User manual

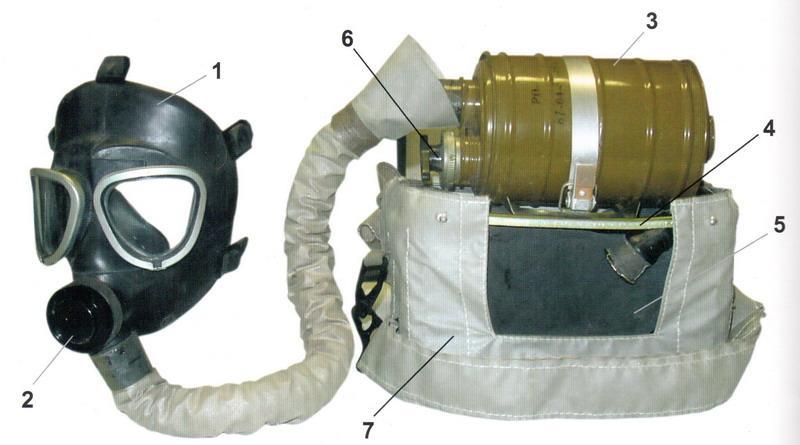

In order to assemble the PMK-2, you must strictly follow the assembly instructions.

- The box is inserted into any hole in the mask. Sealing is carried out along the outer zone of the neck. Therefore, the holes are tight and have a small diameter.

- The fairing is installed on the FPK flange from the inside. When installed correctly, the element hole points towards the valve box. The grill serves as a protection against tight contact between the cover and the entrance at the bottom of the box.

- The connecting nodes are inserted from either side. It depends on the specific type of work. The junction points appear as two notches on the cheek areas of the mask.

- The plug is fixed on the opposite side from the nodes.

- The connection of the FPC with the neck to the mask is made through an adapter. For the KDP and the PMK-2 device, several transitional parts are used. One adapter is connected to the mask using a connecting tube, the second one connects the FPK with an additional cartridge.

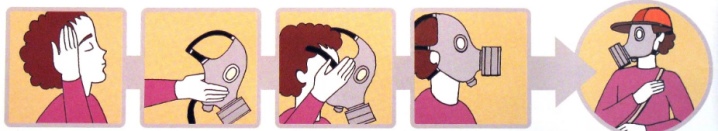

To put on the device correctly, a certain sequence of actions is also required:

- pull the device out of the bag;

- take the gas mask with both hands by the sealed edges located below;

- take a side strap in each hand, the thumbs are outside the mask, the rest are inside;

- stretch the fasteners in opposite directions;

- chin fixation is performed in the lower part of the obturator;

- put on the headgear using up / back movements.

PMK-2 is a protective device that does not cause discomfort during work. The device has a frame, canvas bag, which is very convenient for storage.

The above recommendations will help you assemble the gas mask correctly, and clear instructions for use will eliminate mistakes at the most crucial moment.

An overview of the PMK-1 and PMK-2 gas masks in the video.

What is it and why is it needed?

As in many other cases, the description must begin with a general definition of the thing itself. The main task that any gas mask solves with varying efficiency is the isolation of the respiratory system, eyes and skin of the face in case of various negative influences. Designers from different countries have created many hundreds of modifications of gas masks and their individual components during 1915-2020. But although a gas mask as a category of devices serves to protect against a variety of sources of danger, the same cannot be said about specific models. A variety of substances can pose a threat to human life, health and full-fledged activity - and the difference in their properties does not allow creating a universal protection. It is not for nothing that even externally, a gas mask sometimes looks very different, and its visual performance primarily depends on the technical features of the device. The main purpose is as follows:

- prompt evacuation of the injured (poisoned or presumably poisoned);

- combat by troops, police and special forces in a chemical hazard;

- protection from threatening industrial factors (sometimes from natural toxins);

- protection of medical personnel, members of emergency rescue teams from potential risks in the provision of assistance, elimination of incidents;

- survey of potentially hazardous areas and facilities in chemical terms;

- protection of firefighters from carbon monoxide when fighting a fire;

- ensuring safety when working in closed containers, underground;

- treatment with toxic substances (disinfection, disinsection, deratization);

- personal survival with the release of toxins, radiation.

What is the difference from combined arms gas masks?

