Prevention and Troubleshooting

To prevent the occurrence of malfunctions in the ignition system, try to follow some simple recommendations:

- do not work on a walk-behind tractor if the weather is bad outside - rains, dampness, frost, or sudden changes in humidity and temperature conditions are expected;

- if you smell an unpleasant smell of burning plastic, do not turn on the unit;

- protect important parts of the mechanism from water penetration;

- replace the spark plugs about once every 90 days; if you actively use the device, this period can and should be shortened;

- the oil used for the engine must be of high quality and of a brand suitable for the given model, otherwise the spark plug will be constantly filled with fuel;

- carry out regular inspections of the ignition system, gears, in order to prevent the use of the unit with broken cables, other malfunctions;

- when the motor heats up, try to reduce the load on the device, so you will protect the mechanism from accelerated wear;

- when you do not use the walk-behind tractor in winter, put it in a dry and rather warm room under lock and key in order to prevent hypothermia of the device.

DIY motoblock repair

Unfortunately, any equipment sometimes fails, so its owner needs to be able to troubleshoot on his own. Of course, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs for free.

Often damage to the cultivator, walk-behind tractor occurs due to improper operation - when bad fuel is poured, heavy loads are allowed or during the time they do not make up for the loss of lubricating fluid. Then the car starts to stall, "bury itself", it is bad to gain momentum (especially if there is an electric motor on it), or even stops starting altogether. But, knowing the device of the unit and the principle of operation of its mechanisms, you can yourself identify the cause of the damage and carry out high-quality repairs.

Fuel system repair

A breakdown of the fuel system can be asserted if the engine:

- does not start;

- stalls under load;

- does not function stably at idle.

To eliminate the malfunction, first check the condition of all filters, including air and oil. If they are slightly clogged, blow out with compressed air or rinse, if there are strong contaminants on them, replace them with new ones. Then they disassemble the carburetor, wash the parts with a special cleaner, clean the fuel mixture supply valve, the tank and the piston system with gasoline. After drying, carefully reassemble.

After the engine is fully assembled, the crankshaft is manually scrolled - it is important that the piston moves freely and the valves work flawlessly. Then they pour in fresh lubricant, start the engine and leave it to work at "idle"

Be sure to check the flow of fuel into the cylinder. Perhaps, after such a repair, the cause of the malfunction will be eliminated and the walk-behind tractor will begin to function without interruption.

Ignition system repair

The breakdown of devices for ignition of fuel assemblies can be judged by the signs when the engine:

- starts, but stalls at idle;

- does not start even with good fuel supply;

- works at "idle", but with some interruptions.

To find out the reason, first check the condition of the candles: if there is damage to the insulator, replace them. Next, the electrodes are inspected and, if necessary, the gap between them is adjusted. They check the condition of high-voltage wires for oxidation of the tips and insulation breakdowns - the damaged wires must be replaced with new ones. Without such repairs, the spark may completely disappear or it will go through the insulation, punching onto the engine housing, and will not be able to ensure the ignition of the fuel assembly.

If at this stage a defect with a spark is not found, then perhaps the reason that the equipment does not start or stalls lies in the generator or coil (for such models as the Neva, Cascade, it serves to form a spark). To check the generator, a measuring device is connected to its terminals. The motor-block starter pulley is scrolled and the readings of the device are recorded - they should be within 12-16 watts. If the indicators are normal, then the reason is contained in the ignition coil and after replacing it, you can put a load on the engine. Most likely, after such a repair, its performance will resume completely.

Transmission repair

The following factors indicate a transmission malfunction:

- the working shaft is motionless, and the output shaft rotates;

- engine speed does not match the speed of the working shaft;

- the engine seems to "choke" from the load.

If at least one of the above reasons manifests itself, they immediately check for the presence of grease in the gearbox. The lubricant in it must be normal, as the lubricant prevents "dry" friction of moving parts and prevents them from overheating.

Then the gearbox is disassembled, the gears are inspected, the chain tension is checked. Whole parts are washed in kerosene, and damaged parts are replaced with new ones. After that, they assemble the structure and make sure that the gears are not skewed.

