How to choose?

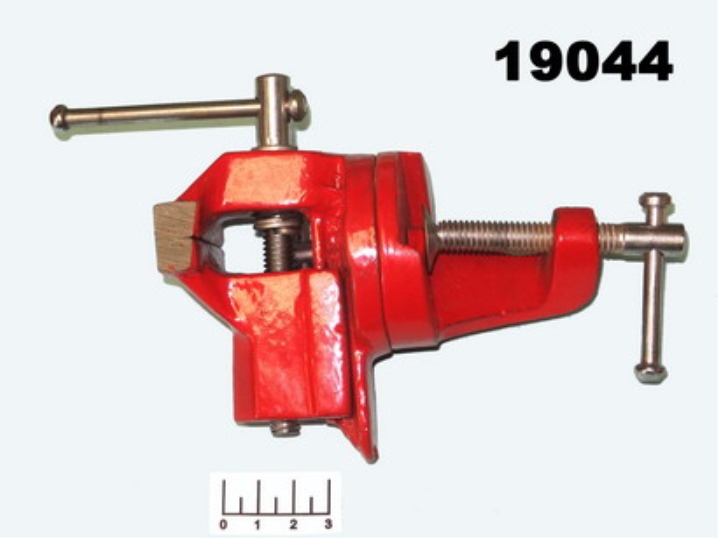

The chair vise is prized for its quick installation even at the edge of the worktable. You can also dismantle them quickly enough. Finally, the chair tool is quite convenient for storage.

The difference between steel and cast iron vise is important. Some cast iron versions are particularly robust and mechanically resistant to damage. It has been found that ferritic cast iron is 10 times stronger than gray alloy. But steel vices are even more popular. With the same strength, even in comparison with cast-iron devices, they turn out to be much lighter.

You also need to pay attention to the characteristics of the device. The larger the size of the parts to be processed, the greater the divergence of the jaws should be.

Here are some more recommendations:

take into account the amount of movement of the part;

pay attention to the margin of safety;

check the quality of clamping of workpieces;

buy a vice only in reliable, proven places;

read reviews on different sites.

Below is a video overview of popular rotary vices from different manufacturers.

