Views

Depending on the characteristics of industrial labor, models of various designs are made. The classification of work boots is divided by purpose, season, materials, style and size. According to the season, footwear is divided into summer, demi-season and winter (insulated).

By the method of protection, they are distinguished:

- from blows, cuts and punctures;

- from vibrations;

- from slipping;

- from chemical burns;

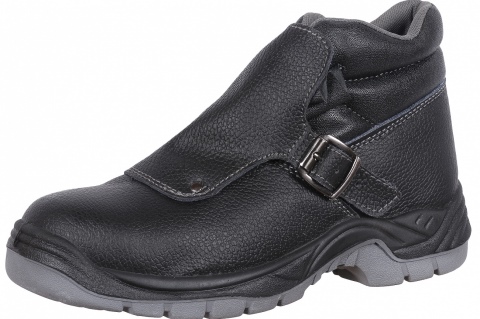

- from splashes of molten metal, contact with a hot surface, extremely high or low temperatures;

- from electric shock.

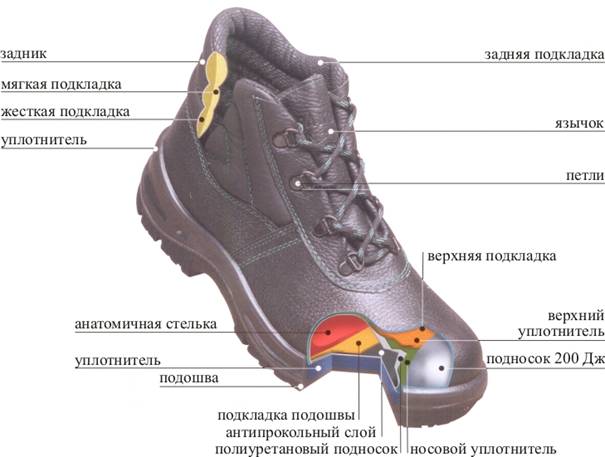

Safety shoes are equipped with various protective pads - with a composite or iron toe cap and high-strength shields. Armor with a metal toe and insole has a significant weight (the heaviest of steel) and is not so comfortable to wear, but more reliable with the risk of punctures and impacts with a force of 5 to 200 J.

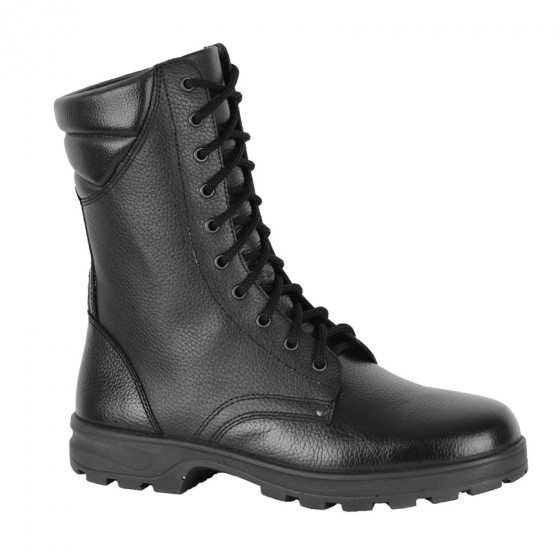

Interesting! Kirz boots are a cheap substitute for natural ones; for a long time the Russian army was equipped with them. After the decree of the Minister of Defense Shoigu, they were replaced by, as expected, more durable leather ankle boots (analogous to the American Corcoran Marauder boots).

However, the servicemen still criticized the domestic products of the manufacturers "Paritet", "Donobuv", "Voentorg" and "Faraday". The sole can be made of rubber, PVC (polyvinyl chloride), PU and TPU (polyurethane and heat-resistant PU), strong and resistant to aggressive environments nitrile (synthetic rubber).

According to the size of the bootlegs, they are divided into shoe covers, ankle boots, low shoes, boots, ankle boots and high boots with full ankle protection, which can go straight to the thigh. Fasteners come with laces or zippers and can be additionally equipped with a protective leather flap and an emergency release system in case of an accident.

Peculiarities

The main feature of summer safety shoes is lightness. So, some models have a warmed winter or demi-season version and a lightweight summer version. The options may differ only in the presence or absence of insulation. According to GOST, summer safety footwear should protect against:

- moisture;

- mechanical stress;

- harmful biological factors;

- electric shock;

- toxic substances and much more.

As a rule, summer work shoes are made of leather or its artificial equivalent. Interior decoration is made from both natural and synthetic fabrics. Often footwear for work outdoors or in hostile environments is made from a special dressing of pig or cow leather called yuft.

Special requirements apply to the soles of special work shoes.

Its material should be wear-resistant, non-slip and protect from aggressive environments, which is generally characteristic of special footwear, but at the same time, the sole should also prevent perspiration, which is important precisely in the warm season of the year.

Most often used for the manufacture of soles:

- nitrile;

- PVC (polyvinyl chloride);

- polyurethane;

- thermoplastic elastomer.