Before installing the assembled gearbox on the walk-behind tractor, the shafts are scrolled to make sure that they rotate evenly and without the slightest grinding. The gearbox is filled with fresh lubricant, and the motor-cultivator is started. In the absence of a leak under the body, perform simple operations with a rotary tiller or a mounted loader and check the functionality of the walk-behind tractor. If its working capacity is restored, it means that all efforts were not in vain, and the repair and maintenance were carried out correctly.

In the spring, we take the equipment to the personal plot. Unfortunately, a situation often arises - the walk-behind tractor does not start. The owner must quickly determine the cause of the failure and correct the malfunction.

How does it work?

To understand breakdowns and fix them, it is important to understand how everything works in a normal situation. Let's stop for greater simplicity only on models with internal combustion engines.

Previously, there were two-stroke walk-behind tractors, but now they are increasingly being replaced by four-stroke counterparts. Diesel devices are also gaining popularity. As for the transmission, it can be made in three different versions.

The traditional approach is to use a gear transmission. Despite a decent level of reliability, this device takes up a lot of space. Power transmission takes place using either a cone or a cylinder. Light motoblocks are mainly equipped with a gear-worm transmission. The typical principle of operation of the walk-behind tractor regulator contains:

- a device that monitors the number of revolutions;

- the rod connecting this device with the throttle valve;

- spring.

The control unit operates on the basis of a pneumatic or mechanical connection. "Pneumatics" means the presence of a kind of wing that responds to the speed of the air flow. Centrifugal options involve placing a special camshaft inside the crankcase. It is complemented by small weights and an easy-to-move stem.The pull is made from wire, and the spring sensitivity determines how accurately the RPM values are maintained.

The role of the gas distribution mechanism is to supply a mixture of fuel and air to the cylinder. But the same device also provides exhaust gas removal. A decompressor is used to influence the compression ratio. Gasoline engines are necessarily equipped with carburetors responsible for preparing the fuel-air mixture. Regardless of the type of fuel, the starting device plays an important role.

User manual

The walk-behind tractor includes not only the engine, but also the gearbox, cutting discs and bearings. All these parts require timely maintenance and attention from the user. Bearings are operated below the surface of the soil and this leads to premature failure as dirt gets into the housing. Correct maintenance requires regular lubrication and cleaning of the element.

The teeth or blades must be sharp, this is the only way to guarantee high-quality soil cultivation. The engine in the design drives not only the cutter, but also the gear, which is responsible for the direction of travel, including reverse.

How to prepare for work?

Work on the walk-behind tractor will be of high quality only if the user properly prepares the equipment and monitors it. Before setting the ignition, it is necessary to check the unit, wear appropriate clothing.

The operator is advised to wear gloves to reduce the vibration generated by the instrument motor. Be sure to use goggles to protect your eyes from debris thrown by the car, as well as boots that will protect your feet from dangerous pointed objects.

The operator must check that all fittings and connections on the unit are tight before starting. If there are screws that dangle freely, they are tightened, thus, it is possible to avoid injury when working on the equipment. Before starting the engine, check if there is enough fuel.

The walk-behind tractor must stand on the treated area when it is started.

How to start?

Turn on the engine by switching the start button. Pull the clutch handle slowly until resistance is felt. Push back on the throttle lever to allow the motor to run.

Always hold the device with both hands. Make sure there are no obstacles or things that might get in the way or cause you to lose your footing.

When the device is already in the proper position on the ground, pull the throttle lever to allow the walk-behind tractor to start moving on the ground. Control is carried out by holding the vehicle by two handles on the steering wheel.

How to plow properly?

It is very easy to plow a vegetable garden on the "Neva" walk-behind tractor. Thanks to the convenient design, a large number of attachments, plowing the land and planting potatoes take much less time from the gardener.

The operator will need to hang up a couling and a plow on the equipment. At the first stage, the attachment must be connected to the hitch, only after that a single element is mounted on the equipment and adjusted. The main adjustment is the setting of the immersion depth, blade angle and bar.

You can plow from the middle of the field, after passing the required section, the walk-behind tractor turns around, setting the clamp into the ground, then starts moving in the opposite direction. You can just start at one end of the lot to the right and work your way to the back, where you can turn around and continue working.

Four cutters are installed on the equipment, they move only at the first speed to ensure high quality processing. It is worth plowing in sunny weather, when the ground is well dried, otherwise more powerful equipment may be required.

