How to change the oil

Most often, the oil change rate depends on the engine and its performance. Changing the oil in the gearbox can be done in conjunction with changing the engine lubricants. It all depends on the type of engine:

- Robin Subaru. First replacement process after 20 hours of working procedure, and then every 100 hours.

- Honda and Lifan - 20 hours, and then after 6 months.

- Briggs & Stratton - 5 hours. Subsequently, a regular check is carried out after 8 hours. A complete replacement process should be carried out every 50 hours of operation.

Replacement:

- the technique is placed vertically without even a slight tilt;

- the breather is unscrewed and cleaned;

- after unscrewing the screw, the oil is drained into a container of at least 3 liters;

- the screw is returned and tightened;

- oil is poured;

- the breather closes;

- the efficiency of the equipment is checked.

Do not forget to follow the instructions for changing the oil

Do not forget to follow the instructions for changing the oil

This is a standard lubricant change plan.

It should be borne in mind that, according to standard recommendations, the frequency of change is regulated in the following order:

- running-in - 30-35 hours;

- simple - 1-2 years;

- working process - 150-200 hours.

Such parameters are set for the workflow without an increased load on the walk-behind tractor. In the case of an enhanced operation, it is better to change the oil every 50 hours of operation, which will allow the entire lubrication system to not clog. This will increase the chances of a full-fledged work without breakdowns.

Walk-behind tractor device

All existing Oka walk-behind tractors have the following device:

- Gas engine;

- rigid frame;

- adjustable steering rods with rubberized grips;

- transmission (chain reducer of reinforced type, V-belt type transmission, mechanical gearbox, clutch, PTO drive);

- chassis (wheel drive);

- gas tank;

- filters (oil and air);

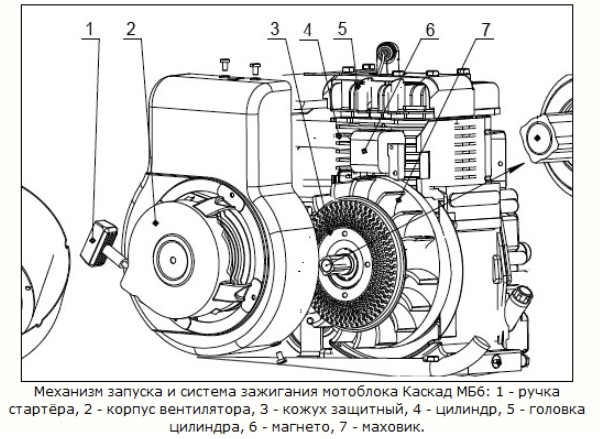

- ignition system;

- inertial starter.

Depending on the modification, Oka walk-behind tractors can be equipped with different engines:

- The Oka MB-1D1 (2, 3) M9 motor-block is equipped with a Honda carburetor engine (HONDA GX-200) with a capacity of 6.5 horsepower.

- The MB-1D1 (2, 3) M10 models have a Lifan gasoline power plant (Lifan168 F-2A) with a capacity of 6.5 liters. with.

- Motoblock MB-1D1 (2, 3) M15 was equipped with a native factory engine KADVI 168F-2A 6.5 liters. with.

- Modifications MB-1D1 (2, 3) M13 and M14 received the power plant Robin Subaru EX17 or EX21, with a capacity of 6.0 and 7.0 liters. with. respectively.

- Models MB-1D1 (2, 3) M and MB-1D1 (2, 3) M1 are equipped with engines DM-1M and DM-1M1, with a capacity of 8 liters. with.

Common to all of the listed power plants:

- one cylinder;

- cycle for 4 bars;

- forced air cooling;

- use of AI-92 or AI-95 gasoline.

It is necessary to start the motor correctly, according to the algorithm specified in the instructions. If certain actions are not followed, there is a high risk of engine failure. We offer you to watch a short video on how to start an Oka walk-behind tractor:

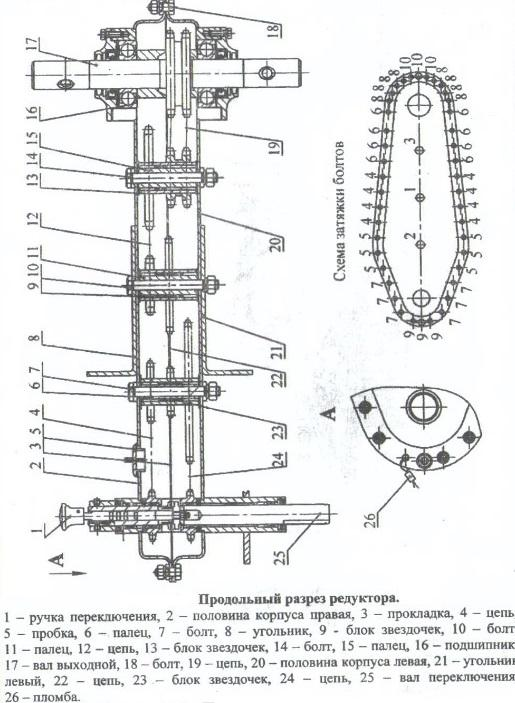

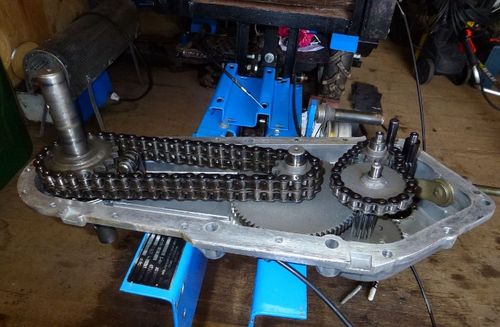

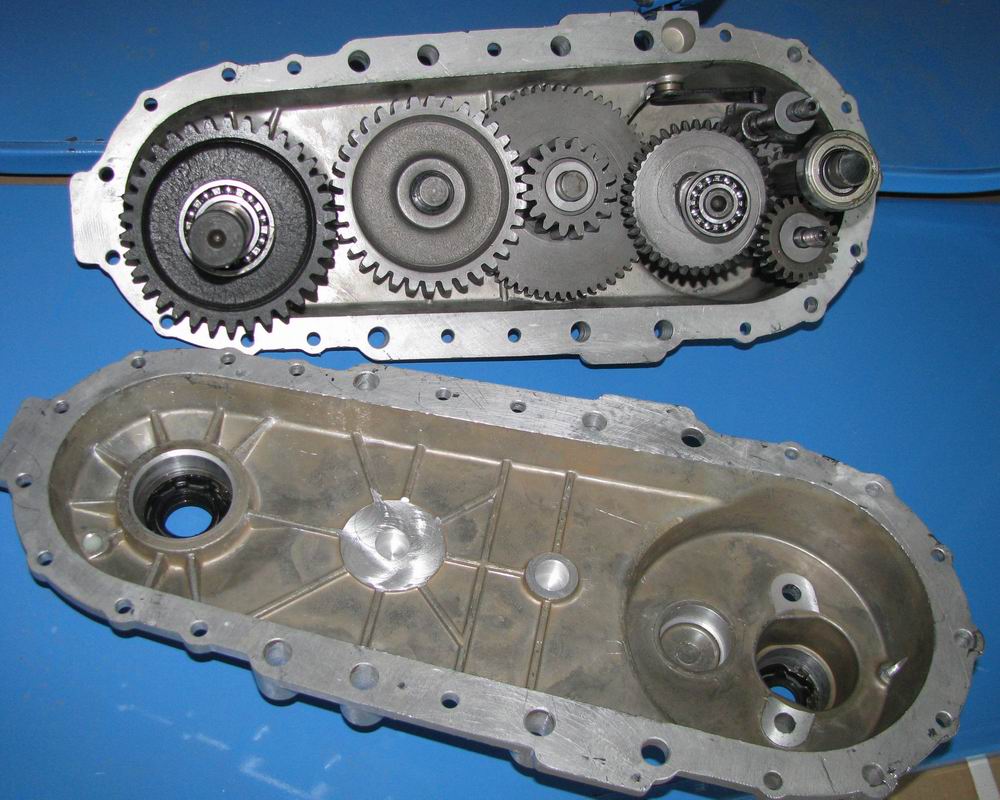

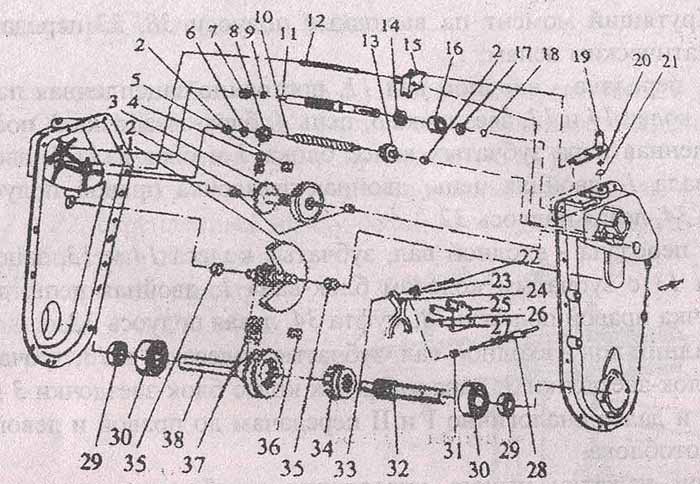

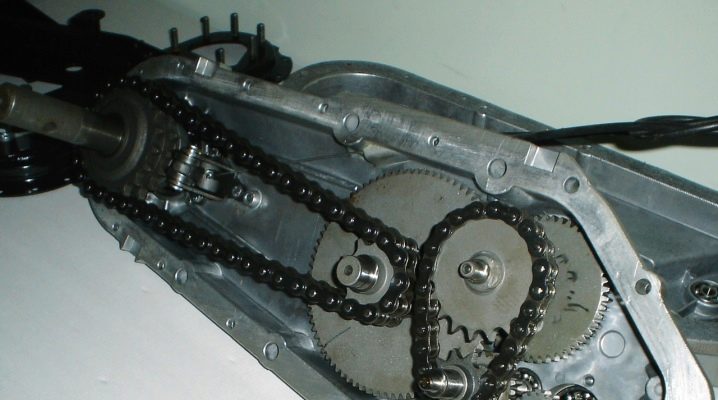

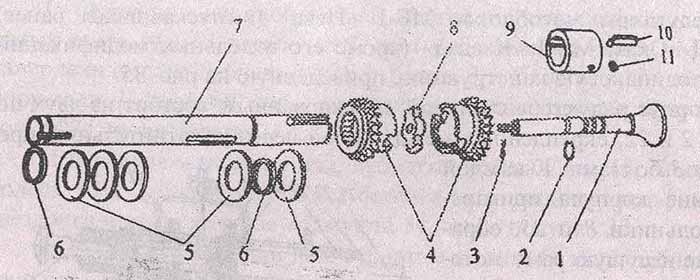

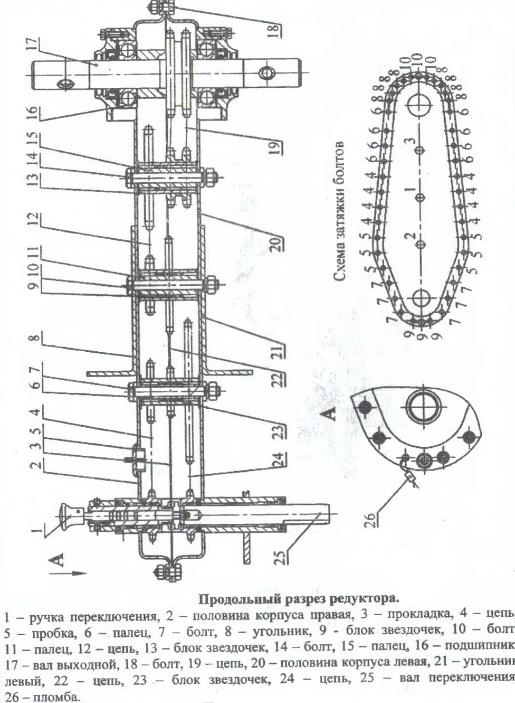

Gearbox device

The motoblock gearbox transfers torque from the engine to the wheel drive. Its construction is as follows:

- asterisks (master and slave);

- chain;

- shaft:

- frame.

We propose to study the diagram of the gearbox of the Oka walk-behind tractor in a section:

Oka walk-behind tractor gearbox diagram

Oka walk-behind tractor gearbox diagram

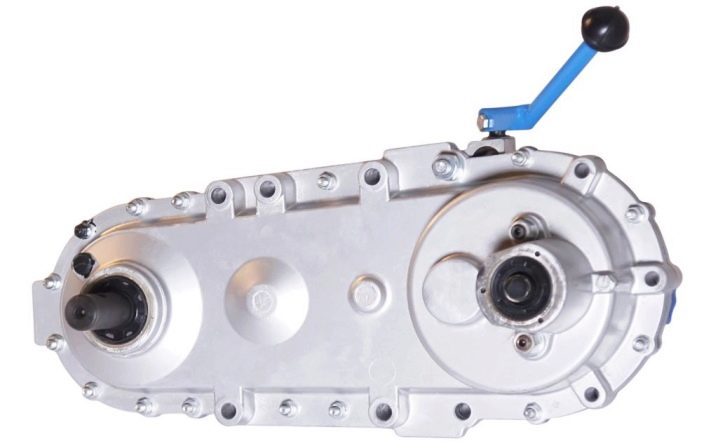

What gearbox can be put on the Oka walk-behind tractor?

