Electric saws.

The fastest of the presented power tools, an indispensable thing when working with a rough cut of a bar, logs as well as preparing firewood. The main advantage of electric saws is working with wooden blanks of large cross-section and arbitrary shape. But if we talk about the ability to cut accurately and accurately, then this is not about electric saws, and again, for the operation of an electric saw, oil is needed to lubricate the chain and tire, which already makes the work dirty.

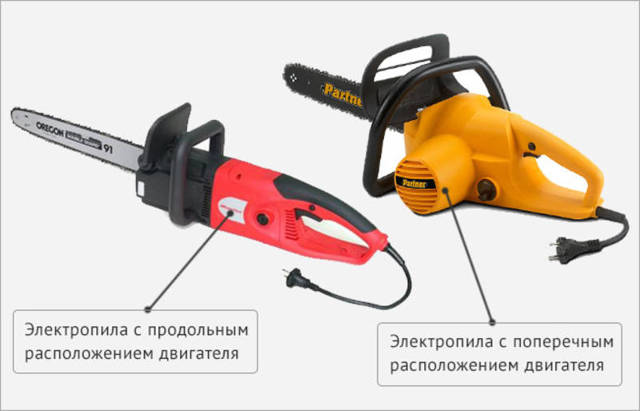

Also, electric saws have different engine locations:

- The transverse (classic) arrangement of the engine is convenient for working in a vertical plane, but the wide dimensions are inconvenient since the center of gravity is shifted to the left.

- Longitudinal arrangement of the motor - Provides a more accurate and accurate cut and a difference from the transverse arrangement of the motor, due to the narrower long body, the saw becomes more maneuverable. The downside of the longitudinal arrangement is the price, here the gearbox is already tapered.

An electric saw is not entirely convenient for working with boards and small section beams, if you need to prepare firewood, it will do (although there are cases when firewood is harvested with a circular saw and boards of 20-30mm are cut with an electric saw). Again, using an electric saw in your apartment will be a little different;) Yes, electric saws require less attention to care than chainsaws, but there is a huge difference in speed, a chainsaw harvesting firewood is faster than an electric saw (but you saw the price of gasoline then). Users often forget about replacing the drive sprocket on an electric saw, which leads the chain to disrepair.

Recommendations

Hacksaws for wood are classified not only according to the purpose of use, they can also differ according to other criteria.

- Blade length. The comfort of the worker depends on how many teeth are located on the saw blade in a row, since with a longer length, fewer saws are made, and a tooth is hammered on such a saw with a lower intensity. There is a general law that the length of a hacksaw blade for wood should be twice as long as the object that is being sawed.

- Teeth size. The size directly affects the cutting time and is inversely proportional to its quality. High-quality and clean cuts are made with a small hacksaw, but at a lower speed and with the application of greater forces. A saw with a large tooth spends less time on sawing, but it gives a ragged cut edge and a rough surface. Usually, the parameter of teeth of hacksaws for wood from foreign manufacturers is TPI (teeth per inch or "teeth per inch"), that is, the more cutting edges are located on 1 inch of the blade, the larger the TPI value, the smaller the tooth.

It is worth paying attention to the table of correspondence of inches to millimeters.

|

1 TPI = 25.5 mm |

6 TPI = 4 mm |

14 TPI = 1.8mm |

|

2 TPI = 12 mm |

10 TPI = 2.5 mm |

17 TPI = 1.5 mm |

|

3 TPI = 8.5mm |

11 TPI = 2.3 mm |

19 TPI = 1.3 mm |

|

4 TPI = 6.5mm |

12 TPI = 2 mm |

22 TPI = 1.1mm |

|

5 TPI = 5 mm |

13 TPI = 2 mm |

25 TPI = 1 mm |

Tooth shape. This parameter determines how the cut will go relative to the wood fiber of the type of tree and the vectors of applied forces (from oneself or to oneself). In addition, there are hacksaws for universal sawing, which have different types of teeth.

Steel grade from which the hacksaw blade is made

Steel is classified according to many parameters, but it is worth paying attention only to how the steel was processed - hardened, not hardened, or combined (not the entire hacksaw is hardened, but only its teeth).

