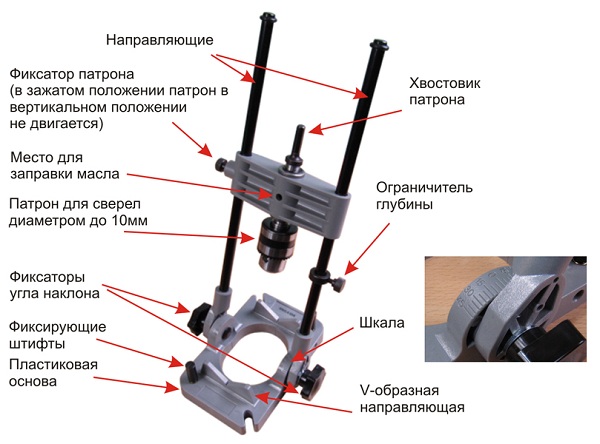

Drill Guide Specifications

The drill stand has several important characteristics:

- Vertical stroke (how far you can move the tool vertically).

- Retaining flange diameter (determines what size tool can be clamped).

- Material.

- The size and weight of the device.

Drilling stands are mobile and stationary. The stationary rails strongly resemble a small drilling machine, they look like a drill tripod. Mobile guides are attachments for drilling tools. Their main advantage is their very high mobility.

An important property of the rack is the method of fastening. The most reliable option is a magnetic mount. There is also a simpler option - this is a vacuum mount.

Mobile tools are securely fixed in the hands and absorb vibration during drilling. Most people choose mobile guides. All thanks to their excellent characteristics. They are very reliable, compact and low cost.

The rating of the best models is represented by the following tools:

Tecmobit wolfcraft

"Caliber 96302". Great budget model. It has good quality and low price. The attachment consists of two rods made of chrome-plated metal and a plastic base. Also, the device has a special tool for fixing the tool. The caliber has proven to be an inexpensive and reliable tool.

Caliber 96302

The Chinese model "KWB 7784" has been at the forefront for a long time. The design of this device is similar to the Russian Caliber. The opinion of consumers on his account is ambiguous. Some consumers speak about the short service life of the device and about its breakdowns. The height of the device is small, only 213 mm. It has a vertical stroke of 160 mm and a tool hole diameter of 43 mm. The weight of the device is a little more than a kilogram.

KWB brand products

Stand DIOLD SMS-43. It consists of a base, a column and a clamp for attaching an electric drill. The base has grooves for the vice. It has a height of 500 mm and a drill hole diameter of 43 mm.

Pay attention to the following manufacturers:

- Dremel - the company manufactures drill machines. They can be used to drill at an angle, polish and grind materials.

- Sparta - Stationary racks. An important advantage is the high quality and smooth movement of the drill.

- Skrab - Often used at home and small workshops. An excellent device for its very modest price.

And these are only the most basic vertical attachments for a drill, besides them, there are many more known and not so many.

Required details

Any stand for a drill, regardless of its size and taking into account the purpose of such devices, has basic structural elements, each of which performs its own functions and must meet certain requirements.

- The bed is one of the main components of the described equipment, which is its base (stand) and ensures the stability of the entire structure. In addition, a vice is located on the bed for fixing the workpieces to be processed. The weight and dimensions of this element depend on the power of the tool used and the list of tasks to be performed.

- Guide post, which is located strictly vertical to the base. Even a slight deviation can damage the workpiece and break the drill or cutter. Depending on the design features of a particular model, this part can be made of different materials.

- Travel mechanism. There are no strict requirements for the device of this node, no templates are applied. Its main task is to provide smooth movement, secured by brackets or clamps of the drilling tool along the tripod. There are many variations of these mechanisms.

- Holder for equipment (drills, hammer drills, screwdrivers). Clamps, pads and other mounting elements are used as an effective fastening.

Mechanism for moving the drill in a vertical direction

A homemade drilling machine must be equipped with a mechanism that will move the drill in a vertical direction. The structural elements of such a unit are:

- a handle with which the carriage with a drill fixed to it is brought to the surface of the workpiece;

- the spring required to return the carriage with the drill to its original position.

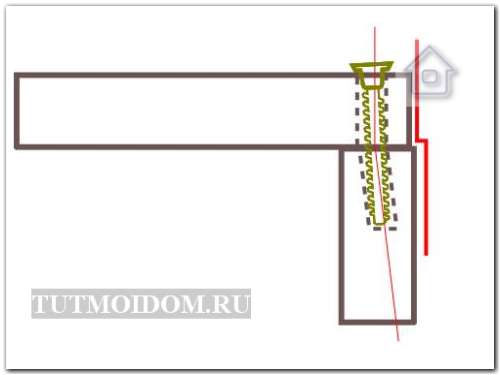

Spring-loaded mechanism for moving the drill

Such a mechanism can be made using two design schemes:

- the spring is connected directly to the handle of the machine;

- the springs are located at the bottom of the carriage - in special grooves.