To better understand the essence of a civilian gas mask, it is necessary to understand its difference from a military model. The first systems of protection against poisoning appeared precisely in the course of hostilities, and were intended primarily to neutralize chemical weapons. External differences between army and civilian apparatus are small. However, for civilian use, simplified designs are usually used; the quality of materials may be lower.

When designing them, they try to ensure, first of all, the normal activity of troops during combat operations, during exercises, on marches and at bases. The level of protection against industrial toxins and poisons of natural origin is either much less than that of civilian samples, or is not standardized at all. In the military sphere, insulating gas masks are much more common than in civilian life. Glasses are usually supplemented with films that reduce the intensity of exposure to particularly bright light.

The filtering element of military RPEs is more perfect than in the civilian sector; also note:

- increased strength;

- improved protection against fogging;

- moisture resistance;

- long period of protection;

- resistance to higher concentrations of toxins;

- decent viewing angles;

- more advanced negotiation devices.

Device and principle of operation

First of all, it is worth paying attention to the design features, structure, composition of the filtering-absorbing unit and, of course, its purpose. This component of the GP is responsible for the effective (almost complete) purification of the air inhaled by a person from the majority of potentially dangerous impurities.

This box is made of ordinary tin or aluminum. Special stiffening ribs give increased strength and resistance to damage to the cylindrical body.

If the device is in storage, then this structural element is tightly closed with a special cap with a gasket to ensure maximum tightness. On the opposite side, that is, in the bottom of the FPC, there is an opening through which air enters the filter. It should also be tightly closed with a special stopper during storage.

One of the important structural elements is the spectacle assembly with observation glasses. During operation, special anti-fog films are installed on the latter. It is also provided for the installation of insulation cuffs at low temperatures. This allows you to maintain full transparency of the glass in almost any operating conditions. In addition, the design of the described unit includes such components as:

- an obturator in the form of a thin strip made of soft rubber for maximum tightness;

- a device with a membrane, which is responsible for the transmission of speech;

- locking mechanisms of breathing blocks;

- a system of straps that allow you to adjust the mask and fix it with maximum tightness.

The last structural element includes a plate (occipital) and 5 straps - one frontal, as well as two temporal and buccal. In the situation with the latter, we are talking about metal fixing devices, and the rest of the straps are fixed with plastic buckles. In this case, all belts have step-type stops.

The principle of functioning of the described apparatus is identical in everything to the algorithm of action of most of its "brothers". At the same time, the civilian gas mask of the 7th series is characterized by such obvious advantages as:

- minimized resistance of FPK;

- the most reliable actuation of valves and minimization of the risks of their damage, provided by the unique shape of the petals;

- the possibility of long-term and maximally comfortable (minimal maxi pressure on the face is created) operation of the device even in the most difficult conditions;

- maximum tightness, which remains even if the straps are damaged.

A high-quality membrane guarantees clear transmission of sounds, which allows the use of communication means.

Appointment

The filtering gas mask is designed to effectively clean the air in a poisonous or contaminated environment. Moreover, it should be borne in mind that each type of such device can protect the user from only one of the types of gas. This suggests that it may be simply unsafe to use a certain type of gas mask without prior notification of the type of toxic substances.

We must not forget about the concentration of harmful impurities that are contained in the atmosphere. Since the current models of filtering gas masks are not equipped with systems for the inflow of fresh oxygen, they can only purify it, therefore they are used if the mass fraction of toxic components in the environment reaches no more than 85%.