When sharpening the teeth, the hacksaw blade is clamped so that no more than a centimeter of the tooth protrudes above the vice. When sharpening, it is recommended to select the triangular section of the file / file. To ensure proper quality, the following sequence must be followed when sharpening:

- sharpen the left edge of each even (farthest from the worker) tooth;

- reinstall the canvas by turning it 180 degrees;

- sharpen again the left edge of each even tooth, which will again be in the back row;

- finish off the cutting edge and sharpen the teeth.

It is worth noting that longitudinal or universal saws are fixed at an angle of 90 degrees. A diamond file is used for sharpening

It is necessary to work with it exclusively horizontally. As a result, sharpened edges sometimes have scuff marks. Such burrs must be smoothed out with a file with the finest notch or with an abrasive bar with a minimum grain size.

How well the teeth of the hacksaw are sharpened is checked as follows:

gently run your hand along the canvas - if the skin feels a sharpened edge and there are no burrs, scuffs - everything is in order;

by shade - well-sharpened edges do not glare when light falls on them, they should be matte;

trial sawing - the hacksaw should go straight, the sawn material should have a smooth, even surface, there should be no frayed fibers;

the finer the notch the tool has, the sharper the saw will be.

It is worth paying attention to the following tips from professionals:

- only high-quality sets of tools are recommended for use, which are used exclusively for sharpening saw teeth;

- for each tooth there should be an equal number of file / file movements; this rule applies even if the impression arises that it is necessary to repeat the passage;

- in the course of one pass, it is prohibited to change the hand and the angle at which the tool moves until one side of the hacksaw blade has been completely passed;

- it is forbidden to change the side of the file / file, that is, it is necessary to pass each side with the same side of the tool;

- Observance of the correct geometry of each cutting segment of a hacksaw for wood gives significant positive effects - both durability of use, and wear resistance, and a small loss of material waste, and an even cut.

We can say that it is not so difficult to process (dilute and sharpen the teeth) such a simple tool as a hacksaw at home with your own hands. Observing the general rules, having certain practical skills and the simplest devices, it is quite possible to give the tool a second life with your own hands and avoid additional costs by buying a new carpentry saw.

How to sharpen a hacksaw at home, see the next video.

Varieties of hand saws

To obtain the maximum result per minute, you need to make 40-50 saw movements. When it moves forward, pressure is performed; in the backward movement, it is absent. The pressure force is determined by the properties of the material on which the work is being carried out. For example, the force of pressure when working with soft metals should be significantly less than when cutting in hard metal.

To obtain the maximum result per minute, you need to make 40-50 saw movements. When it moves forward, pressure is performed; in the backward movement, it is absent. The pressure force is determined by the properties of the material on which the work is being carried out. For example, the force of pressure when working with soft metals should be significantly less than when cutting in hard metal.

In the course of working with a hacksaw, so that the tool blade does not hurt your hands by cracking, it is necessary to avoid sudden movements accompanied by heavy pressure. In addition to hand hacksaws, electric ones are also used. When operating such a hacksaw, from time to time it is necessary to wet the tool blade with a watery emulsion in order to avoid overheating.

Hand saws are divided into several types for their intended purpose:

- transverse;

- onion;

- external (for cutting holes);

- classic hacksaws (longitudinal or transverse cutting);

- spike hacksaws (for cutting connecting spikes).

Bow saws are made from:

- hardwood pulp onion,

- canvases 785-800 mm long,

- bowstring, which is made of linen or twisted hemp cord with a thickness of 3-4 mm.

They can be transverse and longitudinal. For bow and transverse saws, the width of the blade is 22-25 mm, and the angle of sharpening is within 70-79 degrees, the distance between the teeth is 4.5-5 mm.In bow longitudinal saws, the cutting blade is 50-55 mm wide, 0.5-0.7 mm thick, the distance between their teeth is 5 mm, and the angle of sharpening is 45-50 degrees.

Circular saws are used to cut material along a curved path. The cutting part of these saws is 500 mm long, 5-15 mm wide, the distance between its teeth reaches 5 mm, and the degree of sharpening is 55-60. They are usually sharpened straight.

When choosing a hand hacksaw, not only the shape, but also the volume of the teeth plays an important role.

There are 3 types of incisors:

- fine tooth - 2.0-2.5 mm (for cutting small products and high-precision sawing);

- middle tooth - 3.0-3.5 mm (for processing medium-sized parts);

- large prong - 4.0-6.0 mm (for hard cutting of logs and beams).