Varieties

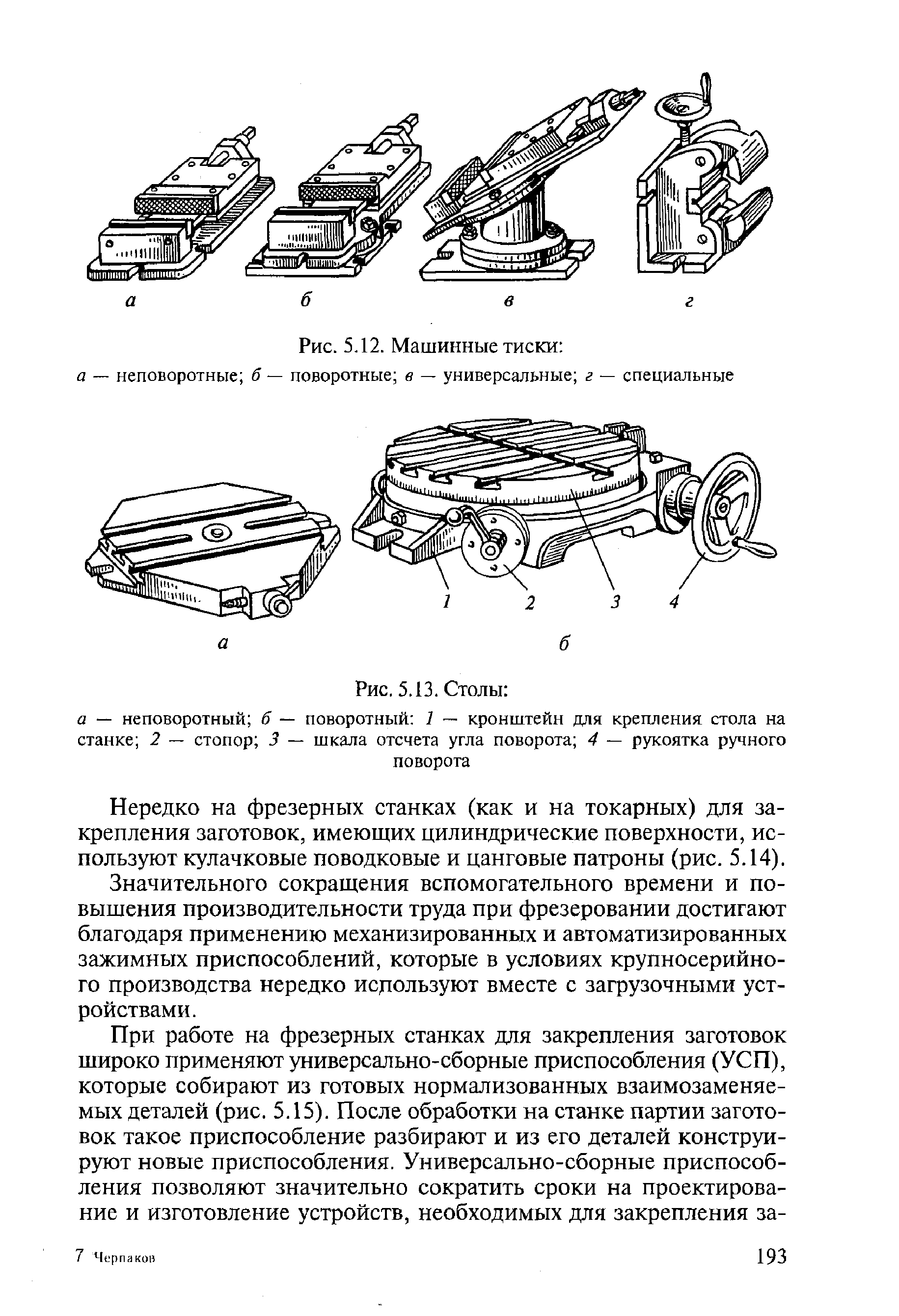

First of all, it should be said about the pivot-type vise. Products of this kind are offered by any self-respecting manufacturer.

Designers can provide a special clamp for a drill. The diameter of the clamp in advanced designs is adjusted quite widely, which expands the overall functionality.

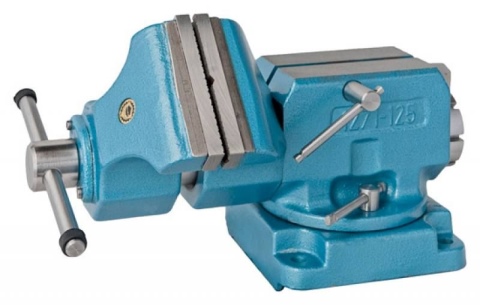

As for the swivel vise, they are used even in fairly serious production. There, such devices are usually used in conjunction with metal-cutting equipment. This refers not only to drilling, but also milling and grinding systems. Many samples of such a vice are equipped with a swivel base by default, but it is recommended to agree on the exact configuration when placing an order.

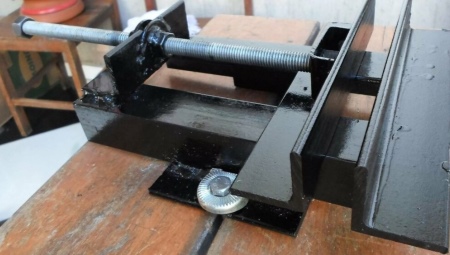

Parallel vices are widely used. The release of such devices is governed by the provisions of the 1975 standard. The moving part moves away from the stationary block as evenly as possible, while maintaining strict parallelism - hence the general name.

Parallel vise:

- are freely placed at any point of the workbench, including in its center;

- can be installed on the floor;

- equipped with a base with three holes;

- can have a base of steel or cast iron alloys, since no mechanical load will act on it.

Some models are rotary in two planes. They are usually made with a two-axis positioning mechanism. Almost all such devices are equipped with a cast iron base, but sometimes steel structures are also found.