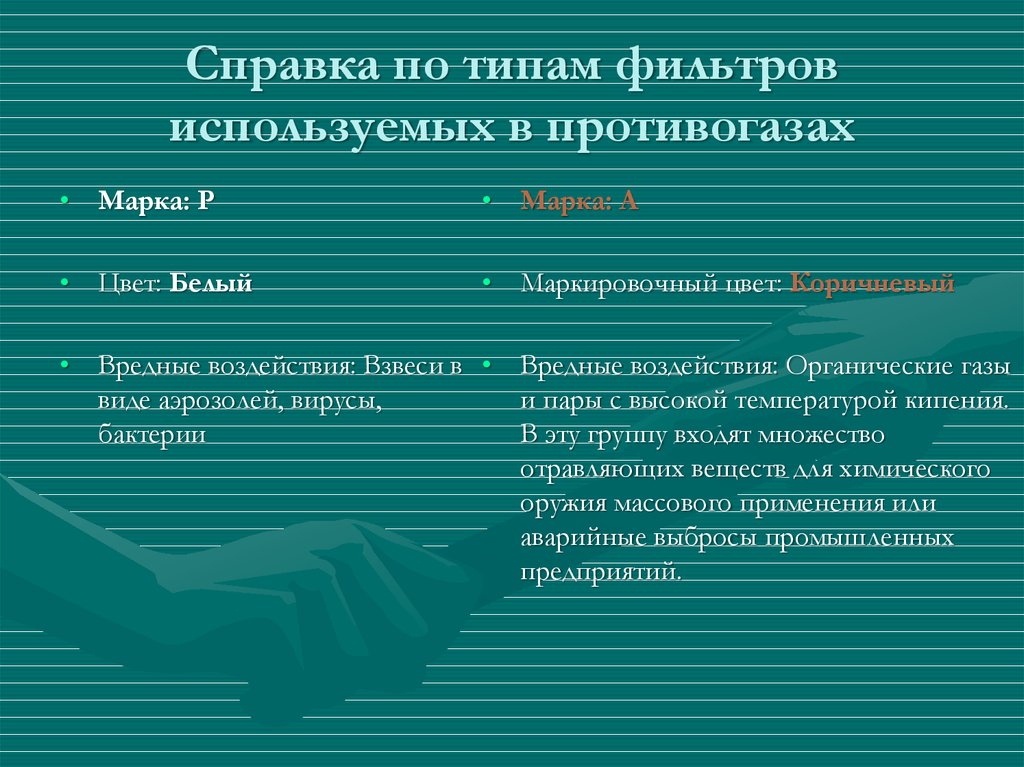

In accordance with it, the ability of a gas mask to contain a specific type of hazardous gas is determined. Let's consider some of the notation.

- Filter grade A, class 1,2,3. Has a brown color coding. Designed to protect against organic vapors and gases, the boiling point of which exceeds 65 degrees Celsius (this can be benzene, butylamine, cyclohexane and others).

- AX, the color coding is also brown. Such masks are designed to protect against organic gases and vapors, the boiling point of which is less than 65 degrees.

- B, class 1,2,3. It has gray markings. These filtering masks are designed specifically to "insure" against the negative effects of inorganic gases and vapors. The only exception is carbon monoxide.

- E, class 1,2,3. Yellow color coding is characteristic. These types of filtering gas masks are designed to protect a person from sulfur dioxide, acid gases and vapors.

- K, class 1,2,3. Green marking. The purpose of such specimens is to protect against ammonia and its organic derivatives.

- M0P3. Indicated by white and blue markings. Air filters of this type are designed to protect against nitrogen oxide and aerosols.

- HgP3. The markings are red and white. Protect people from mercury vapors, aerosols.

- C0. The marking is purple. Models of this type are designed to protect humans from carbon monoxides.

Answers on questions

Consider the most common questions from people who first encountered the purchase or use of gas masks.

Does a gas mask protect against viruses?

A gas mask, like a cloth respirator, is able to protect against airborne viruses. For this, an anti-aerosol filter of protection class 3 is installed. The main condition is not to wipe the gas mask with your hands inside.

The world's best gas mask

The best protective agent is considered to be the one that is capable of saving a person's life at the time of a chemical, bacterial, atomic attack or pollution.

Experts, based on reviews and assessments, have compiled a list of TOP-5 popular manufacturers of gas masks:

- 3M;

- Source;

- UVEX;

- Sibin;

- STAYER.

The PMK-S gas mask, a model that is in service with many rapid reaction units of the Russian Guard and the FSB, is recognized as the best protective equipment for personnel. Protects from exposure to radioactive dust, many toxic and chemical substances, vapors, aerosols.

What kind of poisonous substances do gas masks not protect?

The outdated model of the PG-7 gas mask is not able to protect against carbon monoxide, vapors of substances with a low boiling level, for example, acithelen, butane, methane, etc.

What determines the reliability of a gas mask?

The reliability of a protective device is determined by its maximum protection power and tightness. The higher the protection class, the more reliable the gas mask will be.