There is also an international classification, it also classifies hacksaws, but not by the height of the teeth, but by their number, which is 1 inch of the cutting layer. Such a standard has taken root among domestic manufacturers, so you should not be surprised if the instrument label contains foreign designations PPI or TPI. The number behind these letters will represent the number of teeth per inch of length. The larger the number, the smaller the tooth (for example, PPI 8 or TPI 14).

Chain saws

Often, when working with wood, it is not the cleanliness and accuracy of the cut that is important, but its depth. This is precisely the task that a chain saw solves - a powerful device with an electric or gasoline engine, designed for felling and cutting firewood.

It has two main interrelated technical parameters:

- Engine power;

- Bus length.

A bar is called two flat plates connected to each other with a small gap for installing a saw chain. At one end it has a driven sprocket, and at the other there are cutouts for the tensioner.

Electric chain saw

The power of the electric chain saws ranges from 1.5 to 4 kW. When choosing a device for household work on the site, it is better to stop at a power of 1.5 to 2 kW with a saw bar length of 30 to 40 cm.This is quite enough not only for sanitary pruning of the garden, but also for harvesting firewood.

If necessary, you can dissolve a board, log or timber with such a tool, although you will not get high quality and accuracy of the cut.

There are two types of chain saws:

- With lateral (transverse) engine placement;

- With longitudinal motor installation.

Chainsaw

The main thing that gives the owner a chain chainsaw is autonomy. With such a tool, you can go into the forest and cut firewood there. For such a significant plus, you will have to pay a price: chainsaws are more complex in design than electric ones. This difference is especially felt when buying a cheap “but-hiring” device. Problems with starting, carburetor, rings and spark plugs are frequent companions of such a purchase. Therefore, it is better to purchase a more expensive chainsaw than to lose money using an economy option.

Characteristics and device

The chain saw is presented in the form of a device consisting of a motor that generates torque, and a removable saw part, consisting of a guide bar and a chain with a cutting edge stretched over it. The unit also includes a drive sprocket, a rear handle with a start button and a front handle equipped with a protective shield. The engine can be longitudinal or transverse. The transverse placement ensures that the drive sprocket is on the same axis with the motor and greatly simplifies the design. However, with this arrangement, the engine is sideways, which causes certain inconveniences when working in confined spaces. Models with a longitudinal arrangement do not have such a drawback, however, they cost a little more. The principle of operation of the unit is as follows: the engine transmits torque to the drive sprocket, which, in turn, moves the chain closed in a ring along the guide rail.

The main technical characteristics of chain saws are engine power, shaft speed and bar length.

- In terms of power, devices are divided into 3 categories: low-power, medium and extra-powerful. The former have a power below 1.5 kW and are designed for delimbing, sawing thin wood or plastic workpieces. The middle class models are equipped with an engine with a power of 1.5 to 2 kW. They represent the largest group of devices. They are used in the woodworking industry, when cutting firewood for stoves and fireplaces, as well as in construction and repairs. The devices of the highest class are equipped with an engine with a power of more than 2 kW, thanks to which they are used when performing forestry work and are able to saw logs with a diameter of 30 cm.

- The length of the bar affects the depth of the cut and depends on the power of the engine. So, tires 40 cm long are used in combination with a motor with a power of more than 2 kW, 35 cm canvases with a 1.8 kW engine, and tires with a size of 30 cm are intended for low-power devices.

- The speed of rotation of the shaft has a direct effect on the productivity of the tool: the higher it is, the more workpieces the device can cut in a certain time. However, when choosing a speed, the power of the engine must also be taken into account. A low-power motor will not make a large number of revolutions, all the advantage will come to naught.

Longitudinal sawing. Peculiarities

The rip cut is carried out along the growth of the fibers. This sawing consumes a lot more energy and heats up the machine much faster than cross-cutting. Nevertheless, such costs are fully compensated by the fact that the surface of the sawn timber is smooth when ripping. But in the case of a cross-cut, the surface is rough and even chipped.

In fact, ripping is similar to chopping a shoe with an ax, in which a wedge blade splits the fibers bound by lignin, making further splitting easier. In the course of longitudinal cutting of timber or chipboard, the cutting surface of the tool breaks the lignin, after which it cuts the fibers with cutting movements.