After the first time, the land should stand for a month, then it is plowed again. They start in spring, so that the virgin soil is processed for the last time in the fall, for the third time.

How to set the ignition on a walk-behind tractor

Consider how to adjust the ignition of the walk-behind tractor. The ignition system of the walk-behind tractor is quite simple

Before installing the ignition, it is important to make sure that this design creates a spark, which in turn will ignite the fuel fluid in the combustion chamber.

In order not to contact specialists in trifles and save your money, you need to understand how the ignition is adjusted and the ignition coil settings are carried out. Let's consider how to set the ignition on the MB 1 and MB 2 walk-behind tractor.

You can set the ignition with a spark. It is necessary to turn the crankshaft so that the marks of the pulley and the gas mechanism coincide. The gas distributor should point to the high voltage wire of the cylinder.

It is necessary to slightly unscrew the nut, which changes the position of the mechanical structure, which determines the moments of the high-voltage pulse.

Then you need to get the high-voltage wire from the system cover. He is in its center. Then place the contacts at a distance of 5 mm from the cultivator.

After that, you should turn on the ignition.

Next, you need to turn the mechanical structure, which determines the ignition moment, clockwise to the 200 mark

Carefully turn the above structure to the other side

A spark is generated between the central high-voltage wire and the ground of the cultivator. After that, you need to quickly tighten the interrupter nut to avoid ignition.

You can set the ignition by sound. If the owner has good hearing, then this method of checking and adjusting the ignition is fine. In other words, it is a non-contact check of candles.

The contactless method assumes the following procedure:

- First you need to start the engine.

- Then you need to slightly loosen the distributor.

- Slowly turn the breaker housing in 2 directions.

- The mechanical structure, which determines the moment of spark formation, must be strengthened in the state of the greatest power and the greatest number of revolutions.

- Then listen carefully. Clicking should be heard when turning the discontinuous system.

- After all the steps taken, you need to tighten the distributor nut.

The strobe method works as follows:

- First you need to warm up the engine.

- After that, attach the stroboscope to the walk-behind tractor.

- The sound-sensitive sensor must be connected to the high-voltage wire of the cylinder.

- Dismantle the vacuum hose and plug it.

- The stroboscope will emit light that must be directed at the pulley.

- Start the engine of the unit again, leave it idling.

- Turn the distributor.

- Fasten as soon as the pulley mark points to the mark indicated on the cover of the walk-behind tractor.

- Tighten the interrupter nut.

The above is how to check the ignition coil. When installing the system, it is advisable to use the instructions, especially for owners who are faced with this for the first time.

Adjusting the coil is not a difficult task.

How to set and adjust?

If your walk-behind tractor does not start well, you need to pull the starter cord for a long time or the engine responds with a delay, most often you just need to set the ignition correctly. The procedure is described in the instruction manual of the device. But what if you don’t have it at hand, and you don’t remember where you put this useful brochure?

Follow the guidelines below.

Close the spark plug with a square, press its body against the cylinder head by turning this element of the ignition system in the opposite direction from the hole in the end of the cylinder. Turn the crankshaft. You can do this by yanking the starter cord. As a result, a bluish spark should slip between the electrodes. If you do not wait for the spark to appear, check the gap between the stater and flywheel magneto. This indicator should be equal to 0.1 - 0.15 mm.If the gap does not correspond to the specified value, it needs to be adjusted.

You can try setting the ignition by ear, especially if yours is quite thin. This method is also called contactless. To do this, start the engine, slightly loosen the distributor. Slowly turn the breaker in two directions. At the maximum power and number of revolutions, fix the structure that determines the moment of sparking, listen. You should hear a clicking sound when you turn the breaker. After that, tighten the distributor mount.

Warm up the motor, connect the stroboscope to the power circuit of the motoblock device. Place the sound sensor on the high voltage wire from one of the engine cylinders. Dismantle the vacuum tube and plug it. The direction of the light emitted by the stroboscope must be towards the pulley. Run the engine idle, turn the distributor. After ensuring that the direction of the pulley mark coincides with the mark on the device cover, fix it. Tighten the breaker nut.