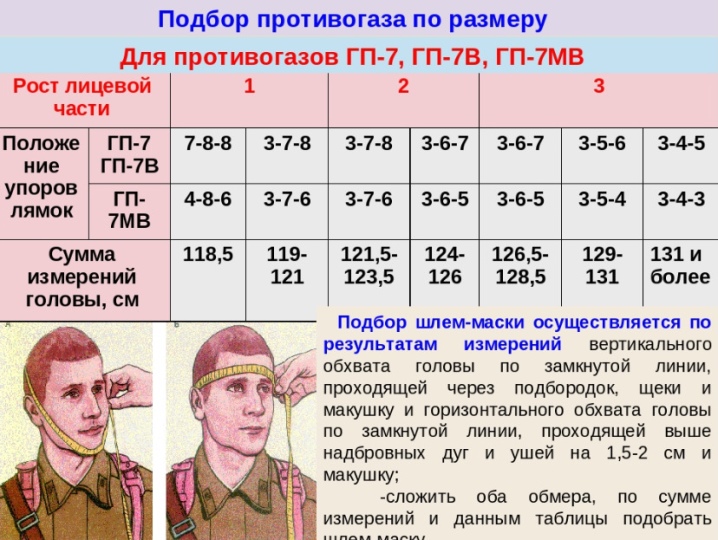

With insufficient tightness or improperly selected size, toxic substances will enter the respiratory system, which will lead to poisoning or death of a person.

Can a filter gas mask be used in case of fire?

In case of fire and the release of carbon monoxide, various protective equipment is used: masks, respirators and also gas masks.

However, it is worth knowing that the filter type of gas masks is unable to protect a person from carbon monoxide. The content of the filter (activated carbon) is designed to pass low molecular weight chemicals.

Rules for using a gas mask

The rules for using a filtering gas mask include a series of sequential actions:

- A bag with a packed gas mask is put on over the shoulders from right to left so that the belt is on the right shoulder, and the bag itself is located on the left side of the person with the flap outward. The height of the bag is adjusted to the level of the belt.

- The gas mask is removed from the bag and visually checked for the integrity of all connections and the cleanliness of the eyepieces. After the check, the gas mask is put back in the bag until it is needed. In the presence of an increased danger, the bag valve remains open.

- When a threat arises, the gas mask is removed from the bag. How to put on a gas mask:

- hold your breath and close your eyes;

- take the mask with both hands by its lower part so that the thumbs are outside the mask, and the rest are inside;

- with a movement from the bottom up, quickly and carefully put on the mask on the face, smoothing out the emerging folds;

- exhale and open your eyes.

It is important to have experience in maintaining even breathing because it contributes to the even operation of the filter, thereby extending the useful life of the filter box.

If the outer part of the filter becomes dirty during operation, it must be cleaned.

Removing the gas mask is done in the opposite direction to putting it on - forward and up.

Before returning the gas mask to the bag, you must first check its cleanliness.

The rules for using an insulating gas mask in terms of putting on a mask do not differ from the rules for a filtering gas mask, but they require a number of preliminary steps:

- Before using it, you need to check the size marking of the gas mask.

- Check the mask, hose, as well as their connections, for defects.

- Check the integrity of the glasses of the eyepieces.

- Check that the hose is securely fastened.

- Secure the end of the hose to a metal post driven into the ground to limit the possibility of chafing and being blown away by the hose.

- Put on a mask.

Gas masks as a means of individual protection will not lose their relevance for a long time. Therefore, it is useful for every citizen to understand both their classification and the rules of operation. In addition, civil defense courses should not be ignored, where you can get an array of useful information and skills in case of a real threat to life and health.

Rating: / 5 -

of votes

Filtering and self-contained respirators: what's the difference?

The respirator is the most common personal respiratory protection device. This is a simple device that cleans the air inhaled by a person from harmful substances. There are even improved professional types of respirators. They supply purified air, and the exhaled air is chemically purified. The air then becomes breathable again. And today we would like to talk about the differences between the two types of respirators - filtering and insulating, as well as the device of filtering gas masks and respirators.

How are filter respirators different from insulating respirators?

The main difference between filtering and self-contained respirators is the different ways of supplying air.Is the respirator classified as a filtering RPE? Absolutely! Since filter respirators are a large group of personal respiratory protection equipment. The essence of this group is as follows:

There is no air supply in filter respirators - the inhaled air is simply cleaned with a special filter element. Depending on the area in which the filter respirator will be used, it can be a dust or gas mask. They also produce universal (combined) models. Filter respirators have built-in filters that are an integral part of the half mask. Among other things, replaceable cartridges are used as filter elements.