The properties and scope of each material are very specific.

An alternative to these excellent materials for summer work shoes is polyurethane. However, it is more susceptible to mechanical stress and has a lower hygienic quality. Thermoplastic elastomer is suitable for making the soles of summer special footwear, but it is very unstable to oil products.

The industry produces safety footwear for both men and women.The classification and range of work footwear for men is much wider due to the greater variety of "male" types of activities associated with hazardous factors. Some types of summer safety shoes are equally used by both men and women (shoe covers, galoshes, some types of boots and slippers).

Criterias of choice

Choosing the right work boots is partly a matter of external preference, but it is equally important to make sure that they are able to perform their direct function of protecting your feet from injury. If there is a threat of heavy objects falling onto the leg, choose last with different shields, for example, with metatarsal protection of the metatarsal bone on the top of the foot

According to the type of material, there are two types of toe caps - iron (steel or aluminum) and composite (carbon fiber, plastic or Kevlar).

The size should correspond not only to the insole, but also to the fullness of the leg. Modern manufacturers have learned to make more anatomical, asymmetrical pads that fit the shape of the toes and feet.

Operating tips

Safety shoes must be used strictly in accordance with their seasonal use. Leather specimens get wet, albeit slightly, and this must also be taken into account. You must not violate the regulations that are announced by marking or entering in the accompanying documentation. When the period of wearing is over (after the end of work or at the end of the season), the shoes are cleaned, washed and put in order.

Shoe and take off safety shoes, you need to take care of them in the same way as in normal cases. Cleaning should be carried out only by means and methods that are safe for a particular material. Do not use organic solvents for cleaning, even if the shoes are declared resistant to them.

After infection with poisons, radioactive substances and biological agents, specific disinfection is imperative.

An overview of the boots from the Technoavia company in the video below.

The best manufacturers and models

In any craft, the correct organization of labor significantly increases its efficiency. In this sense, work shoes of many foreign manufacturers are the best investment, as a guarantee of high efficiency (efficiency) and increasing the potential of specialists, respectively, good business profitability in the future.

The American company Red Wing Shoes has been making excellent leather boots and shoes for casual and professional use since the early 1900s. With more than a century of experience, she cherishes and develops her skills in the manufacture of handmade shoes.

All the anatomical features of the female foot were taken into account when designing the lasts for women's boots and shoes. “Red Wings” are responsible for the quality of raw materials themselves, constantly experimenting with the processing of materials and leather dressing; if the sole is worn out, it can be replaced at the factory.

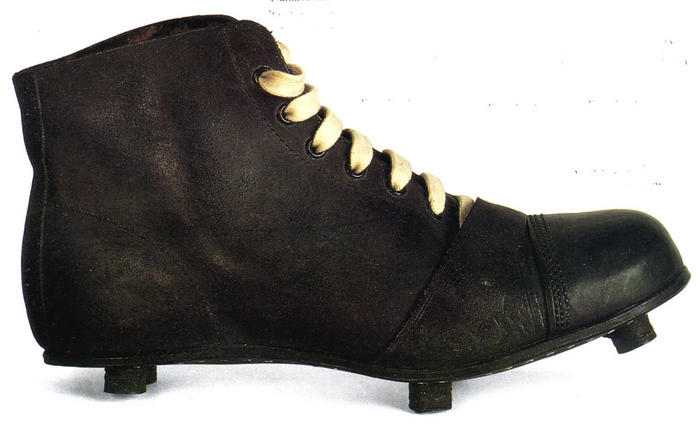

The vintage Lone Wolf boots are made in Japan based on the 1930s US work shoes. Every detail is produced with the utmost care. Japanese models such as Mechanic Boots Black from Lone Wolf are also highly valued.

Timberland is the manufacturer of the famous brand of bright mustard color Yellow Boots. At one time, he made a splash with his then innovative technology of seamless connection of a rubber sole with a leather upper. The triple seam made of nylon thread gave special strength to the structure, so Timberlands became famous for their unique reliability and moisture resistance.

And the Italian companies Cofra, Pezzol and Panda Safety are the leading European manufacturers of high-tech footwear, insulated and for demi-season, with improved anatomical characteristics, protective composite pads and soles for all types of surfaces and hazardous conditions.

Appointment

The saying "All safety rules are written in blood" means that according to the Labor Code of the Russian Federation, Art.229 after any industrial accident, a special commission is obliged to conduct an inspection with the participation of a labor protection specialist. Legislative norms oblige employers to create safe conditions for the life and health of workers, and workers are obliged to observe them. Personal protective equipment (PPE) at work from harmful, dangerous and other negative factors includes overalls and footwear.

Manufacturers are obliged to check and indicate the properties and classification of work shoes according to the list listed in the Interstate Quality Standard SSBT GOST 12.4.127-83, where there are various physical and mechanical, ergonomic, hygienic indicators: the required thickness and strength of various parts, linear dimensions, permissible operating temperature , permeability of aggressive media and toxic substances, and much more.