Breakdowns and ways to eliminate them

Several reasons are being considered because of which the Agro walk-behind tractor may not work:

- the candle does not spark;

- the ignition coil (magneto) is out of order;

- wiring problem.

It is not difficult to check the candle, it is enough to unscrew it and inspect it carefully. If carbon deposits are present on the walls, this means that the part has been flooded with fuel. Carbon deposits are removed by exposing them to an ignited burner in a gas oven. It is not enough to just clean the spark plugs, you need to check the entire fuel supply system for leaks.

To understand whether the magneto works, a cap with a connected wire is put on the spark plug from above, and the lower part of the ignition element is brought to the body. Turn the flywheel. If the spark is not visible, the problem must be looked for in the coil. But that's not all

Be sure to pay attention to the state of the gap between the central electrode and the side one. Take a simple blade and insert it into this gap

If the blade fits securely and tightly, then everything is in order. Otherwise, you should lightly hit the center electrode, after which it will move.

Another elementary cause of system malfunction is poor contact of high-voltage wires. They need to be removed and carefully cleaned or replaced with new ones. In technical equipment with an electronic ignition system, the wire is automatically blocked by a command of a special safety device.

This is interesting: why there is no spark at the Cascade walk-behind tractor.

To prevent the ignition system from causing problems, you must follow the following tips, which will help not only extend the life of the mechanism, but also save the car owner's money:

- do not work on a walk-behind tractor in adverse weather conditions (wet weather, frost, high humidity);

- if you smell of burnt plastic, you should immediately turn off the engine until the reasons are clarified;

- spark plugs should be changed at least once every three months;

- for the effective operation of the walk-behind tractor, it is necessary to use only high-quality spare parts and fuels and lubricants;

- unsuitable engine oil can lead to flooding of spark plugs;

- conduct a constant inspection of the entire system, right down to the wires.

All faults are of the same type for the ignition systems of agricultural Russian motoblocks, including those produced by Agro. The ignition is adjusted in the same order. It won't take much time to repair the cultivator's ignition system with your own hands. The main thing is to identify the malfunction in time. Candles require constant checking, and if this is not done, then you can forget about your powerful assistant for many months.

Major malfunctions and their causes

No matter how high-quality and expensive the walk-behind tractor you have purchased, you should not think that it will never require proper repair during its operation.Even high quality and reliable equipment can fail. If such a nuisance happens, the walk-behind tractor will need to be properly repaired. Problems are different.

For example, such agricultural machinery can start to operate only on suction, give out recoil when wiring, emit blue or white smoke during operation.

Let's get acquainted with a list of the most common problems with such units, as well as analyze what is usually their cause.

Does not start

Most often, in the described technique, its "heart" suffers - the engine. The part has a complex design and structure, which makes it more susceptible to various breakdowns. There are times when agricultural machinery stops starting at one "fine" moment. This common problem can occur for several reasons.

To find out it, you will need to carry out a number of procedures.

- Check the exact position of the engine (if there is a tilt of the central axis, then it is advisable to return it to the right place as soon as possible, so as not to face more serious problems).

- Make sure there is sufficient fuel flow to the carburetor.

- Sometimes there is a clogging of the tank cap. It is also advisable to inspect it if the equipment has ceased to start normally.

- Often, the walk-behind tractor does not start if there are any shortcomings in the operation of the fuel system.

- The spark plugs and fuel tank valve must be cleaned. If this condition is not met, the engine will not start as it should.

Doesn't develop momentum

Sometimes the owners of walk-behind tractors are faced with the fact that their equipment stops gaining momentum as needed. If the throttle lever has been pressed, but the speed does not pick up after that, and power is inevitably lost, then perhaps this indicates an overheating of the engine.

Shoots the muffler

A common problem in motor vehicles is a shooting sound emitted by a silencer. Against the background of loud characteristic bangs, the equipment usually blows smoke, and then completely stalls. This malfunction can be eliminated on its own.

Most often, the cause of the "shooting" silencer is several nuances.

- An excessive amount of oil in the fuel composition can lead to this problem - in such a situation, you need to drain the remaining fuel, and then thoroughly wash the pump and hoses. Finally, fresh fuel is filled in, where there is less oil.