Self-contained respirators are more complex in design. There are two types of self-contained respirators — self-contained and hose-type. Self-contained respirators have a separate oxygen cylinder that a person will breathe. Professional self-contained respirators have a regenerative cartridge. It purifies the exhaled air, after which it becomes breathable again. A hose-type respirator works in a similar way, however, clean air is supplied only if there is insufficient oxygen in the air that a person breathes.

All of the above applies if you want to know what is the difference between an insulating and filtering gas mask.

Application of different types of RPE

The differences between insulating and filtering gas masks determine the main areas of their application. Special services (MES) use both types of RPE. For example, the purpose and arrangement of filtering gas masks and respirators correspond to the conditions for carrying out rescue, recovery and fire-fighting measures of a different nature, but without leaks of toxic substances, including carbon dioxide.

Insulating RPE is used to eliminate accidents in chemical industries or to extinguish fires of a higher category.

In the medical unit, putting on a filtering gas mask or respirator is considered one of the important skills that all service employees are among the first to master. Unfortunately, a methodological plan for putting on a filtering gas mask or respirator cannot be found in the literature approved by government agencies.

Information regarding the use and donning of RPE can be found in civil safety textbooks, instructions for use of RPE, as well as in books based on the official translation of OSHA or NIOSH recommendations (USA).

Popular models

In the line of civilian gas masks, the GP-5 model stands out. It is found quite often, the cost of the product is quite acceptable. However, it is very difficult to work with optical devices and perform actions that require a good view. You cannot look down because of the filter. Glasses are blown from the inside, but there is no intercom.

Technical specifications:

- total weight up to 900 g;

- filter box weight up to 250 g;

- the field of view is 42% of the norm.

GP-7 has the same practical properties as the fifth version. Additionally, a modification of the GP-7V is produced, which is equipped with a drinking tube. The total weight is not more than 1 kg. Folded dimensions 28x21x10 cm.

Also popular are:

- UZS VK;

- MZS VK;

- GP-21;

- PDF-2SH (children's model);

- KZD-6 (full-fledged gas protection chamber);

- PDF-2D (wearable children's gas mask).

Front part

Gas masks GP-7 have a face-piece in the form of a mask, which is complemented by round-shaped observation glasses for eyes. The viewing glasses are made of quality material and covered with anti-fog films. If the gas mask will be used at low temperatures, it is supplemented with an insulating cuff, which helps to maintain the transparency of the glass during long-term operation.

The front part of the IHL is created for three heights. It includes several elements:

- The volumetric type mask, which has an independent obturator, is a strip of thin rubber that ensures reliable sealing of the face of the mask on the head.

- Spectacle knot.

- Intercom (membrane).

- Inspiratory and expiratory valve assemblies.

- Cowl.

- Headrest. It is needed to secure the face part, consists of an occipital plate and five straps - they are securely fixed when the mask is fitted to the face.

- Pressing rings, which fix the films on the glass.

Combined Arms Gas Mask

A combined-arms gas mask is a means of protecting the respiratory tract, mucous membranes of the eyes, nose from the effects of chemically active substances with toxic, bacterial, radioactive effects that are contained in the environment. Its principle of operation is based on purifying the air using a special filtering element and isolating sensitive parts of the human head using a helmet - mask. These protective equipment are recommended to be used in cases where the composition of the surrounding atmosphere contains at least 17% oxygen, since the gas mask does not produce it.

In service with the Armed Forces in our time, there are the following types of filtering gas masks: PMK (-2.3), PBF, PMG, PRV-U, -M (missile troops), PFL (VVS).

The composition of the combined arms gas mask

Various types of combined-arms gas masks are produced, which differ in the shape of the mask, the attachment of the filter box and other elements. But in general, they consist of the following components:

- front case with inspection unit. Provides protection for the face, eyes. They have various shapes, depending on the design, and up to 5 sizes;

- valve box. Performs the function of air flow distribution during inhalation and exhalation;

- cowl. Represents air duct channels for blowing glass, which are poured together with the front part;

- intercom. Provides the ability to conduct conversations, improves their quality;

- obturator. It is designed for a better mask fit. It looks like a thin strip of rubber wrapped in the inside of the mask;

- a device for receiving liquid food;

- fastening system. Provides retention of the gas mask on the head and improves sealing.

- filter - absorber. It can be made in the form of a box, a special element. It performs the functions of cleaning the inhaled air from aerosols, using a smoke filter, and from vapors, dust with a special composition of coal-catalyst;

- connecting tube. It is made of rubber, in a fabric braid for conducting purified air from the filter into the mask;

- non-fogging films. Installed in the spectacle part;

- hydrophobic jersey cover. To protect the filter from the ingress of large particles;

- bag for transporting protective equipment.