Often during ripping, internal stress in the sawn timber is detected, caused by uneven shrinkage of the fibers, which are compressed or, on the contrary, stretched, clamped by the surrounding fibers and are in this position until the sawing begins.

A significant problem arises during ripping. It consists in the fact that the edges of the sawn board may close together. But this problem can be avoided. It is not worth cutting boards that have unevenly distributed annual rings, that is, the appearance, which indicates improper drying. Not suitable for ripping and cracked sawn timber.

Longitudinal sawing of wood should be carried out with a margin for the release of internal stress. This option makes it possible in the future, with the help of planing or sawing, to get rid of flaws. Do not forget that the discs used for cutting must be sharp and clean, as new as possible.

The best brands of chainsaw chains

According to the reviews of the owners of these units, a rating of chains for chainsaws has been compiled. Below are the manufacturers that make the best chainsaw chains.

- Stihl is a very well-known Swiss brand that produces saw chains from high-strength chromium-nickel steel. They do not stretch when heated like normal ones. This is achieved through the use of a special method of hot riveting in production. In addition, this manufacturer has patented the lubrication method - “grooves”, which are supplied to all leading links.

- The company does not design chains, but manufactures them using the best patented technologies. Thanks to this, a high quality product is achieved.The company also provides a wide range of services to customers, providing warranty service for its products. In addition, the company's customers have the opportunity to purchase original spare parts for mechanisms.

- Oregon is a division of Blount Inc. The company is considered one of the best among the companies that produce saw blades for chainsaws. Oregon also produces various accessories and spare parts for tools from other well-known brands. The saw elements of chainsaws are made of a special patented alloy, and a chromium alloy is applied to the teeth. To facilitate the sharpening process, there are marks on the teeth indicating the angle at which this operation should be performed. In addition, the chains have a system that reduces vibration and an original design, thanks to which the lubricant is evenly distributed.

- Carlton is an American company. All elements of the chain of this manufacturer have increased hardness, since they are shot blasting at the manufacturing stage. The cutting links have a long edge, which makes it possible to produce a large number of sharpenings.

- Windsor. The company has patented a superalloy that is highly heat resistant and does not stretch. Forged links and sealed rivets are used in Windsor sawing elements to ensure high reliability.

- The chain is made of alloy steel with chrome plated teeth. The latter are sharpened in a special way, and a hypoid lubricant is applied to the chain, which facilitates the sawing process. The company also uses the shot peening method in the manufacture of chains, which increases the strength of the links.

One of the most important elements of the chainsaw is the chain, which is the working part of the tool, and takes all the loads. It dulls quickly enough, and also wears out. The duration of its operation is influenced not only by the frequency of the chainsaw, but also by the quality of the product itself.

It is the chain that affects the efficiency of the chainsaw, therefore, special attention should be paid to this element, when choosing it

Sawing types

The saw is a cutting sharp tool with a large number of blades that is capable of working in a closed cut. A kerf is a rather narrow gap that appears in wood when cutting shavings with sharp teeth of a working tool. Usually, the sidewalls are distinguished from the cut, as well as the bottom, it is with them that the blade enters into interaction. Depending on the angle of inclination and the location of the saw in relation to the wood, several types of sawing are distinguished.

- Longitudinal. In this case, the plane is parallel or approximately parallel to the wood fibers. Sawing frames operate according to this mechanism, as well as band and circular saws used for sawing logs, as well as beams into boards, when the material is cut in the longitudinal direction both in length and in width.

- Transverse. Here the saw is located perpendicular or approximately perpendicular to the fibers. In this case, the sawing itself is carried out manually using cross-cut saws and hacksaws, as well as on miter machines. This method of processing wood fibers is used for cutting into round billets, removing wood defects, as well as for giving lumber of the required quality and dimensions.

- Mixed. In this case, the plane of the tool can be located in the range from 10 to 80 degrees in relation to the wood.

Speaking about which method of sawing is better, it should be noted that the transverse one is considered more simplified, since this scheme does not have a complex gearbox, which is required to rotate the axis by 90 degrees, the gears function much more efficiently, thanks to which the crosscut saws are more durable, the risk of the motor coming out of tuning is much lower and overall the instrument lasts longer.