is also necessary to drain the oil.

The next step is to remove the gear lever with all its components.

Next, unscrew the bolts from the cover and the nuts from them.

Then you need to put the device on the left half of the case and very carefully with a knife unscrew the bolts that connect the two halves of the case.

The sprocket is removed from the intermediate shaft.

Then - the shift roller, fork and block shaft.

What kind of oil is poured

Many people are interested in what kind of oil to pour into the gearbox of the walk-behind tractor? To answer this question, you need to take into account several factors, the main of which is the manufacturer's recommendation regarding the type of oil.

In the store, you should also pay attention to the degree of viscosity of the oil, which is indicated on the packaging. In addition, there are special additives - substances that increase the beneficial properties of the lubricant.

Gear oil

In general, oils can be of various types:

- SAE. These types of oils cope very well with sudden changes in temperature, so they can be used all year round.

- The selection process is as follows: you need to look at the number that is in front of the letter W - a lower value will indicate that the oil is very well adapted to low temperatures (the smallest is 0W). If the letter W is not on the label, then this oil is suitable for the summer period.

- API. In this case, the letters in the marking will indicate the type of engine - gasoline or diesel. Accordingly, a certain letter will say that the oil is suitable for gasoline units, and the other for diesel ones.

- The numbers will talk about the type of engine, i.e. number 4 means oil should be used for a 4-stroke engine, etc. The EC value is the degree to which energy is saved, i.e. the higher the value, the better the quality of the oil.

- ASEA. The largest number in the labeling will indicate that the oil can function in very difficult conditions.

- GOST 17479, 1-85. These indicators characterize the degree of viscosity of the oil. As a rule, after this parameter, alphabetic and numeric values are written, and their absence indicates that the oil is universal.

Transmission oils for filling gasoline and diesel motoblocks

As for the gearbox, gear oils must be used to fill it.For example, semi-synthetic oil ZIC 10W40, designed for gasoline and diesel motoblocks, would be a good choice. API indicator - SM / CF, ACEA - A3 / B3, A3 / B4, C3.

Another worthy oil is Super T-3 85W-90 from Gazpromneft. Its technical data will be as follows:

- API indicator - GL-5;

- viscosity grade - 85W90;

- temperature indicator of loss of fluidity - -280C;

- flash point - 2170C;

- package length - 270 mm;

- packing width - 130 mm;

- packing height - 240 mm.

This gear oil is also supplied in a 4-liter container, which costs about 600 rubles.

Transmission oil

This is not the whole list of oils that can be poured into the gearbox of the walk-behind tractor. In principle, any person who is familiar with the basic parameters of the oil can independently determine what is needed for his walk-behind tractor.

How to make a gearbox for a walk-behind tractor with your own hands

Between worm and chain reducers for a walk-behind tractor there are differences in several important characteristics: gear ratio, efficiency, number of shafts and gears, angular speeds and power.

What are the gearboxes for the walk-behind tractor

Non-collapsible gearboxes are usually installed on cheap walk-behind tractors. The design of such a unit is not particularly reliable. It also has a short service life. In addition, it is impossible to carry out repairs or disassembly-assembly. In the manufacture of such units, low-quality metal and non-cased parts are used. In order to understand why it is impossible to use the gearbox for a long time, you need to familiarize yourself with its diagram.

It is customary to install collapsible gearboxes on expensive walk-behind tractors. Thanks to this, you can disassemble the gearbox of the walk-behind tractor and carry out maintenance. The gearbox of the walk-behind tractor is repaired to increase the service life, if high-quality spare parts are used when replacing defective elements.

It is imperative to regularly diagnose the gearbox in order to repair the required unit in time. Regular lubrication of the gearbox should also be carried out, which will allow the unit to be used for much longer. Most often, a gearbox for a walk-behind tractor is used to convert a high angular speed to a low one. The input shaft shows a high speed and the output shaft shows a low speed.

In order to avoid unexpected breakdowns, it is necessary to carry out regular maintenance in order to successfully operate the agricultural machine. If the change in angular speed occurs in steps, the gearbox is called a gearbox, if the change occurs continuously, it is called a variator.

Homemade angular gearbox for walk-behind tractor

The walk-behind tractor gearbox can be made by yourself. To do this, you will need to calculate the rated power (Pn); Pn = Pe (hp) xFS, as a result of which the correct type of angle is determined for the bevel gear. Torque and RPM are also calculated.

You also need to determine the operating conditions of a homemade gearbox for a walk-behind tractor, which includes: radial and axial loads on the shaft ends, minimum and maximum temperatures, determination of environmental conditions, intermittent or non-intermittent operating cycle, type of lubricant.

After determining the technical parameters, you can start assembling the bevel gear. To do this, select the housing for the bevel gearbox.

For example, you can use a factory one, from a Ural or Dnepr motorcycle. Then, based on the diameter of the gearbox housing, we make the gear shaft bearing housing from steel. Here we use an appropriately sized drill and a vernier caliper. Then, in accordance with the intended dimensions, we select the gear shaft bearings (2 pcs).

Install a steel flange on the back of the gearbox. It will have a steel washer and a flange bearing inside. Using a few screws, attach the steel flange to the generator body.Before that, we select the driven gear shaft, steel key and drive gear. All units are connected to the transmission mechanism and the shaft of the rotary generator. The V-belt drive pulley is located on the transmission mechanism and is attached to the driven pinion shaft with a nut and a spring washer. To assemble a homemade bevel gear, you will need the following tools: a caliper and a ruler, a straight and Phillips screwdriver, metal drills, metal files and files, wire cutters and pliers, rubber gaskets, a vice and a hammer.

It is interesting: Which Lynx walk-behind tractor is more reliable - we disassemble together