According to the first option, the structure is performed according to the following scheme:

- on the machine stand, two metal plates are fixed with screws, between which an axis is installed, where the installation handle will be placed;

- on the other side of the rack, plates and an axis are also installed, on which one end of the spring is fixed, and its other end is connected to the handle;

- the pin with which the handle is connected to the installation carriage is placed in a longitudinal groove made in it.

It is based on an old stand from a photographic enlarger "Crocus" made in Poland

If the springs are in the lower part of the return mechanism, then the device handle is also fixed with two plates and an axis that provides its movement. The springs with such a design scheme are located in the lower part of the grooves of the guides, which are modified with the help of metal corners that limit their movement.

The principle of operation of the drilling machine, in which the springs are located at the bottom of the carriage, is quite simple: going down during the drilling process, the carriage with a drill fixed on it presses on the springs, compressing them; after the mechanical action on the springs ceases, they are unclenched, raising the carriage and the drill to their original position.

Features of self-production

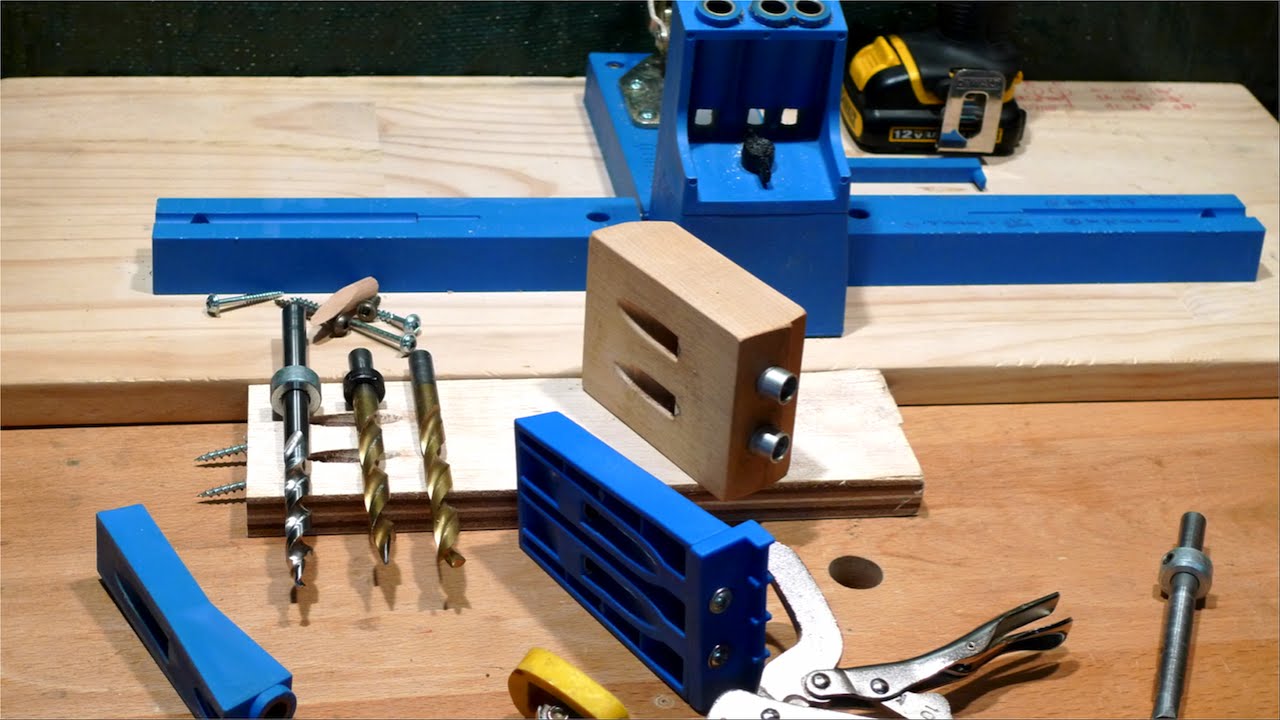

When designing a conductor for a confirmation, it is necessary to correctly calculate what functions it will have to perform in the future. It needs to be done under the most commonly used fasteners in the house. If such a device is required by furniture makers for permanent work, then it is better to buy a factory sample, which is highly accurate. In addition, manufacturers often include additional fasteners, stops and templates in the kit.