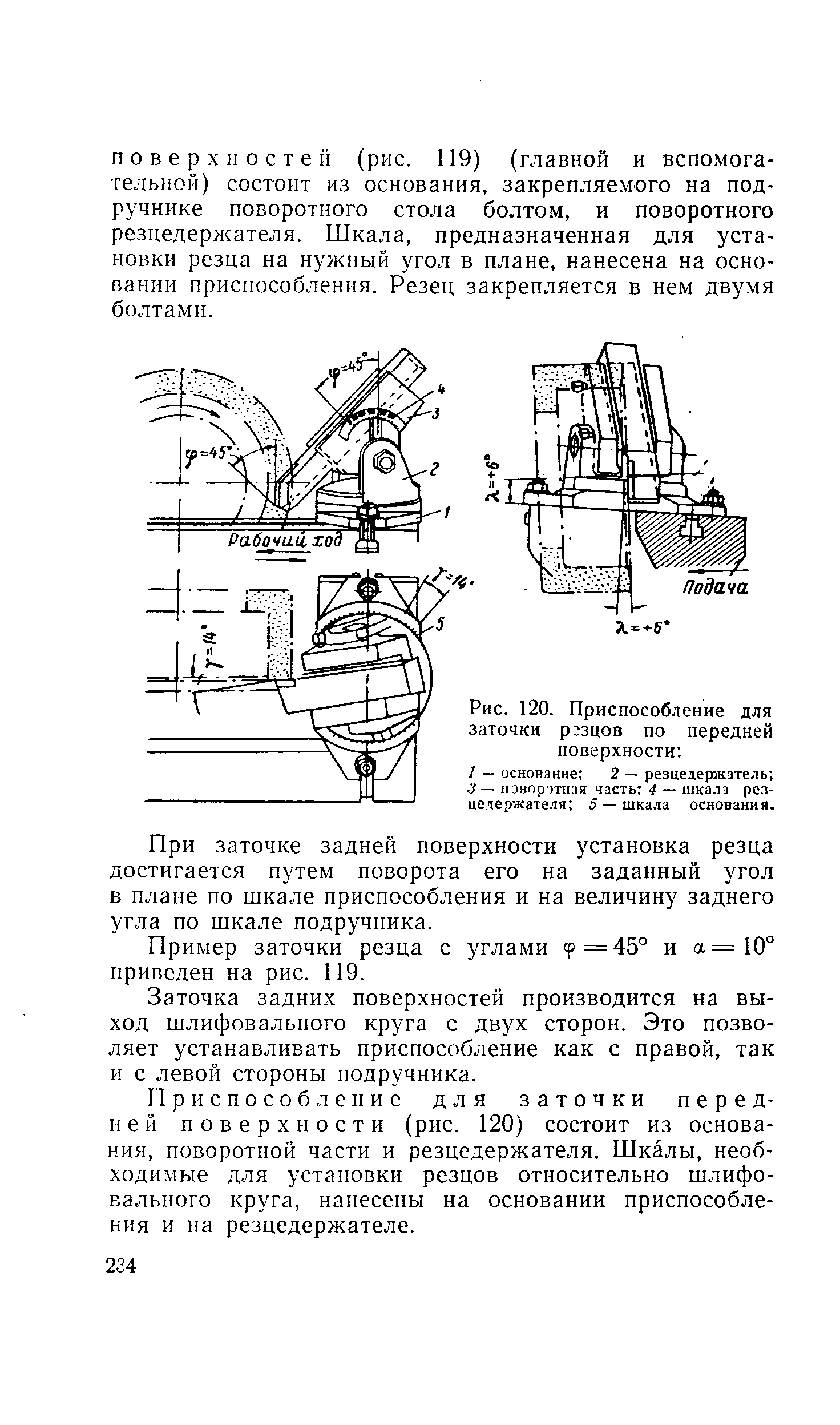

The three-turn vise deserves special attention. They can be used even for the most difficult and demanding jobs. Such a tool is useful for sharpening and finishing cutters in various installations.

Another three-turn vise is useful for systematic dressing of diamond wheels.