- The muffler can begin to emit pops and smoke even when the ignition of the walk-behind tractor was incorrectly set. If the whole mechanism as a whole works with some delay, then this will result in the "firing" of the muffler.

- The muffler can emit such characteristic sounds if there is incomplete combustion of fuel in the engine cylinder.

Smokes

If you notice that the walk-behind tractor began to emit black smoke during operation, and an excess of oil appeared on the spark plug electrodes, or they were covered with carbon deposits, then this will indicate one of the listed problems.

- The reason for the smoke of the equipment may be the fact that an excessively saturated mixture of fuel will be transferred to the carburetor.

- If there is a breach in the sealing of the carburetor fuel valve, the technician may also start to smoke unexpectedly.

- The oil scraper ring can be very worn out, which is why the equipment often begins to emit black smoke.

- If the air filter is clogged, these problems occur.

Varieties of motoblocks

Depending on the weight, there are 3 main types of these agricultural machines.

It is important to note that any DIY repair of motoblocks should be carried out strictly in accordance with the technical features of a particular sample. The types of such equipment are as follows:

- Light type. Its weight ranges from 10 to 50 kg.Due to its mobility, the speed of its work is significantly higher than that of other devices, however, due to its low power, it can only work on small areas of soil.

- The average type of motoblocks is represented by products weighing from 60 to 100 kg. Such devices are used for a variety of purposes.

- A more professional version of this agricultural technique is heavy professional devices. Due to the fact that their weight exceeds 100 kg, they are not able to work very quickly, however, they can be used to process a large area of land due to the high power of these samples.

Next, you should consider in more detail what malfunctions may arise during the operation of such devices and, as a consequence, what will depend on the implementation of such a procedure as repairing a walk-behind tractor.

1 Generator selection

A walk-behind tractor or a motor-cultivator can be equipped with an electric generator. Such a device makes it possible to feed an electric lamp of illumination or headlights in order to work freely at night, or to charge the battery. The battery in the unit is installed so that you can quickly start the device with a starter and then power the electrical parts.

Automotive generator on a walk-behind tractor engine

When buying a generator for a walk-behind tractor, you should pay attention to the power. During operation, the power of the device must be greater than the installed load

This means that if all electrical equipment on the unit is working, there should be no voltage drops in the generator. The power of the generator will not necessarily be 220 volts, the main thing is that the power is greater than the required load. You can put a tractor or car generator on a walk-behind tractor (motor-cultivator).

1.1 Installing a generator on a walk-behind tractor with your own hands

For self-installation of the device, you need to familiarize yourself with the main parts of the structure:

- A pulley that transfers mechanical energy from the engine to the device shaft using a belt.

- Metal case with front and back covers.

- The rotor is a steel shaft with two steel bushings, between which the field winding is located. The winding lines are connected to slip rings.

- The stator is a rewind consisting of a set of steel sheets assembled together. Such a part is made in the form of a pipe, and it is in it that the power of the device is produced. The part can be made by hand.

- The voltage regulator maintains the voltage at the same level as the load changes.

- The brush assembly is a plastic mechanism that helps the device to function properly.

It does not take much time to install the generator on the walk-behind tractor, but this is a very important detail for the normal operation of the device. The structure is connected to the walk-behind tractor using e-mail. diagram showing all necessary connections.

1.2 Electrical diagram

If the electrical circuit is incorrectly connected, the generator winding may fail. Such a device can be connected with two wires. The electronic unit has four wires, two of which are blue, they connect the energy converter. The other two wires are red and black. The red wire is the voltage output, it powers the headlights, signal and other electrical appliances. They also use it to charge the battery. The black wire is connected to the ground of the power device. You can connect the device yourself.

Alternator test connection diagram

The generator produces electricity. energy that goes to the rectifier in the electrical unit. The unit has a voltage equalizer and a current regulator. These devices are needed so that the voltage does not change, regardless of the performance of the device.

The current regulator controls the amount that goes into the battery. The engine turns on and transmits torque to the rotor through a belt.The part begins to generate voltage into the electrical unit. Starting the motor has reduced the capacity of the battery, so all electrical parts will be powered by the electrical box.