When designing a conductor for a confirmation, it is necessary to correctly calculate what functions it will have to perform in the future. It needs to be done under the most commonly used fasteners in the house. If such a device is required by furniture makers for permanent work, then it is better to buy a factory sample, which is highly accurate. In addition, manufacturers often include additional fasteners, stops and templates in the kit.

The price of such a device for professional use ranges from 400 to 1100 rubles. It depends on the direct capabilities of a particular unit, the number of holes to be made, their length, and so on. Many are interested in how to make a furniture conductor with their own hands. Dimensioned drawings are a must for novice craftsmen, since they allow you to make a high-quality design on the first try. Similar schemes can be found on the Internet.

Basically, the conductor has the following elements:

- The basis of the product. It is directly applied to the plane of the furniture, on which holes will be drilled.

- Guide bushings. A drill goes through them.

- Surface clamping parts. As a rule, they are located at the end of the conductor.

Next, you need to take care of the correct direction of the sleeve. It can be made from stainless steel pipe. The length of the sleeve must be at least twice as long as the hole in which it will be located at the corner. The bushing in the hole should be tight. The simplest and most common option is a shaft fit. A corresponding hole is drilled in the corner under the already known diameter of the bushing, and after that the fit is made. A low interference fit is recommended.

There are times when the jig needs to be made for drilling deep holes. Then the sleeve is made with a shoulder. The number of possible holes, their length and the distance between them are selected for the specific needs of each master.

Several options can be used to attach the device:

- Spring stop. The conductor will snuggle against the material being processed using a spring force. For these purposes, you can use any flat spring with the required force.

- Fastening to a tree with self-tapping screws. With this method, the jig is pressed and held on the working surface due to the frictional force. This method of fastening allows you to use the resulting marks for the subsequent centering of the part. When working with chipboard, you need to use this method with great care.

- Clamps with rubber gaskets. This method is dangerous due to possible displacement of the hub axis. This happens because the weight of the conductor increases, and the bushings give in to bending. Therefore, you must first attach the jig to the surface, mark the future hole, and then start drilling.

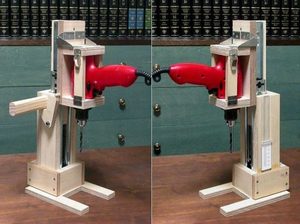

Machine tripod manufacturing

The machine will consist of the following parts:

- Bottom part;

- metal vertical guides;

- upper part with cartridge.

Bottom part

It is a board or thick plywood, in which we drill two holes for the guides. These holes should be slightly larger in diameter than the guides in order to be able to set them exactly at 90 degrees in the future.

Metal vertical guides

They are two rods of the same size. Fastened to the bottom of the product using cold welding or epoxy.

In order to set them straight at a 90 degree angle, you can use a regular block of wood, which should also have straight cuts on both sides.

After the glue has completely dried, we make the upper part.

Top part with chuck

It is made from a bar as follows. On the block, we accurately measure out three holes, two along the edges, they will be through and one in the center. In the central hole, the depth on both sides will be equal to the width of the bearings, which will be glued with the same glue to the chuck axis and the central hole in the upper part of the machine.

We install bushings in the side holes, which will walk freely along the metal guides, but there should be no backlash. The sleeves must be matched exactly to the diameter of the guides.

We also glue these bushings so that they are tightly fastened and do not fly out.

We take the cartridge and glue the guide to its axis.

We put on the guide on the axis of the cartridge, remove the excess glue. The guide must also fit snugly on the chuck axis. We get the following.

We install a bearing of a preselected size on the chuck tube.

We spread it with glue, install it in the central hole of the upper part of the machine.

On the other hand, we do the same, install the second bearing.

As you can see, the tube is clamped in the chuck. Instead, you can clamp the drill. It is needed in order to further install the cartridge at an angle of 90 degrees, relative to the bottom of the product.

After the cartridge has been installed and the glue has dried, we remove the upper part of the product from the guides, put springs and washers on the metal rods.

Springs can be purchased at any hardware store. Then we put on the upper part.

Plugs can be installed on vertical rods. Cut out at the bottom of the product hole for easy drilling.

It turns out like this.

Checking the product for accuracy and quality of work

Installs the drill, drill a hole

we insert a metal rod or a drill of a suitable diameter into it.

We measure with a corner to perform a right angle after drilling.

Our expectations and efforts were justified. The machine works precisely.Can be used when performing work.

Result of work

If you liked my article, please put your thumbs up. I hope you find it useful.

Good luck.

Brands

The described equipment is a comfortable and useful addition, providing quick and reliable fixation of drilling tools for performing stationary work with high precision. Taking into account the demand, many manufacturing companies have launched the production of such devices. All models presented in this market segment differ from each other in design, functions, equipment and cost.