It is best to use a collapsible chain reducer, which consists of a collapsible housing with bolted connections. Unlike a non-separable gearbox, such a mechanism can be easily repaired and will last more than one year. A gear reducer can be installed on more powerful equipment, a worm gear in walk-behind tractors is rarely practiced.

The device and principle of operation of the carburetor

Carburettors are gas distribution devices inherent in gasoline engines. The function of the carburetor is as follows:

- regulates the amount of incoming gasoline and air;

- saturates the air with gasoline vapors.

We suggest that you familiarize yourself with the carburetor diagram for the Oka:

Repairs and malfunctions

Despite the fact that the motoblocks of the Salute model range are reliable, in some cases malfunctions occur in the gearboxes.Let's consider the main problems that can be encountered and how to deal with them:

- Poor recoil after changing the oil (no sealing, re-install the oil seal and apply the sealant).

- A metallic noise is heard (usually due to lack of lubrication, service should be performed immediately).

- The mechanism hums (there is an excess of mixture in the gearbox, it is required to drain the excess fluid).

This is interesting: repair of the gearbox of the Neva MB 2 walk-behind tractor.

Other malfunctions associated with broken bearings or gears, as well as anthers, may also appear; here it is required to immediately replace worn parts.

Currently, special equipment includes many high-quality structural elements. However, even despite this, it can be damaged. Often, the failure of units is associated with a lack of lubrication, which has an extremely detrimental effect on the metal. That is why, in order not to face unnecessary waste of funds, it is recommended to carry out maintenance in a timely manner. In this case, the working apparatus will perform all the duties assigned to it for a long time.

Operation and maintenance Neva MB-2

Changing the engine oil

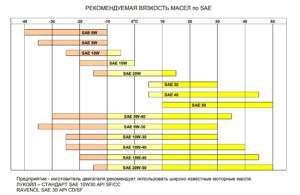

The manufacturer recommends using such well-known brands of engine oil for the walk-behind tractor as LUKOIL - SAE 10W30 API SF / CC standard, as well as RAVENOL SAE 30 API CD / SF.

Recommended viscosity of oils for motoblocks Neva

At temperatures above 4 degrees Celsius, using thickened oils (for example, grade 10W30) will lead to increased consumption of this type of fuel, therefore, in the cold season, it is recommended to check the oil level in the engine more often, not allowing its mark to drop below normal.

An oil change is carried out after the walk-behind tractor has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is completely drained from the tank, and then a new one is added until the oil level reaches a special mark. The drain plug is then screwed on tightly and wiped dry.

The first start-up and running-in of the Neva MB-2 walk-behind tractor

The first start-up must be done according to the following scheme:

- make sure that the walk-behind tractor is in a complete state (the height of the steering rod and handles must correspond to the height of the user);

- you can start the engine only if the walk-behind tractor is located on a flat surface;

- check the oil and fuel level in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- idle time (without load and movement) should be about 10 minutes, then you can move from a place and operate the walk-behind tractor.

The running-in period is the first 20 hours of the walk-behind tractor, after which you need to change the oil

During this period, the most important:

- do not run at full throttle;

- work only on pre-prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that is included in the kit;

- the "Neva" MB-2 walk-behind tractor during the running-in period can be loaded only at ¾ of the power;

- shifting gears in the gearbox can only be done when the rotation of the drive pulley is completely stopped;

after the first 20 hours of operation after the first start, change the engine oil.

How to check the oil in the gearbox of the walk-behind tractor?

Monitor the amount of oil constantly. Otherwise, neglect of technology will lead to fatal consequences. Fresh oil is poured every 50 hours. Along with this, excessive loads should be avoided, which ultimately lead to the rapid development of mechanisms and components. Let's go directly to changing the oil:

- We install the equipment on a flat area. We find a probe, 70 cm long.

- The dipstick is bent and pushed into the hole for filling the oil until it stops, after which we take out the rod.

- We observe the oil level, which should be at least 25 cm.Add 2 liters of oil to the dry gearbox, at least 1.5 liters.