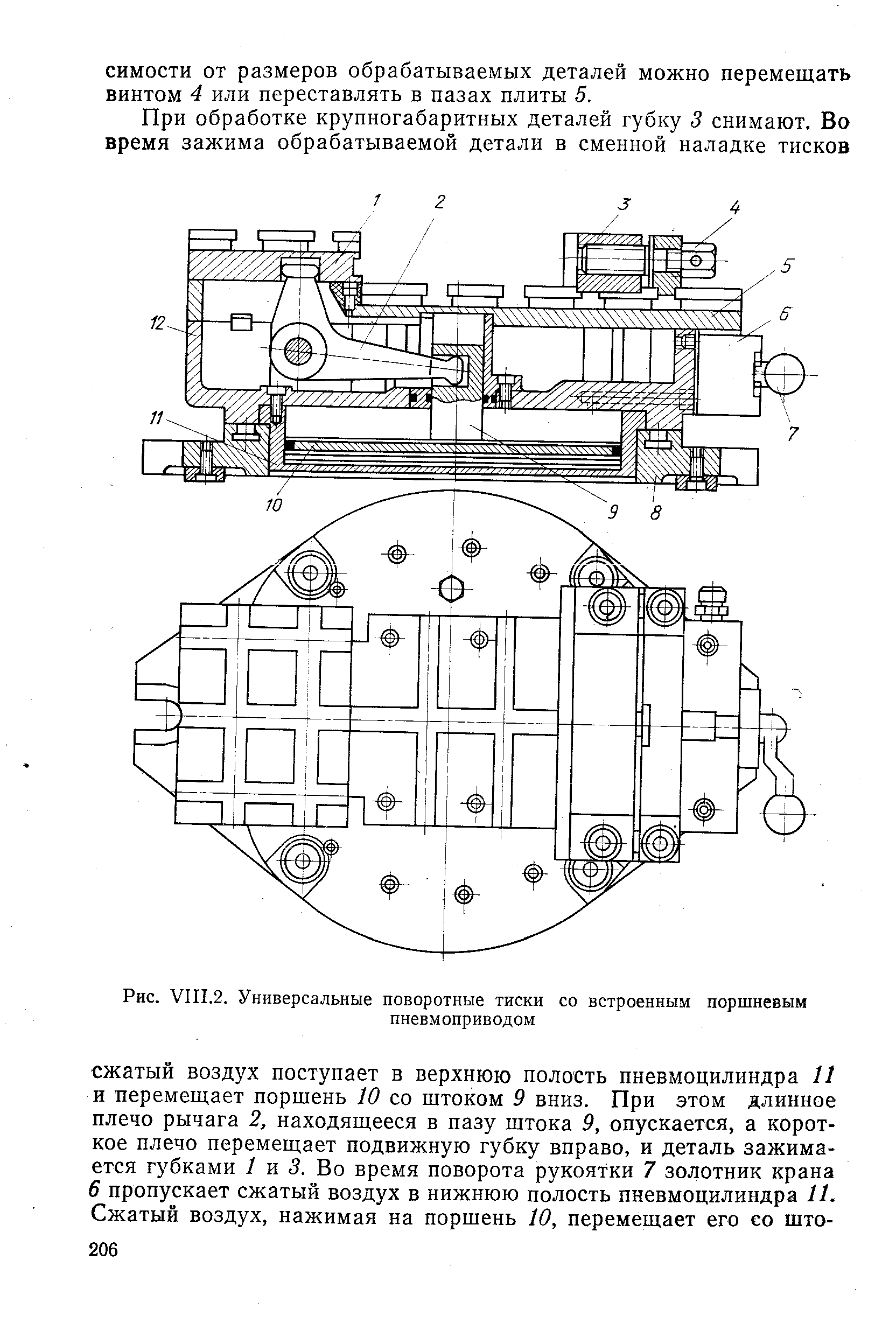

It remains to disassemble one more type of tool, namely a pneumatic vise. They are no longer operated manually, but by the energy of compressed air. Power clamping is often used in production lines, especially in their locksmith areas. In this case, the squeezing force can reach 1500 kg.

Of course, no mechanical devices of the traditional type are capable of such a result, or even a close one.

High-speed pneumatic vices were created back in the 1940s-1950s. But more or less perfect developments of this kind appeared only in the 1960s. It was then that they began to be widely used in the locksmith and machine format.The problem is that the old stocks of such a tool have come to an end, and new copies bought abroad are unsatisfactory in a number of characteristics. Therefore, in recent years, the restoration of the production of pneumatic rotary vices in our country has begun.

Peculiarities

When characterizing the rotary vise, it is impossible to ignore their main advantage over non-rotary devices. This is the very possibility of turning the workpiece in an arbitrary way. In a non-rotating vise, to perform this seemingly simple manipulation, you have to take out the workpiece, and then fix it again. This immediately increases the overall time spent.

It is worth noting that the rotary vise is in demand primarily in drilling work, and may even be included in the delivery of the drilling machine.

But the exact same technique is sold separately. Including for household use. The pivoting vise often contains an anvil. It not only expands the range of operations performed, but also increases the overall strength of the tool.

Manufacturers

The FIT 59425 model is in demand. The device weighs 0.965 kg. The width of the jaws is 50 mm. The frame is made of cast iron. The device is intended mainly for locksmith work.

The WILTON 65021EU swivel vise model can also be a good choice. The weight of the device in the package reaches 15.45 kg. The width of the jaws is 0.225 m. They open up to 0.345 m. The frame is made of cast iron.

The features of such a product can be considered:

- carpentry purpose;

- quick release;

- automatic movement.

Another attractive option is the Glazov vice. For example, model 18667. The device is intended for locksmith work and has jaws 0.14 m wide. The frame is made of high-quality steel. The jaws can open up to 0.18 m.

The following brands are also widely represented on the Russian market:

- "Caliber";

- Forsage;

- Skrab;

- "Bison";

- Hammer;

- Stalex.