One of the popular brands is Enkor. The company offers the consumer high-quality devices for working with tools with various characteristics (power, weight and diameter of the body neck).

Sparky products are in no less demand.

In the reviews, the owners of this technique pay attention to the increased stability provided by the presence of a high-quality base plate cast from cast iron

Also today in the popularity rating there are other models of racks.

- Caliber is a reliable and versatile design that transforms hand-held drilling tools into a compact, stationary machine.

- The Dremel is a device characterized by functionality, durability and affordable value. These models allow vertical drilling, angle drilling, polishing and horizontal grinding of materials.

- Sparta - stands that turn both drills and screwdrivers into stationary devices. The main advantages include the presence of a high-quality mechanism responsible for the smoothness and uniformity of the supply of the fixed tool.

- Skrab is a rotary modification that has become a rational option for use in small workshops, garages and home conditions. The design combines strength, durability and affordable cost.

In addition to all of the above, users highlight the Diolod and Artu models. The former are used with equal efficiency in domestic and industrial conditions. Depending on the modification, the diameter of the neck of the tool body, which can be fixed in the holder, varies.

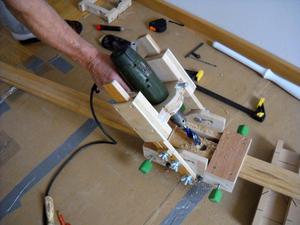

How to make a DIY drilling attachment

Before proceeding directly to the manufacture of the device, it is necessary to determine for what purposes it will be used, and then select the optimal design.

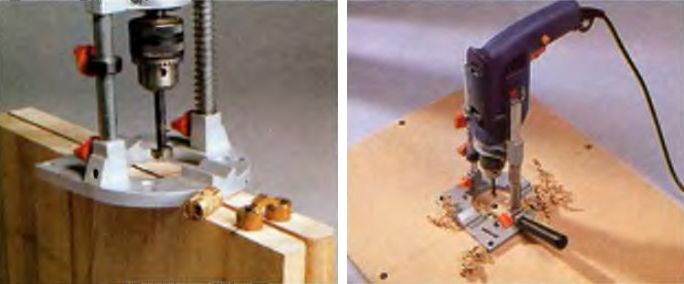

Conductors differ in functionality and type of execution. The following types of devices are most in demand:

- Overhead. Fixtures are placed on the part to be processed and fixed to it by means of mechanisms or manually. They are used for drilling holes in flat products.

- Swivel. The tool is used when it is necessary to make holes in products with a cylindrical section. They have vertical and horizontal pivoting axes, allow drilling at the desired angle.

- Universal. They are suitable for small-scale production, they allow you to carry out changeovers in the shortest possible time.

- Tilting. They are used in cases when the technology requires drilling holes in several planes.

- Sliding. No attachment is required for these attachments. The device is simply applied to the desired section of the workpiece.

- Pinned. They differ in ease of use, but are limited in movement over the surface of the product.

Having made drilling jig on your own, you can save a hefty amount for more important needs.

For the construction you will need:

- Bulgarian;

- welding machine;

- drill;

- locksmith tools.

The device is made in the following sequence:

- A piece of reinforcement with a square section of 10x10 mm is selected.

- A piece of the desired length is cut off, the edges and edges are cleaned.

- Marking is made for the template holes.Their center should be located at a distance of at least 8 mm from the edge. A distance of at least 32 mm is maintained between the centers of the nearest holes.

- In the pre-marked centers, a hole with a diameter of 5 mm is drilled.

- To create a stop, you need a metal plate 1 mm thick and 2.5 mm wide, bent at right angles.

- A thread is cut in the plate and in the fittings for fastening the clamp.

- Both parts are combined into a single structure.

Having certain skills in handling a simple tool, it is not so difficult to make a drilling device. For infrequent household use, such a device is quite sufficient. If all else fails, then the easiest option is to purchase the device in specialized or construction hypermarkets.

Conclusion

Drilling work is one of the most frequently performed during the manufacture of various structures. Moreover, a home craftsman most often solves this problem with a household drill. However, for the most part, the hole being created does not differ in exact dimensions. And this can create certain difficulties when using it for its intended purpose.

You can get out of this difficult situation with the help of drill guides, which you can make yourself. This idea seems quite attractive for the reason that any owner can make such a nozzle, given that any available means can be used for this. However, having realized all the attractiveness of the guide, it must be remembered that it cannot become a full-fledged device for a drilling tool, therefore, resort to using this nozzle should only be in emergency situations. Otherwise, the drill guide will fail pretty soon.