Application procedure

A combined-arms gas mask is used in case of contamination of the atmosphere with poisonous, radioactive substances, as well as the need to carry out work in places hazardous to life. Such places can be:

- sewerage systems;

- closed rooms where paintwork was carried out;

- technological premises of the gas, chemical industry;

- emergency situations at work, areas of the terrain, in connection with the contamination of their territory.

Before use, gas masks are checked for serviceability, complete set, it is necessary to open the valve of the filter box. A bag with a gas mask is worn on the right shoulder and located on the left side. On command or before entering the contaminated area, the following actions are performed:

- take a deep breath, hold your breath, close your eyes;

- get the combined-arms gas mask from the bag. He takes the helmet-mask in such a way that the thumbs are from the outside, and the rest are inside the protective equipment and put it on the head;

- straighten distortions, folds;

- open your eyes and exhale completely.

A combined-arms gas mask must not be operated in an aggressive, poisonous environment for more than 30 minutes, as well as in the presence of cracks on the front part, damage to the mask, rupture of the hose, dents on the filter box.

A combined-arms gas mask is an indispensable tool for ensuring the safety of people during the occurrence of chemical disasters, accidents and other situations associated with contamination of the area with poisonous, radioactive, bacteriological substances. In our online store you can get a free consultation, purchase a product you are interested in and receive recommendations for its use.

The principle of the insulating gas mask

Before using the insulating RPE, the regenerative cartridge is launched. It should be ensured that oxygen is released and distributed inside the mask, continuously supplied to the respiratory system of the person.

- In isolation apparatus with compressed oxygen at the base, the air exhaled by a person enters through a valve into a recovery cartridge, where it is freed from carbon dioxide.

- The resulting gas mixture is fed into a breathing bag, saturated with oxygen from a cylinder and penetrates under the rubber mask of the device, allowing a person to breathe.

- In gas masks using chemically bound oxygen, the converting cartridge absorbs and purifies the vapor of carbon dioxide and water, while releasing oxygen.

- Then the purified and enriched air enters the breathing bag, then into the inhalation valve.

Device and principle of operation

The basic principle of operation of any isolating protective device is based on the absolute isolation of the respiratory system, purification of the inhaled air from water vapor and CO2, as well as on enriching it with oxygen without performing air exchange with the external environment. Any insulating RPE includes several modules:

- front part;

- frame;

- breathing bag;

- regenerative cartridge;

- a bag.

The front part provides effective protection of the mucous membranes of the eyes and skin from the toxic effects of hazardous substances in the air. It ensures the redirection of the exhaled gas mixture into the regenerative cartridge. In addition, it is this element that is responsible for supplying the gas mixture saturated with oxygen and free from carbon dioxide and water to the respiratory organs. The regenerative cartridge is responsible for absorbing moisture and carbon dioxide present in the inhaled composition, as well as for obtaining an oxygenated mass by the user. As a rule, it is performed in a cylindrical shape.

The trigger mechanism of the cartridge includes ampoules with concentrated acid, a device for breaking them, as well as a starting briquette. The latter is needed to maintain normal breathing at the initial stage of using the RPE, it is he who ensures the activation of the regenerative cartridge. An insulating cover is required to reduce heat transfer from the regenerative cartridge if it is supposed to use the RPE in an aquatic environment.

The breathing bag acts as a container for inhaled oxygen released from the regenerative cartridge. It is made of rubberized elastic material and has a pair of flanges. Nipples are attached to them to fix the breathing bag to the cartridge and the front part. There is an additional pressure valve on the bag. The latter, in turn, includes direct as well as check valves mounted in the body. A direct valve is necessary to remove excess gas from the breathing bag, while a reverse valve protects the user from air ingress from the outside.

The breathing bag is placed in the box, it prevents excessive squeezing of the bag during the use of the RPE. A bag is used to store and transport the RPE, as well as to ensure maximum protection of the device from mechanical shock. It has an inner pocket where the block with anti-fog films is stored.