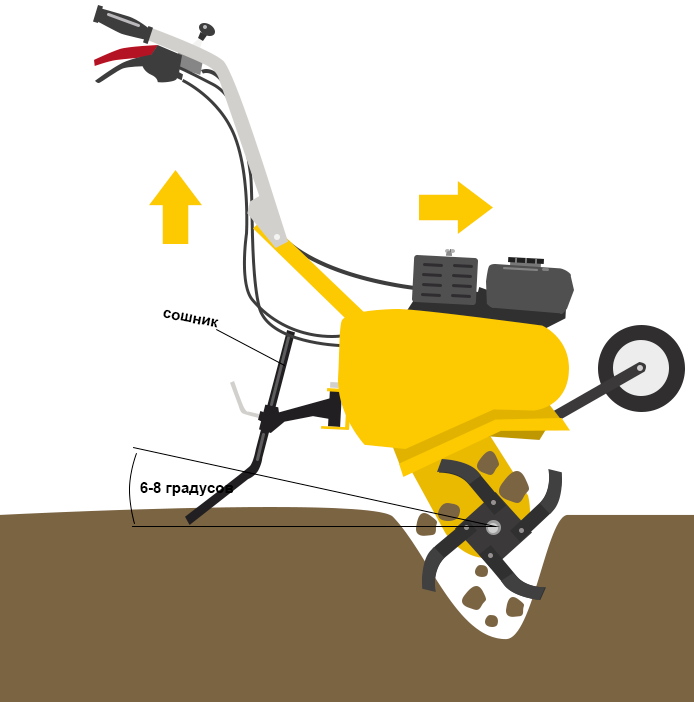

The reasons for the strong burying of the cutters

Photo 10

In photo 10, you can see that the walk-behind tractor has stopped moving forward, the cutters have gone deep into the soil layer. In simple terms - the walk-behind tractor is buried in the ground! Why might this be happening? Below are the main reasons why the walk-behind tractor is buried, as well as ways to eliminate them.

1. The soil on the site is highly moistened and clogs the knives, you must wait until the earth dries up.

2. The coulter is very deep in the soil, it is necessary to adjust the coulter.

3. Insufficient number of revolutions, it is necessary to set the gas regulator to the maximum value and check the speed mode (select an increased gear of the walk-behind tractor).

4. The soil on the site is highly compacted, therefore it is necessary to cultivate the site in two times:

- Primary tillage at the minimum depth of the coulter.

- Final tillage is carried out when the coulter is buried to the required depth.

5. Incorrectly installed cutters of the walk-behind tractor, check the correct installation of the cutters.

These are the most common reasons that the milling cutters of the walk-behind tractor go deep into the ground and the walk-behind tractor stands in place.

Inclusion of motoblocks of popular brands

Depending on the model of motor vehicles, the launch takes place in different ways. If the algorithm is not performed in the correct sequence, then serious damage to the device is possible. For example, the Agro, Neva or Salyut motoblocks have a four-stroke engine, so oil and gasoline are poured separately. This also applies to motoblocks Kaskad, Luch and Khoper.

When starting the well-known Neva model, the ignition lever is moved to the "on" position. This opens the petrol valve and closes the air supply. In this case, the throttle stick is in position ¾ from the maximum value. Pull the starter and open the air damper. If the launch is done in winter, then it is done gradually.

Motoblock Ural is switched on as follows: put the gear lever in neutral position. In this case, the gas tank remains open. Close the choke and start the engine.

Note! Before starting the engine, check the spark plug. Very often, in the Ural model, engine oil leaks into the engine cylinder.

Only 92nd gasoline is poured into Patriot motor vehicles, since 95th at many gas stations is below 92nd in quality. The model has a special oil container, which is designed for the air filter. There is a mark on the container, above which it is not recommended to fill in oil. Otherwise, it will leak into the carburetor.

The Patriot is launched in the following order: the throttle lever is set to the maximum position. They turn on the fuel supply and ignition. Pull the starter rope slowly until resistance occurs, then pull it with a sharp motion and the engine starts. The throttle lever is set to the middle position, and the cold start to the right.

Motoblocks of various models start up easily if you know and adhere to some of the features of their design. If you adhere to the rules and recommendations that are spelled out in the instructions, you can avoid damage to the unit and extend their service life

It is important to periodically conduct examinations as a preventive measure. This will allow you to notice a minor breakdown in a timely manner and fix it in time.