At the moment of crushing the ampoule with acid in the starting device, the acid goes to the starting briquette, thereby causing the decomposition of its upper layers. Then this process goes on independently, moving from one layer to another. During this time, oxygen is released, as well as heat and water vapor. Under the action of steam and temperature, the main active component of the regenerative cartridge is activated, and oxygen is released - this is how the reaction starts. Then the formation of oxygen continues already due to the absorption of water vapor and carbon dioxide, which a person exhales. The period of validity of insulating RPE is:

- when performing heavy physical work - about 50 minutes;

- with loads of medium intensity - about 60–70 minutes;

- with light loads - about 2-3 hours;

- in a calm state, the period of protective action lasts up to 5 hours.

Order of use

In a normal situation, when the danger is small, but predicted, a gas mask is worn in a bag on the side. For example, when they go to the side of a dangerous object. If necessary, to ensure freedom of hands, the bag is allowed to be moved back a little. If there is an immediate danger of the release of toxic substances, a chemical attack, or at the entrance to the danger zone, the bag is moved forward and the valve is opened. It is necessary to put on a helmet-mask at a danger signal or in case of immediate signs of an attack, release.

The process is as follows:

- stop breathing while closing their eyes;

- take off the headdress (if any);

- snatch out a gas mask;

- take a helmet-mask from below with both hands;

- press it to the chin;

- pull the mask over the head, excluding folds;

- place glasses exactly against the eyes;

- exhale sharply;

- open their eyes;

- go to normal breathing;

- put on a hat;

- close the flap on the bag.

Filters need to be changed systematically. A torn, punctured, severely deformed or dented apparatus must not be used. Filters and additional cartridges are selected strictly for specific risk factors. The size of the mask must be chosen very carefully.

The following video demonstrates the test of a civilian gas mask GP 7B.

Personal respiratory protection

Filtering military gas masks

| Gas mask PBF | Exit to section | Gas mask RSh - 4 |

Filtering military gas mask PMG (PMG-2)

Gas mask PMG

The EO-18K gas mask box has the shape of a cylinder with a height of 9 cm and a diameter of 10.8 cm.

Marking on the EO-18K is made with waterproof mastic on the cylindrical part of the body:

first line - PC index - EO-18K;

the second line - the symbol of the manufacturer's enterprise, month, the last two digits of the year of manufacture, batch number;

third line - series and PC number.

The device of the ShMG helmet-mask of the PMG gas mask: body, spectacle assembly, fairing, valve box, intercom, PC connection unit, in which the inhalation valve is located.

The helmet-mask SHMG has cutouts in the helmet part and a neck band for fixing the helmet-mask on the head.

The valve box is made in the form of a rubber tube with two mushroom-type exhalation valves. The frontal arrangement and dimensions of the glasses of the spectacle assembly provide the ability to work with optical devices.

To ensure the convenience of working with weapons and military equipment different professionals and for taking into account the individual characteristics of military personnel, the front parts of the SHMG are produced with a left-sided (90%) and right-sided (10%) location of the PC connection unit.

The bag has the shape of a rectangular parallelepiped. It is made from a single layer of fabric, has one compartment and two outer pockets for boxes of anti-fog films, membranes and APIs.

There is no valve on the bag. The bag is closed by folding the front and back walls and rolling them into a bundle, which is fastened to the body of the bag with two loops with buttons or buttons.

Gas mask PMG-2

The filtering and absorbing box EO-62K has the shape of a cylinder 8 cm high and 11.2 cm in diameter.

PC marking is applied with waterproof mastic to the cylindrical part of the body:

first line - PK index - EO-62K;

second line - batch number, series and PC number;

on the protective screen (under the stopper) in the form of a convex stamp are indicated: the numbers in the circle - the symbol of the manufacturer, the month and the last two digits of the year of manufacture.

The device of the helmet-mask ShM-66Mu of the PMG-2 gas mask: body, spectacle assembly, fairing, valve box, collapsible intercom.

In the front part, there are cutouts for the auricles, which ensures normal audibility.

Marking on the front of the ShM-66Mu is applied in the form of a convex imprint from the mold: in the chin, in a circle, the figure indicates the height of the helmet-mask, the last two digits of the year of manufacture, quarter (dots).

The device of the helmet-mask ShM-62 of the PMG-2 gas mask: body, spectacle assembly, fairing, valve box.

The design of the valve box is similar to that of the ShM-66Mu valve box.

The size assortment and marking of ShM-62 are similar to the assortment and marking of ShM-66Mu.

The PMG-2 gas mask bag is similar to the PMG gas mask bag.